What is a wood lathe. Choosing a desktop lathe for wood

For everyone who is interested in turning, sooner or later the question of acquisition arises. A modern woodturning machine is a universal unit for mechanical processing of wood. It's built for multifunctional action. He has dozens of operations on his account. These are turning, threading, drilling, creating holes and puzzles. It processes ends, shaped blanks, conical and cylindrical surfaces. The lathe is equally indispensable for woodworking industries of various sizes, as well as for framing and carpentry workshops.

Buying a lathe requires a reasonable approach, a balance of all the pros and cons. After all we are talking about very expensive equipment. How to choose lathe on the tree, so that the investment was justified? You can look at hundreds of sites, but you will never be sure of the correct choice. The first step is to designate the task area for the future machine. This will determine the selection options.

DESIGN AND DIFFERENT TYPES OF LATHES

The machine for turning wood works consists of:

- Beds (the basis for placing the necessary mechanisms and elements).

- Driver chuck (headstock). Responsible for the rotation of the workpiece.

- Spindle. Adjusts the rotation speed.

- Back grandma. Provides fixation of the part.

- Movable pedestal. Sets the optimal distance to the workpiece

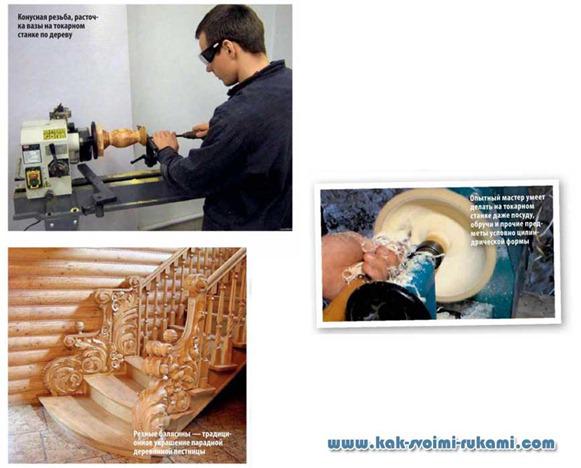

Examples of work done on a wood lathe

Lathes are desktop type and mounted on a bed. The beds can be cast iron, stable and durable. There are lightweight cast aluminum frames. Their advantage is the complete absence of corrosion. A desktop (portable) lathe is cheaper. It can also be installed on a special workbench or stand. To do this, there must be appropriate mounting holes on the housing.A wood lathe can weigh from 18 kg to 90 kg. The larger the weight value, the less vibration will be felt. It's comfortable. But for home craftsmen, buying overall lathes is unprofitable. You can get by with a mini-machine.

The machines also differ in phase. There are two options here - 220 V or 380 V. A single-phase machine is often bought for the home. It all depends on the network you have. A three-phase lathe is usually more powerful. This is a productive stationary equipment, so it is not needed for rare private housework.

The main criteria for choosing a lathe are the power and accuracy of processing parts. If turning is a hobby, then fundamental accuracy is not required. Of course, if it is possible to perform fairly accurate work on the machine, then this is good. But the price of a functional and very precision machine higher.Often masters working at home take care of silent operation. A low power machine makes less noise. If you choose a lathe from famous and reliable brands, then a very powerful engine also has noise protection.For a more detailed acquaintance, we have prepared the most important technical characteristics of lathes. They directly indicate their working potential.

POWER - THE MAIN INDICATOR OF PERFORMANCE AND ENDURANCE

When choosing power, the main thing is to decide what you need the machine for. If for a hobby or products from the category of "folk art", then buy an inexpensive household-class lathe. These are mini machines. They are ideal for small batch production. They start counting their power indicators from 350 watts and end at 500 watts. For medium-volume work, you should choose a wood lathe with a power of 500W-1000W.

The power of the lathe is over 1000 W - this is already relevant for the large-scale industrial sector. Important recommendation: for professional work with loads, choose more powerful machines. Then, when the index of turning or drilling is set to the maximum, you will not hear engine slip and a drop in speed from them. But if the motor is weak and does not pull the load, then this has a bad effect not only on the quality of work, but also on the engine resource.

