How to make a pig skin at home. Proper dressing of fox skins at home.

The quality (value) of animal skins depends on their breed characteristics, feeding and keeping conditions, slaughter time, correct shooting of skins, their primary processing, storage conditions and dressing methods. The concept of "quality of skins" includes the following properties: size, defectiveness (defects); grade, wear (strength), thickness of the skin, density and evenness of the fur, color, appearance and other. To obtain good-quality skins from animals, the following conditions must be observed:

- For a tribe, select the largest purebred animals with a typical color, thick and uniform hairline;

- slaughter for skins should be carried out in the period from November to March, and always after molting;

- the conditions for keeping and feeding animals must meet zootechnical requirements when they are grown for slaughter for skins;

- strictly observe the rules of primary processing, conservation and storage of skins.

Nutria and rabbits different breeds have different hair density. For example, rabbits of such breeds as: silver-brown, Soviet marder, Soviet chinchilla, white giant, Viennese blue, silver have the most dense hairline. Therefore, young animals of these breeds should be grown for slaughter for skins, first of all. Rabbits of the breeds: gray giant, veil-silver have a significantly lower density of hairline. However, among them there are many individuals with very thick hair.

To obtain high-quality skins, young animals up to three months of age can be kept in groups (5-6 heads in a cage, with a floor area of 0.2-0.3 sq.m per rabbit). Group keeping in the same cage of males older than three months of age is unacceptable, since at this time they become aggressive and often, during fights, injure each other, which leads to damage to the skins - the vice "snacks". To avoid this, males from the age of three months should be kept alone or castrated. After castration, they can be kept four heads per cage.

For breeding use, young animals are left in the herd, which by the time of slaughter for the skin, reaches the highest live weight and has a typical color for this breed.

When determining the term for slaughtering animals for the skin, the state of molting and the season of the year are taken into account. A good-quality skin with lush thick and shiny fur can only be obtained from faded animals. Slaughter should be carried out mainly from November to March. When animals are slaughtered summer period receive, as a rule, skins of the third and second grades, since at this time, even faded animals have a sparse hairline.

Shedding is understood as a change in the hairline in animals, which depends on the age of the animals and the season of the year. In rabbits, the molting stage is determined by the presence of pigmented (dark) skin areas and the growth of new hair, which are clearly visible when the hairline is inflated against the direction of hair growth on different areas the body of the animal, as well as the strength of the bonds with the skin of the remaining old hair, which is checked in various parts of the body by lightly twitching them. If the hair is easily pulled out, then this means that the rabbit is in the molting stage.

Distinguish diffuse molting- scattered throughout the body, and zonal- passing through separate areas of the skin. During diffuse molting, mainly single guide and guard hairs fall out and grow again over the entire surface of the body; with zonal - the hairline is replaced symmetrically, moving from one zone to another.

In addition, rabbits have age(peculiar to the young), and seasonal(in adults) molting. In adult rabbits, spring molting occurs at the end of March - beginning of April, and autumn - in September - October. Shedding individuals have a thick, lush, shiny and elastic hairline. The formation of winter hair usually ends in early November. In this form, it remains until April. When slaughtering rabbits at this time, as a rule, skins of the first grade are obtained, and in the rest of the year - no higher than the second grade. The speed and time of molting of animal hair is significantly affected by the conditions of keeping, feeding and health of animals. In sick or emaciated animals, molting is delayed or stops altogether, while in healthy and well-developed animals it proceeds relatively quickly and coincides with the indicated periods.

SHOOTING

![]()

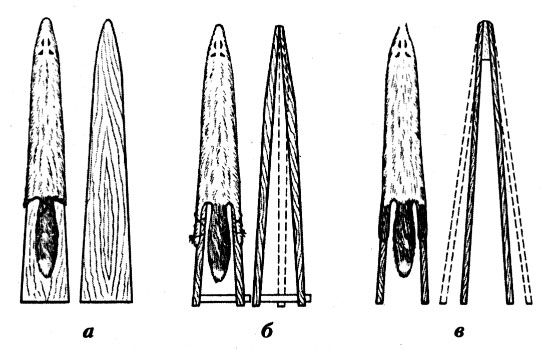

Photographing rabbit skins. The most widely used are two types of shooting rabbit skins - "stocking" (tube) and "layer".

To remove the skin with a stocking, it is necessary to make circular incisions around the hocks and inguinal limbs, as well as skin incisions along the inner surface legs, thighs and perineum. Then the front legs are cut off, along the carpal joint; tail; ears, at the very base. Having seized the skin at the hips, they carefully pull it down, towards the head, with a stocking, while the hairline is turned inward. In places of strong connection of the skin with the body, a knife is used. After the release of the forelimbs, they proceed to shooting the skin from the head. This is done in the following way. Knife makes incisions around the mouth, nostrils, eyes; cut off the mimic muscles, tightly connected with the skin of the head.

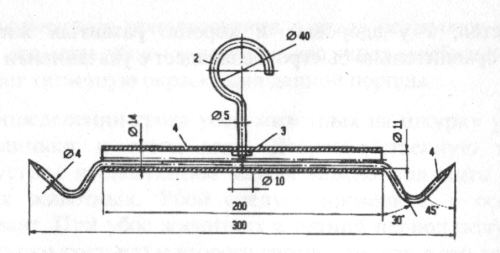

Hung spacer:

1 - metal tube; 2 - steel wire hook (M5 thread is cut at the base)

When shooting the skin in a layer, circular ^ incisions are made in the skin around the carpal and tarsal joints. Cut the skin from the lower lip along the midline of the neck, chest, abdominal wall to the anus; then from the annular incision of the wrist along the inner surface of the forearm and shoulder, through the chest, to the annular incision of the other limb, and, from the circular incisions of the tarsus, along the inner surface of the lower leg and thigh, to the anus. After that, the skin is removed (pulled off) first from the abdominal and chest walls of the carcass, and then from the hips and shoulder, and finally from the spine (back, loin, neck) and head.

Photographing nutria skins. The time between slaughter and skinning should be kept as short as possible to avoid under-warming. Nutria skins are removed with a tube. Shooting begins with skin incisions. Make incisions on the paws and tail, on the border of their omission, as well as along the edge of the rump to the anus. The anus is cut around. After the incisions are made, it is better to hang the carcass at chest level. With a well-sharpened knife, the skin on the thighs, in the groin and on the rump is separated. Then the skin is carefully pulled up to the forelimbs and pulled out. Removed from the front legs, the skin is easily pulled up to the head. When shooting from the head, the skin is taken not by the rump, but as close to the neck as possible. Pulling it with the left hand, with the right hand, they carefully cut the muscles, ear cartilage, the skin around the lips and eyes. When shooting the skin, you cannot pull it with great force, since the skin in this case is greatly stretched, as a result of which the fur thins. On the removed skin, a muscular film remains, with the skin under it, cuts of meat and fat, which are removed during subsequent processing.

Shooting goat and sheep skins. Skins from goats and sheep are removed in layers. To do this, make a longitudinal skin incision from the neck and beyond, in the middle of the chest and abdomen to the base of the tail. Then cross-sections are made along inside front legs to the hock joint. Next, in a circle, cut the skin on the front legs. Then the front legs, along the incision at the carpal joint and the hind legs, along the incision line of the hock joint, are separated from the body. From the chest and abdomen, from the longitudinal line of the cut, as well as from the legs, the skin is removed with a knife, and then manually. To do this, the carcass is hung up by threading wooden lath(length - 30 - 40 cm, diameter - 3 - 5 cm) with notches at the ends, between the tendons and the tibia of the hind legs. The skin from the hanging carcass is removed from top to bottom, avoiding tears and cuts. To save good qualities skins, it is very important to properly skin the animal, preserve it well and save it for dressing.

PRIMARY PROCESSING OF SKINS

In order to avoid excessive contamination of the fur, hair loss and steaming, it is not recommended to pile the skins taken from rabbits in a pile, and leave them in the cold in winter, due to freezing and damage to the leather tissue. It is better to hang paired (only removed) skins on a hanger, and after one hour, trim and degrease. Subcutaneous muscles, fat deposits, tendons are removed from the skin. Cuts and tears that appeared during the shooting of the skins are sewn up with a furry seam. For degreasing, the skin is pulled on a wedge-shaped rule or on a conical blank with the skin outward. Having fixed the skin and the blank, the fat is removed with a knife, dead end, spoon or other adapted tool. The blade of the tool is placed at a right angle to the mezdra, fat is driven off only in the direction from the tail to the head, because. when the tool moves in the opposite direction, the hair roots are cut and they fall out (defect - "draft"). After degreasing, the skin is thoroughly wiped with sawdust, a rag, rags or newsprint slightly moistened with gasoline. The hairline is degreased only with sawdust of deciduous trees.

