Steel round bar GOST 8560 78. Library of GOSTs and regulatory documents

USSR STATE COMMITTEE ON STANDARDS

Moscow

STATE STANDARD OF THE UNION OF THE SSR

RENTAL CALIBRATED HEXAGONAL. ASSORTMENT Rolled-stock calibrated hexahedronal. Range of products. | GOST Instead |

|

Decree State Committee USSR according to the standards of August 2, 1978 No. 2079, the validity period is set |

||

| from 01.07. 1979 until 01.07. 1984 | ||

1. This standard applies to rolled calibrated hexagonal sizes from 3 to 100 mm.

(Revised edition, Rev. No. 2).

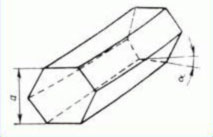

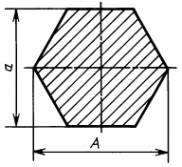

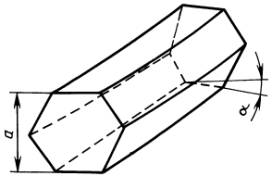

2. The dimensions of the cross-section of rolled products and the maximum deviations for them, depending on the accuracy classes, must correspond to those indicated in the drawing and in table. one.

Table 1

The size of the rolled product (diameter of the inscribed circle a or turnkey size), mm | Limit deviations, mm | Diameter of circumscribed circle, A, mm | Limit deviations, mm | Square cross section, mm 2 | Weight 1 m length, kg |

