Technical regulation of standardization and provision. Technical regulation and standardization

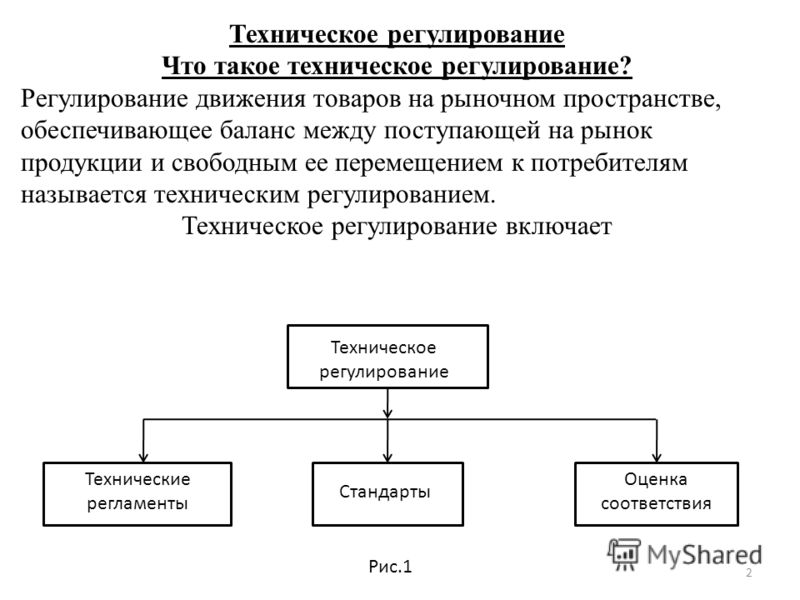

Technical regulation What is technical regulation? The regulation of the movement of goods in the market space, which ensures a balance between the products entering the market and its free movement to consumers, is called technical regulation. Technical regulation includes Technical regulation Technical regulations Standards Conformity assessment Fig.1 2

Types of regulatory measures Group I Group II Group III Measures based on legislation on responsibility for the quality and safety of supplied products Measures taken by the state to ensure product safety Use of standards, codes of practice, voluntary certification, introduction of management systems, informing buyers, liability insurance for damages, etc. 2 Technical regulation Standard Code of practice Conformity assessment 3

Technical regulation (TR) is a document containing technical requirements that are mandatory for execution and application, either directly, or by referring to a standard or set of rules, or by including the content of these documents and adopted by an authority. A standard is a document developed by consensus and approved by a recognized body. A set of rules is a document that recommends technical rules and (or) a description of the processes that characterize all stages life cycle products. Conformity assessment is an activity related to the direct or indirect determination that the relevant requirements are being complied with. Voluntary certification - certification, which is carried out at the initiative of the applicant for compliance with any requirements defined by him. 4

Principles of technical regulation Objectives Means and methods Result 1. Protection of life, health of citizens, property 2. Security environment 3. Increasing the competitiveness of products, works, services 4. Prevention of actions that mislead purchasers 1. Establishment mandatory requirements(TR) 2. Establishment of requirements on a voluntary basis (ST) 3. Conformity assessment: confirmation of conformity (declaration, certification) 4. State control (supervision), accreditation 1. Competent choice of products, works, services by purchasers 2. Conditions for free movement goods 3.Technical and information compatibility 4.Interchangeability of products 5.Innovations Table 1 Pic. 3 5

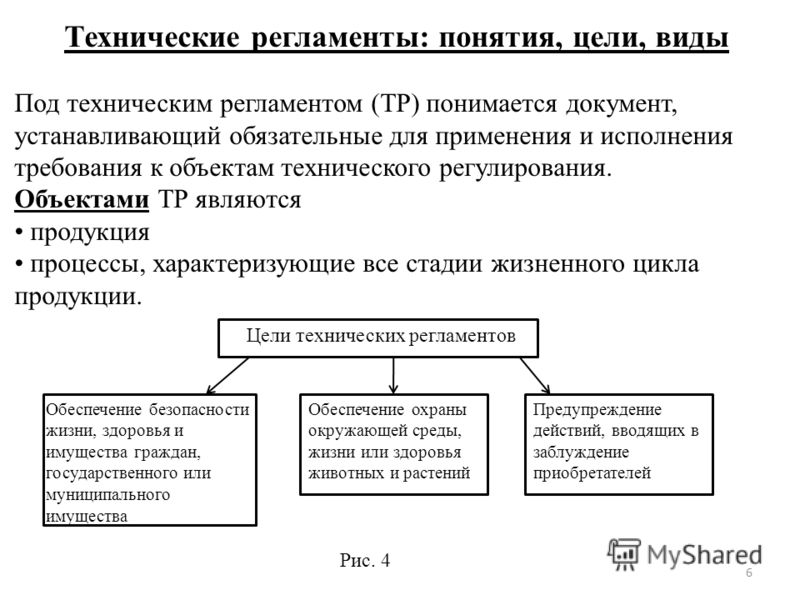

Technical Regulations: Concepts, Purposes, Types A technical regulation (TR) is understood as a document that establishes mandatory requirements for application and implementation of requirements for objects of technical regulation. The objects of TR are production processes that characterize all stages of the product life cycle. Goals technical regulations Ensuring the safety of life, health and property of citizens, state or municipal property Ensuring the protection of the environment, life or health of animals and plants Preventing actions that mislead purchasers Pic. 4 6

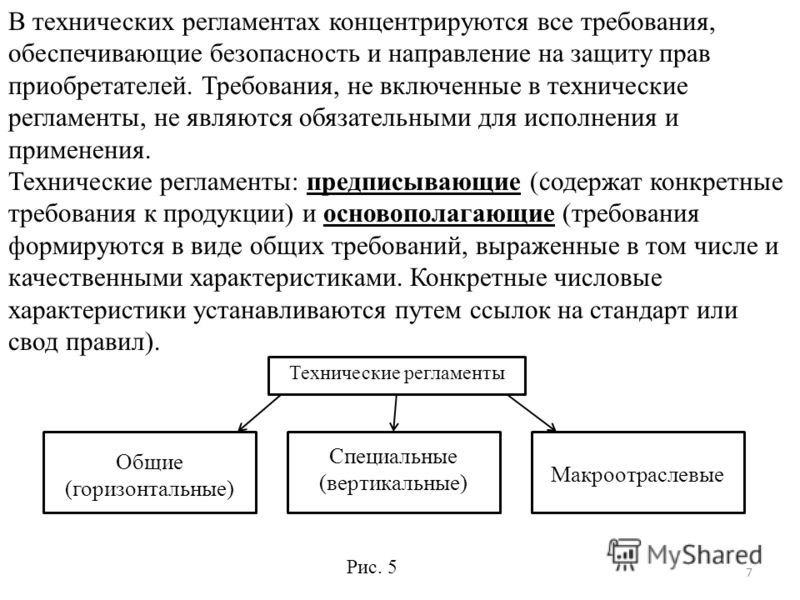

The technical regulations concentrate all the requirements that ensure security and direction to protect the rights of purchasers. Requirements that are not included in the technical regulations are not mandatory for execution and application. Technical regulations: prescriptive (contain specific requirements for products) and fundamental (requirements are formed in the form of general requirements, expressed, among other things, by qualitative characteristics. Specific numerical characteristics are established by referring to a standard or set of rules). Technical regulations General (horizontal) Special (vertical) Macroindustry Pic. 5 7

General (horizontal) TRs are developed for wide product groups on issues of ensuring one or more types of safety. Special (vertical) TRs are developed for individual types of products for which there are specific types of risk of harm that exceed the degree of risk taken into account by the general TR. Macro-industry TRs link general and specific TRs. The structure and content of technical regulations TR contains the following sections: 1. Scope and objects of technical regulation; 2.Basic concepts; 3. General provisions concerning the placement of products on the Russian market; 4.Requirements for products; eight

5. Application of standards (presumption of conformity); 6.Conformity confirmation; 7. State control (supervision); 8. Final and transitional provisions; 9. Applications. Section 1 establishes the scope of the PR in relation to the categories of objects: products only; products and individual processes associated with it; products and processes associated with all stages of its life cycle. Section 2 provides definitions of concepts that are important for an unambiguous understanding of the provisions of the TR. Section 3 specifies the conditions for placing products included in the scope of the TR on Russian market. 9

