Design and construction of highways: norms and recommendations. Road design: recommendations

AT modern world highways are real arteries that unite all big cities and small settlements into a single network. Meaning highways for the development of industry, trade and Agriculture hard to overestimate.

It is often possible to increase trade turnover only by improving transport links. On the roads on their cars people are in a hurry, and truck drivers are carrying millions of tons of various cargoes. The traffic on the roads is simply enormous.

Therefore, the design of highways is very difficult task which only real professionals can handle.

In general, road design is a complex set of survey works, which include not only design calculations, but also economic calculations.

What connects the survey and design of roads

Initially, comprehensive studies of the target area are carried out. Thus, the survey and design of roads are inextricably linked, because the area must have the appropriate man-made, climatic and geological conditions.

The development of the project and the complex of construction works itself are determined and regulated by legal documents. At the same time, the design standards for highways imply, in addition to creating a road, a complex of additional structures, the development of a communications plan, afforestation, etc.

Create a road project

Create a road project In addition, experts must determine technical specifications, calculate the optimal number building materials, attract the appropriate number of special equipment and workers, set the stages and terms of construction, calculate the payback period for all funds spent during construction.

It is necessary to complete all the work not only in the shortest possible time, but also as correctly as possible - making a few slightest mistakes is enough for the construction deadlines to be disrupted, and the roads themselves to fail in a matter of months.

What is the beginning of the design of the subgrade of roads

The complex of construction works provides for the digging of a road trough, the construction of the roadway itself, as well as the installation of curbs and paving stones, but the most important thing when choosing a coating is the functional purpose of the road, and as a result, the density of traffic flow and the estimated speed of movement.

Design of public routes

Highways, both urban and suburban, are constantly under the influence of permanent and temporary mechanical loads, as well as many climatic factors. This is especially noticeable in our country, where the number of freeze-thaw cycles per year can reach dozens.

Also, snow drifts, precipitation, groundwater and a number of other factors have a destructive effect on the roadway. This is the main reason why road design is such a complex job, which can only be trusted by experienced and sufficiently qualified engineers.

To develop a project, the implementation of which will solve the transport issue in a particular region, a specialist must have a certain amount of information. Only in this case it is possible to guarantee the required level of safety and ease of use of the route for passenger and freight traffic.

How the track is designed

When designing a highway, an engineer always takes into account that it not only combines federal and administrative points, but also must meet safety standards for drivers, passengers and pedestrians. To do this, it is necessary to take into account certain standards for the design of roads that provide the required level of convenience and safety.

If during the design process errors were made in the calculations of the prospective use of roads, this leads to problems. If they are not eliminated by quality repair in no time, the road will be quickly destroyed.

Therefore, when designing a highway, it is necessary to calculate not only the loads that exist at the moment, but also a long-term plan for twenty years. If the plan is created without taking into account the perspective, it is considered to be of poor quality.

Perspective road construction plan

Perspective road construction plan Particular importance must be given to the technical classification of the course. The type of roadway, the number of lanes and a number of other parameters specific to each road depend on this. Therefore, it is especially important to determine the status of the road. Here it is also very important to calculate the load from the traffic flow, which will probably increase over the years.

Read also

Installation of a ramp in the entrance

After the completion of the calculations, the result is drawn up in the form of a working draft. It must necessarily include technical and budget documentation, as well as detailed drawings containing data on the curbs, sidewalks, signs, road markings and other important elements highway.

The working draft is also completed with an explanatory note. It justifies in detail each solution that will be used in the construction.

Explanatory note to road construction plan

Explanatory note to road construction plan They also contain recommendations for laying communications, engineering networks, local estimates and much more. Be sure to include all the necessary information for landscape design and creating conditions to guarantee the safety environment.

The work doesn't end there. The working draft is checked by several specialists, who not only check whether the draft complies with GOSTs and SNIPs, but also subject it to several examinations. At the same time, experts from the state inspectorate, as well as the inspectorate of the district where the new road will be built, the calculations for which are being carried out, may be present.

SNiPs and road design standards

It should be understood that the basics of road design provide for the competent and most rational and careful use of available natural resources, minimizing harm to the environment, and in addition, the use of modern techniques that reduce the overall cost of construction, as well as the maintenance of such roads and energy consumption.

In particular, SNiP, which regulates the design of roads and their construction, has the number 2.05.02-85. The corresponding manual for this SNiP contains methodological recommendations for project development and construction work. In addition, this road design manual also contains the basic rules and regulations along with the technical classification of roads.

Any benefits are developed in addition to SNiPs. These manuals contain recommendations and norms for the design of roads for various conditions.

It is worth considering such important point: the design of the subgrade of roads must take into account special conditions, for example, soft soil, because the characteristics of the road must correspond to the prevailing conditions, otherwise it is not even necessary to talk about the acceptable service life of the route.

Informative video about road design in AutoCAD.

Until recently, the norms and foundations for the design of highways in Russia were based on outdated SNiPs, which no longer corresponded to the real picture of road congestion and traffic flow. Since about 2006, a steady trend towards the improvement of the road classification system has become noticeable. Since that time, new GOSTs and design manuals have begun to be introduced.

What you need to pay attention to when preparing for laying the road

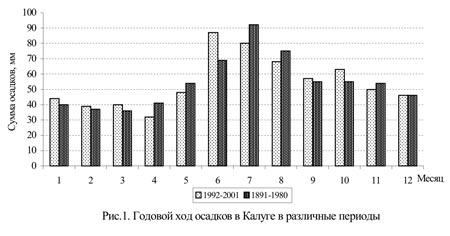

When performing all work on the survey and design of roads, experts pay Special attention soil conditions and climate features in the region, first of all, the amount of precipitation in the cold season.

Soil studies make it possible not only to clarify the bearing capacity of the soil (and, accordingly, to resolve the issue of the need to compact the existing soil), but also to find out how deep the groundwater lies in different times of the year.

If the water level is deep enough, it is not able to have a significant impact on the road. At a shallow depth of occurrence, a "play" of the soil can take place, in which its surface changes dramatically depending on the time of year.

In this case, the construction of roads is carried out using additional materials that ensure the strength and reliability of the foundation. Working on the site of future construction, the engineer evaluates the landscape and selects the best places for building bridges, as well as laying underground utilities.

Hydrological data, together with the climatic features of the region, allow him to choose the thickness of the pavement, which will, on the one hand, reduce costs, and, on the other hand, guarantee the reliability and durability of the road even with heavy traffic of heavy trucks.

Introduction

The course "Project for the production of works and organization of the construction of roads" is the main academic discipline included in academic plan automobile and road institutes and faculties.

The construction of roads is faced with the task of quickly eliminating impassability and bringing the road network in the country in accordance with its density and quality in accordance with the requirements National economy road transport. The elimination of off-roads will drastically improve the social conditions of life, increase the vital activity of those areas where the network of existing roads is being re-laid or improved.

Roads in rural areas reduce losses during harvesting, improve the living standards of rural residents, increase the motor resource of all transport and special means.

"The project for the production of works and the organization of the construction of roads" is an academic discipline that considers the choice and application of methods for conducting work on the construction of roads based on their national economic significance, natural conditions, availability mineral resources and requirements to ensure uninterrupted, round-the-clock, year-round, convenient and safe movement cars on the built road.

Most road structures are affected by the load from cars, they are also subject to the active influence of numerous natural factors(heating by solar rays, freezing and thawing, moistening by precipitation, wind erosion, etc.)

