Conventional designation GOST for an equal-angle corner. Steel corner

Steel angle is one of the most commonly used options for high-quality rolled metal products. In appearance, this metal product resembles a blank in the shape of the Russian letter "G". The material is plain steel or carbon steel. The same raw material is used for the production of rolled metal such as galvanized sheet steel, which has increased resistance to corrosion.

Hot-rolled steel angle is made in different sizes. Depending on the length of the shelves, products are divided into two types:

- equal-shelf;

- unequal.

At equal-shelf corners, the shelves will be the same. As for the width of the edges at the unequal corner, here the rolled products are divided into small and large products. Each of them may differ from the other in such a parameter as the accuracy of rolling. There are two options for accuracy - normal and high. Accuracy is selected depending on the purpose of the corners.

There are three technologies for the production of such a product as a steel equal-shelf corner GOST:

- hot rolled method;

- cold rolled method;

- bending technology.

Hot-rolled and cold-rolled varieties of sheets can also be subsequently bent after basic processing.

Where is this type of rolled metal used?

The scope of products is a variety of areas, including the construction of metal structures, furniture production, interior decoration, as well as industrial branches and construction. An equal-shelf steel angle made of very strong hot-rolled steel is often used to create the most durable load-bearing structures. Another area where they are often used is when mounting a variety of frames. Another popular type of rolled metal is a metal channel.

As for the corners produced using cold-rolled technology, they are best suited specifically for finishing works. However, they can be used in conjunction with doorways, racks, window sills.

Steel bent corner unequal has found wide popularity in the field decorative finishes, as well as in various auxiliary structures. The fact is that he does not have high strength characteristics, that is, it is not able to withstand significant loads. However, its accuracy rates are among the highest.

If you need a high-quality metal-rolling corner in Moscow at really great prices, then be sure to contact us. We have an incredibly wide range of steel corners GOST, made only from the most reliable materials. Our official website is very easy to navigate, with detailed catalogs and extremely accurate summary tables that include all available items for purchase. You will be amazed by our range, which includes each of existing species rolled metal products.

What types of corners exist

Hot-rolled steel corners of equal and unequal flanges can also be made in a bent version. Hot-rolled equal-shelf angles are manufactured in accordance with GOST 8509-93, bent equal-shelf angles are manufactured in accordance with GOST 19771-93. As for bent unequal-shelf and hot-rolled unequal-shelf products, they are produced in accordance with GOST 19772-93 and 8510-86, respectively.

As a material for the manufacture of products such as corner steel price which is very profitable for us, can be carbon steel of standard quality of different grades, as well as high-strength steel - that is, low-alloyed. You can read more about brands in the tables we have already mentioned.

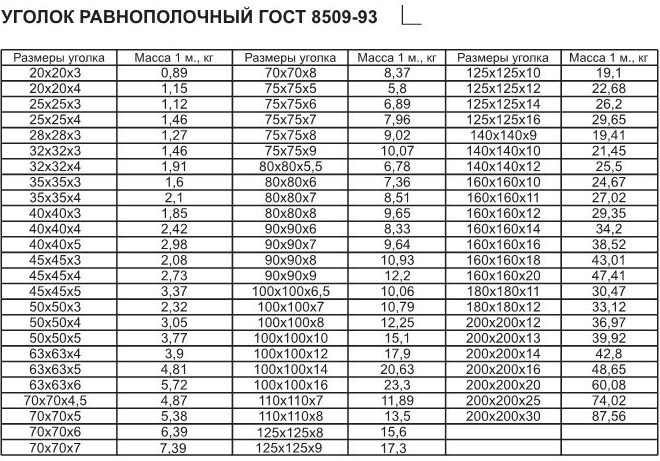

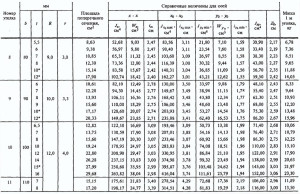

Mass of hot-rolled equal-shelf (GOST 8509-93)

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In the company "MSB" we offer to buy hot-rolled steel equal-shelf corners GOST, which have high or ordinary accuracy rates. Length parameters vary from 4 to 12 meters, depending on the dimension. As with many varieties of such rolled metal, the length can be measured, non-measured, multiple dimensional or limited. If necessary, corners are produced that exceed the standard 12 meters in length. You are guaranteed to find every product option with us.