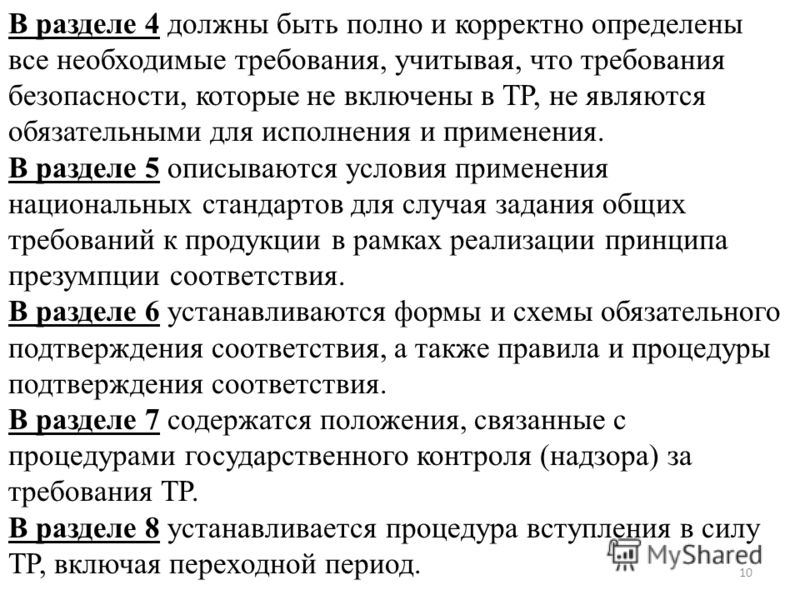

In section 4, all necessary requirements, given that the safety requirements that are not included in the TR are not mandatory for execution and application. Section 5 describes the conditions for the application of national standards for the case of setting general requirements for products as part of the implementation of the principle of presumption of conformity. Section 6 establishes forms and schemes for mandatory conformity assessment, as well as rules and procedures for conformity assessment. Section 7 contains provisions related to procedures state control(supervision) for the requirements of TR. Section 8 establishes the procedure for the entry into force of the TR, including the transition period. ten

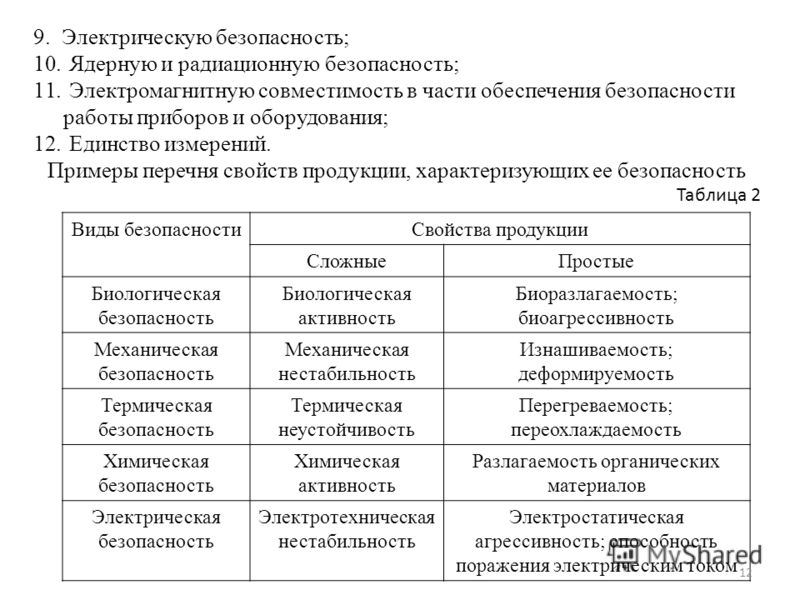

Establishment of Mandatory Requirements in the Technical Regulation Mandatory requirements in the TR are established taking into account the degree of risk of causing harm. Risk is the probability of causing harm to the life or health of citizens, property, the environment, taking into account the severity of this harm. Safety is defined as the absence of unacceptable risk. The TR establishes requirements that ensure: 1. Radiation safety; 2.Biological safety; 3.Explosion proof; 4.Mechanical safety; 5. Fire safety; 6.Industrial safety; 7. Thermal safety; 8.Chemical safety; eleven

9. Electrical safety; 10. Nuclear and radiation safety; 11. Electromagnetic compatibility in terms of ensuring the safety of the operation of instruments and equipment; 12. Unity of measurements. Examples of a list of product properties that characterize its safety Table 2 Types of safetyProduct properties ComplexSimple Biological safety Biological activity Biodegradability; bioaggressiveness Mechanical safety Mechanical instability Abrasion; deformability Thermal safety Thermal instability Overheating; hypothermia Chemical safety Reactivity Degradability of organic materials Electrical safety Electrical instability Electrostatic aggressiveness; electrical shock capability 12

State control and supervision over compliance with the requirements of technical regulations Goals of state control and supervision (CC and N): 1. Ensuring safety; 2. Identification of counterfeit products, goods with incorrect labeling. GK and N is carried out by the following entities Federal authorities executive power Executive authorities of the Russian Federation State institutions authorized to conduct Civil Code and N Pic. 6 13

Civil Code and N is carried out in relation to products exclusively in terms of compliance with the requirements of the TR and exclusively at the stage of circulation. For violation of the requirements of TR, the manufacturer is responsible in accordance with the legislation of the Russian Federation. An effective post-market surveillance procedure is characterized by two important elements A: 1. Significant penalties for non-compliance; 2.High probability for suppliers that nonconforming products will be identified. Surveillance procedures after the products have been placed on the market should be sufficient to identify nonconformities, take the necessary measures and punish those responsible. The effectiveness of GC&N can be improved if it provides for the responsibility of all participants in the supply (manufacturer / importer, wholesaler and retailer) 14

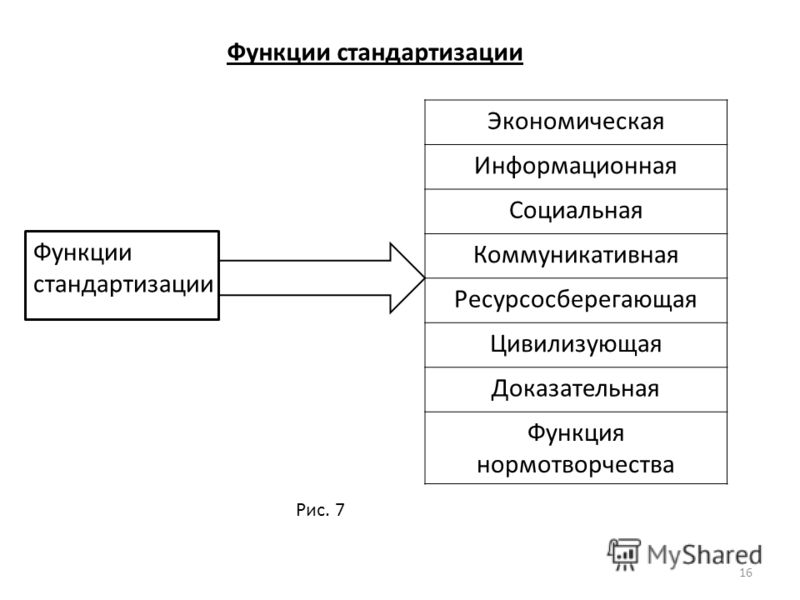

4. Standardization Standardization is the activity of establishing rules and characteristics for the purpose of their voluntary reuse, aimed at achieving order in the areas of production and circulation of products and increasing the competitiveness of products, works and services. Standardization activities are aimed at developing requirements applied on a voluntary basis The nature of standardization, its role in improving product quality Two properties (features) of standardization: 1. The ability to streamline and system-formation, ensuring the reduction and prevention of unjustified diversity; 2. Compatibility (pairing) of objects, phenomena, processes that are in direct or indirect connection. fifteen

Principles of standardization The most important principles of standardization. 1. Voluntary application of standards and provision of conditions for their uniform application. 2. Application of the international standard as the basis for the development of the national standard. 3. Balance of interests of the parties that develop, manufacture, provide and consume products (services). 4. Dynamism and advanced development of the standard. 5. Inadmissibility of creating obstacles to the production and circulation of products to a greater extent than is minimally necessary. 6.Efficiency. 7. The principle of harmonization. 8.Clearness of the wording of the provisions of the standard. 9. Consistency. 17

