DIY brick baths projects. installation of steam and thermal insulation of walls

Reading time ≈ 4 minutes

The bath has long become one of the invariable attributes of country life. If there is no way to contact the construction team, or you just want to put your hand on everything, a brick bath with your own hands will become profitable investment money and strength. Below step-by-step instruction, video and photo report will help in creating a budget bathhouse that will last for decades.

The foundation of a brick bath

After the place is chosen, the markup is made, the arrangement of the foundation begins. The best option- strip foundation. To do this, you need to dig a trench, put together a formwork from the boards, sprinkle the bottom of the trench with sand (a sand cushion helps to evenly distribute the load). Reinforcement can be done using masonry mesh. The depth of the bookmark will depend on climatic conditions.

In this situation, a strip foundation was made for a bath with a size of 2.4x4.7 m. The height of the foundation is 30 cm, the width is 15 cm. You can prepare the concrete solution yourself, you can order it ready.

Since it is planned to build a brick bath, you need to wait for the foundation to stand. The start time of laying depends on the type of foundation and the characteristics of the concrete solution.

To protect against the appearance of fungus, mold, before starting masonry work, you can treat the foundation with waterproofing Hydroshield.

Walling

During construction brick bath with your own hands it is easier to use a one and a half red brick.

To determine the amount of material, it is necessary to divide the planned width and height of the walls by the height and width of the brick multiplied by each other. This method is used if the laying is carried out in one brick, as in this case.

At the same time, it is necessary to leave ventilation gaps, plan windows and doors. Jumpers are mounted above doors, window openings.

Roof

Floor beams are installed directly on the bricks in the prepared holes. The ends of the beams that will be in contact with the brickwork are wrapped with roofing material, only the end part remains open. The simplest option is a shed roof. After laying the beams, the flooring is made of boards.

To equip the waterproofing, the beams are wrapped in fabric asbestos, which is fixed with a stapler. When the beams are hidden on top, a mixture of clay and sawdust is applied. For this roof, a proportion of 2 buckets x 2 buckets is sufficient. When the mixture dries, it is sprinkled with sand.

The location of the chimney requires special attention. Compliance with the recommendations of experts will help to avoid a fire. Wood must not come into contact with the chimney. This area is sutured with a metal sheet.

The place where the stove will stand and the chimney will pass inside the room is insulated with metal.

The space around the chimney in the ceiling area is insulated with expanded clay. The lower reflector is attached to the armature.

Another sheet of metal is installed on top of the expanded clay layer.

During the construction of a brick bath, the Rus-9 furnace was used.

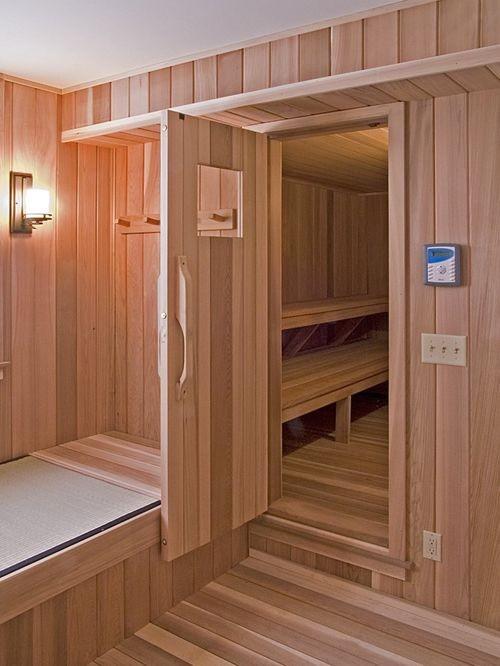

Brick bath interior

The next step in phased construction brick baths - floor. Porcelain stoneware is a practical and aesthetic option. So that the tile does not deteriorate during the winter, it is better to put it on a frost-resistant solution.

Errors in masonry will quickly make themselves felt in such wet spots after heavy rainfall as in the photo. If a similar problem manifests itself, you will have to miss all the seams.

After installing the stove and installing the chimney, you need to make a test firebox to make sure that everything is done correctly.

They are subsequently sewn up with boards. Boards are not used near the firebox. Then you get a deepening suitable for storing a small amount of firewood.

As a result, the wooden floor will create comfortable conditions for people leaving the steam room. And finishing the space in front of the firebox with porcelain stoneware will ensure fire safety.

It is better to sew up the ceiling in the steam room with lime clapboard.

For the ceiling in the dressing room, an ordinary pine lining is suitable.

The walls are sheathed with clapboard. In places where the skin will be in contact with the wall, do not use metal fasteners. After finishing the interior space, the heating time to 80°C was reduced to 50 minutes.

Own bath is an indispensable tool for meeting friends and relaxing after a busy day at work. But for many people, turning to construction company for the construction of a turnkey bath - too expensive. And they prefer to build on their own.

This is a rather complex process in which a huge number of details must be taken into account. Already at the stage of designing and budgeting a future bath, many questions may arise. We hope that this article will help clarify many of them.

There are no ideal building materials. Brick baths have their pros and cons, which must be considered when choosing a project.

Advantages:

- long service life. With a reliable foundation and proper operation, a brick bath will last much longer than similar buildings made of wood and other materials;

- security. A brick building is much better protected from fires than wooden buildings;

- variety of choices architectural forms. The strength of the structural elements of a brick bath allows you to create buildings of complex configuration, original layouts and roof shapes.

Minuses brick baths also have. Among them:

- relatively high cost. The construction of a brick building will cost an order of magnitude more expensive than timber or concrete structures;

- the need for additional thermal insulation.

