Do-it-yourself Siberian bath tub. Hot tub for a bath: is it possible to do it yourself

Everyone loves to give advice, we have a country of advice and we are no exception. It is important that these tips help. We share our many years of experience in construction.

1. In the construction of the working part of Chang Bath contact the manufacturer of vats, he will be able to give you the best conditions and cost the product itself - a cast-iron tub for a bath, it is precisely this that is the most expensive of the materials.

2. Always design and calculate the quantity of materials so as not to overpay for the quantity. Order a service from a company that can solve a set of turnkey construction activities. This will save you time (which is expensive) and nerves (you will sleep peacefully).

3. Order a complete set of all material and bring it from one company, only in this case you will receive a comprehensive guarantee for the product. The working part of Chang Bani is like the heart of a car, the most important part that comes into contact with fire, it is the stove and chimney that must be properly made.

4. Choose the company with the longest warranty period or number of oven cycles. This will add confidence in the future.

5. The Contractor Company must have an office. This gives you the opportunity to contact him again, recommend to your comrades, friends and keep your warranty on the Product's performance (in this case, you will always be helped to resolve issues).

6. You work only with trusted companies that have customer reviews, at least 3-5 pieces. Recommendations from clients are very important today.

7. Cohesive and professional the team has its own tools, machines and a license for installation work, can work by bank transfer, again for a guarantee.

8. Always conclude an agreement and write down all the necessary and important conditions for cooperation and warranty obligations.

9. Look for the best ratio of price, quality, deadline. Do not strive for cheapness if you are building for yourself and remember the wise words: “The greedy one pays twice”

Correctly calculate the chimney and brick base for installing the vat

Correctly calculate the chimney and brick base for installing the vat

Choose the right location for your cast iron tub. The Carpathian vat is always installed near the reservoir. By the way, this is good business! Will beat himself for the season. The average market price is 210,000 rubles per tub. We sell them for 164,000 rubles.

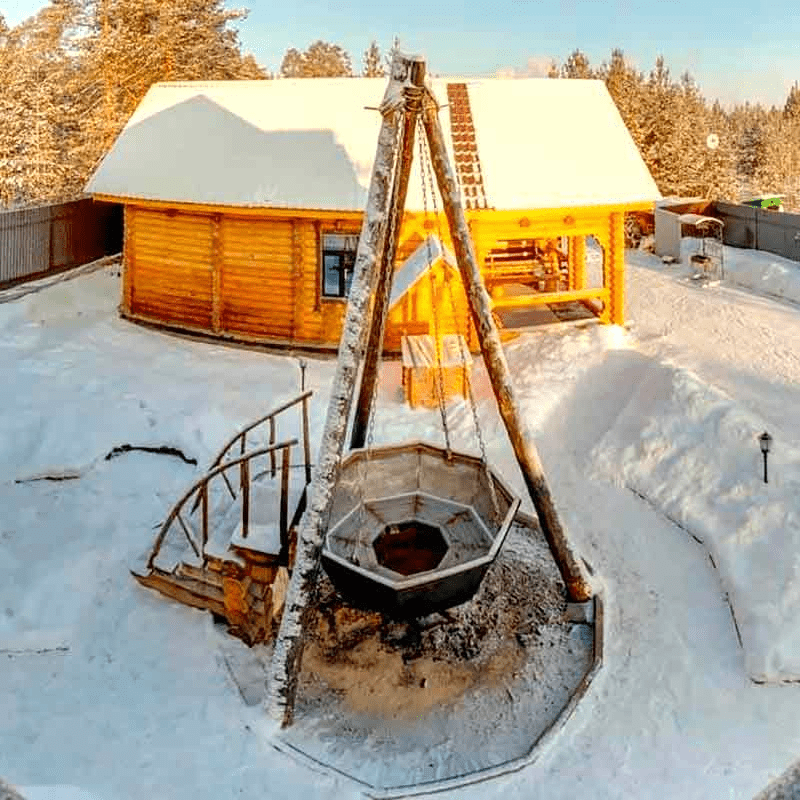

A rejuvenating cast-iron vat is a free-standing or attached to a bathhouse or gazebo, an open-air structure or a canopy (as you like) is a round stove on which a large cast-iron cauldron (bowl, font, vat) is installed. The most common shapes are hemisphere or truncated hemisphere. Chan is located right above the fire, which looks very unusual and fabulous. The beautiful and unusual design of this vat design is so attractive that it will look stylish and original, no matter where it stands. A bath in a vat can be a great addition to a Russian classic bath or a Finnish sauna, and you can swim in it all year round; it’s even more pleasant in winter... Just imagine, you are lying in a vat, there is fresh air around, stars in the sky, snow all around... And you feel good, warm, smells of summer herbs...

Why is he a youth vat? And what is its usefulness? The human body is 65% water, and therefore, when you bathe in a vat, each cell of the body warms up deeply and evenly. The water in the tub heats up to 42-45 degrees. The temperature is controlled by adding cold water. At the sight of this design, many fear that the bottom of the vat burns some parts of the body ... However, this is impossible, because the walls of the vat are 3-4 cm thick and flat river stones are laid on the bottom. The bathing procedure takes an average of 1.5-2 hours. Typically, such vats are installed on the shore of a reservoir, therefore, after sitting in a vat for about 15 minutes, it is recommended to plunge into cool water, and then back into the vat. Thanks to this contrast, there is a feeling that many small needles permeate the whole body ... And so several times. It is said that the adoption of 10 such procedures eliminates colds for at least 1 year. Also, bathing in such a vat relieves rheumatism, sciatica and osteochondrosis. And for lovely women, this is an amazing opportunity to get rid of extra pounds and cellulite and find a beautiful body.