DIMENSIONS OF PROCESSED WORKPIECES

The length and diameter of the workpiece are important when choosing. For entry level works, you can buy a household lathe. It works with small blanks or medium-sized blanks. The length of such blanks is up to half a meter, the diameter is a quarter meter maximum. It is clear that you can’t accelerate much on a household machine.

If you need to process "hundreds" daily, then, of course, choose a wood lathe of a higher class. From professional equipment. Such machines have extension cords so that you can sharpen long details. It is possible to turn parts with a length of about 1 meter.

SPINDLE AND ITS FEATURES

Spindle speed and thread pitch determine productivity. That is, the speed and quality of processing. These two values are responsible for a timely and full-scale processing process. The higher the requirements for the volume and speed of work, the higher the spindle speed should be. It is clear that the power of the motor must match. The lower the power, the lower the spindle speed.

The very quality of processing depends on the indicators of the speed of rotation of the spindle. The spindle of the lathe can make from 400 to 3500 revolutions per minute. Quality machines always have a speed controller.

DISTANCE BETWEEN CENTERS

The part is fixed in two ways - between the centers of the rear and front headstocks or a faceplate. Accordingly, the values of these distances vary in three intervals in different machines. This can be a value up to 600 mm, up to 1000 mm and over 1000 mm. Here you need to choose the option you need, based on the dimensions of the material being processed. The distance between the centers determines the accuracy of the fastener. By fixing the part correctly, you will avoid part runout during rotation.

RPM ADJUSTMENT

When working on a lathe, there is a need to change the speed of rotation of the workpiece. For various operations it is necessary different speed. Speeds are chosen depending on the type of wood being processed and the required processing accuracy. Therefore, lathes are equipped with speed control.

There are two types of adjustment - smooth and stepped. Step adjustment is fixed at each value. The machine can have three to five speeds to choose from. To change them, groups of pulleys are installed. They throw the transmission belt to the desired point.

Smooth adjustment is considered an order of magnitude better. You do not need to stop the machine to change the speed. The process of switching speeds occurs smoothly, without jerks and fixations. The built-in variator is responsible for smooth adjustment.RPM control is directly related to RPM.

AVAILABLE DIGITAL DISPLAY

The digital display is a significant advantage in work. It displays a digital indication of rotational frequency on the headstock. This allows you to read speed values. With the help of the display, the adjustment is much more effective. You establish visual control over the work. This opportunity has a positive effect on the patency of problem areas.