Roads are built in a wide variety of, often very complex natural conditions. The sharp difference in climatic soil-soil, hydrological and other conditions of the areas where the road is laid requires that road construction engineers know the specifics of the work and the use of machines and materials in each of these areas. These features of the construction and service of roads should: be taken into account when drawing up projects. Therefore, builders must accurately implement projects.

Typical subgrade structures developed taking into account the terrain, soil, geological, hydrological and climatic conditions. In the presence of unfavorable conditions, the subgrade is erected according to individual projects. These conditions include: embankments over 12 meters high; excavations with a depth of more than 12 meters; the presence of weak soils at the base of embankments; swamps more than 4 meters deep; landslide slopes; crossing steep and deep beams and ravines; karst phenomena; excessively saline areas; mudflows; rock falls; snow avalanches, etc.

1. Characteristics of the design object

1.1 a brief description of construction area

construction road mounting

Construction area - Republic of Karelia, second climate zone and a second storm area.

The second road-climatic zone is characterized by excessive soil moisture, low volatility and high level ground water. The zone is characterized by podzolic soils, taiga and mixed forests.

The Republic of Karelia has following characteristics:

The average annual air temperature is +2.3°C.

Absolute minimum -32°С, maximum +33°С.

The average annual wind speed is 3.7 m/sec.

The prevailing wind direction is northwest.

The amount of atmospheric precipitation for the year is 589 mm.

The maximum daily rainfall is 98 mm.

The average date of the formation of a stable snow cover is 25 X.

The average date of destruction of the snow cover is 15 III.

The number of days in a year with stable snow cover is 155 days.

The average of the largest ten-day snow cover heights for the winter is 32 cm.

The estimated thickness of the snow cover with a probability of exceeding 5% is 95 cm.

The average length of the period from negative temperatures- 152 days.

Average depth freezing clay and loamy soils - 1.35 meters, and sandy loam and sand - 1.62 meters.

Production time earthworks(beginning - April 24, end - October 20, duration - 180 days).

The construction of the road will take place in conditions of slightly rugged relief, characterized by the presence of flat spaces, river valleys with gentle slopes and wide calm watersheds.

1.2 Basic technical standards and indicators of the road

This course project presents a project for the construction of a subgrade for a road of category III.

The main parameters adopted during the design are shown in Table 1.1.

Table 1.1. - Main settings

CharacteristicsAccording to SNiP 2.05.02-85On the sectionDesign speed, km/h100100Number of traffic lanes22Width of subgrade, m1212Width of the carriageway, m77Width of shoulders, m2.52.5Length of section, m-2270Smallest radius of the curve in plan, m6001300Smallest radius of the convex curve in the longitudinal profile0, m1400 concave curve in longitudinal profile, m30009000Smallest length of a straight line, m300920Maximum length of a straight line, m2000-35001270Maximum longitudinal slope, %03020

2. Design solutions

.1 Calculation of scopes of work

B \u003d 12 + 2 * 0.95 * 1.75 \u003d 15.325

L = 15.325 + 12 / 2 = 13.6

S=L*H=13.6*0.95=12.92

Vp = 12.92 * 2270 = 26744.4

B = 16.6 + 2 * 1.6 * 1.5 = 21.4 = 12 + 4.6 + 21.4 / 2 = 19 = 19 * 1.6 = 30.4 = 30.4 * 100 = 3040

3. Project of organization and production of construction and installation works

Deforestation

Scope of work:

.Felling forests with non-pressure saws.

Branch cutting.

.Hauling timber with tractors.

Driving machine: TDT-55 skidder (Psm = 60 m3 /shift).

The composition of the brigade:

Feller

feller's assistant

tractor driver

checker

Twigs

The volume of cut down forest is calculated by the formula:

S = L* 0.5 * Rep = 2270 * 0.5 * 36 = 40860 m 2 = 4 ha 2 (3.1.1)

Vp = Gl * Sl = 125 * 4 = 500 m3 (3.1.2)

where, Гл - Liquid stock of timber.

Sl - The area of wood felling.

The required number of teams-shifts is equal to:

Tr \u003d Vp / Psm \u003d 500 / 60 \u003d 9 shifts.

Stump uprooting.

For uprooting stumps, the driving machine is a tractor T-170 with a picker-collector MP-2V.

Phour = 50 pieces/hour.

Pcm \u003d P hour * T \u003d 50 * 8 \u003d 400 pieces / shift (3.1.3)

where, T is the duration of the shift.

Vp \u003d S * Qunit \u003d 9 * 340 \u003d 3060 pcs. (3.1.4)

where, Qed - The number of stumps per hectare.

N = Vp / Psm = 3060 / 400 = 8 shifts

Removing the vegetation layer.

The vegetation layer is cut with a CAT D6K bulldozer

Vp = L * Votv = 2270 * 36 = 180000 m2 (3.1.5)

The performance of the bulldozer is determined by the formula:

Psm \u003d 3600 * (T - tzp) * Kt * q * Kp * Ki / tc * Kr \u003d 3600 (8 -0.3) * 0.85 * 2.2 * 1 * 1 / 1.1 * 30.67 = 16156.8 / 33.37 = 479.003 m2 (3.1.6)

where, T is the duration of the shift in hours.

Tzp - time spent on refueling and inspection of the car.

Kt - working time utilization factor = 0.85.

q is the volume of the drawing prism.

Q=0.5*L*H 2 * Kop = 0.5 * 3100 * 1500 * 1.3 = 4.5 (3.1.7)

where, L - blade length (3100)

H - blade height (1500)

Kop - experienced coefficient (1.3)

Кр - coefficient of soil loosening (1)i - loss coefficient Ki = 1 - 0.0045Ltr

1 - 0.0045Ltr \u003d 1 - 0.0045 * 36 \u003d 0.62 (3.1.8)

where, Ltr - length of soil movement (36)

Tc - tsinla time.

tc = lp/Vh + lt/Vp + lt/Vx + tp + t0 + 2tp = 3 / 3.800 + 36 / 6.900 + 36 / 13.400 + 3 + 32 * 8 = 22.01 (3.1.9)

where, lp - occurrence length (3-6 m)

lt - length of the ground movement path (36 m)

Vh - bulldozer speed when digging (m/s)

Vp - speed of the bulldozer about moving the soil (m / s)

Vx - bulldozer cold running speed

tp - time spent on gear shifting (3-5 sec)

t0 - blade lowering and raising time (3 sec)

tpov - time taken to turn (8-10s)

Find the volume of the cut plant layer:

Vp = L * Bot = 2270 * 36 = 81720 m2 (3.1.10)

N = Vp / Psm = 81720 / 4400 = 19 shifts.

Reconsolidation of the natural base.

Additional compaction is carried out by a roller with pneumatic wheels CAT CS76XT, the number of passes is 4. The shift capacity is determined by the formula:

Psm \u003d Vp (B - C) / n * Kv * T \u003d 5500 (2.1 - 0.7) / 4 \u003d 15708 m2 / shift

B-drum width (2.1 m)

T - shift duration (8 hours)

Definition of scope of work:

Vp = Stotal * 70% = 26703 m2 (3.1.12)

N = 26703 / 15708 = 1.7 = 2 shift teams.