Choose a project

foundation type

When building baths, three main types of foundation are most common.

| foundation type | Description | Illustration |

|---|---|---|

| Monolithic or prefabricated strip base | A reinforced concrete strip is poured under the internal partitions and along the perimeter of the walls of the building, which is subsequently waterproofed and insulated. In the process of building the foundation, the vents necessary for the ventilation of the underground space of the bath are equipped. |

|

| Columnar | Supports are installed at points of increased loads - under heavily loaded girders, bearing walls, in the corners of the building. Supports can be made from various materials, namely: Blocks (buried to the point of permafrost and surface); |

|

| Screw | Screwed into the ground screw piles. Further, heads are installed on them, a reinforcing cage is laid, a strapping from a bar or a concrete grillage is poured. |

|

When building a brick bath, the most the best choice there will be a deep strip foundation. Its construction takes more than one day and is quite expensive, but you can be sure that the foundation will not sag under the weight of massive walls.

Strip foundation for a brick bath - photo

Strip foundation for a brick bath - photo  The plan of the trench for the strip foundation - corresponds to the position of the future walls, partitions and the stove of the bath

The plan of the trench for the strip foundation - corresponds to the position of the future walls, partitions and the stove of the bath

Video - Strip foundation. Choice and ground rules

Video - Strip foundation - technology

The depth of the foundation and the width of the foundation also play an important role. When determining these parameters, it is necessary to build on the type of soil, climate and wall width. The foundation should be laid below the freezing level of the soil, and to determine its width, it is necessary to take the estimated thickness of the walls and add 10 centimeters on each side.

Downloads - approximate calculations strip foundations of various configurations and areas. The thickness of the tape, the amount of reinforcement, the estimated cost of materials are indicated in the documents.

Wall masonry type

It can be lightweight and solid. With continuous masonry, bricks are laid in at least two rows without voids between them. With lightweight - two walls are laid out of bricks, and voids are left between them, which are filled with heat-insulating material (fine slag, basalt wool etc.).

During the construction of baths, as a rule, a lightweight type of masonry is used, since it allows you to reduce the weight of the walls and, accordingly, the load on the foundation. It is also important that with lightweight masonry, much less brick is consumed.

Tip: solid masonry should be used only in cases where increased structural strength is needed.

The best option for laying walls - silicate brick (white color). You can also use clay (red). It is more durable, but also more expensive.

| Name | brand | Size | Appearance | Retail price | Picture |

|---|---|---|---|---|---|

| Single solid brick | M100 | 250x120x65 | Ceramic, solid, grooved | RUB 10.11 | |

| M125 | 250x120x65 | Ceramic, solid, single, grooved | RUB 11.48 | ||

| M100 | 250x120x65 | Full bodied, smooth | 12.55 rub. | ||

| M175 | 250x120x65 | Full bodied, smooth | 14.12 rub. | ||

| M100, M125, M150 | 250x120x65mm | Fluted | 19.6 rubles |

|

GOST 530-2012. CERAMIC BRICK AND STONE. General specifications. Download file

Calculation of the number of bricks

To avoid unnecessary expenses, it is necessary to accurately calculate the amount of brick that will be needed for masonry. To do this, first calculate the area of the outer and internal walls, then the area of \u200b\u200ball door and window openings is subtracted from it and the resulting figure is multiplied by the thickness of the walls.

Also when calculating required amount bricks, it is necessary to take into account the thickness of the mortar joints and the thickness of the bricks. Beginners often do not take this into account and buy 30-40% more bricks than what is really needed for construction.

Tip: Trying to make these calculations yourself is not necessary at all. On the Internet, you can find building tables and services for calculating the required number of bricks for masonry, taking into account their size and seams.

Video - Building a brick bath with your own hands

Video - A good example of building a brick bath

Location and size of premises

In the simplest projects, a bathhouse can consist of just one room in which you can soar, wash, and change clothes. But such options are not very comfortable. Classical Russian baths provide for the presence of three rooms: a dressing room, a steam room and a washing room.

dressing room

This room plays the role of a dressing room. It can also store fuel for the stove (coal, firewood) and bath accessories. Often this room is used as a rest room and, in addition to wardrobes, armchairs, sofas, and a table are installed in it.

Dressing room - wardrobe

Dressing room - wardrobe

According to technical standards, each person in the dressing room should have at least 1.3 square meters of area. And this is not counting the area occupied by boxes with firewood, cabinets, hangers, etc. The recommended area of the dressing room is up to 6 square meters. There should be a window here.

Tip: it is important that the door to the steam room opens towards the dressing room. If the door goes towards the dressing room, it will be easier to open it in an emergency, if someone becomes ill in the steam room.

In this room, according to technical standards, each person should have at least 1.2 square meters of area. As for the washing equipment, it depends on the financial capabilities of the owners of the bath and the total size of the room. The most budget options include washing in a regular trough or a pouring bowl. With a large washing room and a sufficient budget, you can install a full-fledged bathtub, a shower cabin and even a small pool in this room. The truth in these cases will have to bear additional expenses for plumbing.

Tip: with sufficient space in the washing room, you can install a special table or trestle bed for massage.

Video - The device of the Russian bath

steam room

This is the main room in the bath. And it is necessary to calculate its dimensions with special care.

| Parameters | Description | Illustrations |

|---|---|---|

| Height | It should not exceed 2.5 meters. Otherwise, the steam will be small and it will be unstable. It is also not recommended to make the ceiling very high, since in this case you will have to spend much more time on kindling. |

|

| Area | It must be determined based on the type of stove and the number of people who will use the bath. If a metal stove is used in the bath, you need to make a steam room a little bigger size than at brick oven. Distance from shelf to metal furnace must be at least 1.25 meters, otherwise there is a risk of getting burned, since these types of stoves heat up the air a lot. For each person in the steam room there must be at least one square meter of area. And this is without taking into account the area of the stove (on average, the stove also occupies about 1 square meter) and the fire-prevention distance to the walls. It turns out that, for example, the area comfortable steam room for three people should be at least 4.5-5 meters. |

|

Tip: in order to save money, you can close up the spaces under the shelves and thereby reduce the heated volume of the steam room. This will reduce fuel costs. Indeed, in this case, the heated volume of the heated area will decrease, but not to the detriment of the spaciousness of the room.