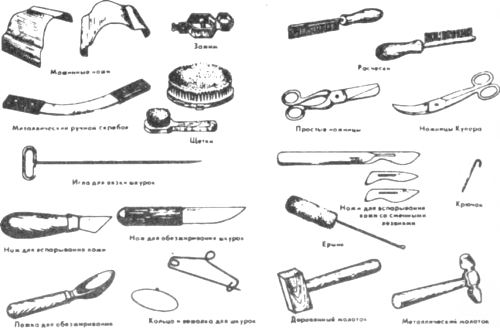

TOOLS FOR PRIMARY SKIN PROCESSING

The skins of nutria are degreased immediately after shooting their carcasses. The remaining fat and cuts of meat are cleaned from the skin tissue, especially on the head, neck, at the root of the tail and under the front paws.

This work is carried out on a smoothly planed oval-shaped board (blank). The blank is made of dry wood (not coniferous) with a diameter of 14 - 15 cm and a length of 75 - 100 cm. The skin is put on the blank with fur inside. Skins are degreased with knives of various shapes. The most convenient is a knife with a long straight blade, a slightly curved tip and a rounded handle. The blade of the knife should be thin, but strong (not bending). Easily curving knife, you can trim the leather fabric. When degreasing, with their left hand they grab the skin by the rump and pull it towards themselves, and right hand, armed with a knife, cut the film together - with cuts of meat and fat. The blade of the knife is held at an angle of 40 - 45 degrees in relation to the surface of the skin tissue of the skin. Care must be taken to avoid undercuts, especially when degreasing white nutria skins, as their skin is thinner and the hair sits deeper than in standard animals. The peeled skin is wiped with sawdust, a rag, rags.

In the process of shooting and degreasing the skins of rabbits and nutria, cuts in the skins or tears of old snacks are sometimes formed, which must be sewn up before straightening the skins on the rules. Cuts and tears are sewn up with white N10 threads, a thin needle, over the edge. The leather fabric is sewn together with a frequent and even stitch so that the edges of the skin touch and do not find each other.

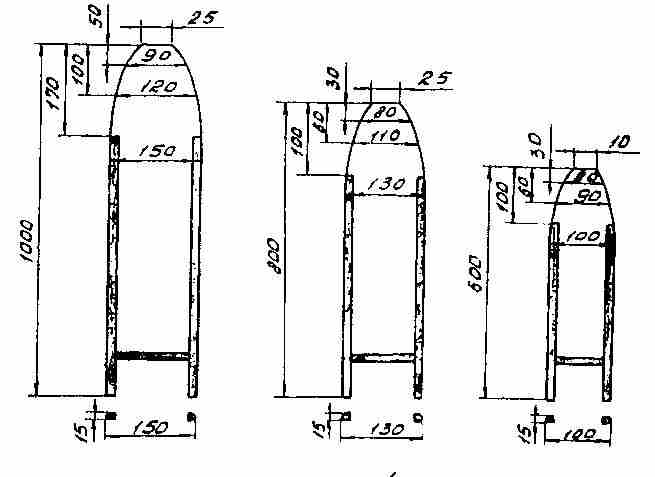

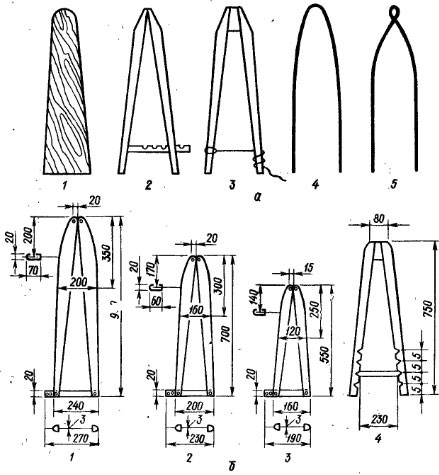

Rules for different designs:

1 - standard for large and small skins; 2 - sliding; 3 - rule-board; 4 - wire rules

SKIN PRESERVATION

Conservation of skins is carried out to ensure the possibility of their long-term storage and transportation, while maintaining their marketable qualities obtained by raising animals and primary processing of skins.

Thanks to canning, the content of free water in the skin is reduced, and bactericidal substances are introduced into the skin, which kill microorganisms and suppress their development.

The most famous types of conservation are:

- fresh dry

- dry-salted

- wet-salty

- pickle (preservation with organic acids)

FRESH-DRY conservation. The skin, with the skin outward, is pulled onto a spinning wheel and fixed with nails, if the skin is removed with a "stocking". If the skin is taken off with a "canvas", then it is stretched on a frame or hung on hangers with the skin up. Spines, frames or hangers with skins are placed in the driest and most well-ventilated places. Drying near hot stoves, batteries, fires and in the sun is completely unacceptable. To protect against insects, the skins are pollinated with poisonous or repellent preparations. You can just cover with gauze.

With excessively hot and fast drying, the core becomes keratinized, the proteins gelatinize. Overdried or improperly dried skin is difficult to dress, some of its sections are not dressed at all.

Under normal drying conditions, the skin is ready in 3-4 days. It is quite hard (like cardboard), flexible and springy well.

Before packing, the skin must be carefully inspected to identify and destroy possible pests and lightly knock out the hair with a stick. Wipe the coat with sawdust (deciduous trees) moistened with gasoline or turpentine for degreasing.

Special bags or inhalers with camphor, naphthalene, paradichlorobenzene, etc. are put into the packed skin. insect repellants.

DRY SALT conservation. It is most widely used in places where humidity does not exceed average values.

The stretched skin is covered, from the mezdra side, with fine table salt and rubbed evenly over the entire surface. After the salt is rubbed into the mezra, the whole mezra is once again covered with an even layer of salt, 0.5 - 1 cm thick. The skin covered with salt rests for 3-6 days. During this time, the mezra is gradually dehydrated and brine appears on its surface, which must be wiped from time to time with a rag. When salting a large number of skins to remove the brine, it is recommended to use a pedestal - these are knocked down on a frame with legs 15 - 20 cm high, 2 sheets of thick lacquered or painted plywood, set in a hut. The freshly salted skins laid from the skin to the skin are stacked in a pile on the undercarriage. In this form, the skins are well salted and do not fade, the remnants of blood and brine flow down the sides of the undercarriage. Inspection of the skins on the stock is carried out after 2 - 4 days. If poorly salted and under-salted skins are detected, those places of the skin are salted where there is not enough salt or it is too wet or bloody.

To speed up conservation, especially during prolonged rains or near water bodies, it is recommended to add a mixture to salt per 1000 grams:

- potassium alum 20g

- ammonium chloride 40g

- insecticides 100g

When the secretion of the brine stops and the flesh acquires an even light gray color, the salt is shaken off the surface of the flesh and the skin is hung out to dry for 3-5 days. Conservation can be considered complete.

WET SALT Preservation it is mainly applied to the skins of a sea animal - a seal, a walrus, etc. The skin, cleaned of fat, is spread with the skin up and covered with a layer of salt, 1 cm thick. Then, a saturated solution of sodium chloride - brine is prepared in an oxidizing container. AT ready solution freely lower the skin for 3 to 7 days. Having taken it out of the brine, the skin is slightly squeezed, spread with the flesh up and again covered with salt. In this form, without shaking off the salt, it is folded skin to skin in an envelope and placed with other similarly prepared skins in a wooden or polyethylene container, carefully sprinkling the layers with salt.

This preservation method is not suitable for light skins (for example, polar bear), as the fur becomes rusty-red and the value of the skin is lost.

PICKLE conservation. Otherwise, it is called acidic. The skin is stretched on a spinning wheel or a frame (board), with the skin side up, and the entire surface is smeared with a solution of acid and sodium chloride using a brush or swab. This operation is called namaz. Preservative solution - pickel.

The PIKEL solution is made up of a mixture of organic acids - acetic, formic, lactic, or any one of them can be used. The ratio between the acids can be any, but their total content in the solution should not exceed 3%. Recommended pickling solution:

- concentrated acid (or mixtures thereof) 30 g

- table salt 30 g

Namaz is repeated every 5-6 hours for 1-2 days, depending on the thickness of the mezdra. After each namaz, the skin is folded in half, skin to skin. Pickel can be prepared in advance - it does not deteriorate in a separate, non-oxidizing container.

For poorly cleaned skins, it is better to use the dipping method rather than namaz. At the same time, the skin is lowered into the pickel solution, all completely and freely, for 3 - 1 hour, depending on the thickness of the skin. The skin in the pickle must be periodically mixed.

Pickling solution for the dipping method:

- concentrated acid (or mixtures thereof) 60g

- table salt 60g

Pickel consumption - 2 liters per 1 kg of skin.

The readiness of the skin is judged by the fact that the flesh acquires a light gray color and becomes rough to the touch, the finger does not slip on the surface of the skin.

A true indicator of the readiness of the skin during pickle preservation is the dryer - a white cross that remains if you fold the skin into a quadruple fold and squeeze this fold tightly with your fingers.