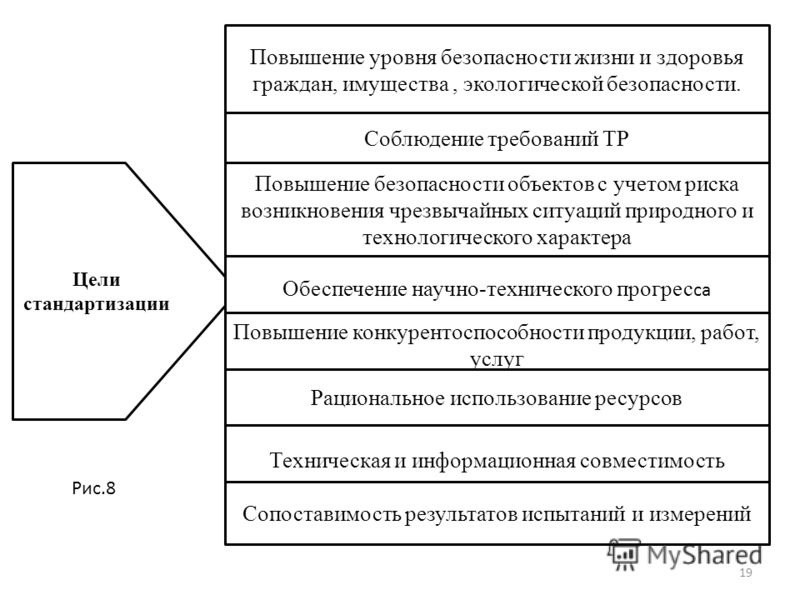

10.Objectivity of requirements verification; 11. Providing conditions for uniform application. Goals of standardization. The purpose of standardization is to protect the interests of consumers and the state on the quality of products, processes and services. Tasks of standardization The main task of standardization is to create a system of normative and technical documentation that defines progressive requirements for products manufactured National economy, population, defense, export, as well as control over the correct use of this documentation. eighteen

Goals of standardization Improving the level of safety of life and health of citizens, property, environmental safety. Compliance with the requirements of TR Improving the safety of facilities, taking into account the risk of emergencies natural and technological nature Ensuring scientific and technological progress Increasing the competitiveness of products, works, services Rational use resources Technical and information compatibility Comparability of test and measurement results Fig.8 19

The main tasks of standardization 1. Providing mutual understanding between developers, manufacturers, sellers and consumers; 2. Establishment of optimal requirements for the range and quality of products; 3. Establishment of optimal requirements for compatibility; 4.Unification; 5. Ensuring the unity and reliability of measurements; 6. Establishment of requirements for technological processes; 7. Creation and maintenance of classification and coding systems for technical and economic information; 8. Assistance in the implementation of the legislation of the Russian Federation by methods and means of standardization; 9. Establishment of common terms and designation in the fields of science and technology and in sectors of the national economy, etc. 20

Standardization methods. A standardization method is a technique or set of techniques by which the goals of standardization are achieved. Streamlining is a universal method in the field of standardization of products, processes and services (associated with the reduction of diversity various products, parts, units). Standardization methods OrderingUnification Aggregation Fig.9 21

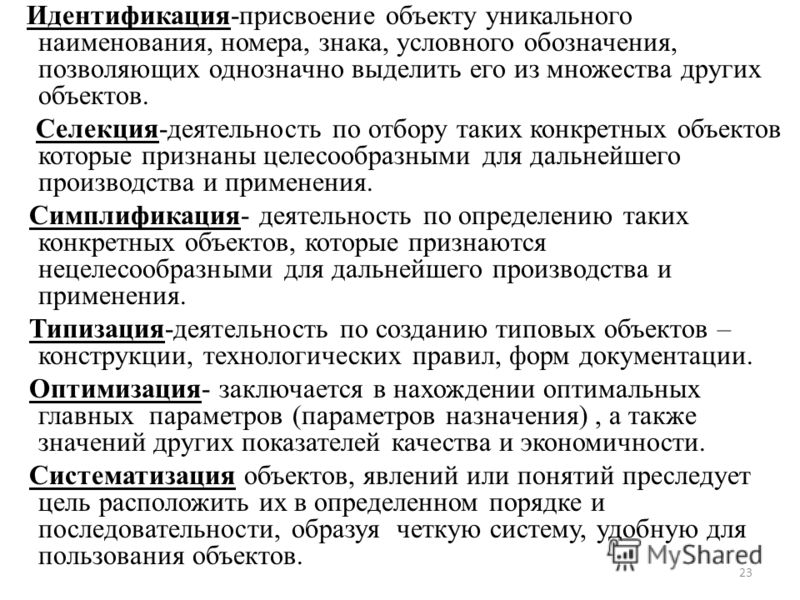

Identification - assigning an object a unique name, number, sign, symbol, allowing you to unambiguously distinguish it from many other objects. Breeding is the activity of selecting such specific objects that are recognized as appropriate for further production and use. Simplification is the activity of identifying such specific objects that are recognized as inappropriate for further production and use. Typification is the activity of creating typical objects - designs, technological rules, documentation forms. Optimization - is to find the optimal main parameters (destination parameters), as well as the values of other indicators of quality and efficiency. The systematization of objects, phenomena or concepts aims to arrange them in a certain order and sequence, forming a clear system that is convenient for using objects. 23

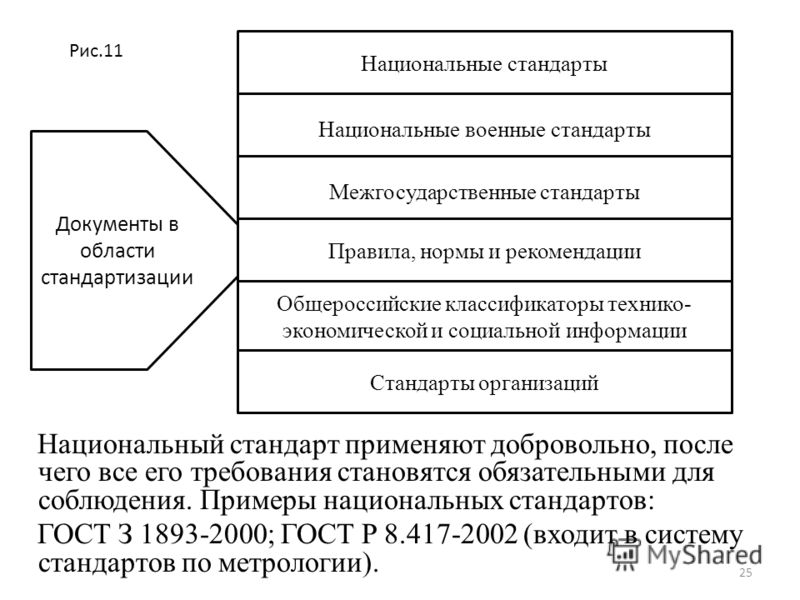

Unification products - actions aimed at reducing to a technologically and economically justified rational minimum the unjustified variety of various products, parts, assemblies, technological processes and documentation. Aggregation is a method of creating machines, instruments and equipment from separate standard unified units that are reused in the creation of various products based on geometric and functional interchangeability. Documents in the field of standardization Standard (St) - a document in which, for the purpose of voluntary reuse, product characteristics, implementation rules and characteristics of production processes, performance of work or provision of services are established. 24

The national standard is applied voluntarily, after which all its requirements become mandatory. Examples of national standards: GOST Z; GOST P (included in the system of standards for metrology). Documents in the field of standardization National standards National military standards Inter state standards Rules, norms and recommendations All-Russian classifiers technical, economic and social information Standards of organizations Fig.11 25

All-Russian classifiers - regulatory documents distributing technical and economic and social information in accordance with its classification. There are more than 30 classifiers in the Russian Federation, which are part of the Unified System for the Classification and Coding of Technical, Economic and Social Information (ESKK). Standards of organizations of all kinds, incl. commercial and scientific, can be developed and approved or independently based on the need for their application (to improve production, use scientific achievements, use the results of measurements and developments, etc.) The standards of organizations are mandatory only for employees of these organizations. 26

Types of Standards A product standard is a standard that specifies the requirements that a product or group of similar products must satisfy in order to ensure that it is suitable for its intended purpose. Standards (St) St for products St for processes, operation St for services St fundamental St for terms and definitions St for control methods Fig.12 27

St on products are: common technical requirements (General requirements to groups of homogeneous products) and technical standards (requirements for specific products). Articles on processes establish requirements for the performance of various types of work at certain stages of the product (service) life cycle. The article on the service establishes the requirements that a group of homogeneous services (services of transport, tourism, etc.) or specific services (classification of hotels, freight transportation) must satisfy in order to ensure that the service complies with its purpose. The fundamental articles establish general organizational and methodological provisions for a certain area of activity, as well as general technical requirements, norms and rules. There are two types - organizational and methodological and general technical. 28

Article on terms and definitions - standards that establish the terms to which definitions are given. Articles on control methods should provide a comprehensive check of all mandatory requirements for product quality. Must be objective, product quality, accurate and provide reproducible results. For each method, establish: 1) test tools and auxiliary devices; 2) the procedure for preparing for testing; 3) the procedure for conducting tests; 4) procedure for processing test results; 5) rules for registration of test results; 6) allowable test error. Specifications In the Federal Law "On Technical Regulation" specifications(TS) are not presented as standardization documents. 29

