The exact weight of the lathe TV 4. Specifications of the machine

The TV 4 semi-automatic lathe has been familiar to many of us since school. It was originally created for use in training workshops for lessons on the theoretical and practical aspects of the processing of (cold) metals using cutting.

This model allows you to perform the following operations:

- threading (both taps and a cutter can be used);

- turning of conical type surfaces;

- processing of cylindrical surfaces (both internal and external);

- trimming the end parts of the workpiece.

Any lathe for metal TV 4 has a reliable base, represented by a pair of cabinets, on which a cast-iron cast-iron bed is installed. It has a caliper, rear and front headstock. The latter contains a gearbox and feeds.

Both pedestals have a U-shape and stiffeners located in the lower and upper parts. The front one serves as a "storage place" for the drive motor and its reversible on / off button, and the back one - for the electrical panel.

Along the base (that is, the bed) there is a pair of guides that are needed to ensure the movement of the tailstock and caliper (in the longitudinal plane). By the way, the first is necessary for fastening:

- cutting tool(axial);

- revolving/thrust center.

One of the most important structural units - the spindle - is located in the headstock. Depending on the operations performed, a four- or three-jaw (with the possibility of self-centering) chuck, a faceplate, or a driver-type chuck are attached to it. These devices allow you to securely fix the part / workpiece.

Thanks to the feed box, the considered model of the unit is capable of threading (which is reflected in the name of the machine). Through this node, the caliper and apron are driven. In addition, it is possible to change their speed, determine the thread pitch, and set the direction of movement.

There is a tool holder on the support, in which you can install up to four different tools at once! Accordingly, no changeover of equipment is required when switching from processing one type of surface to another. Also on the caliper there is a handle for turning on / off the mother nut and spindle speed.

About the characteristics of the model

Now it's time to consider the characteristics lathe TV 4. They are shown in the table:

The electric motor with which the model is equipped has a power of 600 watts.

Cost of equipment

Of course, the price of the TV 4 lathe, which sellers offer today, cannot but rejoice. You can officially purchase this model for 204,000-205,000 rubles. But what is frustrating is that it is impossible to purchase new equipment: its production has been discontinued. Accordingly, the pleasure of working on it will depend on the degree of wear and care for the care of the previous owner of the equipment.

Despite this, this model continues to be one of the most popular among home craftsmen who decide to organize a mini-workshop in their apartment or house.

TV 4 lathes are designed and manufactured by the Educational Equipment enterprise, located in Rostov. The device is intended for studying the processing of steel parts. In view of this, the equipment has certain characteristics that distinguish it from professional equipment. There is a big difference between machines used in industry and equipment used to train beginners.

purpose

The main requirements for training equipment are safety and ease of setup. Students, working on the equipment, learn how it is structurally arranged, get acquainted with the processing of parts.

Initially, TV 4 Shkolnik lathes were created for various turning operations. Their design is arranged classically. This is typical for such devices. On such equipment it is possible:

- Turn and bore a variety of steel parts by rotation;

- Cut end sections with great precision;

- Cut thread. It must be remembered that the device can only form metric threads. It is simply impossible to make other types of carving;

- Drill.

In order to increase the functionality of the equipment, it needs to be upgraded. This can be done by studying in detail its design features and getting acquainted with the technical characteristics. Modernization should not adversely affect the performance of the device, the safety of work.

The control parts of the training machines are arranged in a special way. In view of this, teenagers can process steel blanks without problems. Short stature and short arms are not a problem when working on training equipment.

Design

To increase the level of equipment reliability, its pedestal is made of thick-walled sheet steel with auxiliary stiffening ribs. This design makes it possible to maximize the compact arrangement of the control parts and key components of the lathe in question.

The cabinet is considered the main part of the device. At the back is an electric motor. It serves to drive the headstock of the spindle. The control block is located in front: keys for starting / disabling / activating the reversion. The cabinet is equipped with all electrical equipment. For maintenance and repair, the access door must be opened.

The TV 4 lathe includes the following main components:

- Front grandma. Mounted on the left side of the frame. To change speeds, a box is connected to it. The design of the headstock and the box is common. The transmission of spindle rotation is carried out by means of a chuck with three jaws;

- transfer unit. Serves to transmit rotation from the spindle unit to the gearbox. The gear ratio of this lathe is one fourth. Design feature it is considered that it is impossible to mount other pairs of gears. The gear ratio is a constant value;

- Gearbox. In order to adjust the feed level, you need to turn a special handle. The shaft and lead screw cannot rotate at the same time. The trough, which is located at the top, is intended to supply lubricant.