The pickled skin is dried. Pickled skin does not rot, does not fade and is not afraid of pests. In essence, this is a semi-finished dressing of skins, but pickle preservation, in no case, replaces the full dressing of skins.

It is possible to make pickle preservation with inorganic acids (hydrochloric, sulfuric, etc.), but these acids inevitably, to one degree or another, destroy the dermis of the skin, as a result of which the mezra gradually disintegrates, the normal natural color changes due to the destruction of pigments, and the hair falls out.

Rabbit-breeding raw materials are preserved in several ways, but the most common and most accessible is the fresh-dry method, when the skins are dried without the use of preservatives, to a moisture content in the tissues of 10-17%. Fat-free and wiped skins are stretched on the rules with the flesh outward, evenly, without wrinkles and folds. The back and belly (belly) should fall in the middle, and the sides should fall on the edges of the rule. The skin is stretched so that its length in the straightened form does not exceed three times the width in the region of the hind legs. The skin distributed and stretched on the rule is fixed (with small nails, twine or thin and flexible wire) and dried. Rabbit skins are best dried with room temperature, in a heated room - in winter and under a canopy or in a barn - in summer. Optimum temperature drying of skins is in the range of 20 - 35 degrees, and the relative humidity should not exceed 30 - 60%.

Goat and sheep skins can only be preserved when cooled, but no later than two hours after shooting.

The most common dry-salted method, as it achieves the best canning result. With the dry-salty method; the cooled skin is spread on a clean floor or flooring, with the skin up and well straightened, sprinkled with clean salt, and the thickest areas are rubbed with salt. The second sheepskin is laid on the first sheepskin (with wool to the inside), then the third, etc. Salted skins are left to lie in a dark, dry and cool place for 2-3 days. After that, the skins are still salted and rolled up in a bag, like a fleece. Inside the package, the mezdra does not dry out - it gradually salts out in 6-8 days. The skins are then dried; in summer under a canopy, in winter - in a heated room, at a temperature of 20 - 30 degrees. When 0.8% naphthalene is added to the salt, the preservative effect of the salt is enhanced. Fresh-dry canning involves the usual drying under a canopy. With this method, the skins are saved only if they are kept dry all the time. Even with slight moisture, conditions are created in them for the development of putrefactive bacteria. Known acid-salt method, for which a preservative mixture is prepared from 90% sodium chloride, 5% aluminum alum and 5% ammonium chloride. The consumption of the mixture is 1.5 kg per skin. The mixture must be stirred. Preservation of sheepskins in this way ensures the preservation of the quality of the skins during their long-term storage. The skins are laid in the same way as with the wet-salt method. This method of preserving goat and sheep skins is used successfully at any time of the year.

STRAIGHTENING AND DRYING SKINS

Fat-free skins of rabbits and nutria must be straightened on the rules and placed in the dryer. When landing on the right Special attention give the shape of the mandrel of the skins. The skins are ruled with leather fabric outward on wooden rules. Rules made of thick metal wire recommended in some manuals should not be used because with a temperature difference between the rules and skins at the points of their contact, hair falls on the skins and clearings without fur (bald patches) form. Rulers are made in three sizes, with a width in the middle part of 200 mm, 160 mm, 120 mm. The right selection rules for the size of skins provide normal (without stretch marks) editing of skins of any size. The skin is put on the rule freely, keeping the natural size. On a strongly stretched skin, the hairline turns out to be sparse, which is why its quality decreases, and consequently, its value also decreases. When dressing the skins, the ratio of width to length must be observed, as 1:2.2 - 1:3. The skins are dried in a well-ventilated room at a temperature of 25 - 30 degrees. In order to constantly maintain this temperature, the room must be equipped with an appropriate heating system. It is not allowed to accelerate drying by raising the temperature in the dryer, by placing the skins near the stove. It is necessary to regularly monitor that the drying of the leather tissue takes place evenly, over the entire skin, without streaks. Therefore, if necessary, the skin is turned, interchanged with other skins on the rack. The skins on which droplets of fat have appeared can be wiped with a rag, rags, paper.

SKIN TREATMENT AND CURRENCY

Here are general provisions, methods, methods and recipes with the help of which it is possible to produce skins, both domestic and wild animals.

Dressing skins is a complex, time-consuming process that requires compliance with the temperature regime, norms for the concentration of solutions, the duration of their exposure, unremitting attention, experience with chemicals. Deviation from the technological norms of dressing leads to damage to the fur raw materials. In order to learn how to dress skins and gain sufficient experience in this, it is better to start with obviously defective raw materials, and try to prepare solutions yourself, choose convenient dishes, organize workplace. Only after a positive result is obtained on defective raw materials, it is possible to start dressing skins High Quality.

Dressing is understood as a complex processing of skins by mechanical and chemical influence in order to change the properties of the skin, making it suitable for use and long-term storage skins and fur products.

The two most effective methods are:

- fermentation (bread or Russian way)

- pickling with organic acids

All other operations performed on skins are related to the processing of skins. But the whole process of working with skins wears common name - dressing.

It should be distinguished dressing after fresh-dry, dry-salted and wet-salted canning from dressing after pickle (acid) preservation.

In the first three cases, dressing consists of the following workflows in a strictly defined order:

- 0tmoka

- Mezdrovka

- Degreasing wash

- Dressing-fermentation or pickling

- Tanning

- Drying

- Relaxation

- breakdown

- Mezdra cleaning

- hair cleaning

When dressing skins preserved by the acid (pickle) method, the same order is preserved, but the process is much shorter:

- Tanning

- Drying

- Relaxation

- breakdown

- Mezdra cleaning

- hair cleaning

OTMOKA- this is the process of soaking a canned skin, in order to bring it into a paired state, with a perfectly soft and elastic mezra.

Soaking is carried out in a sufficiently capacious, non-oxidizing dish.

Skins for soaking are laid so that the solution can completely cover them, and so that the skins do not float, they are sunk with some kind of load. Soaking lasts 1-4 days, depending on the thickness of the skin and the duration of storage after canning. To avoid the development of microorganisms, soaking should be carried out at a temperature of no more than 18 - 20 degrees.

- Borax crystalline - 30 g

- Carbolic acid (phenol) - 2 g

- Table salt - 50 g

- Zinc chloride - 3 g

- Formalin - 1 g

- Water - 1 liter

Borax speeds up the soaking process.

Phenol inhibits the development of microorganisms.

Table salt binds and removes part of the soluble proteins from the mezdra.

Zinc chloride contributes to a good fixation of the hair in the mezra and is especially useful when working with rotten skins. Its presence in the wash solution is not required, but desirable.

Formalin is used only in the case of rotten skins. From formalin, the quality of the mezdra worsens somewhat (it becomes somewhat hardened), but decay stops and hair loss will be stopped.

Strongly dried skins (especially thick-skinned), not amenable to soaking completely or in separate places, must be loosened, for which the method of fattening is used - swelling of the skin. The skin is placed in a 3% solution of acetic acid, after swelling of the skin, add to this solution table salt(50g). The skin in this solution is mixed and left in it for soaking. Nazhor gradually disappears, the mezra takes water well. Soaking goes on as usual.

Poorly soak skins that are not sufficiently cleaned of fat, as well as skins with a keratinized surface of the mezra, as a result of accelerated drying. Horny areas of the skin do not accept water, are cut off with great difficulty during skinning, do not lend themselves to dressing, remaining hard, rigid and brittle. These are live bait - separate white areas on the surface of the mezdra. When soaking such skins, special amplifiers are used.

If the hair is firmly held in the skin and well fixed, then you can use alkaline enhancers by adding to the wash solution:

- ammonia- 50 g or

- soda ash - 10 g

- water - 1 liter

With weak hair, the use of alkaline enhancers can lead to its complete loss. In these cases, it is recommended to add 1 gram of organic acid to the wash solution. A stronger concentration of organic acid causes the flesh to burn. To protect against nazhora, 30 grams of table salt is added to the soaking solution.

Do not use hard water for soaking. If there is no soft or normal water, then ammonia (10 - 12 g) is added to hard water or it is pre-boiled with some kind of alkali to neutralize.

The most well and quickly soak the skins preserved in the dry-salted way, somewhat worse - after the fresh-dry conservation.

The success of dressing skins depends on the quality of soaking.

The readiness of the skin and the completion of soaking are judged by the following signs:

- the flesh was soaked evenly over the entire area;

- cartilage in the area of the ears, nose, ligaments of the fingers is completely soft and flexible-elastic (very important when dressing skins for stuffed animals).

- the hair is held in the mezdra firmly and does not stretch.

When the soaking is over, the skin is taken out of the soaking bath, slightly squeezed and hung on hangers to drain the water. If the fur is lush and water does not roll off the hair well, then the skin is slightly shaken and beaten out with sticks. Having dumped excess water, proceed to the mezdrovka.