||

h 10 | h 11 | h 12 |

|||||

3,0 | 0,040 | 0,060 | 0,100 | 3,4 | 0,2 | 7,79 | 0,061 |

3,2 | 0,048 | 0,075 | 0,120 | 3,7 | 8,87 | 0,070 |

|

3,5 | 4,0 | 10,61 | 0,083 |

||||

4,0 | 4,6 | 13,86 | 0,109 |

||||

4,5 | 5,2 | 17,54 | 0,138 |

||||

5,0 | 5,8 | 21,65 | 0,170 |

||||

5,5 | 6,3 | 26,20 | 0,206 |

||||

6,0 | 6,9 | 31,18 | 0,245 |

||||

6,5 | 0,058 | 0,090 | 0,150 | 7,4 | 36,59 | 0,2087 |

|

7,0 | 8,1 | 42,44 | 0,333 |

||||

8,0 | 9,2 | 0,4 | 55,43 | 0,435 |

|||

9,0 | 10,4 | 0,5 | 70,15 | 0,551 |

|||

10,0 | 11,5 | 86,60 | 0,608 |

||||

11,0 | 0,070 | 0,110 | 0,180 | 12,7 | 0,6 | 104,8 | 0,823 |

12,0 | 13,8 | 124,7 | 0,979 |

||||

13,0 | 15,0 | 0,7 | 146,4 | 1,150 |

|||

14,0 | 16,2 | 169,7 | 1,330 |

||||

15,0 | 17,3 | 194,9 | 1,530 |

||||

16,0 | 18,4 | 221,7 | 1,740 |

||||

17,0 | 19,6 | 0,8 | 250,3 | 1,960 |

|||

18,0 | 20,7 | 280,6 | 2,200 |

||||

19,0 | 0,084 | 0,130 | 0,210 | 21,9 | 312,6 | 2,450 |

|

20,0 | 23,0 | 346,4 | 2,720 |

||||

20,8 | 23,9 | 0,9 | 274,7 | 2,940 |

|||

21,0 | 24,2 | 381,9 | 3,000 |

||||

22,0 | 25,4 | 419,2 | 3,290 |

||||

24,0 | 27,7 | 498,8 | 3,920 |

||||

25,0 | 28,8 | 541,3 | 4,250 |

||||

26,0 | 30,0 | 1,0 | 585,4 | 4,600 |

|||

27,0 | 31,2 | 631,3 | 4,960 |

||||

28,0 | 32,3 | 679,0 | 5,330 |

||||

30,0 | 34,6 | 779,4 | 6,120 |

||||

32,0 | 0,100 | 0,160 | 0,250 | 36,9 | 1,1 | 886,8 | 6,96 |

34,0 | 39,2 | 1001,0 | 7,86 |

||||

36,0 | 41,6 | 1,3 | 1122,0 | 8,81 |

|||

38,0 | 43,8 | 1251,0 | 9,82 |

||||

40,0 | 46,1 | 1386,0 | 10,88 |

||||

41,0 | 47,3 | 1456,0 | 11,40 |

||||

42,0 | 48,5 | 1527,0 | 11,99 |

||||

45,0 | 51,9 | 1754,0 | 13,77 |

||||

46,0 | 53,1 | 1,4 | 1833,0 | 14,40 |

|||

48,0 | 55,4 | 1,5 | 2000,0 | 15,60 |

|||

50,0 | 57,7 | 2165,0 | 17,00 |

||||

53,0 | 0,120 | 0190 | 0,300 | 61,2 | 1,7 | 2433,0 | 19,1 |

55,0 | 63,5 | 2620,0 | 20,6 |

||||

56,0 | 64,6 | 2715,0 | 21,3 |

||||

60,0 | 69,3 | 3118,0 | 24,5 |

||||

63,0 | 72,7 | 3437,0 | 27,0 |

||||

65,0 | 75,0 | 1,8 | 3659,0 | 28,7 |

|||

70,0 | 0,190 | 0,300 | 80,8 | 4244,0 | 33,3 |

||

75,0 | 86,5 | 1,9 | 4871,0 | 38,2 |

|||

80,0 | 92,3 | 5542,0 | 43,5 |

||||

85,0 | 0,220 | 0,350 | 98,0 | 1,2 | 6257,0 | 49,1 |

|

90,0 | 104,0 | 1,3 | 7015,0 | 55,1 |

|||

95,0 | 110,0 | 7816,0 | 61,4 |

||||

100,0 | 115,0 | 1,4 | 8660,0 | 68,0 |

|||

Notes:

1. At the request of the consumer, calibrated hexagonal rolled products are manufactured in other sizes not specified in tab. one . Limit deviations in this case must comply with the standards established for the nearest larger diameter.

2. The cross-sectional area and linear density of calibrated hexagonal rolled products are calculated from the nominal size. The density of rolled products is taken equal to -7.85 g/cm 3 .

3. For rolled products from high-alloy steel grades and alloys subjected to heat treatment and etching, limit deviations in size are set at 30% more than the quality h 12.

3. Rolled calibrated hexagonal is produced in bars. At the request of the consumer, rolled products are produced in coils.

(Changed edition, Rev. No. 1, No. 2).

4. Depending on the purpose, the bars are made:

measured length;

multiple measured length;

random length with a remainder of up to 10% of the mass of the batch;

limited length within unmeasured.

The remainder is considered to be bars with a length of at least 1.5 m.

5. Bars are made in lengths from 2 to 6.5 m. At the request of the consumer, bars are made in large lengths.

(Revised edition, Rev. No. 1).

Items 6, 7 are excluded, Amend. No. 1).

8. Limit deviations along the length of bars of measured and multiple measured lengths should not exceed:

30 mm - with a length of bars up to 4 m;

50 mm - with a length of bars over 4 m.

9. The curvature of the bars should not exceed the values specified in Table. 2.

table 2

Bar size, mm | Ultimate curvature depending on the tolerance field |

|||

per 1 m length, mm | full length, % |

|||

h10 andh11 | h1 2 | h10 andh11 | h12 |

|

up to 25 | 0,2 | 0,3 |

||

St. 25 to 50 | 0,1 | 0,2 |

||

St. 50 | 0,1 | 0,1 |

||

The deviation from straightness must be uniform along the entire length. At the ends of the bars, short longitudinal bends are not allowed.

(Revised edition, Rev. No. 1).

10. Twisting of bars per 1 m of length (Fig. 2) should not exceed 3°.

(Revised edition, Rev. No. 1).

11. The cut of the bar must be at right angles to its longitudinal axis. Permissible slant of cut should not exceed:

0,2 a- with the size of bars up to 15 mm;

0,17 a- with the size of bars up to 16 mm;

3 mm - with a size of bars over 16 to 30 mm.

(Revised edition, Rev. No. 1).

12. The length of the crumpled ends of the bars should not exceed the norms specified in Table. 3.

Table 3

Bar size | Length of crumpled ends, no more |

up to 25 | 20 |

St. 25 to 50 | 25 |

» 50 » 70 | 30 |

13. The radius of the chamfer is determined at the request of the consumer and should not exceed the values specified in Table. 4.

Table 4

Bar dimensions | Radius of rounding of edges for groups, no more |

|

1 | 2 |

|

up to 25 | 0,5 | 0,5 |

St. 25 | 0,5 | 1,0 |

(Introduced additionally, Rev. No. 1).

GOST 8560-78

INTERSTATE STANDARD

RENTAL CALIBRATED

HEXAGONAL

ASSORTMENT

|

Moscow Standartinform |

INTERSTATE STANDARD

|

HEXAGONAL CALIBRATED STEEL Assortment Calibrated hexahedronal rolled-stock. Dimensions |

GOST Instead GOST 8560-67 |

Edition (January 2008) with Amendments No. 1, 2, approved in April 1983, December 1988 (IUS 7-83. 3-89).