Bath procedures involve not only a direct visit to the steam room, but also cooling the body in cool water. In baths of a large area, it is customary to equip a full-fledged pool for this purpose, which can be located both inside the building and on the veranda or near the entrance. A font is a kind of reduced copy of the pool, which can either complement it or completely replace it.

In Russia, peasants used a simple barrel for water procedures, but today, thanks to the variety and availability of building materials, you can build a font of any shape, size, and install various devices that will make the washing procedure even more pleasant.

The font can be round, oval, corner, square, rectangular or polygonal. Installation is permissible in the washing department of the bath, inside the glazed veranda/terrace, under a separate canopy or just next to the bath on the site.

In addition, a pouring bucket is called a font. It is attached to the wall and connected to the water supply. Inside the container is a float mechanism that prevents overflow. Such a font is the most budgetary and compact of all available models.

Table. Classification of fonts according to the material of manufacture

| Material | Description |

|---|---|

| Used cedar, larch, oak. From above, the material is treated with wax or other safe protective composition, leveling the harmful effects of moisture on wood. Wooden fonts not only look chic, but are also environmentally friendly and have a positive impact on the health of users. Sometimes wooden products are completed with a PVC liner. It is recommended to fill the font with water at least once a week to avoid drying out of the material, and after the procedures, close the container with a lid / film / wooden deck. It is also necessary to ensure good ventilation of the bottom, which introduces its own characteristics into the installation process of the product. The cost of wooden fonts is from 22 to 80 thousand rubles. Making such a container with your own hands is much cheaper. |

|

| Fonts are made in the form of a vat. The bowl can be installed in a pit, on tripods, support legs, suspended on chains, and there are also options with the location of the font over a wood-burning stove. The bottom of the font is lined with stones or wooden shields. The cast iron bowl is not easy to install on your own due to the large weight. Welded structures are relatively lighter, but less attractive in appearance. The bowl itself will cost 130-180 thousand rubles, a tripod, benches and other devices will cost another 30-50 thousand. It is only possible to make a welded steel bowl with your own hands if you have experience with a welding machine. |

|

| Durable design that resembles a swimming pool as much as possible. Such a font is equipped only in the pit. Outside, the concrete walls of the font are painted with rubber paint or finished with ceramic tiles, mosaics, and a special film for pools. The arrangement requires a competent drafting of the project indicating the location of the water supply / drain systems, physical strength and at least minimal knowledge about the principles of constructing concrete monolithic containers. |

|

| Polypropylene containers are produced in 2 versions - with a wall thickness of 5 and 8 mm. The weight and price of such fonts are relatively low. The font bowl can be reinforced with stiffeners or a metal frame. Installation of plastic fonts will be discussed in a separate article. |

Wooden dome. We collect the bowl with our own hands

To make a bowl yourself, first of all, it is worth evaluating the amount of free space in the room or in the territory adjacent to the bath. The font will be equipped with a drain siphon with an overflow drain and connected to a water supply system so as not to carry water in buckets manually. Choose a place that is most convenient for laying communications - sewer and water pipes, and if you want to add a hot tub or a solid fuel stove for heating water, it is worth considering the possibility of laying electrical cables and a chimney pipe.

Check out the proposed projects of wooden fonts. Choose an option that suits volume, height and shape.

All fonts are assembled from panels with a thickness of 35 to 50 mm, and two options for fastening elements are provided at once:

- adhesive. The ends of the joined panels are fixed with moisture- and heat-resistant glue. The finished font is pulled together with 3-4 steel clamps. It is not recommended to build such a font if there are asthmatics or allergies among the expected visitors;

- thorn-groove. The slats are connected according to the lining principle. The result is a smooth wall surface. The main advantage of the method can be considered the absence of cracks even with a slight drying of the material.

For example, we consider the assembly of the bowl using the tenon-groove method. In the process of work you will need:

Step 1. First you need to assemble the bottom of the grooved boards. They are laid out on the working surface in a row, the tongues are coated with glue and connected into a rectangular shield, fixed with clamps and left in this position until dry.

Step 2 Prepare boards for the walls. With the help of a cutter, a semicircular longitudinal groove is made on the sides of the boards on one side, and a protrusion of the same shape on the other. Next, cut out transverse grooves in the lower part of the boards 42 mm wide and 20 mm deep. The distance from the end to the lower edge of the groove corresponds to the height of the bottom of the font together with the legs.

An example of the manufacture of the walls of the font (sweep)

Step 3 The shield from the boards is dry, you can form the bottom. An oval or a circle of the required size is drawn with a pencil on the surface of the shield, and then the excess is cut off with an electric jigsaw. From the bottom side, two bars are screwed with screws at a distance from each other - these will be the legs of the font.

Step 4. In the bottom, closer to the wall, they drill a hole for the drain, insert a tube, attach it to the siphon from below, which is screwed to the boards with screws. The area where the siphon adjoins the tree is coated with sealant.