SKIN SKIN consists in its mechanical processing, in order to remove the inner layers of the musculoskeletal and adipose tissue, as well as to loosen the fibrous tissue of the dermis in order to prepare it for perception chemical substances, in the process of further dressing.

When skinning, the remains of fat and muscles are removed from the inner surface of the skin, and with sharp knives (with a thick skin), the skin is cut so that it becomes the same thickness and as thin as possible over the entire surface of the skin. This operation must be carried out with great care in order to prevent cutting through the skin and scraping it to the bare roots of the hair.

Skinning is done on the skin spread with the skin upside down. You can spread the skin on any flat or, better, oval surface. Any sharp knife can be used, but it is more convenient to use a specially made knife or scraper with cutting edge on the end part, the edges of such a knife should be rounded. The movement of the knife during skinning, first from the tail to the head, along the ridge, and then from the ridge to the sides.

So that the fat does not get on the hair and does not stain the wool, the skin during skinning, it is recommended to sprinkle with dry sawdust of hardwood or burnt gypsum, which absorb fat well and reduce the slip of hands on the surface during work.

LAYOUT made with blunt knives - dead ends. You can use a regular blunt knife or scraper, as in the case of skinning, only blunt. This operation is performed in order to maximize the kneading, softening the mezra, squeezing and driving fat from the mezra under the pressure of the dead end on the mezra.

No matter how cleanly the skin is beaten and broken, it must be well washed and degreased.

WASHING AND DEGREASING skins produced, in different ways, depending on the degree of fat content. Fat skins (seals, bears, badgers, etc.) are processed twice, first in a degreasing bath, and then in a washing bath.

For a degreasing bath, a warm solution is prepared:

- washing soda - 8 g or caustic soda - 5 g

- water - 1 liter

The skins in the solution should float freely, they need to be mixed periodically. If the solution becomes dirty after 1-2 hours of degreasing and becomes rusty-brown, then it should be replaced with a fresh one. Thick mezra over the entire surface or separate thickened areas should be treated with a stiff metal brush before degreasing, otherwise complete degreasing of the thickness of the mezra cannot be achieved. The degreasing process for greasy skins lasts 2-3 hours.

With a thin and even skin, it is enough to lightly rub the skin with your hands in a degreasing solution.

The end of degreasing is characterized by the fact that the core of the skin turns white and its fat content ceases to be felt - the core creaks under the fingers.

Having finished degreasing, proceed to washing the skin. The skin is removed from the degreasing bath and rinsed in clean water, after which it is transferred to the washing bath. Here it is poured with a warm soapy solution (100 grams of soap per 1 liter of water) or a solution of washing powder that has no contraindications for wool. Washing the skin consists in carefully rubbing it with your hands until a characteristic squeak appears on the wool.

After washing, the skin is rinsed well in clean water.

If necessary, degreasing and washing with appropriate rinsing is repeated.

A well-washed and rinsed skin is lightly squeezed out, shaken from the remnants of water and hung on hangers to dry. Here it is pierced with sticks and, wiping with a clean, dry rag, the remaining water is carefully removed from it. Water after washing should be removed as completely as possible, since if water remains on the skin, this will disrupt the course of the subsequent operation - pickling or pickling.

For thin skins with low-fat skins, the degreasing and washing processes can be combined into one process if the use of soap and washing powders gives the desired results.

SEWERING the skins consists in using chemicals produced during the fermentation of dough or kvass to remove sticky substances from the main layer of the mezra - the dermis, free collagen fibers from them, change them physicochemical characteristics increasing their strength and softness.

A solution for pickling - jelly or kvass is prepared as follows.

Kvass is made from wholemeal oatmeal (with bran), stirring 200 grams of flour (per 1 liter of hot water). Bread yeast (7 grams per 1 liter of water) or pieces of rye bread(200 - 300 grams per 1 liter of water).

You can prepare a pickling solution in advance, 1 - 2 days before starting work with the skin. This is done in a container that is not susceptible to oxidation. Dishes with talker “put in heat (30 - 40 degrees) and leave until soured; after about a day, white bubbles and a characteristic odor appear bread kvass. With the appearance of signs of souring kvass, the skin is immersed in kvass. In the next 2-3 days, the softening properties of kvass weaken and it will have a tanning effect on the mezra.

Therefore, it is better to lay the skins in a freshly cooked and cooled talker. At the same time, during the first two days, while the mash is sour, the mezra will gradually soften, and then, as the acidity increases with the development of fermentation, the fermentation process will also pass.

Before lowering the skins into the mash, add table salt (20 - 30 grams) to prevent the jelly from rotting during fermentation (3 kg of kvass is needed for every 1 kg of skins). The skin should float freely in the jelly, it must be turned daily, while stirring the mass of jelly, each time immersing the film formed on its surface to the bottom or removing it.

The skins are ready in a few days: 5 - 7 thick skins, 3 - 5 medium skins, 2 - 3 thin skins.

Skin ready is determined by the dryer held for a sufficiently long time on the quadruple fold of the thickest sections of the skins.

Overexposure of the skin in kvass is dangerous, as it leads to hair loss and flaking of the skin.

The fermentation method is quite complicated in determining the time for the skin to be ready, the film that forms on the kvass causes trouble, the process is accompanied by unpleasant odors and a lot of dirt. Therefore, fermentation should be used only in the absence of chemicals for pickling, the process of which causes less trouble and trouble, and gives better results.

PIKELING(treatment of skins with organic acids) is a process that is easier to implement and, at the same time, a method of chemical treatment of skins that is excellent in its results.

Pickel solution (pikel) can be prepared in advance, since the unused solution does not deteriorate during storage. The amount of the required solution is 3 liters per 1 kg of skins; the skins should float freely in the pickle.

The composition of the pickling solution:

- Concentrated acid (acetic, lactic, formic or a mixture of them) - 60 g

- Table salt - 30 g

- Water - 1 liter

The duration of pickling is 5 - 48 hours, depending on the thickness of the core.

The readiness of the mezdra, as the end of the pickling process, is judged by the appearance of dryer on the quadruple fold. With the advent of the dryer, the skin can be immediately removed from the pickel. Pixel overexposure indefinitely long time completely safe for the skin.

The skin taken out of the pickel is slightly squeezed out, folded into an envelope with the skin inside and deposited for a sore bed, for 10-12 hours at room temperature. The bed is required. During this time, the skin soaked with pickel is finally worked out, the skin will reach. Overexposure on the bed for the skin is safe.

IN PERCUSSION PIKELING

- rabbit skins - t - 30-40 C, H.K. = 7

acetic acid - 10-15 ml

table salt - 40 g - fur sheepskin - t- 38 C, H.K.=8, 6-8 hours

sulfuric acid - 4 ml

table salt - 50 g - fur coat sheepskin - t - 38 C, 10-14 hours

sulfuric acid - 5 ml

table salt - 40 g

Spread pickling is carried out on the leather tissue with more concentrated solutions and the skins are sent to the bed.

tanning skins. Tanning is carried out after pickling, in order to fix the separation of fibers obtained during pickling, to make the fur skin resistant to heat, moisture, chemicals and enzymes. Tanning is usually carried out with a solution containing basic chromium salts, the raw material becomes resistant to moisture, heat and chemicals. If you do not carry out tanning, then when wearing a product made from only pickled skins, there is a violation of its strength under the influence of rain and snow, the so-called pickling.

The skin stretched on the frame, sticks or board is lubricated from the skin side:

- Salt solution - 50 g

potassium alum - 100 g

Lubrication is carried out 3-4 days, 2 times a day. After that, the skin is dried without removing it from the board. - Infusion (decoction) of oak, - willow, pine bark or horse sorrel roots until the skin no longer absorbs the infusion (decoction). Lubrication is repeated 5-6 times at intervals of 1-2 hours. Then the skin is moistened with water and rubbed with fine table salt for 2-3 days, 2 times a day.

- Special "dough" table salt - 5 parts

oatmeal - 20 parts

wheat flour - 1 part

hot water - 300 parts

after cooling, kvass grounds - 10-15 parts

The skin is folded in half along the ridge with the skin inside and left to lie down, for 1 - 2 days in a dark place. Then it is dried near a heated oven or warm battery, the dough is removed, the mezdra is sprayed with salt water and soaked with an infusion or decoction of oak, willow, alder, pine bark or horse sorrel roots.

After tanning, the skin is soaked on the skin side with heated fat (lard, fish oil, castor oil), crumpled in the hands, lubricated again and rubbed against a stretched rope until the skin becomes soft. After that, the skin is moistened with water, rolled up into a tube, wrapped in a rag and left to lie down for 10 - 12 hours. Then the skin is dried in a stretched form.

DRYING it is made on hangers or on sticks with the flesh up. After drying the skin a little, the skin is turned upside down and the pile side is dried until completely dry. Then the skin is again turned upside down and finally dried. A well-dried core should be similar in hardness to cardboard.