By the Decree of the USSR State Committee for Standards dated August 2, 1978 No. 2079, the introduction date was set

01.07.79

The validity period was removed according to protocol No. 7-95 of the Interstate Council for Standardization, Metrology and Certification (IUS 11-95)

1. This standard applies to rolled calibrated hexagonal sizes from 3 to 100 mm.

2. The dimensions of the section of the rolled products and the maximum deviations for them must correspond to those indicated in Fig. and in table. .

Heck. one

Table 1

|

Maximum deviation, mm |

Diameter of circumscribed circle, A, mm |

Maximum deviation, mm |

Cross-sectional area, mm 2 |

Weight 1 m length, kg |

|||

|

1,0 |

|||||||

|

1,1 |

|||||||

|

1,3 |

|||||||

|

1,3 |

|||||||

Notes :

1. At the request of the consumer, calibrated hexagonal rolled products are manufactured in other sizes not listed in Table. . Limit deviations in this case must comply with the standards established for the nearest larger diameter.

2. The cross-sectional area and linear density of calibrated hexagonal rolled products are calculated from the nominal size. The density of rolled products is taken equal to 7.85 g/cm 3 .

3. For rolled products from high-alloy steel grades and alloys subjected to heat treatment and pickling, limit deviations in dimensions are set at 30% more than h12.

3. Rolled calibrated hexagonal is produced in bars. At the request of the consumer, rolled products are produced in coils.

4. Depending on the purpose, the bars are made:

Measured length;

Multiple measured length;

Random length with a remainder of up to 10% of the batch weight;

Limited length within unmeasured.

The remainder is considered to be bars with a length of at least 1.5 m.

5. Bars are made in lengths from 2 to 6.5 m. At the request of the consumer, bars are made in large lengths.

3 - 5. (Revised edition, Rev. No. 1).

6, 7.(Deleted, Rev. No. 1).

8. Limit deviations along the length of bars of measured and multiple measured lengths should not exceed:

30 mm - with a length of bars up to 4 m;

50 mm - with a length of bars over 4 m.

9. The curvature of the bars should not exceed the values specified in Table. .

table 2

|

Ultimate curvature depending on the tolerance field |

||||

|

per 1 m length, mm |

full length, % |

|||

|

0,1 |

||||

|

0,1 |

0,1 |

|||

Heck. 2

The deviation from straightness must be uniform along the entire length. At the ends of the bars, short longitudinal bends are not allowed.

10. The twisting of the bars per 1 m of length a (dev.) should not exceed 3 °.

11. The cut of the bar must be at right angles to its longitudinal axis. Permissible slant of cut should not exceed: 4 .

Table 4

mm

(Changed edition, Rev. No. 1, 2).

RENTAL CALIBRATED HEXAGONAL.

ASSORTMENT

GOST 8560-78

USSR STATE COMMITTEE ON STANDARDS

Moscow

STATE STANDARD OF THE UNION OF THE SSR

|

RENTAL CALIBRATED HEXAGONAL. ASSORTMENT Rolled-stock calibrated hexahedronal. Range of products. |

GOST Instead |

|

|

By the Decree of the USSR State Committee for Standards dated August 2, 1978 No. 2079, the introduction date was set |

||

|

01.07. 1979 |

||

The validity period was removed according to protocol No. 7-95 of the Interstate Council for Standardization, Metrology and Certification (IUS 11-95)

1. This standard applies to rolled calibrated hexagonal sizes from 3 to 100 mm.

(Revised edition, Rev. No. 2).

2. The dimensions of the section of rolled products and the maximum deviations for them, depending on the accuracy classes, must correspond to those indicated on 1 and in.

|

The size of the rolled product (diameter of the inscribed circle a or turnkey size), mm |