Step 5. The walls of the font are formed: the boards are carefully assembled around the bottom, inserting the protrusions into the grooves.

To simplify the work, a marking line should be drawn along the bottom perimeter at a distance of 20 mm from the edge. This will allow you to put the boards evenly around the entire circumference. The last board must be inserted from above and hammered so that it falls into place.

Step 6 After the assembly is completed, the walls of the font are pulled together with a metal clamp in the lower part, and its edges are nailed to the boards with small carnations and tightened with a bolt. In the same way, hoops are installed at the top and in the middle of the product.

Belts for tightening boards. When the metal clamps are fixed, the slings will be removed

Step 7. The inner and outer surface of the font is carefully sanded with sandpaper. The walls must be absolutely smooth.

Font inside - photo

Step 8. The finished font is installed in a permanent place, after which the siphon hose is connected to the sewer pipe or led to the drain hole.

On this, the manufacture and installation of the font is considered complete. If you wish, you can mount a bench inside and install an attached ladder outside.

Edged board prices

edged boards

Installation of benches in the font

For the manufacture of benches, the same boards can be used as for the walls.

Step 1. They begin work with markings for supports: they are determined with the size of the seat and put marks on the bottom with a pencil. If the size of the font allows, benches are installed along the perimeter of the walls, and then marks for supports are placed along the walls every 40-50 cm. In small fonts, 2-4 support posts are installed at the same distance from each other. For racks take a bar 40x40 mm and up to 20 cm long.

Step 2 The supports are fastened with self-tapping screws to the walls, deepening the caps a few millimeters into the boards.

Step 3 Depending on the configuration of the bench, the edges of the boards are cut at an angle of 45 degrees or rounded off with a jigsaw to fit snugly against the walls. After processing the edges, the boards are fastened in pairs with transverse rails and polished.

Step 4 The finished seats are laid flat on the support posts, joined adjacent ends and screwed with screws, always sinking the hats into the tree. Then cover the recesses from the screws with waterproof putty for wood.

Wooden font can be heated water. To do this, part of the space in the tank is fenced off with a wooden grate and a special sealed oven is installed.

The upper part of the stove is equipped with a door through which fuel is placed, and on the side there is another blowing hole that goes out. There are models with an external location of the furnace, when only the heat exchanger remains in the font. This option is more suitable for small containers.

It is not easy to make such a furnace on your own, especially for indoor installation, because the design must be absolutely tight and safe. It is much more reliable to purchase a factory model and install it in the font on your own.

Hot tub stove prices

hot tub stove

Hot tub installation

The pouring font is a wooden bucket with a float system, fixed with brackets on the wall of the bath. The float system is located at the top of the bucket, and its pipe passes through the walls of the tank and is connected to a flexible hose that is connected to a water supply or storage tank.

When the bucket is filled with water, the float rises to a certain level and blocks the jet, so that the water does not overflow. As soon as the water level in the font drops, the float opens the hole again. If there is no running water, the container is filled manually.

It is possible to make a bucket out of wood on your own, but in the absence of cooper's skills, this process will take a lot of time, and the product itself will not be as durable and beautiful as a purchased one. But it is quite possible to install such a font even for those who do not have such experience, since installation is very simple. The most important thing is to prepare everything you need in advance so that in the process of work you are not distracted by the search for the necessary details. If you still decide to assemble the font with your own hands, use the drawing.

Scheme of assembly of a pouring bucket top view)

Scheme of assembly of a pouring bucket top view)

To facilitate the work, you need to cut out templates from cardboard according to the above drawing, and cut out parts for a bucket from 100x10 mm boards according to the templates. The product is fastened with rims made of steel tape 50 wide and 2 mm thick. Five-wire is used as rivets for hoops.

To install the font you will need:

- timber 40x50 mm;

- hacksaw;

- drill;

- self-tapping screws and bolts;

- roulette;

- level;

- a piece of strong cord;

- float system;

- flexible hose.

First you need to decide on the place and height of the installation of the font. Usually it is fixed in the washing room, since a drain is already equipped there and water is supplied. So, they determine a convenient place for the font, then calculate the height of the attachment: the tallest member of the family should stand against the wall and stretch their arms to the ceiling. Measure the distance from the floor to the fingertips and add the height of the bucket. As a rule, the mounting height is 2.2-2.5 m.

Leave marks on the wall for attaching the font with a level, measure another 15-20 cm upwards and bring the water pipe to this point. The end of the pipe is connected to a flexible hose. If you plan to fill the font manually, skip this step. Now you can start installing the container.

Step 1. They make brackets from a bar: they cut the bar into blanks of 40 and 60 cm and fold 2 right triangles. Both ends of the long side are cut at an angle of 45 degrees, the parts are fastened with self-tapping screws. All segments must be processed with a planer and sanded to smoothness.

Step 2 From the outside of the triangles, the planks are stuffed, as shown in the photo, then the planks are fastened with three crossbars.

Step 3 At the ends of the protruding corners of the brackets, holes are drilled for the bolts with which the font will be attached. Holes are also drilled on the sides of the bucket, the container is inserted between the brackets and checked how easily it enters.

Step 4 A small hole is drilled in front of the bucket at the very top and a cord is threaded through. A pipe of the float system is threaded into the eye of the bucket, located in the back, and fixed.