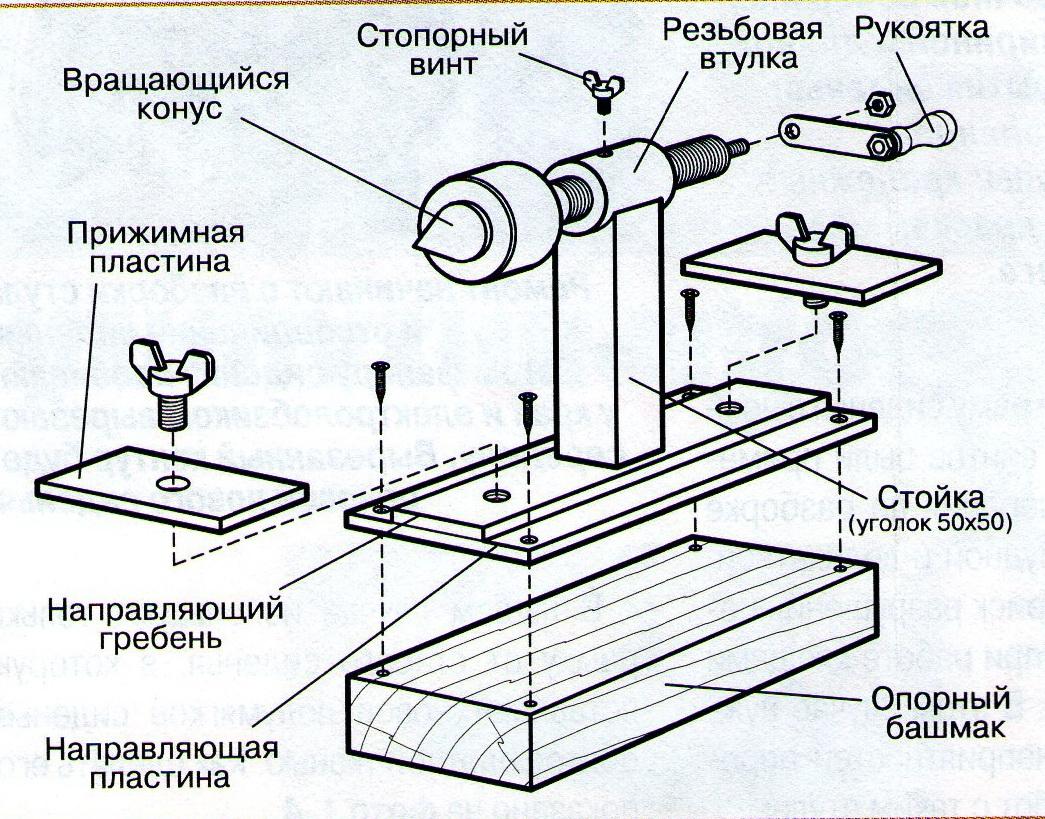

INSTALLABLE COPIER

There are lathes with a copier installed, and there are no copiers installed. The copier is an additional option in the machine. It is an auxiliary device of a removable nature that turns a conventional wood latheto copier. Simplifies processing a large number products of the same type. The copier guides the cutter along a strictly defined trajectory, which prevents the appearance of a difference in the size and shape of the products. To increase the accuracy of work, it is worth choosing a lathe with a copier.

REVERSE SWITCH

Reverse - reverse gear. This is also an additional feature. Not all machines are equipped with reverse. The essence of the reverse in the machine is that it provides the rear feed of the carriage and spindle. This speeds up the work. You do not need to re-feed the workpiece if the need arises for re-turning. You can just turn on the reverse function.

Which wood lathe is better - there is no definite answer. It all depends on your tasks, opportunities, professional knowledge and financial resources. Advice and feedback are also important.users.

Experience and the above points will guide you in choosing a wood lathe that meets your expectations.

A specialized wood lathe allows you to get wood from wood various products and their copies, provided that a copier is available. A woodworking lathe is lighter than a metalworking lathe and also uses less powerful electric motors. If we are talking about industrial applications, then CNC models are relevant here, and the faceplate serves as a workpiece clamp.

All machines on the market can be divided into three groups.

- Industrial. These are mainly CNC models, the weight of which is about 100-200 kg on average. The power of the used electric motors is 1 kW. Distinctive features- this is increased productivity, wide functionality and the ability to put production on stream. Retainer - faceplate or headstock.

- Semi-professional or designed for small production. The weight of the units varies from 40 to 100 kg. Power ranges from 500 to 900 kW. Specifications allow you to use a semi-professional type woodworking machine for a small production or workshop.

- Household. They are desktop. A similar woodworking machine weighs no more than 40 kg. The bulk of such units usually weighs 20-25 kg. Differ in compactness, mobility, but not productivity. They serve only to obtain single products, although they can be equipped with a CNC module.

Depending on the functionality, turning units can be:

- Combined. Their specialization is the performance of a wide range of operations on a single machine. At the same time, the price of such machines is high, and their processing quality does not always correspond to the expectations and invested funds;

- Specialized. Specialized machines allow you to make various crafts, wood-based products, working according to certain limited patterns.

It is important to note that specialized devices are divided into three subtypes:

- Turning and milling. With their help, you can make, process and bore grooves.

- Turning screw. Such a woodworking type of specialized machine is used to work with cone-shaped products, threading.

- CNC. Multifunctional devices that perform a whole cycle of woodworking operations. An important feature of the CNC module is that it automatically performs all the work. Operator involvement is minimal. Its task is to set desired program from the CNC list.