Drying should be done away from fire, hot batteries, in a shaded from the sun and well ventilated place.

The dried skin can be kept indefinitely before further processing, but it is always better to finish the dressing right away.

WORKOUT aims to soften the core of the dried skin in order to prepare it for breaking. Softening consists in light wetting of the cardboard-like core (2-3% aqueous solution of carbolic acid or, after fermentation, old kvass). The skin is gently moistened with a soft brush or tampon, then the skin is folded in half along the ridge with the skin to the skin and rolled tightly into a roll, the roll is wrapped in a damp rag, and then in oilcloth or polyethylene film and put under oppression for 1 day. When the skin is unrolled, the skin should be soft over the entire surface and acquire a grayish color. If some parts of the mezdra are poorly removed and remain hard, then they are re-moistened with carbolic water for additional local softening.

LAYOUT is the final stage in the processing of the skin, which ends, in fact, the real dressing of the skin. The essence of the breakdown is to make the mezra completely soft and elastic by mechanical processing.

Collagen fibers after the previous chemical treatment are easily amenable to mechanical stress and, retaining their high strength, become quite flexible and elastic. The breaking process consists in repeatedly pulling the skin with a sharp bend through the corner of the board, a metal bracket, through a rope or slingshot. The breakdown is carried out first along the ridge over the entire area of \u200b\u200bthe skin, and then in the transverse direction.

After breakdown, the mezra acquires a creamy White color, the ability to stretch in all directions, becomes completely soft and elastic. The fur becomes "alive", shiny; its surface is smooth, uniform and fluffy. The dressing of the skin is essentially finished.

CLEANING THE MEZDRA It is produced to ensure that the skin surface is sufficiently even and uniform. They do this on a wooden deck with a 3-layer coating of burlap or skin, put on the deck with the fur down. You can cover the deck with linoleum with a felt base.

The covering of the deck gives it the necessary elasticity, which can protect the skin from possible cuts during stripping.

The skin for stripping is placed on the deck with the flesh up, and then processed with a sharp skin knife, scythe, cycler or other similar tool. To prevent the possibility of slipping of the point and accidental cuts in the skin, the surface of the mezra is sprinkled with chalk, ash or sawdust of hardwood before scraping.

When the scraping is completed, the mezra is cleaned and polished with sandpaper screwed on wooden block, pumice or bars of fireclay bricks. Stripping is carried out until the mezra acquires a milky white color and a completely flat surface.

HAIR CLEANING is made by knocking out the skin "with light blows of a stick, and then it is necessary to iron it over the pile with a clothes brush. Fur on skins with a dense and thick undercoat, after being beaten out with sticks, is carefully rubbed with hot large sawdust of hardwood trees. The sawdust is sifted, heated on a baking sheet and some kind of organic solvent(turpentine, acetone, gasoline, etc.) and mix thoroughly.

Hot, solvent-moistened sawdust is rubbed into the fur, especially into the depths of the undercoat. Then the skin is beaten out with a stick. If required, rubbing sawdust and knocking out are repeated.

The skin after pickling can simply be combed with a rare comb or clean clothes brush. The finished skin is hung out for 1 - 2 days for final drying and is now ready for indefinitely. long storage as a raw material for fur products.

TREATMENT OF RABBITS AND NUTRIAS

Here are a few specific ones that have received wide use ways of dressing the skins of rabbits and nutria.

Method 1. Before starting the dressing, the skins are weighed and, based on the result obtained, all subsequent calculations are made of the required amount of chemical reagents. First, the raw material is soaked in water, at a temperature of plus 40 degrees and a liquid coefficient of 9. The operation is called soaking. Liquid ratio (l.c.) is the volume of processing liquid in liters per unit weight of skins in kilograms. For example, if your mass of dry skins is 1 kg, then you need to take 9 liters of water. The duration of the soak depends on the condition of the skins. If they are paired (recently removed from carcasses), then the soaking time is 3-4 hours. The first stage is exactly the same as for paired skins. The second stage is in a solution containing 15-20 grams of table salt per liter of water. In this case, the skins are in a saline solution for at least 10-12 hours; at the same time they are occasionally moved (turned over). Proper soaking largely determines the quality of the final product and facilitates subsequent operations, because this removes dirt and, after soaking, the skins are more easily amenable to mechanical and chemical action.

After soaking, a second operation is carried out, which is called mind-blindness. Mezdrenie is carried out in two ways. In the first case, the subcutaneous fat layer is knocked down on a blunt staple or spit, (on the fill). In the second case, this layer is cut off on a sharp spit, or on a sharpened rotating circular knife (for cutting). The operation that comes after the mezdreniya is called pickling. Pickling is that the skins are soaked in a solution consisting of acetic acid, sodium chloride and water for 4 to 6 hours. The components of the solution are taken in the following proportions: acetic acid 10-15 grams per liter of water, sodium chloride - 4 grams per liter of water, while the liquid coefficient is 7, and the temperature of the solution is 30 - 35 degrees. After the completion of this operation, the skins are placed on a sore bed in stacks for one day, and after the expiration of the daily period they are squeezed out. In addition to pickling in solution, it is possible to carry out spread pickling, in which the concentration of the solution is twice as high as in the first case. When carrying out smear pickling, the solution is applied to the leather tissue with brushes, the raw materials are given a sore, and so 2-3 more times, followed by sores, during the day. To control the pickling of the skins, they are folded over, and squeezed with fingers at the fold points. If at the same time a white characteristic strip is formed, then the pickling process can be considered completed.

Subsequent process - tanning. For the tanning process, the basic chromium salts are usually obtained from sodium dichromate, potassium (chromic) or chromic alum. It is difficult to prepare a tanning extract from chrompic at home, it is best to use dry chromium tanning agent, which is sold in the form of basic chromium sulfate, with a given basicity. Chrome peak itself and chromium oxide do not have tanning properties. However, all calculations during tanning are based on the content of chromium oxide, which is necessarily present in any amount of chromium extract. The solution in which the tanning skins are immersed must contain the extract in the following ratio: 1.5 grams of chromium oxide per liter of water. Tanning is carried out at a solution temperature of 35-40 degrees and a liquid coefficient of 9, for 6 hours, periodically stirring the solution and moving the skins from the bottom of the dish up and back. In the absence of chromium oxide, chromic alum can be used, which is taken in a slightly larger proportion, 6 grams per liter of water. After the end of the tanning process, the skins are removed from the solution and placed on a bed for 20 - 24 hours. After lying, the skins are carefully squeezed and fattening is carried out.

Fattening carried out with a specially prepared emulsion. The fat emulsion is prepared in the following way: in water heated to 40 -45 degrees, dissolve laundry soap, based on 200 grams of soap per 1 liter of water. Gradually stirring the resulting solution, add lamb or pork fat, at the rate of 80 grams per 1 liter of water and ammonia - 10 ml per 1 liter of water. Very good results are obtained if mutton or pork fat is replaced by fish oil (blubber), in the same proportion. The mixture prepared in this way is applied to the leather fabric with a brush, without soiling the fur of the skin. Burnt skins are stacked in piles for lying, for 20 hours. As a result of the fattening, the skins become softer and more plastic.

Last operation - drying, carried out at a temperature not exceeding 30 degrees. After drying, the skins are laid on a bed and broken over the entire surface on a blunt spit. The hairline is cleaned of contaminants using sawdust (not conifers trees). Finished products should have loose hair and soft plastic leather tissue.

Method 2. Dry skins, the mezra of which was previously cleaned of muscles and fat, must be soaked. To do this, prepare a solution consisting of warm water (about 25 degrees) and table salt, at the rate of 30 grams per 1 liter of water. Too long stored raw materials that do not soak in a day, it is necessary to knead and change the solution from time to time, at least once a day, otherwise the skins will rot. At the end of this process, the skin resembles fresh in softness. Then it is thoroughly washed in warm water with powders like "News", "Lotus", etc., rinsed and ventilated to moderate humidity. Then put the skin back in salt water. After 30 minutes, soda ash is added there, at the rate of 1 gram per 1 liter of water. After the soda dissolves, formalin is poured in two doses, with an interval of 30 minutes, in the amount of 2 grams per 1 liter of water. Stirring and maintaining the temperature at 25 degrees for 6 hours, the skins are kept in this solution. Then concentrated sulfuric acid is poured in, at the rate of 5 ml per 1 liter of solution, the skins are kept in the resulting solution for another 8 hours, stirring it periodically. Next, ammonia is added, in the amount of 4 ml per 1 liter of water! and stirred for another hour. Then the skins are fattened with the following composition: 50 grams of laundry soap and 0.5 liters of spindle oil are added to 1 liter of boiling water, mixed and 20 grams of ammonia are added. The skins taken out of the solution are processed with the resulting mixture at a temperature of 50 degrees. Then the skins are turned inside out with the hair, they are allowed to lie down for a while so that the mixture dries slightly. If you are not satisfied with the softness of the mezdra, then the process is repeated. The processed skins are dried, kneaded, polished with fine emery tape. To make the fur shine, it is wiped with technical alcohol.