3.2 Construction of structures for the regulation of the water-thermal regime.

Digging of drainage ditches

Digging is carried out with a 320DL excavator with a bucket capacity of 0.8 m3

Shift productivity is equal to:

Psm \u003d 3600 * qe * Kn * Kv * T / tc * Kr * ? = 3600 * 0.8 * 1 * 0.85 * 8 / 33 * 1 * 1.7 = 290 m3 /shift (3.2.1)

where, Qe - Bucket volume (0.8)

Kv - coefficient of use of working time (0.85)

Ground density (1.7)

tc - time of one cycle (33 sec)

Finding the area of the ditch:

S = H * B * m + n / 2 * H 2= 1 * 0.5 * 3 + 1.5 / 2 * 1 = 2.6 m2 (3.2.2)

where, H is the depth of the ditch (1)

B-width of the ditch at the bottom (0.5)

M - laying internal slope ditches (3)

N - the laying of the outer slope (1.15)

We find the required amount of work:

Vp \u003d 2 * L * S \u003d 2 * 2270 * 2.6 \u003d 11804 m3 (3.2.3)

The required number of teams-shifts is equal to:

N = Vp / Psm = 11804 / 290 = 40 brigades / shifts.

.3 Erection of embankment from soil into excavations

Soil development

Excavation and loading into dump trucks from the excavation will be carried out by a CAT 330DL ME excavator.

The shift productivity of the excavator is determined by the formula:

Psm \u003d 3600 * q * Kn * Kv * T / tc * Kp * ? = 3600 * 2.4 * 1 * 0.85 * 8 / 33 * 1 * 1.7 = 58752 / 56.1 = 1047 m3 /shift (3.3.1)

where, Qe - Bucket volume (2.4)

Kn - bucket filling factor (0.75 - 1.4)

Kv - coefficient of use of working time (0.85)

Кр - soil loosening coefficient (1)

Soil density (1.7)c - time of one cycle (33 sec)

According to the formula

N = Vp / Psm = 26744 / 1047 = 26 brigades / shifts.

Soil transportation.

Soil is transported from the quarry to the embankment by a CAT AT730 dump truck.

The productivity of the dump truck is determined by the formula:

Psm \u003d (T - tpz) * Kv * qA / (2 * Ltr / Vcp + tp + tozh) * ? = (8 - 0.3) * 0.85 * 17 / (2 * 3.2 / 40 + 0.07 + 0 = 111.265 / 0.391 = 284.5 m3 / shift. (3.3.2)

where, T is the duration of the shift (8 hours)

Tpz - time spent on preparatory and final work (0.3)

qA - bucket volume (17 tons)

Ltr - length of transportation route (3.2 km)

vcp- average speed(40 km)

Vcp = 2Vr * Vp / Vr + Vp = 2 * 30 * 60 / 30 + 60 = 40 km/h (3.3.3)

where, Vr is the speed of a loaded car (30 km)

Vp - speed of an empty car (60 km)

Tp - downtime for loading and unloading of a dump truck (0.07)

Tozh - waiting time for loading (0)

(3.3.4)

Soil leveling.

Leveling will be done with a CAT D6K bulldozer. The performance of the bulldozer is determined by the formula (3.1.6):

Psm \u003d Pbuld * hav \u003d 479 * 0.95 \u003d 455.05 m3

Vfill / Pbuld = 26744 / 455 = 58.77 = 58 brigades / shifts

Moistening the soil with a watering machine.

We moisten the soil with a watering machine PM - 130. The required amount of water is determined by the formula:

V in \u003d Vr *? * Pv \u003d 1047 * 1.7 * 0.03 \u003d 53.4 tons (3.3.5)

where, Vr is the volume of soil produced by the excavator per shift = 1047 m3 /shift.

Soil density (1.7).

The productivity of the watering machine is determined by the formula:

Psm \u003d T * Kv * Qts / 2L / Vcp + 0.083 + Qts \u003d 8 * 0.85 * 3.8 / 2 * 3.2 / 44 + 0.083 * 3.8 \u003d 25.84 / 0.86 \u003d 30, 04 t/shift (3.3.6)

where, L is the average distance to the water source (3.2 km)

Vcp - average speed of transportation (44 km/h)

Qc - volume of the tank (3.8 m3 )

We find the required number of teams / shifts according to the formula:

N \u003d V in / Psm \u003d 53.4 / 30.04 \u003d 2 teams / shifts

Profiling the top of the subgrade.

Profiling of the top of the subgrade is carried out by a motor grader CAT 160K. Shift productivity is found by the formula:

Psm \u003d V * (B * C) / n * Kv * T \u003d 4500 * (4.1 - 0.5) / 3 * 0.85 * 8 \u003d 36720 m2 /shift (3.3.7)

N - number of passes (3)

B-width blade (4.1 m)

C - floor width (0.5 m)

Kv - coefficient of use of working time (0.85)

Sover salary = 2270 * 12 = 27240 * 0.6 = 16344 m2 (3.3.8)

Find the number of teams / shifts:

N = Sover salary / Psm = 16344 / 36720 = 1 brigades / shift

.4 Excavation

Excavation and loading into dump trucks in the excavation will be carried out by a CAT 330DL ME excavator. The shift productivity of which we take from the formula (2.1.1):

Pcm = 1047 m3 /shift

From paragraph 3.3.1 we take the number of shifts equal to: 13 shifts

Soil transportation

We transport the soil from the excavation with a CAT AT730 dump truck. We take all data from paragraph 3.3.2:

Pcm = 284.5 m3 /shift

Reconsolidation of the bottom of the excavation

Additional compaction is carried out by rollers on CAT CS76XT pneumatic wheels, the number of passes along the track is 6. We take the changeable performance of the roller from paragraph 3.1.4:

Psm = 15708 m2 /shift

N = 1 teams / shifts

Profiling the top of the excavation base with a motor grader.

profiling

Psm = 36720 m2 /shift

N = 1 teams / shifts.

3.5 Construction of pavement base

Pcm = 1047 m3 /shift

V = Str * L = 1.9875 * 2270 = 4511 m3 (3.5.1)

Str \u003d H * (W + V / 2) \u003d 0.25 * (8.20 + 7.70 / 2) \u003d 1.9875 m2 (3.5.2)

where, H is the height of the first base layer (0.25)

W - width of the base of the first layer (8.20)

V - width of the top of the bottom layer of the base (7.70)

N = 4511 / 1047 = 5 brigades / shifts.

Transportation

Pcm = 284.5 m3 / shift.

We find the required number of dump trucks using the formula:

N = Pe / Pa = 1047 / 285 = 4 cars.

where, Pe is the performance of the excavator.

Pa - dump truck performance.

Soil leveling

We produce by motor grader CAT 160K. We take shift productivity from paragraph 3.3.5:

Psm \u003d V * (B * C) / n * Kv * T * h \u003d 4500 * (4.1 - 0.5) / 6 * 0.85 * 8 * 0.25 \u003d 4590 m3 /shift

where, V - leveling speed (4500 m/h)

N - number of passes (6)

B-width blade (4.1 m)

C - floor width (0.5 m)

Kv - coefficient of use of working time (0.85)

T - shift duration (8)

H - thickness of the laid layer (0.25)

We calculate the number of teams / shifts: = 4511 / 4590 = 1 teams / shifts.

Sealing the first layer of the base.

/ shift (3.5.3)

B-drum width (2.1 m)

C - width of the overlap zone (0.7 m)

Kv - coefficient of use of working time (0.85)

Find the area of the first layer of the base:

S = B * L = 7.70 * 2270 = 17479 m2 (3.5.4)

We calculate the number of teams / shifts:

N = S / Psm = 17479 / 2380 = 8 teams / shifts

Loading crushed stone for the construction of the top layer of the base.