Construction and type of furnace

To begin with, it is worth deciding on the material of the future furnace. It can be both brick and metal. Each material has its own advantages.

- environmentally friendly;

- durable;

- They warm up the room well and cool down for a long time.

Metal ovens:

- heat up faster;

- are cheaper;

- have less mass.

Video - How the sauna stove works

It is calculated based on the area of the steam room and its structural elements. First you need to measure the total volume of the heated room. When calculating, it is necessary to take into account heat losses, therefore each square meter surfaces not covered with thermal insulation will add 1.2 cubic meters to the total volume of the steam room, glass door- 1.5 cubic meters. If, for example, a volume of 8 cubic meters was obtained as a result, an 8 kW oven will be needed for the steam room.

Furnace type

The main thing is to decide on the type of heater. It can be either open or closed. Open-hearth stoves heat up very quickly, but cool down just as quickly. The stones in them heat up to 200-250 degrees.

Furnaces with a closed heater heat up for a long time - an average of 2-4 hours. However, they take a long time to cool down. The temperature of the stones in them reaches 400-500 degrees. Also, the advantage of such stoves is that the smoke from them does not penetrate from the steam room into other rooms of the bath.

Video - All about sauna stoves

Where to install the oven

It can be installed both directly in the steam room itself (for example, in the center or in one of the corners), and in the adjacent room, namely the dressing room or shower room (in the latter case, the heater is located in the steam room, and the firebox door is located in another room or even on street). In the steam room, stoves with a shortened fuel channel are installed, in adjacent rooms - with an external fuel channel. It is also necessary to take into account the type of fuel for the furnace. If gas is used for kindling, it is impossible to put the stove in the steam room.

In the center of the steam room, only an electric stove with a wooden protective rim around can be installed, since the use of metal models is fraught with burns for people in the bath.

Location selection

The location of the bath depends on many factors.

The building is preferably located near a reservoir. This is especially true for baths, to which it is not planned to conduct plumbing. At the same time, they should be located so as not to be flooded during the flood, so it is best to place them on a hill.

It is better to place the window on the west side, since in the evening there is much more sun from this side.

The bath should be located on the leeward side of the rest of the buildings so that in the event of a fire the fire does not spread to it. True, for brick buildings this is not as relevant as for wooden ones, but if possible, it is still worth following this rule. The distance to other buildings must be at least 5 meters. But this rule must be observed, since such a distance is directly indicated in the technical and sanitary standards.

The front door should be located on the south side, since snowdrifts in winter are much less on this side.

Tip: if the area of the site is small, and the owner wants to place several buildings on it (for example, a tool shed, summer kitchen, bathroom), it is better to combine them with a bath. Otherwise, you may not meet the established technical standards distances between buildings.

Each of the bath rooms is finished differently.

steam room

Of course, this room must be sheathed with wood. But not every breed is suitable. In order not to get burned when touching walls or shelves, preference should be given to species with a minimum wood density that heat up more slowly: maple, aspen, alder, linden, northern pine.

Tip: due to high humidity and temperature changes, the tree will quickly darken. This is quite normal, you do not need to think about repairs, noticing this.

In this room, by definition, there will be maximum humidity, so it is best to tile the floor. Of course, you can also choose wood (preference should also be given to rocks with a minimum density), but no matter how moisture resistant it is and no matter what compositions are processed, gradual darkening is still inevitable.

Advice: ceramic tile does not become damp, but cools down quickly, so touching it bare feet not very pleasant. Can be installed over tiles wooden pallets, then using the sink will be much more comfortable.

dressing room

Any materials are suitable for finishing this room: lining, stone, tile.

Tip: With a limited budget, there is no need to choose the highest quality materials. There will be low humidity in the room, room temperature, so even if you finish the walls with cheap pine clapboard, it will take a long time to make repairs in the room.

thermal insulation

This aspect is very important. After all, if the building does not heat up well, all the titanic work on its construction will be down the drain. It is necessary to start work on the thermal insulation of the bath from the very first stage - the construction of the foundation and the arrangement of the floor in the bath.

Particular attention should be paid to the vapor barrier of the steam room and washing room. Under wood paneling foil insulation is laid (for example, mineral wool) or foil up to 250 microns thick is attached to the insulation layer. It is imperative to insulate both the walls and the ceiling of the room. To warm the dressing room, you can use not foil, but cheaper kraft paper.

To improve thermal insulation, it is necessary to place windows as low as possible and make high thresholds in the steam room. The area of the window glass is also important. The larger it is, the greater the heat loss. Therefore, the project should not provide big windows. Determining their size is very simple. The window area in the bath should not exceed 5% of the floor area. And of course, all the cracks in them should be caulked, and the frames should be tightly fitted to the bindings.

Advice. It will also help reduce heat loss. double glazing windows.

Ventilation

In traditional baths in white, an equipped ventilation system of a supply and exhaust type (with forced or natural circulation). It includes an outlet for air flow and exhaust holes. Air inlets are best placed under the bottom of the stove so that the air heats up faster. The exhaust duct is located just below the ceiling. If the stove is located in a steam room, the exhaust duct must be located at the maximum distance from it. In large steam rooms with powerful stoves, two exhaust channels can be made.

Tip: It is necessary to place special dampers on the outlets in order to control the air flow in the steam room.

Video - Do-it-yourself ventilation in the bath

For some reason, it is believed that the construction of a brick bath takes more money than the construction. If you use only new expensive brick, perhaps this is so. But you can always save money: take a used brick. It will turn out very inexpensive. Even taking into account the fact that exterior decoration and insulation will be required (and insulation of a brick bath is necessary in any case).