Mass of hot-rolled unequal-shelf (GOST 8510-86)

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel unequal-shelf angle GOST, as well as equal-shelf, has the same characteristics of rolling accuracy and length measurement. They can also be produced in lengths longer than the standard maximum of 12 meters.

In any case, if you want to buy a steel angle from the SME company, you can always count on favorable price products. We guarantee quality, reliability and high specifications each item. If you find it difficult to choose, just contact us. SME specialists will advise you, and you will definitely be able to purchase what you need at the moment. We will also help you to correctly calculate the weight of the steel angle.

The parameters of one of the most popular types of rolled metal products - equal-shelf steel angle - are determined by GOST 8509-93. The use of GOST in the production of such products not only unifies its types, but also improves the interaction between producers and consumers. Dimensions and weight of equal-shelf steel angles, which are made in full accordance with normative document, allow you to use these characteristics for accurate calculation of material consumption, which is very important in the implementation of construction and repair work.

Varieties of steel corners of equal-shelf type

Equal-shelf corner, depending on the method of manufacture and the raw materials used for its production, is divided into several categories. All geometric parameters, as well as tolerances they are governed by two regulations:

- GOST 8509-93 (production of hot-rolled equal-shelf angles);

- GOST 19771-93 (production of equal-shelf steel angles obtained by bending).

You can get acquainted with the requirements of GOST and the assortment of steel hot-rolled and bent equal-shelf angles by downloading the relevant documents in pdf format from the links below.

The difference between equal-shelf and unequal-shelf products is that the former have the same dimensions (width), while the latter are different. Hot-rolled corner profiles are made according to the following technology: a hot billet is rolled between special rolls, where it, under pressure, is formed into a product with the required geometric shape and sizes.

In order to make a bent metal corner, sheet metal of the appropriate size is bent on roll forming equipment or on pipe mills. Hot-rolled profiles, due to the peculiarities of their production, are characterized by higher strength, but bent corners also have their advantages: high dimensional accuracy, a light weight, wide assortment.

In the assortment of equal-shelf corners there are products from:

- high strength steels;

- alloyed, high-alloyed steel;

- alloys characterized by increased heat resistance, heat resistance and corrosion resistance.

The most common material for the production of a bent corner is also carbon steel, the characteristics of which must comply with GOST 380-94.

Main characteristics

According to the assortment table of equal-shelf steel angles, you can find out their various parameters: the mass of one running meter; square cross section profiles and other sizes. To calculate the mass of a hot-rolled or bent profile, the density of the material from which it is made is taken as 7850 kg / m 3.

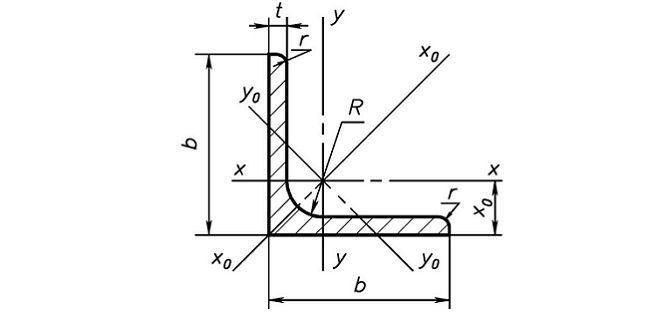

Profile corner radii of equal-shelf steel angles given in the assortment table are not controlled parameters, but they are necessary for product calibration. In the table of assortment accepted the following notation dimensions and other parameters that characterize the steel corner:

- t is the thickness of the walls of the shelves;

- X0, Y0 - distances from the outer edges of the corner shelves to its center of gravity;

- R is the radius of curvature;

- b - shelf width;

- r is the radius of curvature of the edges of the shelves;

- I is the moment of inertia;

- i is the radius of inertia;

- F is the sectional area of the profile;

- Ixy is the moment of inertia, which is developed by centrifugal forces.