Step 5 In a wooden frame and make holes for fasteners, the same holes are drilled in the wall according to the marks. Attach the product to the marks on the wall, bait with bolts. Once again, the location of the fasteners relative to the horizontal is checked to eliminate distortions. Next, insert and tighten the dowels, hang a bucket, connect the pipe to the hose.

Hot tub prices

dousing font

Making a concrete font

If the concrete font will be located indoors, its design should be dealt with at the construction stage of the bath itself. This is due to the design feature, because such a font requires a foundation pit. Usually the depth of the pit is 1.5-1.7 m, and the width and length depend on the area of \u200b\u200bthe room and the preferences of the owner of the bath.

For construction you will need:

- shovel;

- sand;

- tamper;

- reinforcing bars with a diameter of 10 mm;

- wire 5 mm for staples;

- level;

- plywood or wooden boards;

- bars for spacers;

- concrete mortar;

- waterproof plaster mixture;

- waterproofing impregnation;

- roller or brushes.

Step 1. They determine the dimensions of the font and make markings for the foundation pit, taking into account the thickness of the concrete walls - about 15 cm. They dig a hole of the desired depth, level the walls vertically. Since in most cases water is pumped out of such a font by a pump, laying a sewer pipe at the bottom is not necessary. If the drain system seems more convenient to you, a trench is made in the wall of the pit with a slope towards the sewage pit and a plastic pipe is laid in it.

Step 2 The bottom of the pit is covered with sand to a height of 10 cm and compacted very carefully. To facilitate the process and achieve greater density, the sand should be abundantly moistened.

Step 3 The reinforcement is cut into pieces of the desired size and laid on the bottom in the form of a grid of 100x100 mm. The rods are fastened with a thin wire; pieces of brick, pieces of metal or plastic pipes are placed under the grate so that the reinforcing layer does not lie on the ground. On the walls of the pit, the grating is fastened with five-wire brackets, leaving a gap between the soil and the reinforcement of 5-7 mm.

Step 4 Inside the pit, formwork is mounted using plywood sheets or thick boards made of boards. The height of the shields should be 15-20 cm above the walls of the pit; the distance between the formwork and the reinforcing grid is 15 cm. The structure is set using a level gauge and reinforced with spacers from a bar to prevent deformation of the walls under the weight of concrete.

Step 5 The solution is kneaded and poured along the perimeter of the formwork in the ratio: 1 part of cement, 3 parts of sand and 6 parts of fine gravel. Filling is carried out in stages, compacting the solution with a crowbar or a long metal rod. When the space is filled with concrete, the surface of the sides is smoothed with a trowel and left to dry. So that when the concrete dries, the surface does not crack, the sides are covered with a dense film and periodically moistened. It takes about 28 days to harden the walls of the pit.

Step 6 As soon as the concrete is sufficiently hardened, the formwork is removed. This must be done carefully so as not to damage the surface. After dismantling the formwork and complete drying of the concrete, the bottom of the future font is leveled with a screed. Its thickness is from 6 to 8 cm; the ratio of cement, sand and gravel is 1:3:5. Cement is used with M400 and above, since the quality of the solution is of particular importance here.

Step 7 After the bottom has dried, a cement-based plaster mixture is prepared and the walls of the font are covered. The thickness of the plaster layer is from 0.3 to 10 mm.

Step 8 When the walls are dry, the inner surface of the font must be treated with a deep penetration waterproofing impregnation. Apply it with a roller or a wide brush, whichever is more convenient for you. As a rule, 3-4 layers of impregnation are required for a font. Before applying the next layer, the surface must dry well.

Step 9 Decorating the sides and the bowl of the font is in progress. To do this, you can use rubber paint or ceramic tiles. The font, lined with mosaic tiles, looks beautiful. For masonry, waterproof tile adhesive is used.

If there is no experience in laying tiles, liquid rubber is the most ideal option: affordable, durable, easy to apply with a roller or spray gun, does not cause allergies.

The final stage in the construction of the font is the installation of stairs. It can be mounted independently from stainless tubes or bought ready-made in the store. The method of installation depends on the design of the stairs: some models are embedded with their ends into the floor next to the font, others are hooked to the side.

Prices for cement-sand mixture

cement-sand mixture

Video - Do-it-yourself hot tub

Video - Do-it-yourself concrete font

Video - Assembling a wooden font

Oil dance!

But then he fell into another space.

Gray cloudy sky. Rare snow flakes. They fall from these gray clouds. They fall, they fall. Smells like damp winter. Thaw? Or early winter. A light wind carries the smell of smoke. No. It smells like a bathhouse, which is heated in a black way. Nice smell. The smell of burning birch bark.

He moves his head. There is a dull splash. Near the back of the head. He lowers his eyes. Near the face - liquid. Not water. It's thick and smells familiar. A familiar, familiar smell. But too thick.

Sunflower oil! He's up to his neck in oil.

He sits in a container filled with sunflower oil. It is a black cauldron, a large cauldron with a thick rim. There is a large area around the boiler. An area filled with people. How many! There are hundreds, hundreds of them. They stand close. What a big, huge area. Houses surround her.