When building with your own hands, it is not easy to decide. Can help in this matter finished projects. It is not necessary to copy them completely, sometimes it is enough to take an idea, modifying it to suit your own needs. Several projects of small brick baths, which will not be difficult to build with your own hands, are given below.

Bath 4 for 6

In the original version, there are only three main rooms in the bath:

This layout of the bath can be slightly changed. The fact is that entering directly into the rest room is not the best way out, especially in winter: it will be cold every time the doors are opened. There are several ways to eliminate this shortcoming:

- Attach a vestibule outside. And make it insulated so that you can not be afraid of cold air from the street.

- Make a covered porch.

- Install another partition in the rest room, which will separate, say, a meter and a half. turn out long room dimensions 1.5 * 3.3 meters. So that the place does not walk, it is also divided into two rooms. Leave the corridor approximately 1.5 * 1.5. From it will be the entrance to the rest room. And adapt the second room for a wardrobe and a place to store bath utensils.

How the bath plan will look like in this case, see the photo below.

The stove in these projects is drawn with firewood from the steam room. But this is far from the best way for such small room: at least one and a half meters are taken away for organizing the pre-furnace space: there should be a non-combustible stove, firewood and the door will open. Considering that the area of the steam room is slightly less than 5 meters, then this is simply an unaffordable luxury.

It is more rational to put the stove so that it is heated from the rest room. Only this must be foreseen during the construction of the partition: leave an opening that will be slightly larger in size than the removal of the firebox. The metal casing of the firebox is then covered with a heat insulator, and the remaining space is filled with brickwork.

A little about the choice of the oven itself. First of all, you need to choose a stove for the mode in which you will bathe: dry-air (also called a Finnish sauna) or wet (Russian bath). Then you need to focus on the volume of the steam room (not the area, but the volume, taking into account the height of the ceilings). Dimensions also play an important role: decide what size the oven can “stand” in the space allotted to it and select the options. Then, read reviews about the quality and operation of all selected units. Weeding out those that have a controversial reputation, choose already by price.

Another version of the bath 6 * 4 meters, but with a small open veranda and tambour. Here the dimensions of the steam room and shower are small. Two, maximum three people will feel comfortable in it. But for a family bath is a good option.

Since the dimensions here are quite miniature, you will have to look for a tall and narrow stove. Many companies have these. For example, under a brick screen, you can try to fit a small stove from horizontal pipe there is a lot of choice small ovens for a bath at "Termofor" - there are also compact stoves.

Brick bath 4 by 4

Layout options for a small bath for family use 4 * 4 meters are presented in the photo below. There are also several layouts in which the entrance to the rest room is directly from the street. It is rather problematic to fence off some meters at such small sizes - the areas are already very modest. The way out then is to attach at least a small vestibule.

In some layout options, the stove is heated from the steam room, in others - from the dressing room. But you can change this if you wish. As well as rearranging the oven to another wall. It is only important to take this into account when erecting partitions.

Layout of a brick bath 6 * 6

This variant of the arrangement of rooms in the bath is more like a guest house-bath. There is a rather large hall, a decent kitchen-living room from which it is quite possible to make a guest room. Relaxation room, steam room and sink have small size. Part of the washing room is enclosed in a bathroom. Outside there is a veranda. .

The dimensions of the rooms in this bath project are as follows:

- common room 4.4 m 2 ;

- sink with an area of 3.7 m 2;

- steam room 4.8 m 2;

- bathroom 1 m 2;

- hall 4.8 m 2;

- kitchen-living room - 10.1 m 2;

- veranda 4.7 m2.

In this project, a brick bath is presented interesting option location of the stove: it heats almost all rooms. The coldest is the hall. But the stove will need to be selected carefully: it should work both as a heating one and as a bathhouse. Perhaps, to reduce the amount of hard radiation, it makes sense to consider the option in lining (talcochlorite as, or lined with jadeite).

Any of the projects can be taken as a basis. Make adjustments to it, get your own bath that will meet your needs.

Advantages of brick baths

If you have at least a little knowledge of the bricklaying technique, you can build a bathhouse with your own hands. Even if you don't know how to lay a brick, you can learn how to do it. It is desirable to attend the construction, look at the process, ask questions. But if this is not possible, there are quite sensible videos on how to lay a brick. Just pay Special attention on the correct erection of corners - the geometry and strength of the building depend on them.

Compared with wooden baths, there are three significant advantages:

- the brick does not rot and is not damaged by diseases and fungi;

- immediately after erection, you can begin to install windows, doors and finishing work- it does not shrink as much as wood;

- the brick does not burn, because in terms of fire safety they are less dangerous.

It turns out that the laboriousness of the masonry is more than offset by the lack of shrinkage. As a result, it will be possible to bathe much earlier.

Minuses

Immediately you need to say about the shortcomings of a brick bath. First, this material has a high heat capacity and good thermal conductivity. The term "high heat capacity" means that when fired, the brick "pulls" a lot of heat. And until it heats up, the steam room will not heat up either. The second characteristic - good thermal conductivity - means that the brick conducts heat or cold well. That is, if you leave the walls as they are, even thick ones, you will have to heat for a long time. Therefore, they make good thermal insulation in the steam room. But they make it in a bath from any material, even from wood (not always, but often).

The second problem of brick baths is hygroscopicity. Walls absorb water, both in liquid and gaseous state. In the current bath, the humidity is always increased, so this is a problem. It is solved by good vapor barrier.

The foundation will need to be made serious: shallow ones will no longer work. They do it more often, but slab or

The foundation for a brick bath needs a serious one. Shallow ones will no longer work here: the weight of the walls will turn out to be quite decent. Therefore, they make a full-fledged or slab foundation. In some cases (depending on the type of soil), it is possible to make a pile-grillage, but with a metal grillage.