Method 3. With a raw, freshly skinned skin, immediately while it is warm, fat and muscles are removed from the mezra. Then the skin is sprinkled with fine salt, rolled up with the hair outward, and left in this state for two days. Then it is unfolded, the remnants of connective tissue and fat are removed. After that, the skin is immersed in a solution prepared as follows: 70-80 grams of sodium chloride are taken per 1 liter of water and dissolved in water. Next, pour into the prepared saline solution from 7 to 15 ml of concentrated sulfuric acid. In this solution, the skins are from 8 to 10 hours, then they are removed from the solution and the liquid is allowed to drain. Why are skins hung for two hours? After the liquid is removed from the glass skins, the skins are fattened with the following composition: 50 grams of fish oil, 25 ml of oleic acid, 10 ml of 25% ammonia, 1 liter of water. This fat is prepared in two vessels. In the first, fish oil is mixed with oleic acid, in the second - ammonia with water. After preparing such mixtures, the contents of the first vessel are poured into the second, at a temperature of 25-30 degrees, mixed. The resulting fat is lubricated with the leather surface of the skins and left in this state for 4 - 6 hours. Then the skins are straightened and stretched on the rules, first with the fur inward, then with the fur outward and drying is carried out. In the process of drying, the skins are removed several times and carefully stretched in different directions, and when they are completely dry, they are crushed by hand to the end.

Method 4. Dressing of skins by fermentation. Fermentation is classic way skin dressing. At present, it is rarely used, since the processing time is much longer than with other dressing methods. Purebred karakul skins, squirrels, and moles are made only by boasting. Fermentation has a number of advantages compared to other methods of dressing skins. The main one is that the strength of dressed skins almost doubles compared to such a method as pickling. A large amount of flour is needed for fermentation. So, in an enameled or glass bowl, 200 grams of wholemeal oatmeal or rye flour is dissolved in one liter of hot water and stirred until smooth. Gradually stirring, add 20 - 30 grams of table salt, 7 grams of yeast, 0.5 grams baking soda. When the solution has cooled, the skins are immersed in it. The skins are in it for two days, they swell and, as the acidity in the solution increases, ferment. For one kilogram of the weight of paired skins, three kilograms of a solution (kisel mass) prepared by the above method are taken. During the two days that the skins are in the jelly mass, they are periodically turned over, and the jelly is mixed so that a film does not form on the surface and the solution does not rot. The end of the fermentation process is determined in two ways: by pinching and by drying. How to find dryer? To do this, the skin taken out of the jelly is bent four times, in the groin area, with the skin up. Then, at the place where the angle is formed, it is tightly compressed and a fingernail is drawn along the formed rib and released. If the skin is ready, then for some time a white strip - a dryer - will be clearly visible at the place of the nail. The pinch test is done as follows: in the groin area, voskas are plucked, and if this can be done without much effort, then the fermentation process is over. Further, the skin is subjected to any method of tanning and oiling. After that, it is taken away and it is ready for use.

Method 5. Before dressing, the skin is immersed in a concentrated salt solution (30 g/l, preferably 60 g/l). It is recommended to add a little ammonia. Keep in the solution for several hours (or a day) until completely softened.

If the skin is not very dry, then it is abundantly sprayed with salt water from the side of the mezra and left for several hours. Spraying is repeated as the solution dries until the skin is completely softened.

The soaked skin is minced. After skinning, the skin is tanned by one of the three methods listed below.

Method 1

The skin stretched and nailed to the board is moistened from the side of the mezra with a solution:

- aluminum alum - 100 g/l table salt - 50 g/l

This should be done 3-4 days, 2 times a day. After that, the skin is dried without removing it from the board.

Method 2

The skin from the side of the mezra is rubbed with an infusion of oak or pine bark until it stops absorbing the infusion (5-6 times, at intervals of 1-2 hours). Then the skin is dried in a stretched form. Then it is rubbed with fine table salt, for 2-3 days, 2 times a day. Before rubbing, the skin is moistened with water.

Method 3

The skin is lubricated with a special "dough". It is prepared on the basis of:

- wheat flour - 1 part

- oatmeal -20 parts

- table salt - 5 parts

- hot water - 300 parts

This mixture is cooled and 10-15 parts of kvass grounds are added. Now the "dough" is ready. They lubricate the inner side of the skin, the skin is folded in half with the fur up and left for 1-2 days in a warm place. Then the skin is unrolled and dried near a heated oven or battery. After drying, the "dough" is removed, the skin is sprayed from the side of the mezra with salt water and soaked in an infusion of oak or willow bark.

After tanning, the skin is impregnated with some kind of fat: lard, fish oil. The fat is heated and smeared on the skin from the mezdrya side, wrinkled it in the hands, greased again and rubbed on a stretched rope until the skin becomes soft.

After this procedure, it is moistened with water, rolled up into a tube, wrapped in a rag and left to lie for 10-12 hours. It remains to dry the skin in a stretched form and, if necessary, paint it with special dyes for fur.

Method 6. Prepared skins for 3-4 hours are dipped in a solution (at 35-40 degrees) containing 2-3 g / l detergent(powders Neptune, Lotus, Selenium shampoo). Every 30 minutes, the contents are stirred, if the solution becomes contaminated, it is replaced at the rate of Zl per 1 kg of skins.

Soaking - pre-picking. The washed skins are turned inside out and squeezed. Prepare a solution:

- table salt - 40 g

- sodium sulfate - 0.5-1 g

- sodium silicofluoride - 1 g

- detergent - 2 g

- acetic acid - 1-1.5 ml or lactic acid - 0.5-1 ml or formic acid - 0.5-1 ml or sulfuric acid - 0.25 ml

In this solution at a temperature of 34-40 degrees, stirring occasionally, the skins are kept for 12-15 hours. Liquid coefficient - 5.

Upon completion of the soak, the skins are squeezed out and again placed in the old (washing) solution, adding 4 ml / l of 80% acetic acid to it and heating it to 35-40 degrees. Pre-picking, periodically stirring the skins, is carried out for 8-10 hours. Then, slightly squeezed skins with the inside are folded for 10-12 hours for a sore.

Spin. As a wringer at home, it is convenient to use the rollers from the washing machine, wrapping the skin in gauze.

Mezdrenie. The skin is put on with the skin outside on a plank (10-12 cm long and 60 cm wide) with a rounded end. With a sharp knife, cut the edge of the film along the tail part of the skin, then carefully remove it from the tail to the head with a stocking. To remove fat, small sawdust of deciduous trees or dry rags are used. When removing the film, pressing the knife too hard on the skin can damage the hair follicles and cause them to fall out.

Pickling. Depending on the thickness of the skin and the thoroughness of degreasing, the skins are placed in a solution for 1-3 days (35 degrees):

- table salt - 50 g

- acetic acid - 8 mg

- detergent - 0.5 g

The skins in the pickel are often mixed. Pickled skins are folded with the skin inside for a sore, for 24 hours, after which they are carefully squeezed.

Tanning. The skins are placed in a solution (at 35 degrees), for at least 8 hours, with frequent stirring. The composition of the solution:

- table salt - 40 g

- hyposulfite - 8-10 g

- chrome-potassium alum - 6-7 g

Alum is introduced into the pickle solution in two (sometimes three) doses: 2-3 hours after the start of tanning (2 or 3 step tanning). After tanning, the skins are aged for 1 day, folded with the skin inside and pressed on the rollers.

Fattening begins with the preparation of the fat emulsion. It can be made according to the recipe:

On a coarse grater, rub 100 g of laundry soap and dissolve it in 0.5 liters of hot (50 - 60 degrees) water, adding 50 grams of melted animal fat. With stirring, 5-10 ml of ammonia are added to the emulsion. The emulsion is applied to the mezra with a tampon, after which the skins are folded with the mezra inside and left to lie down for 5-6 hours.

Drying. If the room is warm (about 30 degrees), then the skins are immediately put on the rules (spindles) with the core out. When they begin to dry out, they are removed, kneaded thoroughly and with effort, moderately stretched and put on the rules again with the fur outside, for final drying.

breakdown produced on a narrow wooden board. The skin tissue is stretched with a blunt (dead end) knife in all directions. If the skin is dry, then its mezra is slightly moistened before being broken down and placed for several hours with the mezra inside to evenly distribute moisture. After breaking down, the fur is combed.

Method 7. Start the skinning from the tail, just drive it away - then sprinkle wood ash, put to lie down for 10-15 minutes. Then fidget again. And so 2-3 times.