Sand loading for the construction of the first layer of the pavement base is carried out by a CAT 330DL ME excavator. We take the replaceable productivity of the excavator from paragraph 3.3.1:

Pcm = 1047 m3 /shift

We calculate the required volume of sand:

V = Str * L = 1.5 * 2270 = 3405 m3 (3.5.5)

where, Str - area of the first base layer

Str \u003d H * (W + V / 2) \u003d 0.20 * (7.30 + 7.70 / 2) \u003d 1.5 m2 (3.5.6)

where, H is the height of the second base layer (0.20)

W - width of the base of the second layer (7.70)

V - the width of the top of the top layer of the base (7.30)

We calculate the number of teams / shifts:

N = 3405 / 1047 = 4 teams / shifts.

Transportation

The material is transported from the quarry by a CAT AT730 dump truck. The productivity of the dump truck is determined by the formula (3.3.2):

Pcm = 284.5 m3 / shift.

We find the required number of dump trucks using the formula:

N = Pe / Pa = 1047 / 285 = 4 cars.

where, Pe is the performance of the excavator.

Pa - dump truck performance.

Soil leveling

We produce by motor grader CAT 160K. We take shift productivity from paragraph 3.3.5:

Psm \u003d V * (B * C) / n * Kv * T * h \u003d 4500 * (4.1 - 0.5) / 6 * 0.85 * 8 * 0.20 \u003d 9180 m3 /shift

where, V - leveling speed (4500 m/h)

N - number of passes (6)

B-width blade (4.1 m)

C - floor width (0.5 m)

Kv - coefficient of use of working time (0.85)

T - shift duration (8)

H - thickness of the laid layer (0.20)

We calculate the number of teams / shifts: = 3405 / 3672 = 1 teams / shifts.

Sealing the second layer of the base.

Produced by CAT CS78B soil roller. The replacement capacity of the roller is determined by the formula:

Psm \u003d Vp (B - C) / n * Kv * T \u003d * T \u003d 4000 (2.1 - 0.7) / 18 * 0.85 * 8 \u003d 2380 m2 / shift (3.5.7)

where, Vp - working speed roller (4000 m/h)

B-drum width (2.1 m)

C - width of the overlap zone (0.7 m)

Kv - coefficient of use of working time (0.85)

T - duration of the shift (8 hours) - number of passes along the trail (18)

Find the area of the second layer of the base:

S = B * L = 7.30 * 2270 = 16571 m2 (3.5.8)

We calculate the number of teams / shifts:

N = S / Psm = 16571 / 2380 = 7 teams / shifts

.6 Installation of asphalt concrete pavements

Cleaning the base cover from dust and dirt is produced by PM-130.

Finding the base area:

Vp = 7 * 2270 = 15890 m2

Base priming

The work is carried out by the asphalt distributor DC - 40. The productivity of the asphalt distributor is 18 t/shift.

S = 7 * 2270 = 15890 m2

Vp = S * hp = 15890 * 0.9 = 14301 l (3.6.1)

where, S - base area

Hp - filling rate (0.9 l/m2 )

We convert the required volume of emulsion into tons:

* 0.001 = 14.301 tons (3.6.2)

N = 14,301 / 18 = 1 teams / shifts

Preparation of asphalt mix.

The production of asphalt concrete mix is carried out by ABZ ACS. The performance of the asphalt plant is equal to = 443m3 /shift.

Transportation of asphalt mix to the site.

We carry out transportation by dump truck

Pcm = 284.5 m3 / shift.

Determine the number of teams / shifts:

N = 443 / 285 = 2 brigades / shifts.

Laying asphalt mix.

Pcm \u003d B * h * V * T * Kv \u003d 3.5 * 0.08 * 200 * 8 * 0.85 * 1.7 \u003d 646 m3 /shift (3.6.3)

where, B - paving width (3.5)

H - layer thickness (0.08)

V - paving speed (200 m/h)

T - shift duration (8)

Vp = S * h = 15890 * 0.08 = 1271 m3 (3.6.4)

Find the required number of teams / shifts:

N = 1271 / 646 = 3 brigades / shifts.

Podkadka porous a / b mixture.

Rolling is done with a CAT SV44V roller in 4 passes along the track. Performance is determined by the formula:

/shift. (3.6.5)

where, Vp is the operating speed of the roller (4000 m/h)

B-drum width (1.5)

C - overlap width (0.3)

N - number of passes along the trail (4)

Kv - coefficient of use of working time (0.85)

T - shift duration (8)

Produced by a skating rink DY - 48B for 17 passes along the trail. The performance of the rink is determined by the formula:

/shift (3.6.7)

Determine the number of teams / shifts:

Rolling porous asphalt mix.

Produced by the roller OU - 98 for 17 passes along the trail. The performance of the rink is determined by the formula:

/shift (3.6.8)

Laying the next layer. Dense a / b with a thickness of 0.07 m.

Porous mix paving is carried out by CAT AP1055 E. The performance of the paver is:

Psm \u003d B * h * V * T * Kv * ? = 3.5 * 0.07 * 200 * 8 * 0.85 * 2.4 = 912 m3 /shift (3.6.9)

where, B - paving width (3.5) - layer thickness (0.07) - paving speed (200 m/h) - shift duration (8)

We find the required volume of a/b.

S * h \u003d 15890 * 0.07 \u003d 1112 m3

Find the required number of teams / shifts: = 1112 / 912 = 2 teams / shifts.

Rolling is done with a CAT SV44V roller in 4 passes along the track. Productivity is determined by the formula from paragraph 3.3.7:

Psm \u003d Vp (B - C) / n * Kv * T * ? = 4000 * (1.5 - 0.3) / 4 * 0.85 * 8 * 1.7 = 13872 m2 /shift.

where, Vp is the operating speed of the roller (4000 m/h)

B-drum width (1.5)

C - overlap width (0.3)

N - number of passes along the trail (4)

Kv - coefficient of use of working time (0.85)

T - shift duration (8)

Determine the number of teams / shifts:

N = 15890 / 13872 = 2 teams / shifts

Produced by a skating rink DY - 48B for 17 passes along the trail. The performance of the roller is determined by the formula, as in paragraph 3.6.8:

Psm \u003d Vp (B - C) / n * Kv * T * ? \u003d 7000 (1.85 - 0.3) / 17 * 0.85 * 8 * 1.7 \u003d 7378 m2 /shift

Determine the number of teams / shifts:

N = 15890 / 7378 = 3 teams / shifts

Rolling dense asphalt mix.

Produced by the roller OU - 98 for 17 passes along the trail. The performance of the roller is determined by the formula, as in paragraph 3.6.9:

Pcm \u003d Vp (B - C) / n * Kv * T \u003d 7000 (1.7 - 0.3) / 17 * 0.85 * 8 \u003d 3920 m2 /shift

Determine the number of teams / shifts: = 15890 / 3920 = 4 teams / shifts

.7 Construction of roadsides

We will load the material for backfilling roadsides with a CAT 330DL ME excavator. The replaceable productivity of the excavator is taken from paragraph 3.3.1:

Pcm = 1047 m3 /shift

We determine the required volume of soil for the construction of roadsides:

Sside = (B top embankment + B2 roadway) / 2 * (h1 + h2) = (7.7 + 7) / 2 * (0.15 + 0.45) = 4.41 m2 (3.7.1)

where, Top of embankment is the width of the top of the embankment (7.7)

V2 carriageway - carriageway width (7)

h1 - porous a/b thickness (0.15)

h2 - thick a/b thickness (0.45)

Vbar = Sbar * L = 4.41 * 2270 * 2 = 20021 m3 (3.7.2)

Determine the number of teams / shifts:

N \u003d Voboch / Psm ex \u003d 20021 / 1047 \u003d 20 teams / shifts

Material transport

The material is transported by a CAT AT730 dump truck. The productivity of the dump truck is determined by the formula (3.3.2):

Pcm = 284.5 m3 / shift.