These are European houses. And a huge cathedral. He had seen this cathedral somewhere. It looks like Prague. Very similar. Yes, probably Prague. Or maybe not Prague. Warsaw? Or Bucharest. Krakow? Probably Warsaw.

Its main square. And there are hundreds, hundreds of people on this square. They stand and look at him. He wants to move. But he can't.

He's connected. Tied with thick rope.

Bound like he's in his mother's womb. The legs are bent at the knees, pressed to the chest, pulled with a rope. And the hands are tied to the ankles of the legs. He wiggles his fingers. They are free. He touches his own feet. The wrists are tightly tied to the ankles. He sits at the bottom of the boiler. It touches the bottom of the boiler. He's like a float. So he learned to swim. As a boy, he portrayed a float. It was a long time ago. On a wide river It was sunny and warm. Father stood on the shore in a wide straw hat. The father laughed. His glasses glittered in the sun. And he portrayed a float and looked at his father.

Two horses stood on the bank and drank from the river. A naked boy sat on one of the horses and looked at him contemptuously. And he portrayed a float. But it was a long time ago. A long time ago.

And now he's tied up.

And in this boiler. The boiler is on a hill.

This is a platform. Its edges are stapled with thick logs.

He distinguishes them. The thick black edge of the cauldron blocks almost the entire platform. The boiler is standing on something. And two thick chains go tight from the eyes of the boiler to two freshly hewn poles. Chains are wrapped around these posts. Wrapped exactly four times. And nailed with big forged nails. These poles are also on the platform.

And behind the platform begins the crowd. She looks at him. Many smile. In the distance, near the cathedral, something is read solemnly, in a singsong voice. Latin? No. Polish. No, it's not Polish.

It's some other language. Serbian? Or Bulgarian? Romanian! Most likely Romanian. They are reading something. Read solemnly. They even sing a little. Read in a singsong voice about him!

And everyone is listening.

And they look at him.

What they read concerns only him.

They read something about him. Read for a long time.

He tries to move to the edge of the cauldron so that he can at least rest his chin on it and pull himself up. But suddenly he discovers that the rope that binds his ankles and wrists is tied to the bottom of the boiler and keeps his body in the middle of the boiler.

It is pulled to another eye, which is located at the bottom of the boiler, immediately below it. He touches this eye with his fingers. It is smooth and semicircular. A thick rope is threaded into it. He understands that he cannot get out of this boiler in any way. Even with tied hands and feet.

The eye won't let him go.

He screams in horror.

The crowd laughs loudly, hoots.

People are making faces at him, showing him with their fingers. Women hold children in their arms. The children laugh and tease him. He twitches with all his might. And for a second he loses consciousness from horror.

Disgusting vegetable oil! How it stinks. How many. It's easy for them to choke. It sways heavily around his body.

Grandmother poured sauerkraut with this oil. Now there are so many! It suffocates with its scent. Only a slight breeze helps not to suffocate. This smell makes my head spin. Rare and large snowflakes fall into the oil and disappear. They fall and disappear. They fall and disappear.

How good they are. They are not tied to anything. And they don't owe anything to anyone. But now the reader solemnly and loudly shouts out the last word. And the crowd roars. She roars, throws up her hands. It roars so that the roar resonates in the cauldron and barely noticeable tiny waves arise near the cast-iron edges. And then someone enters the platform. It's a teenager with a torch.

He is wearing a suede jacket with copper buttons, red trousers and red shoes with turned up toes.

His face is great. Face like an angel. Long brown hair falls smoothly over her shoulders. On the teenager's head is a red beret with a falcon feather.

The teenager lifts up the torch. The crowd roars.

He lowers the torch under the cauldron, bends down himself.

Seen only takes a teenager. A falcon's feather trembles. There is a faint crackle, then louder. Apparently, it flares up tarred brushwood. The crack gets louder. Dark smoke is knocked out from under the boiler. The teenager walks off the platform.

His beret with a feather flashes already in the crowd. The crowd roars, hoots. He makes another desperate attempt to free himself, straining until he passes gas. They float up in slow bubbles around him.

But the ropes don't budge.

He twitches, swallowing oil, coughing and gasping for air. Oil splashes around. Smelly, thick oil.

But the boiler is still.

You can't even swing it. He shouts so that the echo of his voice, reflected from the cathedral, returns to him three times.

The crowd listens as he screams. Then he roars and laughs. He starts crying and muttering about his innocence.

He tells the crowd about himself.

He calls his name.

The name of his mother.

My father.

He speaks of a monstrous mistake. He did nothing wrong to people. He talks about his noble profession as a doctor.

He lists the names of the sick he saved.

He calls God to be his witness. The crowd listens and laughs. He talks about Christ, about love, about commandments. And suddenly he feels with his heels that the bottom of the boiler has become warm. He screams in horror. And again for a second he loses consciousness. And again the oil, the smelly oil brings him to his senses. He wakes up from swallowing oil. He chokes on oil. He vomits oil into oil. The crowd is laughing. He wants to tell them of his innocence, but he can't. He catches his breath. He coughs. Coughing painfully. Almost screaming. The bottom of the boiler is getting hot. Only the central eye, the eye at the bottom is still cool. It is thick and protrudes from the bottom.

His fingers are holding on to the eye.

He clears his throat.

Gathering thoughts.

Soothes himself.

And addresses the crowd with a speech.

He's talking about faith.