Designations of the main geometric parameters of the hot-rolled angle. Below is a table of the range of this type of rolled metal

Equal-shelf steel corners can be of normal accuracy (marked with the letter "B") and increased (the letter "A" is present in the marking). GOST allows the following deviations in the width of the shelves:

- for products No. 2–4.5 - ±1 mm;

- No. 5–9 - ±1.5 mm;

- No. 10–15 – ±2 mm;

- No. 16–20 - ±3 mm;

- No. 22–25 - ±4 mm.

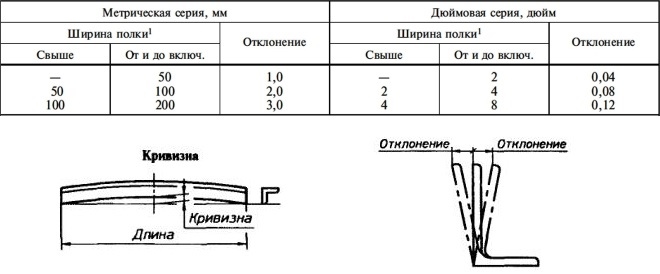

The thickness of the shelf of an equal-shelf steel angle in accordance with GOST may have the following deviations, measured in millimeters (see table).

The customer of a batch of equal-shelf steel angles can agree with the product manufacturer that instead of permissible deviations in wall thickness, a tolerance for deviations in the mass of the product will be used, which can be for profiles:

- No. 2–7.5: from -5 to + 3% (classes "A" and "B");

- with No. over 7.5: ±2.5% (class "A"), from - 5 to + 3% (class "B").

According to the provisions of GOST, steel angles belonging to the equal-shelf category can be sold to the customer with a length of 3–12 m. By prior agreement between the customer and the manufacturer, these products can also be sold with a length exceeding 12 meters. So, GOST stipulates the possibility of tempering equal-shelf steel angles of the following dimensions in the longitudinal direction:

- measured length;

- measured value with the inclusion in the batch of products of random length (the number of such corners should not exceed 5% of the total volume);

- length, which is a multiple of the measured;

- length, a multiple of the measured length, when the batch contains corners of unmeasured length (their number should not exceed 5% of the total volume);

- unmeasured length;

- length, which is in a non-dimensional interval.

Informative video of the Soviet times, covering in detail the nuances of the production of long products.

For the length of measured steel angles and products, the length of which is a multiple of the measured one, GOST establishes the following permissible deviations:

- no more than 4 meters - 30 mm;

- from 4 to 6 meters - 50 mm;

- over 6 meters - 70 mm;

- from 4 to 7 meters (at the request of the customer) - 40 mm;

- over 7 meters (by prior agreement with the customer) - 5 mm for each additional meter of the product.

Parameters according to GOST 19771-93

In accordance with GOST 19771-93, steel corner profiles are made in three categories of accuracy:

- "B" - normal;

- "B" - increased;

- "A" is high.