At the same time, any woodworking unit is capable of:

- crop;

- Turn;

- Drill;

- Make grooves;

- Cut thread;

- Make holes;

- Turn the ends;

- Sanding;

- Make openings.

Specifications

Many craftsmen make a wood lathe with their own hands, while others prefer to purchase ready-made devices. When there are such models on the market as STD 120m, Corvette 74, STD 1000, Holzstar db1100, no chisels or planers are needed.

Experts advise focusing on the following parameters.

- Motor power. Electric motors determine the processing capabilities of the machine, but at the same time affect energy consumption. Industrial models use engines with a power of 1-2 kW. And for domestic needs choose 300-500 watts.

- Workpiece sizes. Here you should pay attention to the center-to-center distances and to the machine bed.

- Spindle head rotation speed. This is the main working tool capable of rotating at a frequency of 400 to 35,000 revolutions per minute. The quality of processing products directly depends on this parameter.

- manufacturer and warranty. Many experts recommend choosing brands like Corvette, STD and Holzstar.

The choice on the presented versions of devices is not limited, but they are well-deservedly popular.

Design features

Let's study general principle design of such equipment.

- The basis is the frame, the quality of which determines the accuracy of woodworking and the stability of the turning equipment. All elements and mechanisms are located directly on the frame. The best option the manufacture of the bed - cast iron and solid casting.

- Workpieces are mounted in driving chucks, which are located on a rotating spindle. A faceplate or tailstock with a rear chuck allows you to fix the product from two sides at once.

- Depending on the length of the cutter, the thrust bearing moves. The cutter partially rests on it during the processing of workpieces.

- Workpieces can be fixed in two ways. For the first, the centers of two cartridges are used, and for the second, a faceplate. If you prefer to make yourself a homemade wood lathe, you will need a faceplate when turning the ends. The peculiarity is that the faceplate provides for fastening products with bolts, and not with points. The faceplate is preferable because it fixes the product more securely.

- The most important design difference between turning units for processing metal and wood is that the woodworking option provides for the manual supply of the cutter to the product.

Popular Models

Working on a wood lathe is a fairly common event in home workshops and industries. If you need a unit for personal purposes, drawings, photo and video instructions will allow you to make an excellent unit with your own hands.

Or pick up the chisels and get to work. Chisels are an outdated alternative to woodworking machines. So chisels, planers and other hand tools will not allow you to achieve the same result as automated chisels, that is, machines. With CNC they will be or without a CNC module, you decide.

The list of popular models includes such modern "chisels":

- Corvette 74;

- STD 1000;

- STD 120m;

- Holzstar db1100.

Let's consider them separately.

- The Corvette 74 is a 550W floor standing unit. The processing diameter and width are 300 and 845 mm, respectively. Corvette 74 weighs 85 kg. The range of spindle speeds on the Corvette 74 machine is from 500 to 2000 rpm. The current cost is 30 thousand rubles.

- STD 1000. Drive unit 22.9 kg. Limit diameter processing of the model is 350 mm. The power of the unit is 400 W, and the rotational speed is from 810 to 2480 rpm. The price of STD 1000 is about 11 thousand rubles.

- STD 120m weighs 100 kg and runs on 380 V. Power is 0.4 kW. The machining diameter is up to 190 mm, and the spindle speed STD 120m is from 1100 to 2150 rpm. The price is about 45 thousand rubles.

- The Holzstar db1100 is a 92kg German machine with 10 speeds and a maximum working diameter of 358mm. The unit is powered by 220 V. Estimated price- 55-60 thousand rubles.

Do you need a CNC model, a heavy-duty faceplate, and a wide range of adjustments if you're going to be doing regular small crafts? No. CNC and faceplate are the prerogative of modern, powerful devices with high functionality. If you want to make ordinary crafts, you can try to assemble the machine yourself.

If large-scale production is planned, work with large products, the faceplate as a latch will become indispensable, and the CNC module will simplify the work.

Carpentry shops and woodworking workshops use equipment such as bench-top wood lathes. They are versatile because they can be used to perform a wide range of tasks related to the machining of wood blanks.