Organization of work on standardization in the Russian Federation Organization of work on standardization is carried out by the national body - the Federal Agency for Technical Regulation and Metrology (Rostekhregulirovanie - the former State Standard) The participants in the national standardization system are: 1) the national body for standardization; 2) technical committees; 3) developers of standards. To conduct work on standardization, standardization services are created at certain levels of government - state, industry, enterprises. International and regional organizations for standardization 1. international organization for ISO standardization(ISO year); thirty

2. IEC International Electrotechnical Commission(IEC year); 3.ITU International Telecommunication Union (ITU year); 4. European Organization for Quality EOC (EOQ year); 5. European Committee for Standardization CEN (CENELEK year); 6. European Committee for Standardization in Electrical Engineering SENELEC (CENELEK year); 7. European Telecommunications Standards Institute ETSI (ETSI year). 31

5. Conformity assessment Requirements for product safety are mandatory and are determined by the regulations. Conformity assessment is a direct or indirect determination of compliance with the requirements for an object. This term combines all the basic concepts from the field, which is now called certification: certification itself, declaration of conformity, which is a form of confirmation of conformity, and accreditation. Two categories of the form of conformity assessment: 1. assessment of products before entering the market; 2. assessment of products at the stage of circulation on the market (GK and N) The rational combination of these categories, established in the technical regulations, allows us to provide the required level of protection of life, health and property of citizens. 32

Application of the Conformity Assessment Form constructive solution for products of mechanical engineering and instrumentation). Registration form pre-market conformity assessment (CA), carried out by the authorities on the basis of an assessment of the manufacturer's documents and providing for inclusion in the register containing a list of approved products. Project analysis - checking the project for product compliance with established requirements and safety criteria - for complex technical products. Conformity assessment is carried out at the pre-market stage through certification or declaration of conformity. The difference between these forms is that certification is carried out 33

A third party, regardless of the manufacturer (seller) of the product, on the one hand, and the consumer, on the other; declaration of conformity is carried out by the first party. In this case, the entire responsibility for the correctness of the declaration of conformity is assigned to the first party. An analysis of the state of production is carried out at the pre-market stage as an element of the certification scheme in order to establish necessary conditions to ensure continued compliance of manufactured products with the requirements confirmed during certification, or as an independent form of assessment to verify the conditions for ensuring the stability of characteristics. Acceptance of objects - control of compliance of the object with the requirements declared by the manufacturer, carried out by the customer's representative. 34

Inspection control is carried out at the market stage in a situation where, after a certain period of time, the properties of the product deteriorate. Inspection control is carried out several times during the life of the product specifically authorized body. State control (supervision - GK and N) - a form of OS, carried out by state control (supervision) bodies in order to verify the supplier's compliance with the requirements of the TR and take measures based on the results of the verification. Confirmation of compliance- documentary certificates compliance of products with the requirements of technical regulations, the provisions of standards or the terms of contracts. It should be noted a clear division of conformity assessment into mandatory and voluntary. Moreover, mandatory confirmation carried out only to objects, requirements 35

To which are established in the technical regulations. Forms of confirmation of conformity Voluntary confirmation of conformity has only one form - voluntary certification. Certification is a form of confirmation of compliance of objects with the requirements of the TR, the provisions of standards or the terms of contracts, carried out by the certification body. Mandatory confirmation of conformity is carried out in two forms: 1. Acceptance of a declaration of conformity (declaration of conformity); 2.Obligatory certification. Voluntary confirmation of conformity Application procedure voluntary confirmation compliance is determined by the voluntary certification system 36

The certification system is a set of rules for performing certification work, its participants and the rules for functioning in general. A voluntary certification system can be created by a legal entity or an individual entrepreneur who establishes a list of objects subject to certification, their characteristics, rules for performing work and the procedure for their payment, and determines the participants in this system. The system can be registered by the federal body (Rostekhregulirovanie), which maintains a unified register of registered voluntary certification systems. The first certification system in the Russian Federation was the GOST R Certification System (1992). Depending on the interest of the parties, certification systems are national, regional, international. 37

The objects of voluntary confirmation of conformity are products of industrial - technical or social - household purpose, processes, works and services, etc. The work on certification is performed by the certification body. A certification body is a legal entity or individual entrepreneur, duly accredited to perform certification work. It carries out confirmation of conformity, issues certificates of conformity, grants applicants the right to use the mark of conformity, suspends or terminates the certificates of conformity issued by it. Certificate of Conformity - a document certifying the compliance of an object with the requirements of technical regulations, the provisions of standards and the terms of the contract. 38

Mark of conformity - a designation that serves to inform purchasers about the compliance of the object of certification with the requirements of the voluntary certification system or the national standard. Certification is carried out in accordance with the schemes established in the certification system. The certification scheme is the composition and sequence of actions of a third party in conformity assessment. Mandatory confirmation of conformity Mandatory confirmation of conformity is carried out only in cases established by TR, and solely for compliance with their requirements. Mandatory confirmation of conformity is carried out in the following forms: 1. Acceptance of a declaration of conformity; 2. Mandatory certification. 39

The priority form is the declaration of conformity, mandatory certification in TR is laid down only in justified cases. The object of mandatory confirmation of conformity is only products put into circulation on the territory of the Russian Federation. The applicant may be a legal entity or individual, or being the manufacturer or seller. Forms and schemes for confirming compliance can only be established by the TR, taking into account the degree of risk of failure to achieve the objectives of the TR. In the TR, several schemes can be established for the same product (at the choice of the applicant). Schemes may include one or more operations, the results of which are necessary to confirm the conformity of products to established requirements: 40

Tests (type samples, batches or units of products); quality system certification; inspection control. Mandatory conformity assessment schemes are divided into two types: Declaration schemes; certification schemes. The final operation is the acceptance by the applicant of a declaration of conformity or the issuance of a certificate of conformity to the applicant. The applicant, on the basis of these documents, marks the products with the mark of circulation on the market. Declaration of conformity with the requirements of TR is carried out in the following way: - acceptance of the declaration based on own evidence; 41

Acceptance of the declaration based on own evidence and evidence of a third party. There are 7 conformity declaration schemes (1d...7d) Examples of conformity declaration schemes An accredited testing laboratory conducts tests of a typical product sample. The applicant accepts the declaration of conformity. The certification body exercises inspection control over the quality system. Table 2 42

Scheme 1e is used for products whose potential hazard is low. Schemes 2d, 3d and 4d are used when it is difficult to ensure that reliable tests of a type sample are carried out by the manufacturer himself, and product characteristics have great importance for security. For products, the degree of potential danger of which is quite high, schemes 5d, 6d, 7d are used. The result of the declaration is a declaration of conformity. The issued declaration of conformity is subject to registration by the federal executive body for technical regulation. 43

Mandatory certification is applied if there is: 1. A high degree of potential danger of products and the state of a certain market sector does not inspire confidence in the objectivity of the declaration of conformity by suppliers of these products (for example, mandatory certification medicines). 2. Belonging of products to the scope of international agreements to which the Russian Federation has joined and which provide for certification similar products. 3. The applicant cannot implement the provisions of the law on mandatory confirmation of conformity. This applies to imported products when the foreign manufacturer does not have an authorized representative in the Russian Federation. 44

There are 7 schemes mandatory certification(1s…7s). Examples of certification schemes scheme Content of the scheme and its executors Designation of the former scheme 1с An accredited testing laboratory tests a typical product sample. An accredited certification body issues a certificate of conformity to the applicant. 1 4с An accredited testing laboratory performs tests of a typical product sample. An accredited certification body analyzes the state of production, issues a certificate of conformity to the applicant, and exercises inspection control over certified products(testing of product samples and analysis of the state of production) 2a, 3a, 4a Table 3 45

Schemes 1s - 5s apply to mass-produced products, schemes 6s, 7s - to individual batches or units of products released by the applicant - manufacturer or sold by the applicant - seller (not manufacturer). Schemes 1s and 2s are recommended to be used for products whose safety indicators are insensitive to changes in production factors, otherwise it is advisable to use schemes 3s, 4s or 5s. Schemes 4c and 5c are also used in the case when the results of testing a type sample, due to their one-time use, cannot give sufficient confidence in the stability of the confirmed indicators during the validity of the certificate. Schemes 6c, 7c are intended for products purchased by sellers and not having a certificate (for example, products purchased abroad). 46

Features of service certification. Provision of a service is the activity of a provider that is necessary to provide a service. The service is subject to voluntary certification. Most of the services have specific features: 1. direct interaction between the performer and the consumer in the provision of services; 2. the impact on the consumer of services of the conditions of service; 3. coincidence in time of the processes of production and consumption of services; 4. assessment of the quality of services directly by the consumer. Service requirements should be clearly defined as characteristics that can be observed and evaluated by the customer. Schemes for certification of works and services 1 - 7. Examples of schemes for certification of works and services. 47