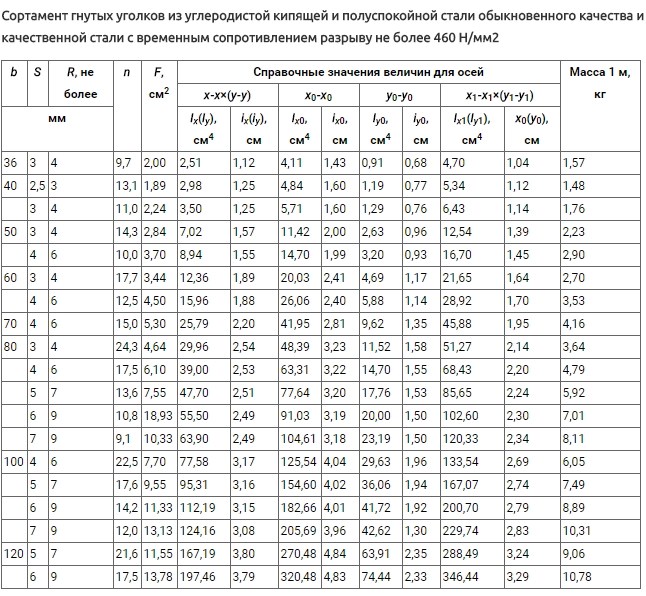

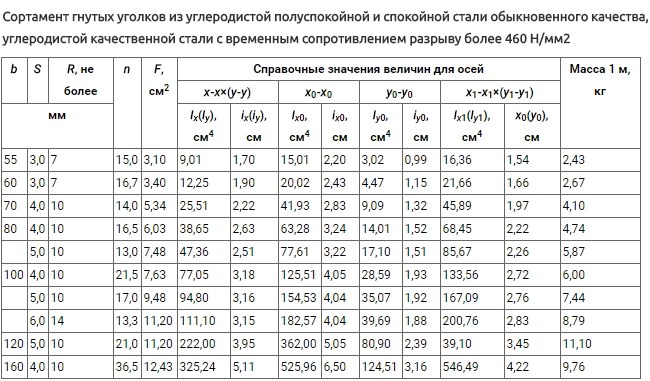

The table, which presents the entire range of bent equal-shelf angles, indicates the main parameters of such products: the mass of 1 linear meter, the cross-sectional area, etc. The tables for the assortment provide data for steel angles of two categories:

- made from ordinary carbon steel, semi-calm and boiling, as well as alloys in which the tensile strength corresponds to indicators up to 460 N / mm 2;

- made from ordinary calm and semi-quiet carbon steel and alloys, the tensile strength of which exceeds 460 N / mm 2.

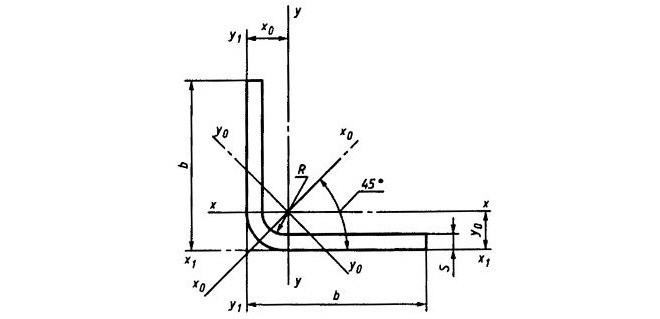

In the tables, which show the parameters of equal-shelf steel angles of these categories, the following designations are accepted:

- S - shelf thickness;

- Y0, X0 - distances between the outer edges of the corner and its center of gravity;

- R is the radius of the profile curvature;

- b - shelf width;

- I is the moment of inertia;

- i is the radius of gyration of the profile;

- F is the sectional area of the profile;

- n=b-S-R/S is the ratio of the calculated shelf overhang to its thickness.

Designations of the main geometric parameters of the bent corner. Below is a table of the range of this type of rental

Table 2: Parameters of angles made of boiling and semi-quiet steel

Table 3: Parameters and reference values for calm steel angles

The values of the cross-sectional area of the profile of a steel equal-shelf angle given in the tables, as well as the weight of one meter of the product, are calculated taking into account the nominal tabular dimensions (the calculations do not take into account the allowable deviations that are inevitable in the production of metal products). The mass of one linear meter is calculated taking into account the fact that the density of the metal from which the corner is made is 7850 kg / m 3.

The width of the shelves of steel corners, depending on the accuracy of their profiling, may have the following deviations:

- high accuracy (up to number 2.5): ±0.75 - ±1.5 mm;

- high accuracy (corresponding numbering over 2.5): ±1 - ±1.75 mm;

- increased accuracy: ±1.25 - ±2.5 mm;

- conventional accuracy class: ±1.5 - ±3 mm.

Equal-shelf steel angles, produced in accordance with the specified GOST, can be sold to the customer in the following lengths (in the range of 3–12 m):

- measured;

- unmeasured;

- length, which is a multiple of the measured;

- measured, while in the batch there are products of random length, the number of which does not exceed 7% of the total volume;

- multiple measured, while in the party there are corners of random length, but their number is not more than 7% of the total volume.

At a reasonable price, the hot-rolled and bent angle made of ordinary carbon steel has good load resistance. various types. Such characteristics allow these products to be successfully used in many areas. Steel corners of this type used to create frame metal structures for various purposes, and also with their help perform reinforcement of concrete structures.

When choosing an equal-shelf steel angle, it should be borne in mind that it has a low corrosion resistance. Therefore, in cases where the resistance of the created metal structure to corrosion is important, it is recommended to replace such a corner with galvanized or aluminum products that will last much longer.