How to insulate

To solve the problem with both heat capacity and thermal conductivity, it is considered more correct to insulate brick baths from the inside. In this way, hot air is cut off from a material with good thermal conductivity. The heat stays inside the room. But at the same time, the brick outside freezes.

This option is best if the bath is unheated. After all, the brick does not withstand so many freeze / thaw cycles. If every time a bath is heated, it thaws and then freezes again, its resource will end in a few years. Then the brick will begin to crack and crumble.

If the bath will be heated constantly, then to internal insulation you will also need to add an external one (for decoration). Then the walls will stand for a long time, and the steam room will heat up quickly, and cool down slowly.

But all these calculations are valid for the case when a solid brick wall is being built. But today it is not the only option. Increasingly, they began to build houses and baths from bricks according to the principle of a thermos. Two thin walls are erected, with a gap left between them. Then there are two options:

- The gap is not filled with anything - the air has excellent thermal insulation characteristics.

- The distance between the two walls is filled with insulation. The cost of construction increases, but the room will also be warmer. If funds are limited, expanded clay can be poured between the walls. But you will need to take care of good waterproofing - expanded clay is also hygroscopic. Therefore, the option, although inexpensive, is not the best. The most optimal, probably, in this case is polypropylene or foamed polyethylene. They do not rot and are not damaged by fungi, have low thermal conductivity, and still do not absorb water in any form.

Building a brick bath with your own hands with a heat-insulating gap is technically more difficult. But build for yourself. And there are not so many difficulties. Get it right. Definitely.

If there is a heat-insulating gap, you still need to insulate the bath from the inside: the inner wall will still take heat away until it warms up. Just the flaws will no longer be so critical.

An approximate procedure for warming a brick bath

The approach to warming a bath is not at all the same as to warming a house. In damp rooms, we need to achieve good ventilation of insulation materials. Firstly, this way they will warm up faster with warm air and condensate will stop falling on them, and secondly, this same condensate will evaporate faster. Therefore, when insulating a brick bath, they make a whole frame.

Here is an approximate sequence of layers of insulation (from the wall to the room):

- a crate made of timber 50 * 40 mm (100 * 50 for a steam room to fit a heat insulator) or an aluminum profile for drywall;

- mineral wool thickness (for a steam room 10 cm, for other rooms 5 cm);

- draft wall (moisture resistant plywood or other waterproof board material, a board well impregnated from fungi and mold, etc.)

- steam and moisture insulation of the Izospan type;

- counter-lattice (slats must be placed vertically so that the air flow does not encounter obstacles);

- clapboard lining.

A considerable thickness of the cake will turn out. And this must be taken into account when planning: the internal volume of the premises will be smaller due to the volumetric design of the insulation.

To "eat" less space, the walls from the inside can be glued with foam glass. It already has vapor barrier, crate and lining. The option is less voluminous (the foam glass layer can be 5-10 cm depending on the region) and environmentally friendly: complete chemical neutrality and the absence of any emissions at any temperature. Only one caveat: foam glass is an expensive material.

Ventilation

In any case, for the timely removal of moisture and the possibility of good drying of all layers of insulation, it is necessary to make ventilation holes. They should be at the top and bottom of the wall. After all, a brick is not able to give all the moisture from the inside to the outside. Therefore, it is necessary to arrange the ventilation of the heater. But the windows should not be through, but should end in a layer of insulation. Then everything will dry well.

Well, so that during soaring the heat is not drawn out, the ventilation holes can be equipped with doors. After steaming, they were opened - all layers dry up.

Windows in the steam room

Almost none of the plans show the windows in the steam room. But for the Russian bath they are necessary. If you plan to create the conditions of a dry-air steam room - a Finnish sauna, you can not make windows in the steam room. If you take a steam bath like in a Russian bath - with a low temperature (50-70 ° C) and high humidity, then making a window is a must. Even two. If something confuses you, they can be made opaque and called ventilation vents.

The main window in the steam room is placed on the wall opposite the front door to the steam room. Its upper edge should not be higher than the lintel. Dimensions - 40 * 40 or 50 * 50 cm. Something like this. It serves for volley ventilation between visits to the steam room or to lower the temperature if the steam room is overheated. During the procedure, it is closed (some open slightly when steaming).

The second - auxiliary - is located under the shelves. It is opened during the drying of the priliks after the bath. This place is usually the most stagnant zone, from where wood rotting and other wood problems begin. The presence of such a window will solve the problem.

When building a brick bath with your own hands, this must be taken into account. After all, in a wooden frame a small window can be cut down in a whole wall, but you cannot do this in a brick one. So don't forget. And you need to dry a brick (as well as any other) bath carefully.

Basic masonry rules

When building brick walls, it is important to monitor the verticality of the walls and corners. It is equally important that the rows are even in the horizontal plane. Therefore, it is imperative to use a good one - to control the horizontal rows, and - to beat corners and check the verticality of the walls.

Here are some basic rules:

- The first few rows are laid out from a whole brick - then all the rest are leveled along them.

- Corners are built first. They are checked for verticality on both sides.

- A cord is stretched between the two corners, along which all the bricks in the row are aligned (nails are inserted into the seam, a cord is fixed on them, only it should be at the same distance from the wall at both ends).

- When laying, it is important to work at such a speed that the laid mortar does not have time to set. In hot weather, in order to slow down the drying of the mortar, the bricks are dipped in water, after which the mortar is applied.

The technique of working with a trowel when laying bricks is demonstrated in the video.

The hardest part is getting the corners right. After all, at the same time, dressing should be observed, and all this should also look good. How to do it correctly when laying a wall in one brick, see the video.

If the wall is one and a half bricks, the corners do this

These lessons clearly demonstrate the technique of working with bricks, mortar, trowel. They will help you build a brick bath with your own hands, and do it correctly.

Must be necessarily log. However, contrary to popular belief, a real steam room can be built from other building materials. One of them is an environmentally friendly, durable and fire-resistant brick.