Table 4 Number of the scheme Evaluation of the performance of works, provision of services Verification (testing) of the results of works and services Inspection control of certified services and works ) Verification (testing) of the results of works and services Control of compliance with established requirements Assessment of the quality system Consideration of the declaration of conformity with the attached documents Control of the quality system 48

Scheme 1 is used for works and services, the quality and reliability of which are determined by the skill of the performer (teacher, hairdresser), and scheme 2 is used for works and services, the quality and reliability of which are due to the stability of the process of performing work, providing services (medical, passenger transportation services) . Scheme 3 is used in the certification of production services. In Scheme 4, the organization as a whole is evaluated with the assignment of a certain category to it (class, category, hotel stars, etc.). When evaluating potentially hazardous work and services apply Scheme 5. Scheme 6 is used for certification of works and services provided on individual orders. Scheme 7 is used if the contractor has a quality system that includes control of all requirements verified during certification. 49

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

Technical regulation and standardization

technical quality production

1. Technical regulations, taking into account the degree of risk of causing harm, establish the minimum necessary requirements to ensure:

radiation safety;

biological safety;

explosion safety;

mechanical safety;

fire safety;

product safety ( technical devices used at a hazardous production facility);

thermal safety;

chemical safety;

electrical safety;

radiation safety of the population;

electromagnetic compatibility in terms of ensuring the safety of the operation of instruments and equipment;

unity of measurements;

2. The technical regulation must contain a list and (or) description of the objects of technical regulation, requirements for these objects and rules for their identification in order to apply the technical regulation. The technical regulation must contain the rules and forms of conformity assessment (including the technical regulation may contain conformity assessment schemes, the procedure for extending the validity period of the issued certificate of conformity), determined taking into account the degree of risk, deadlines for conformity assessment in relation to each object of technical regulation and (or ) requirements for terminology, packaging, marking or labeling and the rules for their application. The technical regulation must contain requirements for energy efficiency and resource saving. Conformity assessment is carried out in the form of state control (supervision), testing, registration, conformity assessment, acceptance and commissioning of the facility, the construction of which is completed, and in another form. Mandatory requirements contained in technical regulations for products or for products and processes related to product requirements for design (including surveys), production, construction, installation, adjustment, operation, storage, transportation, sale and disposal, rules and forms of conformity assessment, identification rules , the requirements for terminology, packaging, marking or labels and the rules for their application are directly applicable throughout the Russian Federation and can only be changed by amending and supplementing the relevant technical regulation.

Requirements for products or for products and the processes of design (including surveys), production, construction, installation, adjustment, operation, storage, transportation, sale and disposal, rules and forms of conformity assessment, identification rules that are not included in the technical regulations , the requirements for terminology, packaging, marking or labeling and the rules for their application cannot be mandatory.

3. The technical regulation must contain generalized and (or) specific requirements for the characteristics of products or for products and the processes of design (including surveys), production, construction, installation, adjustment, operation, storage, transportation, sale and disposal related to the requirements for products, but should not contain requirements for design and execution, except for cases where, due to the lack of requirements for design and execution, taking into account the degree of risk of causing harm, the achievement of the objectives of the adoption of technical regulations specified in paragraph 1 of Article 6 of this Federal Law is not ensured.

5. Technical regulations, taking into account the degree of risk of causing harm, may contain special requirements for products or for products and the processes of design (including surveys), production, construction, installation, adjustment, operation, storage, transportation, sale and disposal related to the requirements for products. , requirements for terminology, packaging, marking or labels and the rules for their application, ensuring the protection of certain categories of citizens (minors, pregnant women, nursing mothers, disabled people).

6. Technical regulations are applied in the same way and equally regardless of the type of regulatory legal act by which they are adopted, the country and (or) place of origin of products or the implementation of design processes related to product requirements (including surveys), production, construction, installation, adjustment, operation, storage, transportation, sale and disposal, types or features of transactions and (or) physical and (or) legal entities who are manufacturers, performers, sellers, purchasers.

7. A technical regulation cannot contain requirements for products that cause harm to the life or health of citizens, accumulated during prolonged use of these products and depend on other factors that do not allow determining the degree of acceptable risk. In these cases, the technical regulation may contain a requirement to inform the purchaser, including the consumer, about the possible harm and the factors on which it depends.

2. Agreement on technical barriers and trade

The Agreement on Technical Barriers to Trade recognizes the right of each country to establish mandatory technical standards- technical regulations and standards, requirements for compliance with which are voluntary. Technical regulations should be based on evidence-based data; must be formulated and applied in such a way as not to create arbitrary or unnecessary obstacles to international trade. Technical regulations should be applied on a most favored nation basis and should not be more burdensome for imported goods than for nationally produced goods. The Agreement requires that each of the WTO member countries establish its own information centers where interested enterprises can receive information regarding:

technical regulations and voluntary standards (current and under development);

conformity assessment procedures (current and under development).

The agreement under the term "standard" means:

product characteristics;

processes and production methods that affect the characteristics, quality of products;

terminology and symbolism;

requirements for packaging and labeling of products.

The agreement establishes that the applicable standards and technical regulations should pursue the goal of ensuring the quality of imported products, protecting human health, animal and plant life or the environment. At the same time, the standards should be applied on a non-discriminatory basis, that is, in accordance with the principle of most favored nation treatment, apply to all WTO member countries and, in accordance with the national treatment, apply equally to foreign and national goods. Standards, technical regulations and rules for their application should be clearly defined and should be applied in such a way as not to create unnecessary barriers to trade. Standards must be based on scientifically proven information and facts. Otherwise, they may be considered as unreasonable barriers to trade. So, for example, in 2001, Argentina, in order to prevent the penetration of low-quality medicines into its territory, compiled 2 lists of countries. The first list included countries in whose control bodies and standards the Government of Argentina had "trust". The second list included countries whose drug production capacity had to be approved by the Argentine Ministry of Health before drugs could be exported to Argentina. India, however, was not included in any of the lists. The Government of India appealed to the Committee on Technical Barriers to Trade, accusing Argentina of creating unreasonable barriers to trade and violating the most favored nation treatment that applies to all WTO member countries without exception.

3. Types of measurements

Measurement - the process of finding the value of a physical quantity empirically using measuring instruments.

The result of the process is the value of the physical quantity Q = qU, where q is the numerical value of the physical quantity in the accepted units; U - unit of physical quantity. The value of the physical quantity Q, found during the measurement, is called real.

The principle of measurements is a physical phenomenon or a set of physical phenomena underlying measurements. For example, the measurement of body weight by weighing using gravity proportional to the mass, the measurement of temperature using the thermoelectric effect.

Measurement method - a set of methods for using the principles and means of measurement.

Measuring instruments (MI) are used technical means that have normalized metrological properties.

Exist different kinds measurements. The classification of measurement types is carried out based on the nature of the dependence of the measured value on time, the type of measurement equation, the conditions that determine the accuracy of the measurement result and the methods of expressing these results.

According to the nature of the dependence of the measured quantity on the measurement time, static and dynamic measurements are distinguished.

Static measurements are measurements in which the measured value remains constant over time. Such measurements are, for example, measurements of product dimensions, constant pressure, temperature, etc.

Dynamic - these are measurements during which the measured value changes with time, for example, measuring pressure and temperature when gas is compressed in an engine cylinder.

According to the method of obtaining results, determined by the type of measurement equation, direct, indirect, cumulative and joint measurements are distinguished.

Straight lines are measurements in which the desired value of a physical quantity is found directly from experimental data. Direct measurements can be expressed by the formula Q = X, where Q is the desired value of the measured quantity, and X is the value directly obtained from experimental data. Examples of such measurements are: length measurement with a ruler or tape measure, diameter measurement with a caliper or micrometer, angle measurement with a goniometer, temperature measurement with a thermometer, etc.

Indirect measurements are measurements in which the value of a quantity is determined on the basis of a known relationship between the sought value and the quantities whose values are found by direct measurements. Thus, the value of the measured quantity is calculated by the formula Q = F(x1, x2 ... xN), where Q is the desired value of the measured quantity; F - known functional dependence, x1, x2, … , xN - values obtained by direct measurements. Examples of indirect measurements: determining the volume of a body by direct measurements of its geometric dimensions, finding the electrical resistivity of a conductor by its resistance, length and area cross section, measuring the average thread diameter method of three delays, etc. Indirect measurements are widespread in cases where the desired value cannot be measured or is too difficult to measure by direct measurement. There are cases when the magnitude can be measured only indirectly, for example, the dimensions of the astronomical or intraatomic order.