1 , average rating: 5,00

out of 5)

Angle rolled products are one of the most demanded and widespread types of metal products. Equal-shelf corner GOST 8509-93, due to its characteristics, is used more often than others.

1 Corner products - production and varieties

The steel corner on application of metal products takes one of the leading positions. It is a shaped steel, the cross section of which resembles the letter L (shaped steel, in contrast to long products, is called products in which at least one tangent to the profile contour intersects the cross section. For sectional circles, sheets and other rolled products, not a single tangent crosses the section ).

These products, with the exception of the stainless steel angle, are made from different varieties low alloy and carbon steel. According to the type of section, they are divided into equal-shelf and unequal-shelf, according to the manufacturing method - bent and hot-rolled. According to these classifications, the following GOSTs have been developed for ferrous metal corners, which they must comply with:

- GOST 8509-93 - equal-shelf hot-rolled corner;

- GOST 8510-93 - unequal hot-rolled corner;

- GOST 19771-93 - bent equal-shelf corner;

- GOST 19772-93 - bent unequal angle.

It should be noted that a product is called equal-shelf, the shelves of which (the sides of the transverse angular section) have an equal width. Accordingly, the dimensions of the shelves are different for the unequal shelf.

Hot-rolled products are produced by rolling a hot billet between rotating shafts of a rolling mill, where the angle is formed under pressure. Bent products are produced by bending on roll forming machines or using pipe mills. The strength of a hot-rolled angle is higher than that of a bent one. But the latter have more precise dimensions, lighter weight, a wide range of shelf sizes and wall thicknesses.

2 Main characteristics for equal-shelf corner GOST 8509-93

When classifying angle bars, it is important to know the brand of metal used in the manufacture, the production method, the dimensions of its shelves, length and accuracy. 8509-93 make from the following varieties become:

- carbon grades St0, St3sp, St3kp, St3ps, St4ps, St4kp, St4sp, St6ps, St5ps, St6sp and the like;

- low-alloy increased strength 12GS, 14GS, 08G2S, 16GS, 17GS, 17G1S, 14KhGS, 09G2S, 15KhSND, 10G2S1, 10KhNDP, 10G2BD, 10KhSND, 14G2AF, 15G2SFD, 16G2AF and others.

According to GOST 8509-93, corner products are produced with a shelf width in the range of 20–250 mm and a thickness in the range of 3–35 mm (at the end of the article there is a table with all types of sizes). In accordance with the width of the shelves, the rolled products are assigned numbers from 2 to 25 (width in centimeters). When designating products, the parameters of the shelves and the thickness of the corner are indicated: 63x63x6 mm (corner with shelves 63 mm and 6 mm thick). Usually, for equal-shelf products, the width of the shelves is indicated once (63x6 mm). Thickness may not be specified.

GOST 8509-93 corner products are produced in lengths of 3–12 m. It is possible to manufacture over 12 m. The following lengths are produced:

- measured;

- measured with non-dimensional in the amount not exceeding 5% of the entire batch of products;

- multiples of dimensional;

- multiples of measured with non-measured in a volume not exceeding 5% of the entire batch;

- off-gauge;

- limited within unmeasurable.

For products of measured and multiple permissible deviations of length should not differ in big side per (in mm):

- 30 - for corners up to and equal to 4 m;

- 50 - longer than 4 to and equal to 6 m;

- 70 - over 6 m;

- according to the customer's requirement 40 - longer than 4 up to and equal to 7 m;

- at the request of the customer for each 5 meter after 7 m - over 7 m.

By accuracy, corner products are classified:

- high - class A;

- regular - V.

In the manufacture of rolled products, GOST 8509-93 regulates the prevention of twisting of products along the axis. The coefficient of curvature of products should not exceed 0.4% of the length, and at the request of the customer - 0.2%. The shelves are at an angle of 90º.

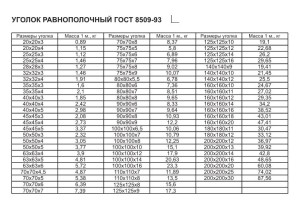

3 Corner and GOST - weight of a running meter

Another very important characteristic of angle bars is the weight of 1 linear meter. This value allows you to quickly convert the required amount of products, indicated by the footage, into its total weight. Knowledge of the mass of rolled metal is necessary when taking it into account at the time of payment and shipment, when choosing a method of delivery and transport. Weight data are even more important in the calculation of metal, building and other structures, as well as for solving other problems and issues.