Degreasing. Water temperature 40-50 degrees, solution:

- table salt - 40-60 g

- mustard powder - 1 handful

- turpentine - 4-5 ml

- washing powder - 10 g

- caustic soda - 3-4 g

- zinc chloride - 1-2 g or sodium silicofluoride - 1-2 g

Exposure time - 1.5 - 2 hours.

Pickling. At 18-20 degrees, withstand 12 hours in solution:

- formic acid - 4 ml

- sulfuric acid -0.25 ml

Tanning. Soak for 1 hour in solution:

- table salt - 40 g

- alum 7-8 g

Add to the solution:

- urotropin - 1 g

- chromium alum or (better) chromium extract 4 - 5 g

Soak in this solution for 4 hours, add alumina-potassium alum (10 g) to the solution and soak for another 6 hours. Squeeze and put on a bed for 12 hours.

Zhirovka. The composition of the solution:

- water - 0.5 l

- castor oil - 150 g

- fish oil - 50 g

- ammonia - 25 ml

- turpentine - 50 ml

- oleic acid - 75 g

- table salt - 1 teaspoon

- flour - 1 cup

All this is thoroughly mixed and brought to 1 liter. Spread the skin with this mass, roll the skin inside and put it on a bed for 12 hours. Then repeat spreading and soaking, dry, sipping the skin from time to time.

Method 8. The easiest way to dress rabbit skins. Produced using sour milk. Paired, freshly removed skins are rubbed with coarse salt and placed in piles with the flesh inside, in this state they lie for 3 days. After that, the salt is shaken off, the skins are rinsed and squeezed, and then their skinning is carried out. The cleaned skins are placed with fur inside, in well-sour (within 5-7 days) cow's milk, in which they lie for three days. Then, they are taken out, rinsed and tanned, using one of the methods already listed. Sour milk (curdled milk) is taken at the rate of 1 liter per one medium-sized rabbit skin.

MANUFACTURING OF SHEEP AND GOAT SKINS

The dressing of sheep and goat skins is a very laborious process. Before starting the processing of the skin, its mass should be determined, since this is very important for the accurate calculation of the concentration and amount of the solution during degreasing, pickling, skinning and tanning. Degreasing is carried out in two stages, in a bath, with a liquid 32 coefficient of 8 and 9 and a water temperature of 35 - 40 degrees, if the skins are dry. For a solution with a liquid coefficient of 9, a detergent is taken (for example, "News" or "Lotus"), at the rate of 3 grams per 1 liter of water. Washing lasts 2 - 3 hours.

You can use one of the old simple and available ways sheepskin degreasing. It consists in lubricating sheepskins with liquid clay. The clay is dried and ground into a fine powder, which is then sifted through a sieve. After that, the clay powder is diluted to the density of sour cream, and this slurry is generously lubricated with the sheepskin core, which is spread on a flat surface. You can smear with a brush or a brush made of bast. Particularly carefully lubricate the mezra in the thickest places. Then the sheepskin is dried.

In summer, in good weather, this can also be done on outdoors. When the sheepskin dries up to such a state that pieces of clay easily fall off, they hang it on a hook and beat the sheepskin with a small but heavy stick until the clay stops falling off it.

After that, it is again smeared with a clay solution, dried and beaten with a stick. For low-fat sheepskins, 2-3 repetitions are enough, for fatty ones - 5-6. greasy spots, then only stains are treated. After all the skin has been degreased, they begin to dry and preserve it.

Soak off. The soaking process lasts 14-16 hours, with a liquid coefficient of 8 and a water temperature of 35 degrees. Skinning can be done with a blunt staple, scythe, or a sharpened, rotating circular knife. Pickling is carried out at a liquid coefficient of 8, a water temperature of 25 degrees for 16-18 hours in a specially prepared solution. The solution is prepared as follows: from the calculation of the liquid coefficient 8, take required amount water heated to a temperature not lower than 25 degrees and dissolve in it 60 grams of table salt, 12 grams of acetic acid per 1 liter of water. The skins immersed in the resulting liquid are turned over from time to time. At the end of the pickling process, the skin is folded inward with fur and kept a little in such a pressed state. If, after the skin was released, a white stripe appeared on the skin, then this indicates that the skin was sufficiently pickled.

Tanning. For the tanning process, basic chromium sulfate or chromic alum is used. To prepare a tanning solution, per 1 liter of water, take 1.5-2 grams of chromium salt, 8 grams of hyposulfite and 40 grams of table salt. Tanning is carried out at a liquid coefficient of 8 and a water temperature of 35 degrees, for 10-12 hours. After that, the skins are taken out and stacked one on top of the other for a sore bed, which lasts for 6 hours. At the end of the sore, the skins are squeezed and treated with an emulsion consisting, per 1 liter of water, of 80 grams of fat, 100 ml of ammonia and 200 grams of laundry soap. The emulsion is prepared as follows. Soap is first dissolved in water at a temperature of 45 degrees, then gradually stirring, fat (mutton or pork) and ammonia are added. To obtain an effective fat emulsion, it is necessary to follow the above procedure for its preparation. The fat emulsion is applied to the mezdra (skin) with a brush or swab and placed on a bed for 20 hours. At the end of the process of dressing the skins of sheep and goats, drying is carried out, at a temperature of 30 degrees and the dried skins are kneaded, pulled, after which fur products can be sewn from them.

RECIPES FOR PREPARING HYDRO-FAT EMULSION

RECIPE 1. Laundry soap (100 grams), fish or other animal fat (1 kg) are placed in boiling water (based on 1 liter). The mixture is thoroughly mixed, removed from heat and 5-10 ml of ammonia are added, mixed again, allowed to cool (so that the temperature is not more than 40 degrees) and applied to the skin of the skins.

RECIPE 2. For one liter of water, the temperature of which should be 40 - 50 degrees, take: 200 grams of laundry soap, 80 grams of lamb or pork fat, 10 ml of ammonia and all components are thoroughly mixed. AT this method emulsion preparation can be replaced: up to 5 percent with machine oil, up to 6 percent with glycerin, up to 50 percent with egg yolk.

RECIPE 3.

Dissolve in 100 grams of boiling water:- laundry soap - 30 g

- machine (spindle) oil - 20 ml

- unsalted pork fat - 30 g

- glycerin - 30 ml

- ammonia - 30 ml

- chicken egg yolk - 3-4 pcs

After mixing, a white creamy paste (fat emulsion) is obtained. It is applied thin layer on the skinned surface with a brush. After fattening, the skins are folded with the skin inside for a 6-hour soak.

RECIPE 4. Glycerin and egg yolk are taken in equal proportions, one to one, beat well and fatten the skins with the resulting composition.

RECIPE 5. 25 grams of spindle or transformer oil, 30 grams of glycerin, 250 grams of egg yolk and 30 ml of ammonia are thoroughly mixed until a characteristic white color is obtained, after which the resulting emulsion is applied to the mezra with a brush or swab.

NATURAL TANNERS. THEIR PREPARATION AND USE

One of the natural tanning agents is willow bark, which is also called belotal, verbolaz, eared willow and water willow. The bark of adult willows is rough and dark in color, it contains up to 12 percent of tannins. Willow bark tanning agent is prepared in the following way: enameled or stainless steel dishes are taken and filled almost to the top with willow bark and small twigs, poured with water and allowed to boil for 30 minutes. Then the solution is drained, 50 grams of table salt per liter of water is added to it and cooled. Dubitel is ready. The skins are kept in it from 12 hours to 4 days, after which they are taken out and given a sore for several hours. Willow bark is also used for tanning, which contains up to 7 percent of tannins.

Another tanning agent is oak bark. A decoction is prepared from it in a similar way. The disadvantage of oak tanning is that it tightens the hide (it becomes more rigid) and slightly stains the fur and skin in a yellowish color.

The following composition is considered the best of natural tanning agents: 2 - 2.5 liters of decoction of horse sorrel roots are added to a bucket of willow broth. Overexposure in such a tanning agent is undesirable, the end of processing is determined in the following way - in the groin area, a small piece is cut off from the skin and on the cut they look like a tanning agent (tannin - slightly yellow color) has penetrated deep into the skin. If the skin is completely saturated, then the process is stopped. After tanning follows a soak, which lasts until full ripening for two days.

In the old days, grass hay was used as a tanning agent. This tanning agent was prepared as follows: well-chopped hay was placed in a tank with a volume of 30 liters. Then it was well tamped and poured with boiling water, then wrapped in an old blanket for steaming. The broth was in this state for 30 minutes, after which it was drained and salted, at the rate of 50 grams of salt per 1 liter of broth. No more than one rabbit skin was immersed in a decoction cooled to 35 - 49 degrees. The end of the tanning process was checked by coloring to the full thickness of the skin on the cut.