Finished brick bath project

Brick bath tolerates well high humidity and elevated temperature. The only thing that needs to be taken care of in a special way is the insulation of the brick bath and the waterproofing of the building. Consider how to build a brick bath, as well as the difficulties that you may encounter.

Let's start with the benefits:

There are also disadvantages that must be taken into account when planning construction:

- Brick buildings require large material costs compared to log cabins;

- Because brick blocks have excellent heat capacity, pairs of this material need to be melted longer. It is worth saying that this problem can be solved with the help of high-quality thermal insulation;

- Brick tends to dampen and crumble, because its vapor barrier properties are much higher than those of wood. Thanks to the arrangement of high-quality ventilation and vapor barrier, problems associated with this can be avoided.

Choosing a place to install a brick bath

It is very important that the site for the construction of a brick bath is dry, therefore, in the case of building a bath next to water bodies, they should be located at a distance of at least thirty meters.

Brick bath project with layout

Brick bath project with layout If this is not done, then flooding is possible during the spring flood.

There are also fire safety requirements. The distance to other buildings must be at least 12 meters in cases where the stove will be fired with wood.

For baths with gas or electric boilers, the drawings must provide a distance of at least 5 meters.

In order to save Money a project of a brick bath attached to the main building on a personal plot can be completed. In such cases, it is much easier to carry out any communications in the steam room.

Foundation for brick baths

Most often for brick baths provide. The gubina of its location should be at least one meter, and in the case of clay soil - more. Consider - :

Walling

As a rule, in order to build walls with their own hands, they use silicate or red brick. To calculate how much brick you need to purchase, you should perform simple mathematical operations: the height and width of the walls are divided by the height and width of the brick blocks. For convenience, all the necessary drawings of the future structure should be at hand.  At the end of the calculation, it is desirable to take into account 5% of broken bricks.

At the end of the calculation, it is desirable to take into account 5% of broken bricks.

Do-it-yourself laying of the walls of the bath is made in two or one and a half bricks. This is with regard to the main walls, and if there is a partition in the bath, then a smaller thickness can be used for its construction.

Consider various options wall construction:

- Walls in which an air partition is provided, 60 mm thick;

- With thermal insulation between the inner and outer rows;

- Walls without an air barrier, with thermal insulation on the inside of the walls.

Walls in which an air partition with thermal insulation is made from the inside are considered the most budget option. Brick on such walls will take less, however, this will not affect the quality of the structure, but this is only when high-quality dressing is performed.

original project brick bath

original project brick bath For do-it-yourself construction of the basement of the bath and the part that is above, they usually use different kinds bricks: solid and hollow, respectively. As for the solution, it is recommended to knead it from sand with grains from 1 mm to 3 mm, cement, water and lime. For convenience, the required level is noted in the solution dilution tank, and then water is added.

At the end of the construction of the walls, the masonry is equipped with pins that are needed to attach the beams to the walls. The overlap is placed directly on the walls, deepening into specially prepared nests. The floor beams from the ends are left open, however, it is better to seal the distance between them and the brickwork with thermal insulation.

How to make masonry with your own hands

If the construction of the bath is done by hand, then some recommendations from professional builders will come in handy.

building a brick bath

building a brick bath We present them below:

- To begin with, two adjacent corners of the future structure are selected, and several brick blocks are placed in these places. A guide thread is stretched between them so that the intermediate bricks lie flat.

- With the help of a guide, the horizontal laying is achieved, as well as the same height of the cement joints.

- Then small areas of walls are laid out at the corners, up to six rows of bricks. To do this, a landmark is attached in each row.

- The solution should not be applied too long section otherwise the mortar may dry out before the bricks are laid.

- The solution should be thoroughly mixed before starting work. The mortar layer to be laid should be 20-25 millimeters thick. It is recommended to ensure that the layer to be laid is even throughout the entire area. This is necessary so that later you do not have to level the masonry.

Silicate brick bath project

Silicate brick bath project For bonded rows, the mortar should be laid in such a way that it recedes from the edge of the masonry by one or three centimeters, depending on the front masonry or masonry in the wasteland. Spoon rows involve laying a solution that recedes from the edges by 2-3 centimeters. During the entire masonry process, attention should be paid to the quality of the seams.

The first row of bricks must be made of solid bricks. broken bricks can be used for spoon rows, and with inside, but their use as a material for the construction of supporting structures or columns is unacceptable.

Brick laying scheme

Brick laying scheme The rows begin to be laid from the outer bricks, and bonded rows should be provided to support the beams. When laying bricks with your own hands, you need to know that they need to be wetted, especially when the work is done at high temperatures.

It should be noted that it is possible to lay bricks around the entire perimeter and start a new row after the previous one is completed. You can also build walls in sections, which is more convenient, but for this it is very important to provide conditions for high-quality dressing.

Brick bath - the ability to fit the building into the exterior of the yard country house. The material is not inferior to a log house with proper insulation and waterproofing of surfaces. The article discusses the pros and cons of the solution. Ready-made projects are given and a guide is given for the independent construction of a bathhouse on the site.

brick bath

For brick, there are fewer restrictions in choosing a place for construction and in implementing the configuration of the premises. A refractory material is chosen for the bath building.

Brick bath: pros and cons

Of the advantages of a brick bath, there are:

- fire safety;

- life time;

- environmental friendliness;

- variety of projects;

- ease of operation.

Clay from which I make bricks - natural material, so we can talk about its environmental friendliness. Wood at the construction stage of the bath is treated with flame retardants and anti-rot preparations, which they carry with them harmful impurities. It is impossible to set fire to the blocks, which is important for the building, because solid fuel stoves are used, in the furnace of which the temperature reaches 600 °. A brick bath will last 60 and more years with proper care. A structure made of timber can withstand the same period, but the cost of maintenance is 2-3 times higher. Rounded or planed timber is not bent, which interferes with the creation of designer buildings. The shape of the bath wall from the blocks is made curvilinear if the project requires it.