To determine the weight of the settlement lot of the corner, you need to find out from the reference book specific gravity 1 m of the product with the corresponding values of the shelf width and metal thickness. This value is multiplied by the number of meters of corner products. The reference book indicates the theoretical value of the mass of 1 m, that is, calculated according to the nominal dimensions and the average value of the density of steel angle 7850 kg / m 3.

The actual value may vary slightly up or down. This, to a small extent, depends on the actual density of the steel grade from which the rolled product is made. And to a greater extent due to the actual dimensional characteristics of the angular profile, regulated by the accuracy class of the product. A table from the reference is given at the end of the article. It also indicates the number of meters of corner products in 1 ton of products.

4 Tolerances and deviations of the main characteristics of the corner

According to GOST 8509-93, deviations of the actual mass of 1 linear meter from the theoretical values should not exceed 3%. At the same time, the tolerances for the width, thickness, and length of the corner can add up to an error of up to 5%. Permissible width deviation (all dimensions in mm):

- width up to 45 - tolerance ±1;

- 50–90 - ±1.5;

- 100–150 – ±2;

- 160–200 - ±3;

- 220–250 - ±4.

By thickness in mm:

- for a shelf width up to 45 mm and a corner length up to and equal to 6 m - -0.3–+0.2 (class A), -0.4–+0.3 (B);

- 50–90 mm and 6 m inclusive – -0.4–+0.2 (A), –0.5–+0.3 (B);

- 50–90 mm and 6.5–9 m inclusive – -0.5–+0.2 (A), –0.6–+0.3 (B);

- 50–90 mm and over 9 m – -0.5–+0.3 (A), –0.6–+0.4 (B);

- 100–150 mm 6.5–9 m inclusive – -0.5–+0.3 (A), –0.6–+0.4 (B);

- 100–150 mm and over 9 m – -0.6–+0.3 (A), –0.7–+0.4 (B);

- 160–200 mm and over 9 m – -0.7–+0.4 (A), –0.8–+0.5 (B);

- 220–250 mm and over 9 m – -0.8–+0.4 (A), –0.9–+0.5 (B).

![]()

By agreement with the customer, it is possible to replace thickness deviations with the maximum mass tolerances:

- for corner numbers 2–7.5 inclusive - –5–+3% (A and B);

- after 7.5 – ±2.5% (A), –5–+3% (B).

The mutual arrangement of the shelves should not deviate from right angle at the top for more than 35 minutes. By agreement, the maximum deviation can be for the width of the shelf (all dimensions in mm):

- 1.0 - for products with a width of up to and equal to 50;

- 2.0 - more than 50 up to and equal to 100;

- 3.0 - more than 100 up to and equal to 200.

At the request of the customer, external corners (including at the top) must have a bluntness not exceeding the value:

- 0.3 shelf thickness - for products up to and equal to 10 mm thick;

- 3.0 mm - more than 10 up to and equal to 16 mm;

- 5.0 mm - over 16 mm.

5 Other references and specifications

Also in GOST 8509-93, reference values of the radii of curvature, cross-sectional area, distance from the outer edge of the shelf to the center of gravity of the corner, the moment and radius of inertia, and the centrifugal moment of inertia are indicated. Some values are used when calculating the rigidity and strength of metal structures that are going to be made from the selected corner products. And some of the parameters are necessary to adjust the caliber of the rolling equipment of the rolling mill.

The characteristics of the steel from which this type of angle is made provide it with good load resistance. various kinds at a relatively low cost. Due to this, hot-rolled corner products are used in almost all areas. Most widely - in construction for the creation of frame and other metal structures, as well as concrete reinforcement.

It should be noted that the corner has a low corrosion resistance. Therefore, if it is intended to be used in high or high humidity, then it is recommended to replace it with galvanized, stainless or maybe.

Weight of 1 running meter and number of meters per ton of angle bars GOST 8509-93

|

Dimensions |

Weight 1 m, kg |

Meters per ton |

|

|

Shelf width, mm |

Shelf thickness, mm |

||