Limit deviations, mm |

Diameter of circumscribed circle, A, mm |

Limit deviations, mm |

Cross-sectional area, mm 2 |

Weight 1 m length, kg |

||

|

h 10 |

h 11 |

h 12 |

|||||

|

3,0 |

0,040 |

0,060 |

0,100 |

3,4 |

0,2 |

7,79 |

0,061 |

|

3,2 |

0,048 |

0,075 |

0,120 |

3,7 |

8,87 |

0,070 |

|

|

3,5 |

4,0 |

10,61 |

0,083 |

||||

|

4,0 |

4,6 |

13,86 |

0,109 |

||||

|

4,5 |

5,2 |

17,54 |

0,138 |

||||

|

5,0 |

5,8 |

21,65 |

0,170 |

||||

|

5,5 |

6,3 |

26,20 |

0,206 |

||||

|

6,0 |

6,9 |

31,18 |

0,245 |

||||

|

6,5 |

0,058 |

0,090 |

0,150 |

7,4 |

36,59 |

0,2087 |

|

|

7,0 |

8,1 |

42,44 |

0,333 |

||||

|

8,0 |

9,2 |

0,4 |

55,43 |

0,435 |

|||

|

9,0 |

10,4 |

0,5 |

70,15 |

0,551 |

|||

|

10,0 |

11,5 |

86,60 |

0,608 |

||||

|

11,0 |

0,070 |

0,110 |

0,180 |

12,7 |

0,6 |

104,8 |

0,823 |

|

12,0 |

13,8 |

124,7 |

0,979 |

||||

|

13,0 |

15,0 |

0,7 |

146,4 |

1,150 |

|||

|

14,0 |

16,2 |

169,7 |

1,330 |

||||

|

15,0 |

17,3 |

194,9 |

1,530 |

||||

|

16,0 |

18,4 |

221,7 |

1,740 |

||||

|

17,0 |

19,6 |

0,8 |

250,3 |

1,960 |

|||

|

18,0 |

20,7 |

280,6 |

2,200 |

||||

|

19,0 |

0,084 |

0,130 |

0,210 |

21,9 |

312,6 |

2,450 |

|

|

20,0 |

23,0 |

346,4 |

2,720 |

||||

|

20,8 |

23,9 |

0,9 |

274,7 |

2,940 |

|||

|

21,0 |

24,2 |

381,9 |

3,000 |

||||

|

22,0 |

25,4 |

419,2 |

3,290 |

||||

|

24,0 |

27,7 |

498,8 |

3,920 |

||||

|

25,0 |

28,8 |

541,3 |

4,250 |

||||

|

26,0 |

30,0 |

1,0 |

585,4 |

4,600 |

|||

|

27,0 |

31,2 |

631,3 |

4,960 |

||||

|

28,0 |

32,3 |

679,0 |

5,330 |

||||

|

30,0 |

34,6 |

779,4 |

6,120 |

||||

|

32,0 |

0,100 |

0,160 |

0,250 |

36,9 |

1,1 |

886,8 |

6,96 |

|

34,0 |

39,2 |

1001,0 |

7,86 |

||||

|

36,0 |

41,6 |

1,3 |

1122,0 |

8,81 |

|||

|

38,0 |

43,8 |

1251,0 |

9,82 |

||||

|

40,0 |

46,1 |

1386,0 |

10,88 |

||||

|

41,0 |

47,3 |

1456,0 |

11,40 |

||||

|

42,0 |

48,5 |

1527,0 |

11,99 |

||||

|

45,0 |

51,9 |

1754,0 |

13,77 |

||||

|

46,0 |

53,1 |

1,4 |

1833,0 |

14,40 |

|||

|

48,0 |

55,4 |

1,5 |

2000,0 |

15,60 |

|||

|

50,0 |

57,7 |

2165,0 |

17,00 |

||||

|

53,0 |

0,120 |

0190 |

0,300 |

61,2 |

1,7 |

2433,0 |

19,1 |

|

55,0 |

63,5 |

2620,0 |

20,6 |

||||

|

56,0 |

64,6 |

2715,0 |

21,3 |

||||

|

60,0 |

69,3 |

3118,0 |

24,5 |

||||

|

63,0 |

72,7 |

3437,0 |

27,0 |

||||

|

65,0 |

75,0 |

1,8 |

3659,0 |

28,7 |

|||

|

70,0 |

0,190 |

0,300 |

80,8 |

4244,0 |

33,3 |

||

|

75,0 |

86,5 |

1,9 |

4871,0 |

38,2 |

|||

|

80,0 |

92,3 |

5542,0 |

43,5 |

||||

|

85,0 |

0,220 |

0,350 |

98,0 |

1,2 |

6257,0 |

49,1 |

|

|

90,0 |

104,0 |

1,3 |

7015,0 |

55,1 |

|||

|

95,0 |

110,0 |

7816,0 |

61,4 |

||||

|

100,0 |

115,0 |

1,4 |

8660,0 |

68,0 |

|||

Notes:

1. At the request of the consumer, calibrated hexagonal rolled products are manufactured in other sizes not specified in. Limit deviations in this case must comply with the standards established for the nearest larger diameter.

2. The cross-sectional area and linear density of calibrated hexagonal rolled products are calculated from the nominal size. The density of rolled products is taken equal to - 7.85 g/cm 3 .