When processing a part with a tool fixed in the tool holder, you need to monitor the volume special liquid providing lubrication of the gearbox. In the trough should always be necessary minimum lubricants. If there is no lubricating fluid, the gears can overheat and break when using a metal lathe.

For clarity, in front of the device there is a table that indicates the permissible speed. This makes it possible to select the appropriate operating mode before starting work with the part.

Characteristics

In order to get acquainted with the performance of educational equipment, you need to study the manual attached to it, as well as the TV 4 passport. In view of this, that work on such equipment is usually carried out by students, it is necessary to pay special attention to operating modes.

The screw cutter has a weight of 280 kilograms (together with all the equipment). Its overall dimensions are 144x47x102 centimeters. Such parameters are considered the most suitable for installation in small classrooms. To transfer the torque to the elements of the device, there is a three-phase electric motor with a power of 1000 watts. It can be connected to electrical network 380 V. If you need to adapt the device to operate from a 220 V power supply, you need to change the engine or mount a special unit.

Specifications and key figures screw-cutting machine these are:

- the largest radius of the part is 100 mm (above the bed), 62.5 mm (above the caliper);

- maximum length of the part - 350 mm;

- turning length - 300 mm;

- the tool holder makes it possible to install a cutter with dimensions up to 10 × 12 mm;

- the radius of the through spindle hole is 16 mm. This allows the use of a bar that has a cross section of 15 mm;

- number of feet in forward/reverse rotation - 6;

- permissible revolutions - 120/160/230/375/500/710 rpm;

- the caliper moves 300 mm (longitudinally), 100 mm (transversely);

- permissible displacement of the cutter slide - 50 mm;

- the angle at which the sled with the installed tool rotates is forty-five degrees;

- the number of degrees of longitudinal feeds of the caliper - 3;

- thread pitch limits - 0.8 / 1 / 1.25 mm;

- the distance that the tailstock quill moves is 65 mm.

In the design of the device there are no nodes that allow forcibly braking the spindle and blocking the control handles. In view of this, the processing of the workpiece does not stop too quickly. This must be taken into account when planning the operation of the device.

According to the accuracy, this metal lathe belongs to the "H" category. This allows you to process steel workpieces and achieve High Quality. Difficulties can arise only with the processing of parts made of hard alloys.

Usage

In view of the fact that the machine is classified as educational equipment, it must be installed and adjusted by specialists. Before starting work, students must study the design of the device, its performance, safety.

To mount the machine, you need to create a foundation 10 cm high. For this, it is possible to use bars made of wood, concrete. It is necessary to ensure that there are no differences in platform heights. You can mount special adjustable supports.

Exist certain rules operation to be followed:

- Preparatory work. The equipment is cleaned of anti-corrosion agent, grease for the gearbox is poured into a special container. When connecting to the electrical network, grounding is mandatory, an RCD is installed;

- Detail processing. First of all, you need to make sure that all the handles are in the standard position. Then you can make settings. The part is fixed between the front and rear headstock. The position of the tool is determined by the mechanisms of the tool post;

- Preventive work. After processing is completed, metal filings are necessarily removed, the integrity and correct operation of the key parts of the machine are checked. Before starting, the amount of lubricant is checked.

This training equipment is not intended for mass production. In view of this, it cannot be subjected to high loads. Any part of the machine can break, for example, the tool holder.

You can learn more about the features of the operation of the device by watching the video below.

Download passport

Lathe TV 4 is designed to perform turning operations in the workshops of schools, colleges for polytechnic education. The machine allows you to perform the following operations:

- turning of external and internal cylindrical surfaces;

- turning of conical surfaces;

- trimming ends;

- threading, both with a tap and with a cutter;

- drilling holes and others.