When choosing a material, take into account the cons:

- heat capacity;

- the need for insulation;

- moisture absorption;

- price;

- foundation.

The thermal conductivity of a brick is higher than that of wood, so it is necessary to insulate the bath with an insulator. Micropores in the blocks absorb moisture, breaking down from temperature changes and losing strength. A brick bath project can cost more than a log of the same size. The weight of the building requires a strong foundation, which also increases costs and creates problems on unstable ground.

What kind of brick is better to build a bath

When erecting the walls of a brick bath, well masonry is used, a feature of which is the presence of an air gap between the planes. This approach allows you to insulate the surface from the inside. Of the blocks used:

- red ceramic brick;

- red porous brick.

Ceramic is suitable for cladding and masonry. Blocks are produced solid or hollow. The former have a greater bearing capacity, the latter - thermal insulation properties. solid brick stacked in two rows, if the walls of the bath are erected from it. Hollow is not suitable for plinths and chimneys.

Porous blocks are a molded mixture with clay to which sawdust is added. During firing, the latter turn into ashes, forming voids, which is important for thermal insulation properties. Thermal conductivity is comparable to that of rounded timber. Advantages: sound insulation, light weight and strength.

Advice! If thermal insulation of the walls of the bath is provided mineral wool and the arrangement of waterproofing, then silicate brick for construction is also suitable.

How to build a brick bath

Before the construction of a brick bath, a place is chosen on the site in accordance with the norms of SNiP. It is removed from the neighbor's fence by 1 m. In this case, the roof slope should end at the owner's site. If there is a building made of wood on the neighbor’s territory, then the distance from the bath to it should be more than 15 m. The same gap is maintained to open sources drinking water and forest area. A brick bath not adjacent to the house is removed by 8 m and from the roadway by 5 m.

After choosing the territory, they are determined with the project, which is necessary for counting the building material and calculating the supplied communications. The number of blocks for walls is determined by dividing the surface area by the brick area. Take into account the thickness of the seam so that there is no excess. Select the type of pitched or flat roof for a brick bath. The latter is not suitable for areas with heavy snowfalls in winter. To reduce the cost of the project, the roof is covered with a profile sheet. Its quantity is determined by the example with bricks.

Windows and doors for a bath made of bricks are made of plastic. They are resistant to moisture and do not deform when the temperature changes. Under the red brick, laminated frames with wood imitation are suitable. One sash is made open for ventilation. Inside the steam room they put small window to reduce heat loss. front door the bath is made of wood or plastic.

Brick bath projects

Above is a project of a brick bath with a size of 6 by 4. It is being implemented on small areas in country houses or cottages. The building is divided into three parts. Half is occupied by a rest room, which is equipped according to personal preferences. The furnace for the steam room is led into it. The washing room is transitional, it is combined with a bathroom to save space inside the bath.

This brick bath project has an attic, on which there is a billiard room and gym. The shower room and bathroom are separated, there is a guest room that will allow you to receive relatives and friends. The area of the steam room is enough for 3-4 people who can be inside at the same time. There is a brazier or barbecue on the terrace.

The option shown in the drawing is a complete one. Vacation home from a brick with a bath inside. It differs from the previous big square and the presence of a font. The last one is filled cold water for a contrast effect on the human body. It replaces the pool and is cheaper. A separate room is provided for storing firewood, which allows not to litter the rest room. The terrace surrounds the brick bath from two sides, expanding the area for outdoor recreation.

The project of a one-story brick bath, in which the bathroom is separated from the shower. To reduce heat loss and store firewood, a vestibule is equipped. The steam room can accommodate 5 people at the same time. The living room has a corner for the kitchen.

Do-it-yourself brick bath: step by step instructions

When the building material is brought to the site where the brick bath will be erected, the area is cleared. Remove debris, branches and grass, remove a layer of sod.

Foundation

The cleared area for the bath is marked out for the foundation according to the selected project. Two pegs are driven in at the corners, as shown in the photo above. Between them they stretch a fishing line or twine. Right angle control. To do this, according to the plan, the diagonals are measured and compared with the actual ones. If something does not converge, then one of the corners is shifted to the middle or out. Racks are fixed so as not to damage them during earthworks.

Dig a pit under the strip foundation of a brick bath. Its depth should be below the freezing point. In areas where the air temperature in winter drops to -35 °, they decrease by 1.8 and deeper. This is necessary for strength so that the heaving soil does not squeeze out the structure and does not lead to cracks.

Advice! On unstable soils, a strip foundation is also used for a brick bath, but it is reinforced with screw or bored piles. The latter are lowered below the freezing of the soil, and the tape is left on the surface.

The walls of the pit are cleaned and leveled so that they do not crumble. A two-layer pillow is laid at the bottom, which consists of sand and gravel. The level of each is 10 cm. The first is rammed and leveled. Soak the surface with water to soften it. The cake is finished with waterproofing. Use roofing material or a similar material that will eliminate the capillary rise of moisture from the foundation to the brick walls of the bath.

On top of the trench under the brick bath, a wooden formwork is mounted to a height of 40 cm. The shields are made of moisture-resistant plywood with a laminated coating, which improves the quality of the base, or from boards. waterproofing material laid with an overlap so that the solution does not squeeze it out. Inside the gutters place a metal crate of reinforcement. The boards are reinforced with struts and jumpers from above.

After pouring the foundation for a bath of bricks, the concrete is compacted with a deep vibrator, which eliminates the cavities and increases the strength of the mixture. The surface is leveled with a trowel to make it easier to maintain it when the walls are pushed out. If the tape is poured under a brick bath in the summer, then the structure is moistened once a day and covered with oilcloth so that the plane does not crack due to moisture evaporation.