Aggregate - these are measurements in which the values of the measured quantities are determined by the results of repeated measurements of one or more quantities of the same name with various combinations of measures or these quantities. The value of the desired quantity is determined by solving a system of equations compiled from the results of several direct measurements. An example of cumulative measurements is the determination of the mass of the individual weights of a set, i.e. calibration according to the known mass of one of them and according to the results of direct measurements and comparison of masses various combinations weights. Consider an example of cumulative measurements, which consists in calibrating a weight, consisting of weights with a mass of 1, 2, 2*, 5, 10 and 20 kg. A number of weights (except 2*) represent reference masses different sizes. An asterisk marks a weight that has a value other than exact value 2 kg. Calibration consists in determining the mass of each weight using one standard weight, for example, using a weight of 1 kg.

By changing the combination of weights, we will take measurements. Let's make equations, where we denote by numbers the mass of individual weights, for example, 1arb denotes the mass of an exemplary weight of 1 kg, then: 1 = 1arb + a; 1 + 1rev = 2 + b; 2* = 2 + c; 1 + 2 + 2* = 5 + d etc. Additional weights that must be added to or subtracted from the mass of the weight indicated on the right side of the equation to balance the scales are designated a, b, c, d. By solving this system of equations, you can determine the value of the mass of each weight.

Joint - these are measurements made simultaneously by two or more opposite quantities to find a functional relationship between them. Examples of joint measurements are the determination of the length of a rod depending on its temperature or the dependence of the electrical resistance of a conductor on pressure and temperature.

According to the conditions that determine the accuracy of the result, the measurements are divided into three classes.

1. Measurements of the highest possible accuracy achievable with the current state of the art. This class includes all high-precision measurements and, first of all, reference measurements related to the highest possible reproduction accuracy of established units. physical quantities. This also includes measurements of physical constants, primarily universal ones, for example, the measurement of the absolute value of acceleration free fall.

2. Control and verification measurements, the error of which, with a certain probability, should not exceed a certain specified value. This class includes measurements performed by laboratories of state control (supervision) over compliance with the requirements of technical regulations, as well as the state of measuring equipment and factory measuring laboratories. These measurements guarantee the error of the result with a certain probability, not exceeding some predetermined value.

3. Technical measurements, in which the error of the result is determined by the characteristics of the measuring instruments. Examples technical measurements are the measurements performed during the manufacturing process on industrial enterprises, in the service sector, etc.

Depending on the method of expressing the results of measurements, absolute and relative measurements are distinguished. Absolute measurements are measurements that are based on direct measurements of one or more basic quantities or on the use of the values of physical constants. Examples absolute measurements are: definition of length in meters, forces electric current in amps, acceleration of free fall in meters per second squared. Relative measurements are those in which the desired value is compared with the value of the same name, which plays the role of a unit or is taken as the initial one. Examples of relative measurements are: measuring the diameter of the shell by the number of revolutions of the measuring roller, measuring the relative humidity of the air, defined as the ratio of the amount of water vapor in 1 cu. m of air to the amount of water vapor that saturates 1 cu. m of air at a given temperature. Depending on the method of determining the values of the sought quantities, two main measurement methods are distinguished: the method of direct assessment and the method of comparison with the measure.

Direct evaluation method - a measurement method in which the value of a quantity is determined directly from a reading device measuring instrument direct action. Examples of such measurements are: measuring length with a ruler, measuring parts with a micrometer, goniometer, pressure with a manometer, etc.

Method of comparison with a measure - a measurement method in which the measured value is compared with the value reproduced by the measure. For example, to measure the diameter of the caliber, the optimeter is set to zero by the block of gauge blocks, and the measurement result is obtained from the indication of the optimeter pointer, which is a deviation from zero. Thus, the measured value is compared with the size of the gage block block. There are several types of comparison methods:

a) the opposition method, in which the measured value and the value reproduced by the measure simultaneously act on the comparison device, which makes it possible to establish the relationship between these quantities, for example, measuring resistance using a bridge circuit with the inclusion of a diagonal of the indicating device bridge;

b) the differential method, in which the measured value is compared with a known value, reproducible measure. This method, for example, determines the deviation of the controlled diameter of the part on the optimeter after it is set to zero by the block of gauge blocks;

c) zero method - also a kind of comparison method with a measure, in which the resulting effect of the impact of quantities on the comparison device is brought to zero. This method measures electrical resistance according to the bridge scheme with its full balancing;

d) in the coincidence method, the difference between the measured value and the value reproduced by the measure is determined using the coincidence of scale marks or periodic signals. For example, when measuring with a caliper, the coincidence of the marks of the main and vernier scales is used.

Depending on the method of obtaining measurement information, measurements can be contact and non-contact.

Depending on the type of measuring instruments used, there are instrumental, expert, heuristic and organoleptic methods of measurement.

The instrumental method is based on the use of special technical means, including automated and automatic.

The expert evaluation method is based on the use of the judgments of a group of specialists.

Heuristic evaluation methods are based on intuition.

Organoleptic evaluation methods are based on the use of the human senses. Assessment of the state of the object can be carried out by element-by-element and complex measurements. The element-by-element method is characterized by the measurement of each product parameter separately. For example, eccentricity, ovality, cutting of a cylindrical shaft. Complex method characterized by the measurement of the total quality indicator, which is influenced by its individual components. For example, measuring the radial runout of a cylindrical part, which is affected by eccentricity, ovality, etc.; control of the position of the profile along the limit contours, etc.

Certification. Compliance confirmation forms.

Conformity assessment on the territory of the Russian Federation may be voluntary or mandatory.

Voluntary confirmation of conformity is carried out in the form of voluntary certification.

Mandatory confirmation of conformity is carried out in the following forms: acceptance of a declaration of conformity (declaration of conformity); mandatory certification. The procedure for applying the forms of mandatory confirmation of conformity is established by the Federal Law on TR.

Voluntary confirmation of conformity is carried out at the initiative of the applicant on the terms of an agreement between the applicant and the certification body to establish compliance with national standards, standards of organizations, codes of practice, voluntary certification systems, and the terms of contracts. The objects of voluntary confirmation of conformity are products, processes of production, operation, storage, transportation, sale and disposal, works and services, as well as other objects for which standards, voluntary certification systems and contracts establish requirements. Certification objects certified in the voluntary certification system may be marked with the mark of conformity of the voluntary certification system. The procedure for applying such a mark of conformity is established by the rules of the relevant voluntary certification system. The application of the mark of conformity to the national standard is carried out by the applicant on a voluntary basis in any way convenient for the applicant in the manner established by the national standardization body. Objects, the conformity of which has not been confirmed in accordance with the procedure established by this Federal Law, cannot be marked with a mark of conformity.

Mandatory confirmation of conformity is carried out only in cases established by the relevant technical regulation, and solely for compliance with the requirements of the technical regulation. The object of mandatory confirmation of conformity can only be products put into circulation on the territory of the Russian Federation. The form and schemes of mandatory confirmation of conformity can be established only by the technical regulations, taking into account the degree of risk of not achieving the goals of the technical regulations. The Declaration of Conformity and the Certificate of Conformity have equal legal force regardless of the mandatory conformity assessment schemes and are valid throughout the Russian Federation.

Certification participants are manufacturers of products and service providers (first party), customers-sellers (first or second party), as well as organizations representing a third party - certification bodies, testing laboratories(centers), the federal executive body for technical regulation.

The main participants are applicants, certification bodies (hereinafter referred to as OS) and testing laboratories (IL). It is they who participate in the certification procedure of each specific object at all stages.

The national certification body - Rostekhregulirovanie carries out its activities on the basis of the rights, duties and responsibilities provided for by the current legislation of the Russian Federation.

The central certification body carries out its activities in accordance with the established standards.

The Certification Council is formed by the central certification body for each area of technology and develops proposals for the formation of a unified product certification policy, prepares recommendations and promotes their implementation.

Mandatory confirmation of compliance is carried out in the following forms:

adoption of a declaration of conformity (declaration of conformity), marking with a mark of conformity (when declaring conformity with the requirements of TR - with a mark of circulation on the market);

mandatory certification, marking with a mark of conformity indicating the code of the authority (in case of certification for compliance with the requirements of TR - with a mark of circulation on the market).

Voluntary confirmation of conformity is carried out in the form of voluntary certification at the initiative of the applicant on the terms of the agreement between the applicant and the certification body. Voluntary conformity assessment can be carried out to establish compliance with national standards, organization standards, codes of practice, voluntary certification systems, and contract terms.

4. Conformity marks

Conformity mark when declaring

Market circulation sign

Mark of conformity with mandatory certification

Mark of conformity for voluntary certification

Interchangeability.