- drilling;

- turning;

- thread cutting;

- creating grooves;

- end processing.

Using a bench lathe, you can to produce elements and details of furniture:

- legs;

- racks;

- stands.

Also, this equipment allows you to make boxes, toys and dishes from wood. Right choice of this equipment, its high-quality installation and the availability of skills in its use allows us to produce high-quality products with minimal cost time and effort of the master.

Bench lathes designed for woodworking are mini-equipment that has a lot of advantages. It has a low weight, which in most models does not exceed 18 kg. It can be easily installed on any workbench. The power of this equipment varies from 350 to 500 W. The most powerful models are equipment for small-scale production, so the weight of the machines can reach up to 90 kg.

Bench lathes designed for woodworking are mini-equipment that has a lot of advantages. It has a low weight, which in most models does not exceed 18 kg. It can be easily installed on any workbench. The power of this equipment varies from 350 to 500 W. The most powerful models are equipment for small-scale production, so the weight of the machines can reach up to 90 kg.

The quality of workpiece processing when using this equipment largely depends on such a factor as the frequency of rotation. The spindle speed can be varied from 400 to 3500 rpm. Adjustment of this parameter should be made, focusing on such factors as the type of wood and the required accuracy of processing the workpiece.

Important indicators of turning equipment

Mini-machines designed for woodworking have a whole set of important parameters that you should be aware of and consider when choosing this equipment.

Power - it speaks about the performance of a particular model, and also indicates the amount of electricity consumed by the equipment during its operation. For mini lathes for desktop use, this the indicator is 350 W.

Spindle speed - this parameter largely depends on the accuracy of the material processing and its hardness. Speed at modern models woodworking machines varies from 400 to 3500 rpm.

Along with the parameters listed above, the cost of turning equipment for domestic use is no less important. Currently on the market there are big choice machines for domestic use, so each House master can choose the equipment that is suitable for the price and its functionality. When choosing a lathe, you should consider not only the price, but also the quality of the equipment.

Device and principle of operation

As with any industrial lathe, for equipment for domestic use, the main element is the bed. All the rest are attached to it. components of this equipment. The most important are:

As with any industrial lathe, for equipment for domestic use, the main element is the bed. All the rest are attached to it. components of this equipment. The most important are:

- headstock equipped with a rotating spindle;

- rear locking stock;

- movable pedestal.

The headstock or, as it is often called, the driver chuck, is designed to rotate the workpiece. For reliable fixation of parts use the tailstock. By means of a thrust bearing it is provided optimal choice distance to workpiece.

Workpiece fixing methods

Two methods can be used to fasten a part to a turning equipment.

- Between the centers of the headstock and tailstock.

- With the help of a faceplate.

The first fixing method is the most common. Most often it is used for processing bars of small length without the need to perform their end processing. With this mounting method great importance has fastening accuracy. It is important that during the rotation of the workpiece there is no runout situation of the part. To eliminate this, use an angular centrifuge.

More reliable is the second method, which is used in cases where the processing of the ends of the workpiece is necessary. It differs from the first method of fastening in that it is fixed with the help of bolts or teeth of the cartridge. This fastening provides reliable retention of the part when performing a comprehensive turning of the workpiece.

From a metal machine, a lathe designed for processing wooden blanks differs in the presence manual feed a cutter, which is a chisel or other wood cutting tool. Its consolidation occurs only if used copier . In all other cases, when processing the workpiece, the chisel is held by the master. He also controls it manually, leaning on the thrust bearing during the operation. The only thing that is done automatically is the spindle speed.

The whole process takes place in two stages. First, roughing is performed, which is done at an angle of 15-30 degrees. Upon completion, finishing is performed at an angle of 45 degrees. When performing both operations, the chip thickness should be no more than 1 mm.

Overview of models of mini lathes

If you are faced with the task of purchasing a wood lathe for domestic use, then when looking for equipment, the choice should be made in favor of imported models. And the point here is not only that the machines of domestic companies are of lower quality in comparison with foreign counterparts.