Walls

Before starting the pasture of the brick walls of the bath, waterproofing the surface of the foundation is performed. To do this, it is cleaned and knocked down the resulting influxes. top cover bituminous mastic on which the roofing material is laid. An overlap of 15 cm is made between the sheets. Solid masonry walls are not used, in which the outer and inner planes are located without a gap. Such a scheme consumes material and needs external insulation.

Metal beacons are placed in the corners of the future bath. They are leveled in the horizontal and vertical plane. Between the posts, pull the cord to the height of the row, taking into account the thickness of the seam. Laying starts from one of the corners. The twine is rearranged as it progresses. The evenness of the plane is controlled by a plumb or fishing line between the beacons. To do this, the latter is shifted outside the wall. The basement of a brick bath is built from blocks without cavities, the walls are built from hollow ones. If work is carried out in late spring or summer, then the bricks are additionally moistened to prevent the mortar from drying out.

Roof and floor

For greater strength, an armored belt is mounted on top, which will prevent the destruction of the brick walls of the bath. Formwork is constructed around the perimeter of the building, a metal crate is laid and concrete is poured. After 2 days, they remove the shields and knock down the influxes. After gaining strength, the upper plane is covered with bituminous mastic and roofing material is laid to protect the roof supports from moisture. A Mauerlat is installed on top of the armored belt. The latter represents wooden beam with a cross section of 10 by 10 cm. It is attached to the walls of a brick bath with anchor bolts or on studs that were laid during pouring.

Install truss system for the roof of a brick bath. It is supported and fixed to the Mauerlat. ceiling beams the lower part of the trusses protrudes or they are mounted separately. Fasten the crate, waterproofing and roofing. From the bathhouse, the draft ceiling is lined with boards and a foil vapor barrier is laid. From the attic, the surface is covered with a membrane vapor barrier and mineral wool is placed between the lags. Close the insulation with another layer of vapor barrier.

The space inside the foundation of a brick bath is covered with sand and rammed. At the level of the plinth, a wooden beam is laid, which serves as the basis for the floor. A log with a section of 25 or 15 by 10 is used. It is fixed with anchor bolts to the foundation or corners to the wall. From below, boards are knocked out that will hold the insulation. Cover the surface with waterproofing and lay mineral wool. Another layer of waterproofing is placed on top and a subfloor is laid in the bath.

Exterior and interior decoration

After installing the subfloor and ceiling, they proceed to the interior and exterior decoration of the brick bath. In the steam room, the walls are covered with aluminum foil, which acts as a vapor barrier. From above, a crate of timber with a section of 5 by 5 cm is stuffed. Stretched in a corrugation electrical cable and draw conclusions under the lamps. A lining made of larch or oak is mounted on the frame, shelves are attached.

Information! A separate foundation is built under the stove in the steam room of a brick bath. The perimeter walls are protected with a stainless steel sheet or freed from insulation and finishing. Pay attention to the node where the chimney passes through the ceiling to rainwater did not flow down it into the bath.

The rest room and dressing room are sheathed wooden clapboard or block house, having previously mounted the frame. IN washing room brick bath wood is used on the ceiling. The walls and floor are laid out with ceramic or porcelain tiles.

If the laying of the walls of the bath was carried out by the well method with a heater inside, then exterior finish not required as it replaces facing brick. In other cases, the walls are insulated with mineral wool, fixing it to glue and plastic dowels. After that, a crate made of metal or wood is installed and the bath is sheathed with a block house, clapboard or siding.

Turnkey brick bath

If the bath is not used seasonally, then it will be equipped with heating. This is necessary to maintain the same temperature so that the wood finish does not lead to fluctuations, and brickwork did not absorb moisture. Install a solid fuel or gas boiler if the heating is water. Install radiators under windows or underfloor heating. In the latter version, the floor in a brick bath, after tamping the sand, is poured with a concrete screed, waterproofing is laid, insulated and a pipe is laid. Only after that lay the finish.

Advice! As an electric heating for a brick bath use infrared film or mats that are mounted under the tile.

Supply and exhaust ventilation is provided, which accelerates the exchange of moisture inside the bath with environment. At the junction of the channels with the steam room, a valve is mounted that blocks the flow of hot air into the rest room. The backlight is made from LED chandeliers and tape to reduce consumption and make the building economical.

Brick bath: photo

The photo shows an example of a bath with a masonry of 1.5 bricks. The insulation is made inside the wall, so no external finishing is required. There is a window only in the rest room to reduce heat loss. For the roof, a metal tile was chosen, which is more expensive than corrugated board, but surpasses it visually.

A small brick bath, the walls of which are lined with a well. There is a dressing room for outerwear and firewood storage.

Brick bath with a terrace. In the summer, they make a place to relax on the latter by installing garden furniture and mangal.

The implemented project of the bath, in which the area of the rest room is expanded with a bay window. The advantage is good natural light.

Brick bath with pitched roof suitable for areas where winter strong winds but little rainfall. Advantage - roofing is cheaper, disadvantage - it is impossible to equip an attic.

In the steam room of a brick bath, a metal stove is installed or laid out from fireclay bricks. The space behind it is left open so as not to spoil the finish.

If necessary, install two heaters. One is made of bricks, the second is electric. Power is calculated by the volume of the steam room in the bath.

If the laying inside the brick bath was done for jointing, then the installation of the lining is not required. At the same time, the vapor barrier of the surfaces is considered.

When laying a wooden floor in a rest room of a brick bath, a recess is made under the firebox window. It is ennobled with tiles or metal sheets.

Conclusion

A brick bath is a building that will please with its service life and health benefits. The project may cost more wooden bath, but its main advantage is fire resistance. The rest room is decorated with pine materials. The latter are not suitable for a steam room, because when heated, they release a resin that can burn the skin. Aspen is suitable for shelves, because it is heat-intensive and does not deform from temperature and humidity. Below is a video with an overview of one of the brick baths.