Determine the number of teams / shifts:

N = Pe / Pa = 1047 / 285 = 4 cars.

where, Pe is the performance of the excavator.

Pa - dump truck performance.

The compaction of sand in the roadside is carried out by a roller with pneumatic wheels CAT CS76XT, the number of passes is 18. The shift capacity is determined by the formula (3.1.11):

Psm \u003d Vp (B - C) / n * Kv * T \u003d 5500 (2.1 - 0.7) / 18 \u003d 2908 m2 / shift

where, Vp is the operating speed of the roller (5500 m/h)

B-drum width (2.1 m)

C - width of the overlap zone (0.7 m)

Kv - coefficient of use of working time (0.85)

T - duration of the shift (8 hours) - number of passes along the trail (18)

Finding the number of teams / shifts

N = 20021 / 2908 = 7 brigades / shifts.

.8 Road construction

Marking

Marking will be done with a marking machine "bumblebee 2-A", based on GAZ - 33021. The performance of the marking machine is:

Psm = 21 km/shift

Scope of work:

V = L * 3 = 2270 * 3 = 6810 (3.8.1)

Find the number of teams / shifts:

N = Vp / Psm = 6810 / 21000 = 1 brigades / shifts.

4. Organization of construction

4.1 Terms of work

Types of workDuration of the shiftDatesDeforestation9Stump removal8Removal of stumps19Digging of ditches20Pipe construction8Digging13Construction of a salary26Construction of a base for a d/o5Construction of a pavement for a d/o5Establishment of roadsides20Equipment of a road1

Conclusion

During the implementation of this course project, I received important knowledge and skills in the development of a work production project and a construction organization project, and a lot of work was done with sources normative documentation.

During my work, I went through the following steps:

Determining the scope of earthworks.

Works on the construction of subgrade and excavation.

Determination of the amount of materials for the construction of each structural layer of pavement.

Works on the arrangement of road pavement.

Appointment of compositions of specialized units for the performance of a certain type of work. Calculation required amount technology for every job.

Drawing up a linear calendar schedule for construction.

Road construction work has been completed.

Skills I learned during development this project, will be useful to me both during further training and during the internship.

Bibliography

1.SNiP 2.05.02-85. Car roads. M.: Gosstroy of the USSR. 1986 -53 p.

2.Abstract of lectures on the discipline "Technology and organization of roads."

.ENiR "Construction, installation and repair and construction works". Collection E2. Excavation. Issue 1. Mechanized and manual land works. - M.: Stroyizdat, 1989 - 224 p.

."Technology and organization of road construction". Proc. allowance / A.N. Kochanov, V.I. Markov, V.P. Selyutin, V.A. Utyshev. - Petrozavodsk: publishing house PetrGu, 2007. - 220 p.

.Manual for the design of the subgrade of roads on soft soils (to SNiP 2.05.02-85)

Job order

Our experts will help you write a paper with a mandatory check for uniqueness in the Anti-plagiarism system

Submit an application with the requirements right now to find out the cost and possibility of writing.

All types design work associated with the reconstruction of existing driveways and the punching of new roads, the design of highways and interchanges in Moscow and the Moscow region.

drain

Development of integrated schemes. Design of rain sewerage. Removal of existing networks from the design area. Relocation of dilapidated and emergency networks on orders from operating organizations. allowable concentration) for discharge into reservoirs for fishery purposes.

Sewerage

Development of complex schemes. Design of urban sewer networks and highways. Design and reconstruction of the sewage pumping station. Removal of existing networks from the design area. Relocation of dilapidated and emergency networks to the orders of operating organizations.

Water pipes

Development of water supply schemes for designed buildings. Design of urban networks and highways. Removal of existing water supply networks from the design area. Relocation of dilapidated and emergency water supply networks by order of city operating organizations. Development of water metering units for residential development in the area of reconstruction and new design.

Heating network

Integrated design of heat supply systems: feasibility study of existing systems, optimization of heat supply schemes, taking into account heat supply sources and energy saving factors. Design of urban highways, steam pipelines and local networks. Development of individual nodes on thermal networks. Design of heat pipelines using open and closed laying methods. Development of standard technological solutions.

collector

Performs work on the design of new, relocation and reconstruction of existing collectors, as well as the design of ventilation and water removal. Design of shield tunnels.

Power supply

Design of external power supply Removal of the existing cables of the MCS "Mosenergo" and MET from the design area. Reconstruction of street lighting networks, design of street lighting for new roads and landscape lighting. Design of food outlets for street lighting networks. Designing new (typical and individual), reconstruction of existing RTP and TP, as well as reconstruction of 6-10KV switchgear cells at supply centers for connecting cable lines. Laying of power supply and distribution cable lines 10Kv for power supply of designed and reconstructed buildings.

Communication networks

Development of projects for telephone and radio installation of residential and administrative buildings, as well as for the laying and reconstruction of telemechanics cables for chambers of thermal networks. Designing the reconstruction of communication networks that fall into the area of road construction and engineering communications, as well as in the area of construction of residential and administrative buildings. City cable networks, long-distance communication cables, optical communication cables and radio cables are subject to reconstruction.

Industrial safety

Project development industrial safety and fire protection underground construction sites. Examination of industrial safety of underground construction facilities.

pic

Carries out the design of the organization of construction of all engineering systems cities. In the projects of the department, the most Hi-tech erection of structures such as microtunneling and directional drilling; the most effective special methods of work are used - these are artificial freezing of soils and dewatering and artificial fixing of soils, "wall in the soil", bored and secant piles. The PIC department works in conjunction with other organizations, such as NIIOSP named after V.I. N.M. Gersevanova, Moscow State Mining University and Gosgortekhnadzor of Russia.

Dendrology

Design of landscaping, landscaping and replanting of green spaces in the design area of roads and utilities.

Traffic management

Development and design of complex local and temporary organization schemes traffic; deployment of road signs, road barriers and guides; scheme road markings; design automated systems traffic control, traffic lights; development of traffic control equipment; design of a contact network of trolleybuses and trams.

Author's supervision

Carries out control over the construction of engineering facilities designed by INZHKOMPROEKT LLC from the initial stage of work to the commissioning of the facility. Provides direct communication between the designer and the builder. Resolves issues arising during construction on project documentation.

engineering structures

Design of engineering structures (pumping stations, treatment facilities, central heating stations, etc.) from the stage of the scheme to the development of working documentation in full.

Performing the functions of the general designer

Performing the functions of a general designer with project management from a feasibility study of options for placing engineering facilities to the development of a detailed design.

Insufficient development and inadequate condition of the transport infrastructure is becoming a significant brake on the economic development of the regions. To change the situation, a special resolution of the Government of the Russian Federation "On the development of transport infrastructure until 2020" was adopted, the provisions of the resolution give clear instructions on the necessary measures to eliminate existing problems. During the development of the project, our company carries out an integrated approach, taking into account domestic standards and modern world technologies, the customer receives the documentation already approved by the state regulatory authorities.

TRANSSTROYPROEKT provides professional road design services in Moscow and in any regions Russian Federation. We design linear objects of any complexity, including overpasses and motorway crossings through railways. One of our specialties is the development of bridge structures that are used at highway intersections.