3. For rolled products from high-alloy steels and alloys subjected to heat treatment and pickling, limit deviations in dimensions are set at 30% more than the quality h 12.

(Changed edition, Rev. No. 1, No. 2).

3. Rolled calibrated hexagonal is produced in bars. At the request of the consumer, rolled products are produced in coils.

4. Depending on the purpose, the bars are made:

measured length;

multiple measured length;

random length with a remainder of up to 10% of the mass of the batch;

limited length within unmeasured.

The remainder is considered to be bars with a length of at least 1.5 m.

(Revised edition, Rev. No. 1).

5. Bars are made in lengths from 2 to 6.5 m. At the request of the consumer, bars are made in large lengths.

3-5 (Revised edition, Rev. No. 1).

Items 6, 7 are excluded, Amend. No. 1).

8. Limit deviations along the length of bars of measured and multiple measured lengths should not exceed:

30 mm - with a length of bars up to 4 m;

50 mm - with a length of bars over 4 m.

9. The curvature of the bars should not exceed the values specified in.

|

Bar size, mm |

Ultimate curvature depending on the tolerance field |

|||

|

per 1 m length, mm |

full length, % |

|||

|

h10 andh11 |

h12 |

h10 andh11 |

h12 |

|

|

up to 25 |

0,2 |

0,3 |

||

|

St. 25 to 50 |

0,1 |

0,2 |

||

|

St. 50 |

0,1 |

0,1 |

||

The deviation from straightness must be uniform along the entire length. At the ends of the bars, short longitudinal bends are not allowed.

( 10. The twisting of the bars per 1 m of length () should not exceed 3 °.

Heck. 2

(

11. The cut of the bar must be at right angles to its longitudinal axis. Permissible slant of cut should not exceed:

0,2 a- at the size of bars up to 15 mm;

0,17 a- with the size of bars up to 16 mm;

3 mm - for bar sizes over 16 to 30 mm.

5mm - for bars over 30mm

9-11 (Revised edition, Rev. No. 1).

12. The length of the crumpled ends of the bars should not exceed the standards specified in.

|

Bar size |

Length of crumpled ends, no more |

|

up to 25 |

20 |

|

St. 25 to 50 |

25 |

|

»50»70 |

30 |

13. The radius of the chamfer is determined at the request of the consumer and should not exceed the values specified in.

|

Bar dimensions |

Radius of rounding of edges for groups, no more |

|

|

1 |

2 |

|

|

up to 25 |

0,5 |

0,5 |

|

St. 25 |

0,5 |

1,0 |

(Introduced additionally, Rev. No. 1).

01.07.79

The validity period was removed according to protocol No. 7-95 of the Interstate Council for Standardization, Metrology and Certification (IUS 11-95)

1. This standard applies to rolled calibrated hexagonal sizes from 3 to 100 mm.

2. The dimensions of the section of the rolled products and the maximum deviations for them must correspond to those indicated in Fig. 1 and in table. one.

Table 1

|

Rolled size (inscribed circle diameter a or turnkey size), mm |

Maximum deviation, mm |

Diameter of circumscribed circle, A, mm |

Maximum deviation, mm |

Cross-sectional area, mm 2 |

Weight 1 m length, kg |

||

Notes:

1. At the request of the consumer, calibrated hexagonal rolled products are manufactured in other sizes not listed in Table. 1. Limit deviations in this case must comply with the standards established for the nearest larger diameter.

Measured length;

Multiple measured length;

Random length with a remainder of up to 10% of the batch weight;

Limited length within unmeasured.

The remainder is considered to be bars with a length of at least 1.5 m.

50 mm - with a length of bars over 4 m.

9. The curvature of the bars should not exceed the values specified in Table. 2.

table 2

The deviation from straightness must be uniform along the entire length. At the ends of the bars, short longitudinal bends are not allowed.

10. The twisting of the bars per 1 m of length a (Fig. 2) should not exceed 3 °.

11. The cut of the bar must be at right angles to its longitudinal axis. Permissible slant of cut should not exceed:

0,17a- with the size of bars up to 16 mm;

3 mm - for bar sizes over 16 to 30 mm.

5 mm - for bars over 30 mm.

9 - 11. (Revised edition, Rev. No. 1).

12. The length of the crumpled ends of the bars should not exceed the norms specified in Table. 3.

Table 3

(Introduced additionally, Rev. No. 1).

13. The radius of chamfering is determined at the request of the consumer and should not exceed the values \u200b\u200bspecified in Table. 4.

Table 4

(Changed edition, Rev. No. 1, 2).