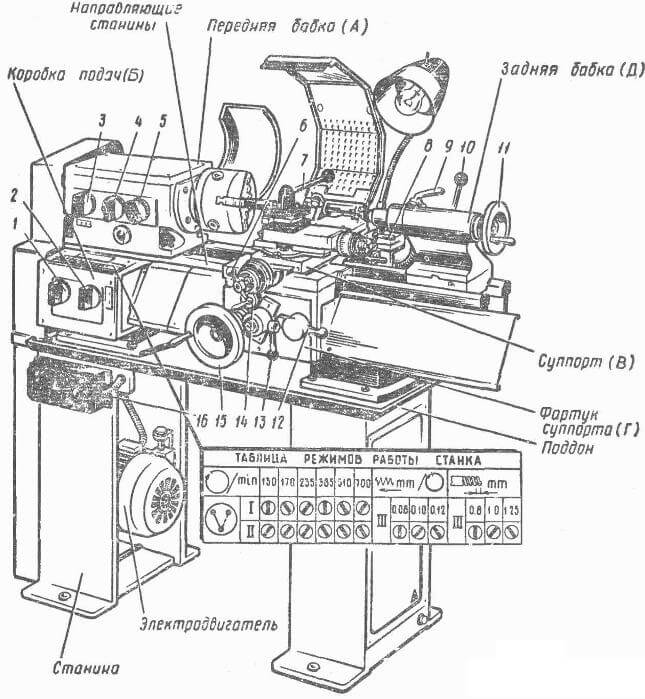

Lathe device

Screw-cutting lathe model tv 4 consists of:

- front cabinet of the machine;

- rear cabinet of the machine;

- machine bed;

- headstock of the machine;

- machine feed box;

- apron;

- guitar;

- caliper;

- tailstock;

- electrical equipment;

- protective elements.

Lathe controls

1.2 Spindle speed setting knob;

3. Handle for setting the feed direction for cutting right or left threads;

4. Setting knob for the amount of feed (S) and pitch (P) of the thread;

5. The handle of switching of a running shaft;

6. Flywheel for manual longitudinal movement of the machine carriage;

7. Button for turning on the rack and pinion;

8. Handle turning on the longitudinal feed of the caliper;

9. Handle for turning on the lead screw nut;

10. Handle manual movement cross slide carriage;

11. Handle for fastening the tool holder;

13. Handle for fixing the tailstock quill;

14. Flywheel for axial movement of the tailstock quill;

15. Lighting transformer;

16. Local lighting switch;

17. Safety block;

18. Magnetic starter;

19. Reversible button for turning on the machine;

20.Lamp;

21. Handle for fixing the tailstock to the guides;

22.Network switch;

23. Protective element

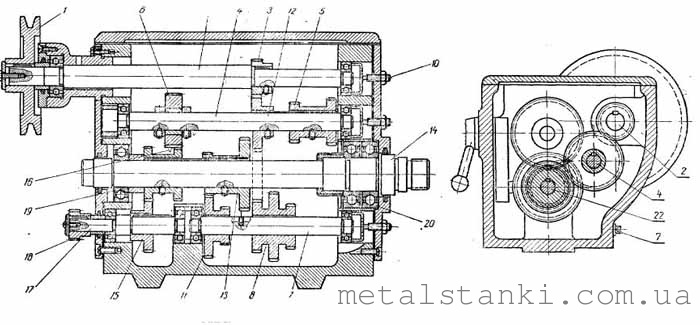

Lathe Headstock

The headstock of the lathe is located on the left side of the bed. It is also called a gearbox.

The rotation of the gearbox spindle is carried out using an electric motor. Through V-belt transmission and gearing system. A chuck is attached to the headstock, on which the workpiece is fixed.

Inside the gearbox, rotational motion is transmitted through shaft 2 and cylindrical gear 3, which is stationary on the shaft, to shaft 4, on which block gear 5 and fixed gear 12 sit.

On the shaft 7 there are movable block gears 8 and 11, which move with the help of handles 1 and 2.

Block gear 8 is engaged with block 5 or gear wheel 12, thereby transmitting torque to shaft 7 and block gear 13 located on the spindle.

The lathe spindle transmits torque to the workpiece, which is mounted in a three-jaw chuck or faceplate with a leash.