During design and construction railways both existing infrastructure is taken into account, as well as its expansion, taking into account new characteristics for cargo transportation. Particular attention is paid to bridges, overpasses, interchanges and access roads to large transshipment bases and enterprises. Projects comply with current SNiPs and industry regulations RUSSIAN RAILWAYS. The documentation is completely ready for transfer to the general contractor. We cooperate with both public and private enterprises.

Highways: construction projects in LLC "TRANSSTROYPROEKT"

The customer receives in our organization full set documents that provide for the design of roads in our country. Their list includes the following:

- explanatory note with the project of the right of way;

- infrastructure projects, including buildings;

- instructions on the organization of construction, as well as the demolition of a linear facility;

- a list of environmental protection and fire safety measures;

- budget documents.

We carry out the design of roads and other linear objects using the advanced trends that have developed today in world practice road construction. The motorways designed by us have a long service life and fully meet the needs of customers. We approach the development of transport facilities projects with special responsibility, as they are more complex than other linear facilities.

Engineering and geodetic works

The work on designing the subgrade of the highway is preceded by an engineering and geodetic study of the site where the construction of the highway is planned. Using special equipment, experienced specialists study all conditions - the composition and condition of the soil, climate, landscape features, and so on. This allows you to choose the right Constructive decisions, the application of which on long years provides normal operational characteristics of flyovers and interchanges.

Based on the collected information, decisions are made on the use of standard design developments, which makes it possible to reduce the financial burden on the customer for the design of road junctions and optimize their cost. Standard Solutions are adapted to specific conditions so that the linear facility fully complies with the requirements of state normative documents regulating the operation of highways in our country.

Integrated design of urban roads

Usage modern technologies allows you to reduce the cost of the object: in project documentation our specialists lay instructions for the construction of the entire infrastructure. The project provides for all the nuances associated with the operational characteristics of a particular facility, taking into account its specifics.

We have a comprehensive approach to the organization of road design. This approach frees the customer from the need to find a third-party contractor to develop the missing part of the project. When ordering design at the TRANSSTROYPROEKT Institute, you receive documents that will go through the approval procedure in supervisory and authorities, including the traffic police. The quality of project documentation is ensured by the high qualification of the performers and the use of modern calculation methods.

We are working on the construction of buildings and auxiliary facilities necessary to ensure the normal functioning of highways at their intersections and sidings. When drawing up the project, it is planned to install all road signs and apply the necessary road markings. As part of the modernization of existing interchanges, we carry out the design of temporary roads and overpasses to ensure the uninterrupted movement of traffic, especially on busy sections of federal and regional highways.

How are highways designed?

First of all, strength calculations are carried out, and then, on their basis, longitudinal and transverse profile calculations are carried out. First, the calculation of the entire technical and financial side project, and then draw up design estimates, which provide an estimate of the cost of construction. As a result, those solutions are chosen that allow the road and infrastructure to be harmoniously and environmentally integrated into the natural environment.

Road design is carried out using automated design systems. Computer mathematical modeling makes it possible to reduce the time and cost of construction, as well as improve its quality.

Favorable conditions for designing interchanges

TRANSSTROYPROEKT LLC designs roads in Moscow, the Moscow Region and other regions of Russia.

When designing, we take into account all the necessary conditions dictated by relief, meteorology, climate, surrounding natural and artificial structures. We also take into account the type of road, the presence of adjacent transport systems, the life of the road, load characteristics and other technical conditions.

As part of the design of a transport facility, we perform project of the entire infrastructure for construction: parking areas, traffic lights, lighting systems.

When developing a road project, everything depends on what speed mode will be used, and how transport access will be arranged. For implementation best solutions in the project, we carry out traffic simulation of traffic.

The benefit of contacting us lies in attractive financial conditions. The specialists of our institute not only include low-cost solutions in the project documentation that reduce the cost of building a linear facility, but also offer affordable prices on its own design of roads and transport interchanges. As a result, on favorable conditions customer receives full finished project, which can be immediately transferred to the contractor for its implementation.

TRANSSTROYPROEKT Institute will in the shortest possible time carry out road design of any linear facility with the necessary throughput. Orders are executed as executive bodies authorities of different levels and management companies, as well as private owners of real estate objects. Our road design company is ready for cooperation. Solid experience and a large number of commissioned flyovers and interchanges allow us to implement any plans of customers.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Ministry of Education and Science of the Russian Federation

Federal Agency for Education

Perm State Technical University

Projectconstructionroads

Explanatory notetocourse project for the operation of SDM

Introduction

1. Road construction

1.1 Determination of the scope of earthworks

1.2 Determining the number of working days

1.3 Pace of construction

1.4 Calculation of the fleet of machines for the construction of subgrade

1.5 Calculation of the volume of material for the construction of pavement

1.6 Locations of the quarry and the pulp and paper plant. Determination of the average haul distance

1.7 Calculation of the fleet of machines for the construction of pavement

1.8 Calculation of the number of auxiliary equipment

2. Calculation of the labor intensity of maintenance and repair

3. Designing the base of mechanization

3.1 Determination of the number of main workers

3.2 Determining the number of support workers

3.3 Calculation of areas for the main workers

3.4 Calculation of areas for engineers, SKP, MOP, auxiliary workers

3.5 Calculation of areas for equipment

3.6 Calculation of the areas of amenity premises and a machine shop

3.7 Calculation of parking space

3.8 Calculation of the area of the field park

Bibliography

Introduction

Modern transport construction includes the construction of roads, airfields, bridges, tunnels, overpasses and other engineering structures. Its concept provides for the implementation of an extensive list of operations as mandatory components technological process. This includes clearing areas of vegetation and soil, mining, moving and laying large volumes of non-rock and rocky soil, mining, processing, sorting, transporting and laying building materials of natural origin, as well as the manufacture of artificial building materials.

Any of the above operations, due to the enormous amount of work, cannot be completed in a short time without the involvement of appropriate machines and mechanisms.

Construction is inevitably associated with the lifting and movement of piece and bulk cargo. These works cannot be carried out without lifting and handling mechanisms and devices,

Lifting and transport, construction and road machines are included in the organizational and technical system. The accurate and uninterrupted operation of this system depends on the reliability and efficiency of the equipment used, which are ensured by its quality, qualification of operators and service personnel, availability Supplies and spare parts, matching the cost of the machine to an economically acceptable level.

After choosing a set of machines, it is necessary to rationally organize their work in order to achieve the highest output at the lowest operating costs. It is important to choose the ratio of productivity and costs that will ensure long, efficient and trouble-free operation of the machine. This requires correctly assigning workloads and operating modes, accurately assessing the expected performance of one machine or a set of machines, and suggesting the correct schedule of preventive measures. Maintenance and to ensure its accurate and qualified execution.

In the course work, the required number of machines for the construction of a highway is calculated, the selection service personnel, as well as the calculation of areas for parking, maintenance and repair of the fleet of cars; residential areas.