SEVERAL SIMPLE AND QUICK WAYS TO PROCESS SKINS

The skin removed by the layer is stretched and fixed on the board with small nails, with the skin outward. Mezdra, for 3-4 days, 2 times a day, lubricate with a warm solution:

- table salt 50 g

- aluminum alum 100 g

- water 850 ml

The skin after processing remains on the board until completely dry, after which it is removed from the board, fattened, dried and broken. The skin removed by the layer is stretched and fixed on the board with small nails, with the skin outward. The mezdra is rubbed with infusion of willow, oak or pine bark until it stops absorbing the infusion. As a rule, the infusion is required to be applied to the mezdra 5-6 times at intervals of 1-2 hours. Then the flesh is moistened with water, rubbed with fine table salt 2 times a day, for three days in a row, dried on the same board, fattened if necessary, dried and broken down.

The skins of the skins are processed with a specially prepared dough:

- hot water 300 parts

- oatmeal 20 parts

- table salt 5 parts

- wheat flour 1 part

cool down

- kvass grounds 10-15 parts

to stir thoroughly.

The skin smeared with dough is folded with the flesh inside, placed in warm place for 1 - 2 days, for drying. The dried dough is removed, and the mezdra is moistened with salt water and soaked in an infusion of willow or oak bark. Finally, the skin is fattened, dried and broken down. When fattening, heated fish or other animal fat is used.

Dressing of skins is carried out according to a shortened scheme - no more than one day (excluding preparatory operations). Carefully degreased skin is placed for 30 - 35 minutes in an alkaline solution, the following composition: three tablespoons of washing powder in a bucket of water, the temperature of which is 35 - 40 degrees. After vigorous and thorough washing, the skin is placed for 24 hours in a warm (18 - 20 degrees) solution consisting of 400 grams of table salt, 35 grams of lactic acid, 10 grams of aluminum alum, per 1 liter of water. After a daily exposure, the skin is re-treated with an alkaline solution and washed with water at room temperature. The skins are dried on the hoop, as they dry, they are stretched, without great effort. In conclusion, the leather skins are processed until the entire surface of the skin is velvety.

The most laborious and at the same time in a simple way handling is fiddling. This method has been used by various peoples since ancient times. The essence of the method is as follows: they take the skin after fresh-dry preservation, moisten its limited area with milk and pull sequentially, centimeter by centimeter. Pulling can be compared to removing dry dirt from clothes. In the process of pulling, the collagen bundles are stratified into individual fibers and partially torn. All this makes the skin soft. A similar result is obtained if the skin is broken on a bracket. Stretched through "dead ends" or kneaded for a long time. Since this mechanical method is very laborious and requires a lot of energy, it is not widely used among leather makers.

SKIN COLORING

The most difficult process of dressing skins at home is coloring. Achieve uniform and uniform color various categories hair having different color zones along the length is very difficult. And if the reader has the opportunity to color the dressed skins at a specialized enterprise, then it is better to take advantage of this opportunity.

For dyeing skins black prepare a solution of the following composition: 3-5 grams of chromic acid, 1 gram of sulfuric acid, 10-20 grams of common salt are taken per liter of water. The volume of the solution should be 10 times the mass of the skins, i.e. the liquid coefficient is 10. In this solution, heated to a temperature of 25 - 28 degrees, the skins are placed for 3 - 4 hours, stirring occasionally with a stick, then they are squeezed out and transferred to a container, with a solution of hyposulfite and sodium chloride, with a liquid coefficient of 10, by 8 - 10 hours, and stir occasionally. The solution is prepared from 10 grams of hyposulfite and 10 - 20 grams of sodium chloride per 1 liter of water. After the skins are taken out of the solution, they are washed in clean water at a temperature of 20 - 22 degrees, squeezed and lowered into a container with a previously prepared dye solution at a temperature of 28 - 35 degrees. The dye is prepared as follows: for 1 liter of water, 2 grams of pyrocakhetin, 4 grams of paraphenylenediamine, 1 gram of washing powder and 1 ml of 25% ammonia solution are taken. The skins are kept in this dye for 30 minutes, then 30% hydrogen peroxide is added to the container, at the rate of 6 ml per liter of solution. The skins are kept in this solution for another 3-6 hours, with frequent stirring. It is very important that they are completely covered with the solution.

If the skins are dyed light brown color, then sulfuric acid is not added to the solution.

Henna, basma, gamma (hair dyes) are often used as dyes, which color the skins in golden chestnut or black. These dyes are widely known and available, they are usually accompanied by rules for their use.

After dyeing, the skins are washed, for 1 hour, in water with washing powder (1 gram of powder per 1 liter of water), then another 30 minutes in clean water, until the dye residues are completely removed.

In conclusion, they are dried, kneaded and combed, sometimes treated with a fat emulsion, for better preservation.

Rabbit fur is beautiful and soft, you can sew various fur products from it - hats, fur coats, vests. Sometimes it's hard to find a good specialist dressing (furrier). Therefore, you have to learn on your own. Dressing rabbit skins at home is a long process. It may not work right away - do not be discouraged. Try again and again. Experience will come with time.

Rabbit skins are used for a variety of products

Slaughter for fur at the age of 6-8 months in November-March. At this time, rabbits have the most fluffy and thick fur coat.

For slaughter, you must prepare a sharp knife, chemicals and salt for dressing, rules.

Primary processing and storage

To obtain high quality skins, a slaughtered rabbit must be properly skinned, that is, carefully separate the skin from the carcass. Take your time so as not to spoil the flesh with a knife, let someone help you.

The dressing of rabbit skins begins with the removal of the remnants of meat and fat. We turn the warm skin inside out with fur and carefully scrape it from the end to the head. The knife is perpendicular to the work surface. You can also remove manually in layers. Avoid processing dry skins. It is very difficult to remove meat and fat from them.

It happens that there is no way to dress the skins right away. To prevent damage to the blanks, they must be preserved. We stretch the skin on the rule. The rule is a capital letter "A". The horizontal crossbar is usually made mobile, so you can adjust the rule to the size of the workpiece. We fix the lower end of the workpiece so that it does not gather in folds. The fur melts into them, and then crawls out.

Sizes of rules for skins

If you leave the blanks not straightened on the day of slaughter, they will deteriorate. Storage of rabbit skins without rules in the cold will not save either - the quality of such products will be low.

The blanks are stored together with the rules in a dry, well-ventilated place. The maximum temperature in it is + 30 ° С. Do not store near batteries or any heat source. Subsequently, they will become brittle. In order to accumulate more blanks, the dried skins are put in a clean, tightly closed box. Moth remedy can be put in bags there. Before soaking, the workpiece must be removed from the rules.

Dressing

It takes a lot of hard work to get quality products. The process of dressing rabbit skins consists of several stages. Each of the stages is important, and none of them can be ignored.

Tools for dressing skins: a) a wooden blank for degreasing, b) a dead end, c) a scythe, d) a knife for degreasing

It is used for canned blanks. The solution contains 50 g of salt per 1 liter of water. To destroy putrefactive bacteria that feed on protein, it is better to add borax or carbolic acid to the solution:

- carbolic acid (in crystals) - 2 g;

- borax - 30 g.

Instead of borax and carbolic acid, you can use any of the drugs listed below:

- zinc chloride - 2 g per 1 liter of water;

- norsulfazol - up to 2 tablets per 1 liter of water;

- formalin - 0.5-1 g per 1 liter of water;

- double sodium sulfite - 2 g per 1 liter of water.

Dry skins are soaked in the solution. For 1 kg of blanks, there are 3 liters of water. A capacious container made of glass, stainless steel or enameled is taken for soaking. We press down so that they do not float up and are at a depth of at least 2 cm from the surface of the water. Soaking ends when the skin becomes like fresh, the mezra has become soft, and the hair is not pulled out of the skin.

Change the solution more often, avoiding fermentation, about 2 times a day. For uniform processing, the workpiece is mixed from time to time. Soaking takes from 6 hours to 4 days.

Soaking skins

Mezdrenie

Soaked skins are allowed to drain, and then wiped dry. The process of skinning is the removal of the subcutaneous layer. It is necessary to completely remove the remnants of fat, cut the meat, the film. If after slaughter the initial processing was thorough, then the skinning is much easier.

The remains are scraped off and scoured on a special convex wooden deck. They clean from the tail to the head, and the sides - from the ridge to the stomach.

Degreasing

To do this, we prepare a special warm solution: for 1 liter of water - 4 g of washing powder. We carefully erase the material until it “squeaks”, that is, the flesh will become whiter and begin to creak on the fingers. We rinse in the water. And now it's the turn of the soap solution. For 1 liter of water (warm) take 10 g of soap. We lather the hairline with our hands directly in the solution. We rinse again. After hanging the skins, shake off the water by tapping with a stick and wipe with a dry cloth.

Degreasing skins is a rather complicated matter.

Pickling

Fur products need strength, or durability. Strength is achieved by treatment with an acidic solution. This processing is called pickling. To prepare the solution is used:

- water - 1 l;

- salt - 30 g;