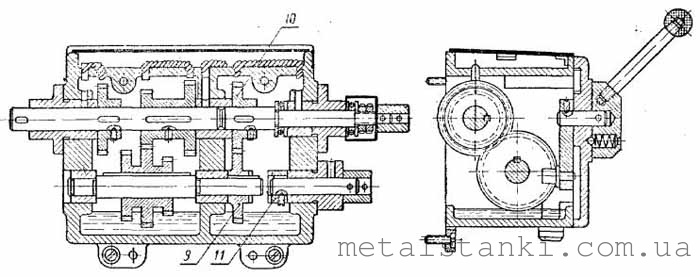

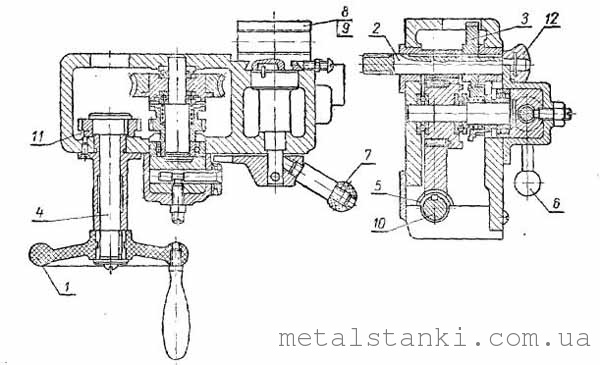

Lathe feed box

The lathe feedbox receives rotational movement from the gearbox with the help of a guitar of replaceable gears.

The feed box mechanism allows you to cut metric threads with different pitches.

The lead screw or shaft is turned on using the handle 5. When the gear 9 moves, it will disengage from the gear wheel 10 and engage with the clutch 11, which transmits torque to the drive shaft. The design eliminates the possibility of simultaneous activation of the drive shaft and screw.

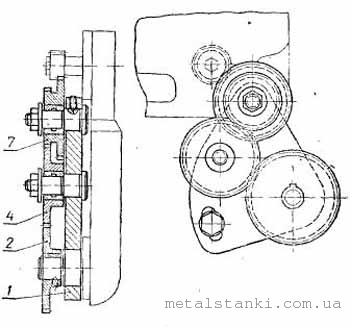

The lathe guitar is designed to transmit torque from the gearbox spindle to the feed box. The guitar of interchangeable gears consists of a bracket 1, on which gears 2, 4, 7 are located.

The gear ratio of the TV 4 lathe guitar is ¼.

The support of the TV 4 lathe is designed to move the cutting tool. There are 4 carriages on the caliper:

- 1st carriage moves along the guides of the frame;

- 2nd moves along the transverse guides of the carriage 1, transversely moving the cutting tool;

- 3rd rotates 45 degrees from the middle position in both directions;

- The 4th carriage, carrying the tool holder, moves in the longitudinal direction along the guides of the carriage 3.

The apron of the TV 4 lathe performs both mechanical and manual longitudinal feed (S) of the caliper using a running shaft and longitudinal - with a lead screw.

The rotation of the flywheel 1 is carried out manual feed drive shaft mounted on shaft 4, on which gear 11 is located. Gear 11 engages with gear 3, sitting on a roller with rack and pinion 2. Gear 2 engages with a rack, which is rigidly attached to the frame.

The feed is carried out by the lead screw, by turning down the handle 7, connecting the mother nut 8 and 9 with the screw.

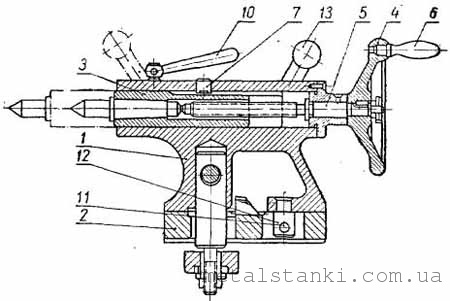

Tailstock lathe

The tailstock of the lathe is designed to support the second end of the workpiece with the help of the center.

The body of the rear tank is located on the base 2, which moves along the frame guides.

In the body there is a quill moving in the longitudinal direction. The tailstock quill is moved by the flywheel 4, which rotates the screw 5. So that the quill does not rotate when moving, it has a key connection, consisting of a screw-key 7.