That he is not afraid to die. Because he is a believer. He tells his life. He is not ashamed of his life. He tried to live with dignity. I tried to do good and benefit people. Of course, there were mistakes. He remembers the girl he made a woman and who had an abortion from him.

And as he found out, she was no longer able to have children later. He recalls how, as a student at a student party in a hostel, he got drunk and threw a bottle out of the window and hit a passerby on the head. He tells how one day he did not go to the patient and the patient died.

He lied a lot in his life.

He slandered friends and colleagues.

He told nasty things about the woman he lived with.

He sometimes spared money for his parents. He didn't really want to have children. I wanted to live freely, enjoy life. Largely because of this, he and his wife broke up. He repents for what he did.

He spoke badly about the authorities. He wanted Russia to go to hell. He laughed at the Russian man.

He laughed at the Emperor. But he was never a criminal. He was a law-abiding citizen. He always paid his taxes regularly. The bottom of the boiler becomes hot.

Tensing, he rests his feet on the eye.

She is a little warm.

With his hands, he holds his own legs on the eye.

He says that the worst thing in the world is when an innocent person is executed. This execution is much worse than murder.

For murder is committed by the criminal.

But even a criminal, by committing a murder, gives the victim a chance to escape.

The victim can run away, snatch a knife from the hands of the killer, call for help.

The killer can miss, stumble. Or just hurt the victim. When a person is executed, they leave no chance of salvation.

This is the horror and ruthlessness of the death penalty. He has always been and remains an opponent of the death penalty. But what is happening now in the main square of this city is much worse than the death penalty.

For this is the death penalty for the innocent.

If they are all gathered here to execute him, an innocent one, then they are committing a great sin.

And this sin will be an eternal shame on their city, on their children and grandchildren. He feels the oil, as it heats up at the bottom, floats up in warm, updrafts, displacing the cool oil. Warm oil pushes cold oil. And cold oil sinks down.

To heat up at the bottom and become warm oil. And float up. He's talking about children standing here, sitting on their fathers' shoulders. The children see him being executed. They will grow up and find out that he was innocent.

They will be ashamed of their parents.

They will be ashamed of their city.

It's a beautiful, beautiful city.

It was created not for executions, but for a joyful, prosperous life. His heels slide off the eye and touch the bottom.

The day is hot. He quickly pushes off the bottom with his heels and wraps his feet around the eye with the rope, holding on to the rope.

He's talking about faith. Faith should make people kinder. People should love people. Two thousand years have passed since the death of Christ, and people still have not learned to love each other.

They didn't feel like they belonged. They did not stop hating each other, deceiving, robbing. People didn't stop killing each other. Can people not kill people? If this is possible in one family, in one village, in one town, then why is it impossible in at least one country? The lug gets hot. Feet get hot.

He pulls them away, but they immediately sink to the bottom.

The bottom is very hot.

The feet are retracted.

But they cannot hang in oil.

They have to rely on something. He sinks to the bottom with his buttocks and burns them. Puts fingers under the buttocks and under the heels. He rests his fingers on the hot bottom. Then to the eye.

The smoke from the fire curls around the cauldron, gets into his eyes. He closes his eyes and screams that they are all criminals. That their city will be judged by an international tribunal. That they are committing a crime against humanity. That, according to the verdict of the international tribunal, they will all be imprisoned.

That an atomic bomb will be dropped on their city. The crowd laughs and cheers. The oil becomes hot.

Hot streams float up.

They, like tongues of a smooth flame, lick his back.

Licking chest.

Nothing can be shielded from them.

They are getting hotter. The eye is already hot. He draws air into his lungs. And he screams with all his might. He curses this city. He curses these people in the square. He curses their parents and their children. He curses their grandchildren. He curses their country.

He starts to sob. He spews every curse he knows. He shouts these curses, sobbing and spitting.

Oil splashes around his head.

It is already completely impossible to lean on the eye.

She is hot.

Very hot. And the bottom of the boiler is already terribly hot.

You can't even touch him.

It pushes off the eye and hangs in the oil. Retracts and hangs. Retracts and hangs.

Retracts and hangs.

Retracts and hangs.

He dances in oil. Oil dance!

He starts to howl. Oil dance!

He howls, turning not to the crowd, but to the roofs of the houses that enclose the square. Oil dance!

These are old tiled roofs.

Dance!

People live underneath.

Dance!

Families.

Dance!

The women are preparing breakfast there.

Dance!

Darn linen.

Dance!

Children cry and play.

Dance!

Children cling to their mothers.

Dance!

And they sleep in their beds.

Dance!

Children sleep, sleep, sleep.

In their beds.

Cushions, embroidered cushions.

Mothers embroider flowers on pillows.

Children sleep on pillows. Sleep, sleep, sleep.

And they don't wake up. They sleep for days.

You can sleep for days.

And don't wake up. Nobody gets punished for it.

If you don't wake up. If you sleep.

He screams and begs to wake him up. He believes in children.

He believes in pigeons on tiled roofs. He loves pigeons. Doves can forgive him. Pigeons forgive all people.

Pigeons don't kill people. I will die?

Pigeons love people. I will die?

The doves will save him. I will die?

He will turn into a dove. I will die?

He will fly away. I will die!

The crowd begins to sing and sway.

Yamru! What is it? Yamru!