If you are faced with the task of purchasing a wood lathe for domestic use, then when looking for equipment, the choice should be made in favor of imported models. And the point here is not only that the machines of domestic companies are of lower quality in comparison with foreign counterparts.

Import models lathes for wood have a higher power class. They can be used for industrial purposes. The choice of such equipment is quite large. Regardless of the country of manufacture, most models are assembled in China. Therefore, when choosing such equipment for your workshop, you need to pay attention to such parameters as price, quality and functionality. The best choice there will be a machine in which the ratio of these parameters is optimal.

Proma DSO-1000

If we talk about the most affordable model of an imported wood lathe, then this is Czech unit Proma DSO-1000. Its minimum cost is 6500 r. It has a power of 400 watts. It has the ability to adjust the spindle speed in the range from 850 to 2500 rpm. The weight of this machine is 35 kg. It is quite compact in size: 1450x250x370 mm.

HolzStar DB450

If you are looking for a machine with the best value for money, then you should pay attention to the HolzStar DB450. This Chinese-made machine has a minimum price tag of 12,000 rubles. In its equipment, this mini lathe has a bed made of cast iron, due to which vibration is minimal during its use. And this means that when performing operations, the processing of small parts will be carried out with high accuracy.

However, the main advantage of this equipment over its competitors is high speed spindle rotation. This parameter can be changed from 500 to 3150 rpm. As for the power of the equipment, this machine has this parameter of 370 watts. The weight of the machine is 38 kg, and its dimensions are small - 820x300x430 mm.

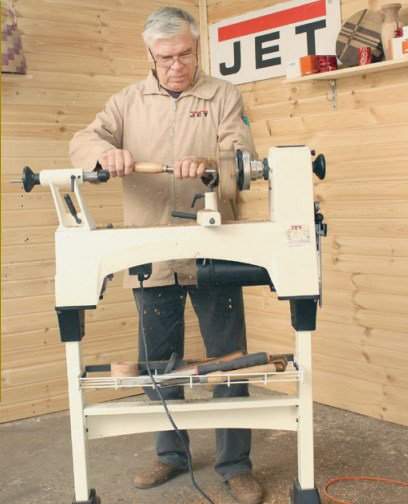

JET JWL-1220

Another model worth mentioning is the Chinese lathe JET JWL-1220. It differs from the models presented above by its high price. The minimum cost of this equipment is 18500 rubles. However, paying that kind of money, you get equipment with a large power of 750 watts.

Another model worth mentioning is the Chinese lathe JET JWL-1220. It differs from the models presented above by its high price. The minimum cost of this equipment is 18500 rubles. However, paying that kind of money, you get equipment with a large power of 750 watts.

The main element of this equipment (frame) is made of gray cast iron. A series of important elements this machine. Due to the choice of such material, vibrations are excluded during operations on this equipment. The engine with which this machine is equipped has 6 speeds and two modes.

When using the first mode, the rotational speed varies in the range from 400 to 3300 rpm. The second has a smooth adjustment from 500 to 3900 rpm. This lathe can be easily fixed using the quick clamping lever. The equipment of the machine has rubber feet, thanks to which its displacement during operations is excluded. Additionally, with a set of equipment, the manufacturer offers a bed extension with a length of 710 mm. As for the weight of this equipment, it is 45 kg.

Safety precautions when using lathes

If you have purchased a lathe and installed it correctly, then there is no need to rush to use it right away. First you need to learn about the rules for working on this equipment. Work safety involves compliance with all requirements and recommendations contained in the operating instructions for this equipment.

If you have purchased a lathe and installed it correctly, then there is no need to rush to use it right away. First you need to learn about the rules for working on this equipment. Work safety involves compliance with all requirements and recommendations contained in the operating instructions for this equipment.

Before turning on the machine, it is necessary to check the correct operation of the devices that provide protection for the user. If during the inspection any defects of the equipment or protective devices with which it is equipped, in this case the malfunctions must be eliminated. To do this, you must first disconnect the equipment from electrical network, and then perform all the necessary manipulations. Workplace should be free from blanks and objects that could interfere with the implementation of the necessary measures.