Using the handle 10, the quill is clamped in the tailstock housing

Technical characteristics of the screw-cutting lathe for metal TV 4

Do you need MAZ vehicles? Order truck cranes, tractors, construction and municipal equipment from an authorized dealer on

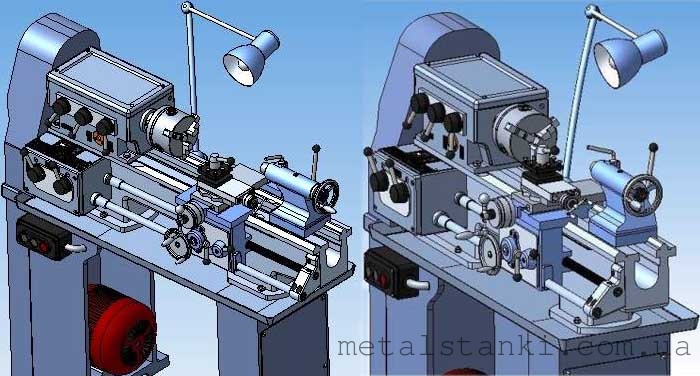

Desktop lathe TV-4 is designed for classes in school training workshops for turning workpieces by cutting. This is not a heavy, semi-automatic machine of H accuracy class, used in labor lessons in school workshops. TV-4 left a mark in the history of the Soviet machine tool industry as a reliable lathe for schools.

Despite its fairly advanced age, the TV-4 machine is still in demand among home craftsmen, due to its small size and good functionality. and low secondary market price. Unfortunately this machine no longer released. The closest domestic analogue of this machine is the TV-9 and TV-7M models, which are also presented in our catalog.

The TV-4 school lathe allows you to perform the following types of turning work:

- turning and boring of cylindrical and conical surfaces;

- trimming ends; segment;

- metric thread cutting;

- drilling and a number of other works.

The design of the main nodes

The screw-cutting lathe consists of the following main units: front pedestal, rear pedestal bed, headstock, feed box, guitar, apron, caliper, tailstock, protective cover, trough, electrical equipment, protective screen.

Front cabinet:

The front cabinet of the TV-4 machine is U-shaped with stiffeners in the upper and lower parts. The drive motor is installed on the back of the cabinet, on the front there is a reversible button for turning the motor on and off

Back cabinet

The rear cabinet is U-shaped with stiffening ribs in the upper and lower parts. In the rear pedestal, a shield with electrical equipment is mounted.

Machine bed TV-4 box-shaped with windows. Has two prismatic guides. The front rail is used to move the carriage, the rear rail to move the tailstock. The bed is installed on two pedestals.

The front TV4 is attached to the left side of the frame.

The installation of the gearbox along the center line in the horizontal plane is carried out by two set screws with nuts.

Technical characteristics of the TV-4 desktop lathe

| Characteristic | Meaning | |

|---|---|---|

| The largest diameter of the product installed above the bed | mm | 200 |

| mm | 125||

| The largest diameter of the processed bar | mm | 15 |

| Distance between centers | mm | 350 |

| Maximum turning length | mm | 300 |

| Spindle RPM Limits | rpm | 120-710|

| Limits of longitudinal feeds | mm/minute | 0,08-0,012 |

| Spindle hole diameter | mm | 16 |

| Motor power | kW | 0,6 |

| Machine dimensions (length, width and height) | mm | 1100x470x1020 |

| Weight | kg | 280 |

TV 4 - machine lathe production domestic Rostov plant. Remember your school, college and probably remember this machine. This is due to the fact that this equipment is widely used in educational institutions. The main purpose of the TV 4 lathe is the development of skills in working with steel products.

Starting to design the machine tool support, tool holder, cutting structures and other elements, the main principle of the developers was to provide high level safety and ease of operation. It is quite possible for a group of students to repair the TV 4 machine under the clear guidance of the teacher.

At the same time, the technical characteristics of the TV 4 machine model are almost the same as the professional ones. turning equipment. This is done so that students can clearly understand the design of the machine, the features of its operation, the nuances of the production of parts with its help.

The TV 4 screw-cutting lathe, as a training aid, initially provides for the possibility of performing the entire list of turning activities on it. Therefore, the design includes a classic caliper, tool holder, engine required power and other parts specific to a professional lathe. Therefore, using TV 4, you can perform:

- Grooving and boring;

- Trimming ends;

- thread cutting;

- drilling.

It is important to note that the machine manual assumes the possibility of making exclusively metric threads. The TV4 unit is not designed for other types.

After the student has studied in detail the TV 4 machine and its design, determined the technical characteristics, managed to perform a number of operations using the equipment, the functionality of the unit is expanded. For this, there is a special instruction, following which, the modernization is carried out quickly and easily.

It is noteworthy that the same support, apron handles, controls, tool holder, the location of the cutters themselves are designed so that teenagers do not experience discomfort when working on TV4. Because the TV 4 machine is a complete study guide, allowing in the future schoolchildren to easily understand more complex, industrial models of lathes.