Folk song? Yamru!

The song of this people? Yamru!

This wonderful people. Yamru!

This damn people. Yamru!

This evil people. Yamru!

The people are singing. Yamru! The people sing and sway. Yamru!

They want him to have a beautiful death. NMR!

But he will turn into a dove and fly away. NMR!

No, this is the choir from Nabucco. NMR!

They are singing. NMR! Va, pensiero, sull'ali dorate! NMR!

And they sway. NMR! They sing. NMR!

Are swinging. NMR! They sing. NMR!

Are swinging. NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! NMR! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam! Yam!

10 tips for the construction of the Chan Ban (working part) - the article, its contents, will briefly show you how to build the working part of the Bath in the vat, what it consists of and how we build it in stages.

ATTENTION! ATTENTION! ATTENTION!

Everyone loves to give advice, we have a country of advice and we are no exception. It is important that these tips help. We share our many years of experience in construction.

1. In the construction of the working part of Chang Bath contact the manufacturer of vats, he will be able to give you the best conditions and cost the product itself - a cast-iron tub for a bath, it is it that is the most expensive of the materials.

2. Always design and calculate the quantity of materials so as not to overpay for the quantity. Order a service from a company that can solve a set of turnkey construction activities. This will save you time (which is expensive) and nerves (you will sleep peacefully).

3. Order a complete set of all material and bring it from one company, only in this case you will receive a comprehensive guarantee for the product. The working part of Chang Bani is like the heart of a car, the most important part that comes into contact with fire, it is the stove and chimney that must be properly made.

4. Choose the company with the longest warranty period or number of oven cycles. This will add confidence in the future.

5. The “Contractor” company must have an office. This gives you the opportunity to contact him again, recommend to your comrades, friends and keep your warranty on the Product's performance (in this case, you will always be helped to resolve issues).

6. You work only with trusted companies that have customer reviews, at least 3-5 pieces. Recommendations from clients are very important today.

7. Cohesive and professional the team has its own tools, machines and a license for installation work, can work by bank transfer, again for a guarantee.

8. Always conclude an agreement and write down all the necessary and important conditions for cooperation and warranty obligations.

9. Look for the best ratio of price, quality, deadline. Do not strive for cheapness if you are building for yourself and remember the wise words: “The greedy one pays twice”

10. Rely on your intuition when choosing a contractor, your life experience and do not save on important elements in construction that affect the overall safety of your building and the people in it.

These tips are not rules for execution, you yourself are experienced and know what and how will be more correct for you. We only recommend.

Photos of the construction of the working part of Chan Ban

how to install chan

how to install chan

Bath tub - replacement of the font. It is made from stainless steel or cast iron. It is a hemispherical bathing container. The product is placed on the site next to the bath, where there is a source of water. From below, a stove is installed or a fire is kindled to heat water. The temperature of the latter is maintained at a level of up to 40 °. The design is heated so that the edges remain cold, so it is impossible to burn yourself during use. The article describes the design of the vat and provides instructions for its installation.

Bath tub

The purpose of the bath tub is to relax the muscles of the human body and saturate the skin and internal organs with minerals. For this, original structures are mounted near groundwater sources. Staying in a hot container is combined with bathing in the cold water of a river or lake, which is similar to a Russian bath. The temperature difference tones the pores and blood vessels, strengthening them. The advantages of a bath tub at home are also considered:

- the ability to get rid of excess weight;

- stabilization of the excretory system;

- beneficial effect on kidney function.

- calming the nervous system;

- improvement of skin permeability;

- pore cleaning;

- relaxing effect on the musculoskeletal system;

- beneficial effect on the respiratory and digestive organs;

- increased immunity due to the removal of toxins from tissues;

- relief of manifestations of rheumatism and osteochondrosis;

- hardening of the body.

According to the reviews of those who appreciated the benefits of bathing in a tub, it is clear that after a ten-day course, a cold recedes for a year.

Cast iron tub for a bath

Cast iron is a high-carbon metal that is heavy. It is impossible to make a bath vat from it at home, so they are assembled in production by pouring into molds. Material advantages:

- heat capacity;

- wall thickness;

- life time.

Due to the thick walls, the water heats up longer, but it also retains the temperature for a long time, which is important at sub-zero temperatures. There are also disadvantages:

- price.

The weight of the tub for four people reaches 1.2 tons. For installation, a forklift will be required to deliver it to the place. It is impossible to remove the container for storage, so a cover is built to protect the product from rusting. When choosing, attention is paid to the quality of workmanship. The edges must be sanded, without flash. Analyze the porosity and uniformity of wall thickness throughout the vat. Take into account the guarantee that the manufacturer is ready to provide. If the container is painted, then the composition must be fire resistant, since the surface will be exposed to open flame.

Information! Cast iron is a brittle metal, therefore, during the operation of the vat, strong blows and sudden changes in temperature are avoided.

Stainless steel bath tub

Bath tubs are also made of stainless steel. They are not cast like cast iron, but are assembled from several parts. The advantages of such a product:

- long service life;

- relatively fast heating;

- appearance.

The metal is not subject to corrosion, so it is left in an open area without fear of destruction. The wall thickness is less, so the container heats up faster than the cast iron version. There is no need for coloring. If the surface is covered with oxides, it is polished. Disadvantages of a stainless steel vat:

- price;

- manufacturing defect.