1. Road construction

1.1 Determination of the scope of earthworks

Initial data for calculation:

Length - 25 km

Construction period - 2.5 months

Coating - cement concrete

Roadway without a dividing strip

Hosted at http://www.allbest.ru/

Earthworks - scrapers

Embankment height - 0.95 m

road profile

Excavation scope

V \u003d B * L * h \u003d 29.1 * 25000 * 0.95 \u003d 425125 m 3

where B=(15+20.7)/2=17.9m - average road width

L - road length, h - embankment height

L "=l+2*h*3=15+6*0.95=20.7m

l=2*3.75+2*3.75=4*3.75=15m

1.2 Determining the number of working days

Number of shifts n=2

Number of days - 60

See - shift (working)

K cm =60*2=120 cm

1.3 Pace of construction

T=L/K cm=25000/120=208.34 m/cm

1.4 Calculation of the fleet of machines for the construction of subgrade

The volume of earthworks per shift

V z.r.cm \u003d V / K cm \u003d 425125/120 \u003d 3543 m 3 / cm

Number of scrapers:

When constructing a subgrade, auxiliary machines are bulldozers and rollers. We use self-propelled scrapers: bucket capacity = 10 m 2; carriage distance = 500 meters.

N speed \u003d V s.r.cm NZ / 1000 \u003d 3543 2.78 / 1000? ten

NZ - coefficient of the cost rate of machine shifts per 1000 m 3 of soil.

10 DZ-32 scrapers are required.

Additional machines:

N Blvd. \u003d V z.r. cm NZ / 1000 \u003d 3543 * 0.29 / 1000 \u003d 1

Requires 1 bulldozer (DZ-27S)

Number of rollers:

N cat.

For soil compaction, we accept 3 rollers (1 cam DU-27, 2 vibration DU-47)

1.5 Calculation of the volume of material for the construction of pavement

Volumes of pavement layers:

where h n - layer thickness

V 1 \u003d 15 25000 0.035 \u003d 13125 m 3

V 2 \u003d 15 25000 0.045 \u003d 16875 m 3

V 3 \u003d 15 25000 0.05 \u003d 18750 m 3

V 4 \u003d 15 25000 0.08 \u003d 30000 m 3

V 5 \u003d 15 25000 0.21 \u003d 78750 m 3

V 6 \u003d 15 25000 0.15 \u003d 56250 m 3

Because crushed stone and sand shrink, then we recalculate the volumes taking into account the shrinkage coefficients (K us. sand. \u003d 1.25; K us. rubble. \u003d 1.25)

V3? \u003d V 3 K uss. pes \u003d 18750 * 1.25 \u003d 23438 m 3

V4? = V 4 K us. rubble \u003d 30000 * 1.25 \u003d 37500 m 3

V5? = V 5 K us. dog. \u003d 78750 * 1.25 \u003d 98438 m 3

V6? = V 6 K us. dog. \u003d 56250 * 1.25 \u003d 70313 m 3

Mass of pavement:

transport automobile road park machine

where j is the volumetric mass of the material (t / m 3)

j a / b \u003d 1.9; j grav. =1.4; j gravel. =1.5; j dog. =1.2

M 1 \u003d 13125 1.9 \u003d 24938 t

M 2 \u003d 16875 1.9 \u003d 32063 t

M 3 \u003d 18750 1.5 \u003d 28125 t

M 4 \u003d 30000 1.5 \u003d 45000 t

M 5 \u003d 78750 1.4 \u003d 110250 t

M 6 \u003d 56250 1.2 \u003d 67500 t

1.6 Pit and asphalt plant locations

Determination of the average haul distance

Hosted at http://www.allbest.ru/

Average carriage distance

L cf. =(2 0.5+2 L/2)/2=(2 0.5+25)/2=13 km

ABZ performance: P ABZ =M/?=57001/960=59.4 t/h

M - mass of asphalt concrete

Working time for 120 shifts, shift 8 hours

We accept asphalt plants with a capacity of 60 t/h

1.7 Calculation of the fleet of machines for the construction of pavement

Weight of materials needed per shift

M cm \u003d? M / K cm \u003d 307876 / 120 \u003d 2565.7 t / cm

The mass of asphalt concrete required per shift:

M cm.a / b \u003d M / K cm \u003d 57001 / 120 \u003d 475 t / cm

We determine the quantity dump trucks:

N himself. \u003d? M cm / P,

where P - the productivity of one dump truck with a hauling distance of 13 km and a load capacity of 25 tons is 92 tons per shift;

N himself. =2565.7/92=27.9

We accept 28 KamAZ 65201 vehicles

We determine the quantity excavators:

N ex. \u003d (V 3? + V 4? + V 5? + V 6?) NC / 1000 K cm \u003d (23438 + 37500 + 98438 + 70313) 4.25 / 1000 120 \u003d 8

We accept 8 excavators EO-4121A with a bucket volume V k \u003d 1 m 3

We determine the quantity bulldozers:

N Blvd. \u003d (V 3? + V 4? + V 5? + V 6?) / 1000 K cm \u003d (23438 + 37500 + 98438 + 70313) / 1000 120 \u003d 1.91

We accept 2 bulldozers DZ-27S

We determine the quantity pavers:

V asph / uk. \u003d (V 1 ? + V 2 ?) / K cm * t cm; N \u003d V asf / uk / P; P \u003d 100 m 3 / h - productivity

V asph / uk. \u003d (13125 + 16875) / 120 8 \u003d 31.3 m 3 / h

N bet / uk \u003d 31.3 / 100 \u003d 1 pc.

We accept 1 asphalt paver DS-1

Accept 1 asphalt distributor DS-82

1.8 Calculation of the number of auxiliary equipment

The number of workshops is taken from the condition that one workshop serves 30-35 cars. We accept 2 self-propelled mobile workshops for maintenance of MTOR-SP machines based on the ZIL-131 car

|

Machine type |

Fuel consumption for 1 car, l/h |

Total consumption, l/cm |

||

|

Scraper DZ-32 |

||||

|

Cam DU-27 Vibrating DU-47 |

||||

|

KAMAZ 65201 |

||||

|

Excavator EO-4121A |

||||

|

Bulldozer DZ-27S |

||||

|

Asphalt paver DS-1 |

||||

|

Asphalt distributor DS-82 |

||||

|

Workshop MTOR-SP |

||||

|

Diz. top. = 7921 l/cm |

Determine the number of tankers:

where? Q - total fuel consumption;

V - tanker tank capacity in liters, for T-401 tanker tank capacity for diesel fuel equal to 4100 l:

N ТЗ = 7921 / 4100 = 1.9 We accept 2 tanker vehicles - T-401 on the ZIL-130 chassis

2. Calculation of the labor intensity of maintenance and repair

The number of maintenance and repairs for KamAZ vehicles based on mileage per shift.

Mileage during the construction period

S page \u003d n l cf. K in. K cm \u003d 3.7 13 2 120 \u003d 11544 km, where K in - return coefficient, K in \u003d 2;

n=92/25=3.7; P=92 t/cm - performance t/cm with a load capacity of 25 tons

n - number of cycles per shift

Periodicity of maintenance and repair

P TO-1 =2500 km

Number of maintenance and repairs

N TO-1 \u003d S page / P TO-1 \u003d 11544/2500 \u003d 4.6 => 4 TO-1

TO2, TO3 will not be carried out during the construction period. dump trucks will not have time to gain enough mileage for maintenance.

The complexity of maintenance and repair

T TO-1 \u003d 6 people / hour

Labor intensity for 1 KamAZ

T A / M \u003d 6 4 \u003d 24 people / hour

Labor intensity for all KAMAZ vehicles

T A / M1 \u003d 24 28 \u003d 672 people / hour

Number of maintenance and repair of road construction equipment

Determine the operating time:;

hours;

Determine the amount of TO:

where H is the operating time in engine hours;

P - the frequency of the corresponding maintenance;

We determine the total labor intensity:

We determine the total complexity:

where N mash is the number of corresponding machines.