Another important point in safety engineering - it is necessary that the machine has a stable position. To do this, it should be placed on a flat and hard surface. The wiring must be laid in such a way that it does not interfere with the work process. In the room where the lathe is used, it is necessary to provide good conditions lighting. The installation of the equipment must be carried out in such a way that there is enough space for its maintenance during operation.

Never leave a running machine unattended. If you need to leave the workshop, you should turn it off. While processing the workpiece, you should carefully inspect it before fixing it in the machine and remove nails, foreign objects, if any, in it.

Turning operations on the equipment should only be performed using a well-sharpened cutting tool. Before processing the workpiece, make sure that it is securely fastened. Before as turn on the lathe, you should make sure that the clamping of the workpiece is secure. If the workpiece is curved or has a large size, then its processing on turning equipment should be carried out at minimum speed.

Conclusion

Many home crafters dream of a desktop wood lathe. This is understandable, because it can be used to perform a wide range of processing operations on wooden blanks. You can buy this equipment today without big problems. There is a wide range of equipment on the market various manufacturers. Among all the variety there are many machines that can be used in everyday life. They have small size and light weight which makes this equipment mobile and easy to move.

In order for the choice of equipment to be successful, you should pay attention not only to the price, but also to the functionality, as well as the quality of the purchased woodworking machine. Preference should be given to imported products. In this case, you will be provided with reliability, functionality and a long service life of the equipment.

In addition, foreign analogues of turning equipment for the home are distinguished by good power. And this makes it possible to perform a wide range of wood processing operations with minimal time. You should be aware that even a mini lathe is a traumatic equipment, so before using it for its intended purpose, you should carefully read the rules for its operation and safety precautions when using it.

The art of woodworking has been beneficial and beautiful since ancient times. Today, the secrets of the craft are available to literally everyone. It is worth buying even a simple machine, and carved balusters, platbands, vases, candlesticks, children's toys will decorate your country house.

Lathe household purpose allows you to make crafts, household items, furniture elements and other products from a bar 25-35 cm long, rare models allow you to work with blanks and meter lengths. Large dimensions of workpieces are a priority stationary machine. But such a unit is good for small production or a serious hobby, it requires a separate workshop.

These are the operations that a household desktop model can handle: giving wooden blanks different geometric shapes, turning and polishing of surfaces. To select a groove, you will need a separate tool - a milling cutter. However, there is also turning-milling machines, but they already go as professional equipment, and not household. They are capable of drilling, countersinking, boring holes and turning grooves, threading, and processing ends.

Between two butterflies

The wood lathe is more than one hundred years old. On the cast-iron frame at all times there are two headstocks, between which the part is fixed by means of rotating centers. The rotation of the spindle results in the rotation of the workpiece. Chip removal is performed by a turning tool controlled by the operator's hand.

The emphasis helps the accuracy of the movements of the cutter. The optimal rotation speed is selected based on the density of the wood and the stage of processing. At one time, the belt pulley was set in motion by the muscular effort of the legs, just like on the old ones. sewing machines or grinding machines. Now the rotation speed is provided by the electric motor. And a modern machine, along with such characteristics as weight, possible dimensions of workpieces, have new ones: power, engine speed and type of speed control.

The working surface should not be lower than the level of lowered hands, preferably a little higher

We change the speed

Turning desktop machines due to the simplicity of the task, the small dimensions of the workpieces and the softness of the wood, they are equipped with low-power electric motors. You can work without counting the kilowatts without thinking about network overvoltage. The engine speed is low, rarely exceeding 3.5 thousand per minute.

All machines are equipped with a mechanism for regulating the speed of rotation, which allows you to remove chips from varying degrees intensity. With manual step control, the value is set depending on the stage of processing and the hardness of the material. The diameters of the multi-stage pulley on the spindle and exactly the same diameters on the motor pulley are adjusted so that when the belt moves from stage to stage, the length of the belt remains unchanged.