Qualities form the basis of the current system of tolerances and landings. Quality is a certain set of tolerances that, for all nominal sizes, correspond to the same degree of accuracy. Thus, we can say that it is the qualifications that determine how accurately the product as a whole or its individual parts are made. The name of this technical term comes from the word "qualitas", which in Latin means "quality". The set of those tolerances that correspond to the same level of accuracy for all nominal sizes is called the qualification system. The standard establishes 20 qualifications - 01, 0, 1, 2 ... 18. As the quality number increases, the tolerance increases, i.e., the accuracy decreases. Qualities from 01 to 5 are intended mainly for calibers. For landings, qualifications are provided from the 5th to the 12th.

System of admissions and landings.

The set of tolerances and landings, which is created on the basis of theoretical research and experimental surveys, as well as built on the basis of practical experience, is called the system of tolerances and landings. Its main purpose is to select such options for tolerances and fits for typical joints of various parts of machines and equipment that are minimally necessary, but completely sufficient. The basis for the standardization of measuring instruments and cutting tools make up exactly the most optimal gradations of tolerances and landings. In addition, thanks to them, the interchangeability of various parts of machines and equipment is achieved, as well as improving the quality finished products. Tables are used to design a unified system of tolerances and landings. They indicate the reasonable values \u200b\u200bof the limit deviations for various nominal sizes.

When designing various machines and mechanisms, developers proceed from the fact that all parts must meet the requirements of repeatability, applicability and interchangeability, as well as be unified and comply with accepted standards. One of the most rational ways to fulfill all these conditions is to use at the design stage as much as possible a large number such constituent parts, the production of which has already been mastered by the industry. This allows, among other things, to significantly reduce development time and costs. At the same time, it is necessary to ensure high accuracy of interchangeable components, assemblies and parts in terms of their compliance with geometric parameters.

Using such a technical method as modular layout, which is one of the standardization methods, it is possible to effectively ensure the interchangeability of components, parts and assemblies. In addition, it greatly facilitates repairs, which greatly simplifies the work of the relevant personnel (especially in difficult conditions), and allows you to organize the supply of spare parts. Contemporary industrial production focused mainly on the mass production of products. One of its prerequisites is the timely receipt of such components on the assembly line. finished products, which do not require additional fitting for their installation. In addition, interchangeability must be ensured that does not affect the functional and other characteristics of the finished product.

Hosted on Allbest.ru

...Similar Documents

The study of the concept of "standardization" and the scope of its application. Definition of standards in the field of quality of services. The main provisions of the technical regulation: requirements for products and packaging, rules and forms of conformity assessment, rules for product identification.

abstract, added 05/03/2015

Basic provisions and rules of conformity assessment. Regulatory and technical support for confirmation of conformity (PS). Stages of conformity assessment of homogeneous products. Analysis of the state of production. Issuance of a certificate of conformity based on test results.

abstract, added 11/12/2008

State regulation and management in the field of technical regulation, standardization and assessment of compliance with the requirements of technical regulatory legal acts. Legal basis ensuring the quality of industrial goods in the Republic of Belarus.

thesis, added 12/25/2011

Technical legislation as the basis of standardization, metrology and certification activities. Theoretical and organizational foundations of standardization. Subject, tasks, ways and methods of metrology. Certification as a conformity assessment procedure.

manual, added 11/13/2013

Conformity assessment (certification). Types of conformity assessment procedures. Declaration of conformity. Organization of works on declaration of conformity. Certification, conditions for ensuring the quality of certification. Functioning of OS of quality systems.

test, added 04.11.2007

The structure and content of the technical regulations for juice products from fruits and vegetables. Certificate of conformity for juice products. System of obligatory certification of production. Negative facts of qualitative and quantitative acceptance of a batch of products.

test, added 04/22/2010

Commodity characteristic, technical documentation and the procedure for confirming the conformity of ice cream ice cream "Semeynoye" produced by OJSC "Ice-Fili". The main raw material for the production of ice cream. Requirements for the finished product, quality control.

term paper, added 03/21/2015

Issues of standardization and certification of alcoholic beverages: the procedure for the inspection control of the equipment and technological scheme for obtaining products. Metrological service at the plant, requirements for microbiological and technometric control.

thesis, added 06/09/2009

Certification of product conformity, establishment of compliance of indicators (parameters) of product quality with specified requirements. Certification procedure. Planning and development of quality assurance methods. Quality control and promotion.

abstract, added 10/13/2008

The study of the principles of product standardization, activities to establish rules and characteristics for the purpose of their voluntary reuse. Analysis of the protection of the interests of consumers and the state on the quality of products, processes and services.

Law of the Russian Federation "On technical regulation". Goals, principles and objectives of technical regulation - page №1/3

TOPIC 1. The system of technical regulation in the Russian Federation.

The problem of ensuring the quality of goods and services.

Law of the Russian Federation "On technical regulation".

Goals, principles and objectives of technical regulation.

The main elements of the technical regulation system.

Quality issues are relevant to all countries, regardless of the degree of maturity of their market economy, and suppliers of products and intermediaries are interested in meeting the requirements of standards in order to ensure the competitiveness of their products and succeed in the market. Therefore, standardization and certification are an element of a modern business strategy and cover all areas public life, ensure not only competitiveness, but also the effectiveness of partnerships between enterprises at all levels of management, since, for example, the standards for processes and documents contain the “rules of the game” that specialists of all enterprises must know and follow in order to conclude mutually beneficial transactions.

Quality(according to GOST R ISO 9000 - 2001. Quality management system. Fundamentals and vocabulary) - this is the degree of compliance of the inherent characteristics with the requirements. The concept of quality includes three elements: object, characteristics, needs (requirements).

|

Quality | |||||

|

an object |

characteristics |

requirements |

|||

|

product |

process |

face |

quality |

quantitative |

needs |

Service(according to GOST R 50646-94. Services to the population. Terms and definitions) is the result of direct interaction between the contractor and the consumer, as well as the contractor's own activities to meet the needs of the consumer.

Characteristics of goods and services is a set distinctive properties that they possess.

The basis of the quality policy of any manufacturer of services or goods is to achieve high customer satisfaction. Not coincidentally, the first quality assurance principle formulated by Edward Deming is that the consumer should get what he wants, when he wants it.

Service quality is a set of characteristics of a service that determine its ability to satisfy the established or implied needs of the consumer.

Quality of service- a broad and multifaceted concept, a set of conditions that provide the consumer with minimal time and maximum convenience when receiving a service.

In accordance with International Standard ISO 8402:1994 (E/F/R). Quality management and quality assurance defines the following concepts of quality management:

Universal requirements for the quality of goods and services

|

Requirements |

Content of the requirement |

|

Appointments |

Functionality |

|

Composition and structure of raw materials and materials |

|

|

Compatibility– suitability of services for joint, non-interaction-free use under specified conditions to meet specified requirements. |

|

|

Interchangeability– the suitability of one service for use in place of another service in order to fulfill the same requirements. |

|

|

Security |

For the life, health and property of the consumer |

|

Environmental friendliness |

Environmental protection and compliance with the rules of nature management. |

|

Reliability | |

|

Ergonomics |

Consistency of product design with features human body to ensure ease of use. |

|

resource saving |

Economical use of raw materials, materials, fuel, energy and labor resources. |

|

Manufacturability |

Adaptability of products to the manufacture, operation and repair with minimal cost with given quality indicators. |

|

aesthetics |

The ability of a product or service to express an artistic image, socio-cultural significance in sensually perceived by a person signs of form (color, spatial configuration, quality of product and room finishing). |

Quality control is a systematic test of how capable an entity is of meeting specified requirements. Non-compliance with a requirement is a nonconformity for which the organization takes corrective action.

|

Quality control of products (services) | ||||

|

measurements |

Analysis |

Tests |

||

|

Analytical Methods |

Determination of one or more characteristics of products (services) in accordance with the established procedure |

|||

|

laboratory |

polygon |

natural |

||

2. Law of the Russian Federation "On technical regulation".

On July 1, 2003, the RF Law “On Technical Regulation” No. 184-FZ of December 27, 2002 came into force, which repealed the laws “On Certification of Products and Services” No. 5151-I of June 10, 1993 and “On Standardization » No. 5154-I dated 06/10/1993. The adoption and implementation of the new law is connected with the process of preparation for the entry of the Russian Federation into the WTO and harmonization of domestic legislation with international ones.

The law regulates relations arising from: development, adoption, application and implementation of mandatory requirements for products, production processes, operation, storage, transportation, sale and disposal; development, adoption, application and execution on a voluntary basis of requirements for products, production processes, operation, storage, transportation, sale and disposal, performance of work or provision of services; conformity assessment.