Machine design

So that the repair and manufacture of blanks using TV 4 does not cause problems and unnecessary questions for schoolchildren, the first thing the teacher's job is to study the design together. It is important here to study all the components, to determine the possibility of replacing a particular spare part. To repair, you first need to understand where everything is located. The design of TV4 is as follows:

- The cabinet is the basis of the design of the machine in question. For its manufacture, thick-walled sheet steel is used, which is reinforced with stiffeners for reliability. This design allows you to provide excellent ergonomics, place all control units, a caliper, a tool holder, a protective apron, so that the student can safely work on the machine;

- An electric motor is located in the back of the machine cabinet. It is powered by 380 volts. That's why educational institutions must provide in advance the possibility of connecting to 380 V;

- The electric motor of the machine, powered by 380 V, drives the headstock;

- A tool holder is located on the headstock of the structure. It is the tool holder that allows you to use one or another type of cutting tool for processing spare parts, metal blanks in the process of gaining skills in working with the machine;

- The front panel of the unit design serves to accommodate the TV 4 control unit. Here you will find the on and off buttons, as well as the button for activating the reverse mode. Responsible for the tool holder, spindle and their drive;

- The back of the cabinet is designed to accommodate electrical equipment. Students can access it only with the permission and under the close supervision of the teacher. Still, 380 V is no joke. To perform repair and preventive measures with electrical equipment, the design of the machine provides special doors.

Based on the design features, which include an apron, caliper, tool holder, electric motor and other components, the main elements can be called:

- Front grandma. It is located on the left side of the bed. In order for the tool holder with the headstock to rotate at one speed or another, a gearbox is connected to the headstock. Structurally, they represent a single node. The three-jaw chuck transmits the rotation to the spindle.

- transmission mechanism. It transmits rotation from the spindle unit to the box. On the TV 4 machine, the gear ratio is 1/4. The design is different in that it is impossible to install other pairs of gears here. Therefore, the gear ratio is a constant parameter;

- Gearbox. To control and change the level of delivery, the student turns a special handle. The scheme of operation of the machine does not allow the lead screw and the roller to rotate simultaneously. In the upper part you can see the so-called trough. It is intended for supply to lubrication mechanisms.

Specifications

After the teacher introduces students to the design and components such as a caliper, apron, electric motor, spindle, talks about the differences between 220 and 380 V, subsequent work involves studying the parameters of the equipment. That is, its technical characteristics.

- The weight. If we take into account all the elements and spare parts of the TV 4 screw-cutting lathe, then its total weight will be 280 kilograms.

- Dimensions. Unit dimensions - 144 by 47 by 102 centimeters. These dimensions are ideal for placement in workshops.

- Motor type - three-phase. Its power is 1 kW, and a 380 V network is used for power supply. It is possible to connect to 220 V, but for this a different type of electric motor and a special auxiliary unit are installed.

- The workpiece on the frame can have a diameter of not more than 200 mm. If a we are talking about the caliper, then above it the maximum diameter is 125 mm.

- The maximum length of the machined part is 350 mm.

- Turning length - no more than 300 mm.

- The spindle design provides for a hole diameter of 16 mm. This allows the use of bars whose cross section does not exceed 15 mm.

- The number of gears, taking into account the reverse - 6.

- Possible rotation speed modes are 710, 500, 375, 230, 160 and 120 rpm.

- The caliper during longitudinal movement shifts as much as possible by 300 mm.

- With its transverse movement - 100 mm.

- The caliper is distinguished by the presence of 3 degrees of longitudinal gears.

An important nuance is that the design of the machine does not provide for a forced stop system for the spindle head. There is also no control knob lock. Because of this, the process of stopping parts after they are finished takes some time. Therefore, these aspects must be taken into account when planning the learning process.

When working on a TV 4 lathe or its analogue in the face of TV6, be sure to follow the operating instructions, do not remove the protective apron. In this way, the work will be done safely and as efficiently as possible. This is due to the fact that TV 4 is a lathe with not the highest accuracy class - H.

Given the technical characteristics, design, feedback on the work of the TV4 lathe, it can be safely called an excellent teaching aid. Allows you to learn how to repair and process parts with your own hands. The current price of this creation of the Rostov plant is 35-50 thousand rubles.