Expert advice

What is important to pay attention to when choosing a machine model, in addition to power and "speed"? In the case of large volumes of work, it is worth choosing a machine among professional equipment designed for a continuous load. The function "Engine blocking" in case of jamming prevents damage to the equipment. Weight is of particular importance. The larger it is, the less vibration is felt.

With electronic speed control, turning is smoother, which makes it easy to pass through problem areas, because the tree belongs to materials that are heterogeneous in density, speed modes also have a place here. They allow you to change the speed of rotation within certain limits.

Preparing the lathe for work

First of all, manufacturers recommend making sure that there are no metal inclusions in the form of nails and the like in the workpiece, because the engine power is not enough to overcome such obstacles. For reliable fastening of the workpiece strictly between the centers of the stocks, so that the axes of rotation coincide, diagonal lines are applied to the wooden ends and the centers of rotation are determined.

In one of the ends, cuts are made along lines 1.5 mm deep, where the teeth of the toothed center of the headstock are stuck. The center of the tailstock is fixed in the workpiece by turning the handwheel. If the ends have different sizes, which happens quite often during the processing of a particular part, then the teeth should fall on the end large sizes, the smaller one is always held by the tailstock.

The tool holder is adjusted so that the workpiece does not touch it during rotation, and the stop is comfortable.

We remove chips

Ideally, there are four stages of workpiece processing: preliminary, roughing, finishing and finishing. The first two require special care and caution from the operator.

The closer to the final processing, the higher the speed needed. However, it should be borne in mind that wood is a flammable material, and at high speeds it may begin to smolder. In order to avoid overheating of the part, short breaks in work should be taken.

Excessive effort will not speed up the turning process, but only reduce the quality of work and shorten the life of the machine. Incorrect movement of the cutter can damage the workpiece as well as cause injury to the operator. When pre-processing a still rectangular workpiece, a minimum rotational speed is required, of the order of 800-1000 rpm, depending on the density, hardness of the wood. So, conifers are relatively soft, and among hardwoods there are also very hard ones, for example, such as oak. In the process of processing, the frequency is increased. At the finishing stage, a speed of about 2500 rpm is required. and higher.

Bringing to gloss

The farther, the smaller the diameters of the workpiece being processed, requiring reconfiguration of the position of the tool rest and adjustment of the spindle speed. Often there is a change of working tool. So, finishing grinding is done with a sandpaper, holding it from below and turning it crosswise. This technique will avoid the annular bands on the workpiece. Ready product waxed and polished. Polishing thick cloth or a cork is produced on a machine at a low speed.

Cutting tool

It is a set of cutters that allows the operator to create miracles from wood, to carve various  forms. By location relative to the workpiece, radial and tangential cutters are distinguished.

forms. By location relative to the workpiece, radial and tangential cutters are distinguished.

Radial are installed perpendicularly, they remove excess volume. Tangential are set tangentially, they form complex surfaces. According to the type of operations performed, the equipment is divided as follows: cutters for rough and finishing, boring, shaped, cutting, etc.

When choosing, pay attention to the steel grade, it must be hardened, the presence of carbide soldering at the end is welcome. Cutters capable of long time keep sharp edges, guarantee experienced master cleanliness and ease of use. Dull "assistants" will not only worsen the quality of processing, but also increase the load on the engine. Firm grip and sufficient leverage provide incisors with handles about 25 cm long.

Joinery

Before turning, carpentry (sawing boards and bars, jointing, etc.) and milling are often required. Most of the preliminary steps for forming blanks, as well as a number of further and related operations, will help you quickly and efficiently perform a multifunctional woodworking machine. In a compact unit, various working units are assembled, such as saw blades, drilling, milling nozzles, knife shafts for planing.

Behind the workbench

The workbench is a multifunctional desktop of a carpenter, turner and locksmith. It is needed both directly for performing operations on the machine or hand tools, and for fitting, assembly of products. It is based on a rectangular tabletop with a built-in tray for improvised inventory, with holes for wedges and combs (with the help of which various parts are attached).

You will also need a couple of clamps for fixing. The countertop itself should be solid, made of thick, even, well-knit boards.