The law defines the basic concepts in the field of technical regulation in a completely different interpretation.

Technical regulation defined as legal regulation relations in the field of establishing, applying and fulfilling mandatory requirements for products, production processes, operation, storage, transportation, sale and disposal, as well as in the field of establishing and applying on a voluntary basis requirements for products, production processes, operation, storage, transportation, sale and disposal, performance of work or provision of services and legal regulation of relations in the field of conformity assessment.

The concept of standardization has undergone fundamental changes. It excluded the normative nature of the activity and the mention of its focus on ensuring the safety of the relevant facilities, as well as the quality of products, works and services.

The law defines the main elements of the technical regulation system, the goals and principles of its organization and functioning, the procedure for accreditation of certification bodies and testing laboratories (centers), the rules for state control and supervision over compliance with the requirements of technical regulations, the procedure for recalling products that do not meet the requirements of technical regulations, a transitional period and transitional provisions have been defined to ensure a phased transition to new system technical regulation and bringing in line with the legal framework of the Russian Federation.

Basic transitional provisions (art. 46):

1. From the date of entry into force of this Federal Law until the entry into force of the relevant technical regulations, the requirements for products, production processes, operation, storage, transportation, sale and disposal established by regulatory legal acts Russian Federation and normative documents federal executive bodies are subject to binding only in the part corresponding to the goals: protection of the life or health of citizens, property of individuals or legal entities, state or municipal property; protection of the environment, life or health of animals and plants; prevention of actions that mislead purchasers.

2. From the date of entry into force of this Federal Law, mandatory confirmation of conformity is carried out only in relation to products put into circulation on the territory of the Russian Federation.

3. Prior to the entry into force of the relevant technical regulations, the Government of the Russian Federation determines and supplements the list annually certain types products for which mandatory certification is replaced by a declaration of conformity carried out in accordance with the procedure established by this Federal Law.

4. Prior to the entry into force of the relevant technical regulations, the conformity declaration scheme based on own evidence is allowed to be used only by manufacturers or only by persons performing the functions of a foreign manufacturer.

5. Until the adoption of the relevant technical regulations, technical regulation in the field of application of veterinary-sanitary and phytosanitary measures is carried out in accordance with the Federal Law "On Plant Quarantine" and the Law of the Russian Federation "On Veterinary Medicine".

6. Until the adoption of a general technical regulation on nuclear and radiation safety, technical regulation in the field of nuclear and radiation safety is carried out in accordance with the Federal Law "On the use atomic energy"and the Federal Law "On Radiation Safety of the Population".

7. Technical regulations must be adopted within seven years from the date of entry into force of this Federal Law.

Mandatory requirements for products, processes of production, operation, storage, transportation, sale and disposal, in respect of which technical regulations were not adopted within the specified period, cease to be valid upon its expiration.

8. Accreditation documents issued in the prescribed manner to certification bodies and accredited testing laboratories (centers) before the entry into force of this Federal Law, as well as documents confirming compliance (certificate of conformity, declaration of conformity) and accepted before the entry into force of this Federal law, are considered valid until the expiration of the period established in them.

3. Goals, principles and objectives of technical regulation.

Technical regulation is carried out in accordance with the principles:

application of uniform rules for establishing requirements for products, production processes, operation, storage, transportation, sale and disposal, performance of work or provision of services;

compliance of technical regulation with the level of development of the national economy, the development of the material and technical base, as well as the level of scientific and technical development;

independence of accreditation bodies, certification bodies from manufacturers, sellers, performers and purchasers;

unified system and rules of accreditation;

the unity of the rules and methods of research (testing) and measurements in the course of mandatory conformity assessment procedures;

uniform application of the requirements of technical regulations, regardless of the types or features of transactions;

the inadmissibility of restricting competition in the implementation of accreditation and certification;

inadmissibility of combining the powers of the state control (supervision) body and the certification body;

the inadmissibility of combining the powers of accreditation and certification by one body;

inadmissibility of off-budget financing of state control (supervision) over compliance with the requirements of technical regulations.

Regulatory documents of a mandatory nature used in the system of technical regulation are defined by law as technical regulations.

Technical regulation- a document adopted by an international treaty of the Russian Federation, ratified in accordance with the procedure established by the legislation of the Russian Federation, or by a federal law, or by a decree of the President of the Russian Federation, or by a decree of the Government of the Russian Federation and establishes mandatory requirements for the application and implementation of requirements for objects of technical regulation (products, in including buildings, structures and structures, production processes, operation, storage, transportation, sale and disposal).

Technical regulations are adopted in order to:

protection of life or health of citizens, property of individuals or legal entities, state or municipal property;

protection of the environment, life or health of animals and plants;

prevention of actions that mislead purchasers.

radiation safety;

biological safety;

explosion safety;

mechanical safety;

fire safety;

industrial safety;

thermal safety;

chemical safety;

electrical safety;

nuclear and radiation safety;

electromagnetic compatibility in terms of ensuring the safety of the operation of instruments and equipment;

unity of measurements.

4. Main elements of the technical regulation system.

The new system of technical regulation determines the establishment and application of mandatory requirements for products, including buildings and structures, as well as the establishment of requirements for voluntary multiple use of requirements for products, performance of work and provision of services. Mandatory requirements are established in technical regulations, confirmation of compliance with the requirements of technical regulations is mandatory and is carried out in the form of mandatory certification or declaration of conformity. The main purpose of establishing and monitoring compliance with mandatory requirements for products is to ensure the safety of life and health of people, animals and plants, the protection of the environment, personal, state and municipal property.

Requirements for voluntary multiple use of products, performance of work and provision of services may be established by standards, voluntary certification systems, terms of contracts. The activity of establishing and applying such requirements is standardization. Confirmation of compliance with the requirements of standards, voluntary certification systems and the terms of contracts is carried out on a voluntary basis in the form of voluntary certification. Thus, the service sector, incl. hospitality and tourism, fully falls into the field of voluntary conformity assessment with ample opportunities for developing standards for organizations, creating systems for voluntary certification and regulation at the level of self-regulatory public associations and organizations. The main goal of standardization in the new system of technical regulation is to increase the competitiveness of products, services, works, ensure their compatibility and interchangeability, as well as ensure scientific and technological progress and improve the safety of life and health of citizens and protect the environment.

Technical regulation system

Mandatory requirements for products, incl. to buildings and structures

Requirements for application on a voluntary basis to products, performance of works and provision of services

Standardization

Technical regulations

Standards

Conformity assessment (PS)

Mandatory PS

Voluntary PS

Requirements of technical regulations

Requirements of national standards, standards of organizations, voluntary certification systems, terms of contracts

Mandatory certification

Declaration of Conformity

Voluntary certification

Topic 2. International cooperation in the field of standardization and conformity assessment.

AT federal law"On Technical Regulation" (hereinafter referred to as the Federal Law) it is noted that international standards (along with national ones) can be used in whole or in part as a basis for the development of technical regulations. It also states that the national standardization body participates in the development of international standards and ensures that the interests of the Russian Federation are taken into account when they are adopted. One of the principles of standardization is the use of international standards as the basis for the development of national standards. Even short excerpts from the Federal Law speak of the importance that legislators attach to international standardization.International standardization- this is a set of international organizations for standardization and products of their activities - standards, recommendations, technical reports and other scientific and technical products. The main international organizations for standardization: International Organization for Standardization - ISO (ISO), International Electrotechnical Commission - IEC (IEC), International Telecommunication Union - ITU (ITU). They are united not only general area activities, but also practically a common production site in Geneva. The very names of the organizations contain the delimitation of their spheres of influence. If ISO develops standards for all sectors of the economy and fields of activity, then IEC specializes in electrical engineering and electronics, ITU - oversees telecommunications and telecommunications. The areas of interest of these organizations often overlap. In such cases, joint bodies are formed to coordinate work and create common documents.

International Organization for Standardization(ISO) is the largest and most authoritative of the above. Its founding date is February 23, 1947. The main goal is formulated in the ISO Charter: "... to promote the development of standardization on a global scale to ensure international exchange of goods and mutual assistance, as well as to expand cooperation in the fields of intellectual, scientific, technical and economic activity". official languages ISO - English, French and Russian. As of July 1, 2003, there are 145 countries as part of ISO - the organization for standardization. The following facts testify to the scale of the organization's activities: over 30 thousand experts participate in technical work, which is carried out within the framework of 187 technical committees (TC), 576 subcommittees (SC), 2057 working groups (WG). Every year in different countries more than 800 meetings of the technical bodies mentioned above are held around the world. The ISO standards park exceeds 14,000 items, and over 800 new and revised standards are published annually.