If there is no ultrasonic evaluation of the quality of welding at the production site, then shells may remain in the seams, which manifest themselves during operation. The disadvantage is leveled by an experienced welder. For 4 people, a bath tub with a diameter of 2 m and a height of 73 cm is purchased. If you want to accommodate a company of 6 people, you need a diameter of 2.2 m. Eight visitors to the bath will fit in a container with a diameter of 2.5 m and a depth of 83 cm.

Advice! It is better if the bath tub is made of food grade stainless steel. Metal with brand 430 is technical and gives oxides upon prolonged contact with water. It is suitable for collecting containers, but will require periodic care and cleaning.

Do-it-yourself bath tub: drawings

Before making a bath vat, they think over the place of its installation with their own hands. Evaluate the binding to communications and neighboring buildings. The service life is taken into account. If it is less than 2 years, then the project is not economically viable. If you wish to place the container inside the bath, the bearing capacity of the foundation and the need to install additional supports are calculated. Do not kindle an open fire in an enclosed space, because carbon monoxide will lead to poisoning. They think over the design of the furnace for the vat and the way the smoke is removed. The method of filling the container and the removal of liquid spilling over the edges are taken into account.

After preparing the site, a drawing is developed. An example can be seen above. Since it is impossible to make a hemisphere with a diameter of 2 meters on your own, the container is assembled from separate parts. Each of them is an equilateral trapezoid.

To give a smooth shape, it is bent at two points, as can be seen in the example of the second drawing. To correctly calculate the components, a scale model is made of cardboard.

The parts are glued with adhesive tape or other material, as can be seen in the photo above.

After measurements, the theory is tested in practice, making a vat of metal according to the drawings on a scale, as shown in the photo. This is necessary to determine the number of consumables and the strength of the seam.

Sheet metal is cut to actual dimensions and bent to a predetermined radius to achieve a diameter of 2 meters or more. The walls are not welded with a solid seam, they are fixed with tacks to make an adjustment if necessary.

If everything is in order, then the joints are completely boiled, making sure that there is no distortion due to thermal expansion. To strengthen the sheet metal, stiffeners are fixed in two levels, as seen in the photo above. They compensate for water pressure and reduce stress on the seams.

If the vat will stand separately, then a frame is built under it. Use a square with a cross section of 60 mm. Provide for the possibility of draining water from the tank. To do this, a piece of pipe with a diameter of ¾ inch is welded to the bottom, a thread is cut at the end and a tap is screwed on. Next, a hole is drilled, connecting the bath tub with a pipe.

Inside, the container is ennobled with a bench, a wooden bottom is made or it is laid out of river stone so that the legs do not touch the surface that is heated. For convenience, wooden railings are fixed along the contour.

For the convenience of collecting ash, if there is no stove under the bath tub, a box is installed according to the example of what is in the photo above. A grill is placed below, a hole is drilled on the sides for air circulation. Install it on guides, which will exclude its displacement from a given trajectory.

For the convenience of climbing into the bath tub, a ladder made of larch or decking is installed. A cover is cut out of plexiglass, which reduces evaporation and contributes to the rapid heating of water.

Installing a vat in the bath

If the tub will be installed in the bath, then you can use the drawing diagram above. On loose soils, a pile foundation is laid. For self-construction, screw metal piles are used. They are a metal rod with a spiral at the end. The latter holds the support, preventing it from going deeper and moving. After installing the supports under the foundation around the perimeter, a concrete grillage is poured, which is tied with reinforcement with piles.

Mark out the area under the bath vat. It will require a separate foundation, because the pressure from it is directed to a smaller area, which can deform or destroy the foundation. A square is selected, the side of which exceeds the diameter of the container by 20 cm. A pit is dug to a depth of 30 cm. Piles are screwed in at the corners so that the upper end is 10 cm below the ground. see and ram. Gravel of medium grain size is poured on top with a layer of 10 cm and leveled.

Stands 5 cm high are evenly placed, on which a metal grate is placed, which will strengthen the concrete structure. Formwork is placed along the perimeter of the pit under the bath vat. Concrete is poured inside and leveled with a rule. It takes a month to set. At this time, the concrete is moistened and covered with a film so that it does not crack. After a month, a stove is installed on the foundation and connected to a metal stand for a bath tub. Make a conclusion for smoke outside the structure. The container is put in place with a lift and fixed to the frame by welding, if necessary.

Another option for installing a bath tub is hanging. A foundation is built under it in the manner described above. At the same time, the platform is expanded for three supports that will hold the container. The latter can be wooden or metal. They are assembled in a pyramid to evenly distribute the load. At four points, metal arcs are fixed to the bath tub, and a chain is fixed to them. The container is lifted and the chains are attached to the top of the pyramid of supports. An overview of the sizes and types of structures is in the video below.

Conclusion

Bath tub - a design that can be installed in the bath complex or separately. The container is placed on a metal stand or placed on a concrete base-furnace. A place is selected that is protected from the winds, has a supply of communications and a drainage system. The water is heated to 40°, which relaxes the body. Keep your head cool while bathing. You can make a chan-font yourself from sheet metal. According to the drawings, blanks are made in the form of an isosceles trapezoid or an equilateral triangle, which are combined with welding seams.