The results of calculations for all types of machines are summarized in the table:

|

Labor intensity, person/hour |

Periodicity |

||||||||||||

|

Scraper DZ-32 |

|||||||||||||

|

Bulldozer DZ-27S |

|||||||||||||

|

Asphalt paver DS-1 |

|||||||||||||

|

Cam DU-27 Vibrating DU-47A |

|||||||||||||

|

Excavator EO-4121A |

|||||||||||||

|

Asphalt distributor |

T SDM \u003d 6260 people / hour

The total labor intensity for maintenance and repair of cars and SDM.

T=? T A/M +? T SDM \u003d 672 + 6260 \u003d 6932 people / hour

3. Designing the base of mechanization

3.1 Determination of the number of main workers

n \u003d? T / F r K mon \u003d 6932 / 921.6 1.15 \u003d 6.5 \u003d\u003e 7

F r - working time fund

F p \u003d K cm t cm K vr \u003d 120 8 0.96 \u003d 921.6

K mon - coefficient of overfulfillment of norms

Kvr - time utilization factor

We accept the main workers in the amount of 7 people:

1) locksmith - 4

2) machine operator - 1

3) welder - 1

4) blacksmith - 1

3.2 Definition of engineering and technical workers (ITR), accounting and office personnel (SKP), junior service personnel (MOS) and auxiliary workers.

Number of engineers

P ITR \u003d 1 person

Number of UPCs

P UPC \u003d 1 person

Number of MOS

P MOP = 1 person

Number of support workers

P vsp \u003d 1 person

3.3 Calculation of areas for the main workers

3.4 Calculation of areas for engineers, SKP, MOP, auxiliary workers

3.5 Calculation of areas for equipment

|

Equipment |

Quantity, pcs. |

Width x length, m |

Total area, m 2 |

|

|

Locksmith workbench |

||||

|

Rack one-sided |

||||

|

Waste Parts Box |

||||

|

Electric welding machine |

||||

|

Grinder |

||||

|

Vertical drilling machine |

||||

|

Tool cabinet |

||||

|

Welding table |

||||

|

Lathe |

||||

|

Hammer (75 kg) |

||||

|

Dressing plate |

||||

|

Hydraulic press |

S rev. \u003d 17.88m 2

The total area for equipment, taking into account the arrangement:

S Art. = ?S rev. K about. \u003d 17.88 3.5 \u003d 62.58 m 2

K about. - environment factor

3.6 Calculation of the areas of amenity premises and a machine shop

Machine shop area

S m.c.f.

Standard sizes production premises 12 x 12 m

Machine shop area 144 m2

Area of household premises

S life. =0.15 S m.c. \u003d 0.15 144 \u003d 21.6 m 2

3.7 Calculation of parking space

|

Machine type |

Specific area of the machine, m 2 |

Total area, m 2 |

||

|

Scraper DZ-32 |

||||

|

Cam DU-27 Vibrating DU-47 |

||||

|

KAMAZ 65201 |

||||

|

Excavator EO-4121A |

||||

|

Bulldozer DZ-27S |

||||

|

Asphalt paver DS-1 |

||||

|

Asphalt distributor DS-82 |

||||

|

Workshop MTOR-SP |

||||

|

Fuel tanker PPAZ-7,0-130 |

||||

We determine the parking area for 70 x 80% of the car park:

S Art. \u003d 1313 0.8 \u003d 1050 m 2

We determine the parking area of the car park, taking into account the passages between the cars:

S Art. \u003d 1.2 * S st.

S Art. \u003d 1.2 1050 \u003d 1260 m 2

3.8 Calculation of the area of the field park

1. Post washing: S m =K about. S sp.max 2=28.5 3.5 2=99.75 m 2

where S m - washing area, m 2;

Maximum specific area of the largest machine, m 2 ;

K about - the coefficient of density of the arrangement of equipment, K about =3.5;

2. EO zone: S EO \u003d S ud.max K vol. 5 \u003d 28.5 3.5 5 \u003d 498.75 m 2

3. Parking area: S st \u003d 1260 m 2

4. Fuel warehouse: S fuel and lubricants \u003d N am 0.023 \u003d 66 0.3 \u003d 19.8 m 2

5. Refueling post: S ref. = K vol. S sp.max 2=28.5 3.5 2=199.5 m 2

6. Timber warehouse: S l.m. \u003d N am 0.27 \u003d 17.82 m 2

7. Tool storage: S in. \u003d N am 0.1 \u003d 6.6 m 2

8. Scrap warehouse: S ut. \u003d N am 0.19 \u003d 66 0.19 \u003d 12.54 m 2

9. Warehouse of aggregates: S ag. \u003d N am 0.4 \u003d 26.4 m 2

10. Office: S con. =S aux. +S life. \u003d 31 + 21.6 \u003d 52.6 m 2

11. Fire post: S pr. \u003d 50 m 2

12. Wastewater treatment plant: S otch. \u003d 100 m 2

13. Checkpoint: S checkpoint \u003d 12 m 2

14. Area of passages: S pr. = S about. * 0.5 \u003d 2355.8 * 0.35 \u003d 825 m 2

15. Area for green spaces: S pr. = S vol. * 0.15 \u003d 2355.8 * 0.15 \u003d 354 m 2? S \u003d 3535 m 2

Bibliography

1. Shelyubsky B.V. " Technical operation road cars" - Transport 1975

2. Guidelines for the implementation term paper in the discipline "Operation of SDM" - Perm, PPI 1991

Hosted on Allbest.ru

Similar Documents

Determination of the volume of earthworks, the number of shifts and the pace of construction. Calculation of the fleet of machines for the construction of subgrade and the amount of material for the construction of pavement. Calculation of the number of main and auxiliary workers and areas for workers.

term paper, added 11/25/2010

Natural and climatic characteristics of the construction area. Analysis of the road project. Drawing up a route plan. Design and calculation of pavement. Determining the timing of work, the required number of vehicles.

thesis, added 07/15/2015

Construction conditions, characteristics of the road under construction. Determination of the standard duration of construction. Development circuit diagram construction. Organization of pavement works. The choice of machines for the production of work.

term paper, added 06/23/2016

Brief description of the construction area, main technical standards and indicators of the road. Development and justification of design solutions, calculation of volumes and main stages of the implementation of construction and installation works. Determination of the necessary time frame for this.

term paper, added 02/07/2015

Climatic characteristics of the area where the highway is located. Accommodation manufacturing enterprises, providing construction materials. Organization and methods of construction and installation works. Calendar schedule for the movement of labor.

term paper, added 04/01/2010

Local estimate for the construction of the subgrade and for the installation of pavement. Estimated calculation for the rise in the cost of work in winter time. Consolidated estimate calculation of the cost of construction of the highway. Analysis of the structure of construction and installation works.

term paper, added 12/05/2014

Features of road construction. Determining the scope of construction work for section No. 19 of the highway, choosing a method for organizing them. Construction of culverts, subgrade and pavement. Transport scheme of deliveries.

term paper, added 06/02/2012

Characteristics of the road construction area - Vologda Oblast. Drawing up a general statement of volumes of road construction materials. Quality control of the construction of structural layers of pavement. Safety precautions when performing work.

term paper, added 12/09/2014

Road and climatic conditions of the highway construction area. Pavement design. Process sequence construction of structural layers of pavement. Determination of the summary need for material resources.

term paper, added 05/24/2012

Analysis of the construction area and determination of the estimated level of groundwater occurrence. The influence of the type of terrain by nature, the degree of moisture on construction methods. Geometric characteristic roads and development of a construction organization project.