Lathes made in Russia. Russian lathe. New Russian CNC lathe

The Russian-made lathe TS1625F3 is an analogue of 16A20F3 and is an industrial equipment designed for semi-automatic turning.

It is processing external and internal surfaces workpieces, which are bodies of revolution. The lathe allows you to work with curvilinear and stepped profiles of any complexity, as well as threading. Available in right and left hand threads different types- cylindrical, conical, frontal cylindrical-conical and others popular in Russia. The thread pitch can be constant and variable, and the machining can be done both in the centers and in the chuck.

Russian lathe equipped with a numerical system program control(CNC). Its design and capabilities make it possible to classify it as a universal metal cutting equipment, the need for which exists at many metalworking enterprises in Russia. It can be used in the production of steel, cast iron and many non-ferrous metals. This Russian CNC equipment shows itself well, both in single production and serial production.

Bed and cabinet of the Russian lathe TS1625F3

The Russian metal lathe has a powerful frame and base cast from durable cast iron. The width of the bed has been increased compared to previous models, providing several benefits. The weight of the machine has increased significantly, due to which the vibration level has decreased. A significant mass of metal provides an extremely high rigidity of the bed, and this made it an almost indestructible part of the machine.

In accordance with current trends in the machine tool industry, this Russian installation has wide guides, the surface of which is hardened by high frequency currents and ground. Thus, the durability of the guides is achieved, as a result of processing they have received high resistance to surface wear. Even after long-term operation in Russian production, the guides retain their surface.

The heavy cast bed of the lathe is placed on a solid base. It provides resistance to deformation during heavy cutting operations. In terms of the dimensions of the bed and pedestal, this Russian machine is close to Soviet-made machines. Thus, we tried to avoid the tendency to lighten the structure and reduce its strength characteristics.

The main actuator of the machine TS1625F3

The Russian lathe has a headstock that transmits high torque from the electric motor to the chuck with three speed ranges. For the production of the Russian machine, an improved spindle assembly with a hole with a diameter of 77 mm was used. The spindle assembly is mounted in reinforced double row radial roller bearings. Two bearings are located on both sides of the assembly, which contributes to rigidity and allows for clearance adjustment during operation. Additionally, the spindle of the Russian lathe is equipped with a double-row angular contact ball bearing. It is used in the production of metal parts with a large mass and dimensions. This design is aimed at long work with intense workloads. It has high precision, which is necessary for CNC lathes.

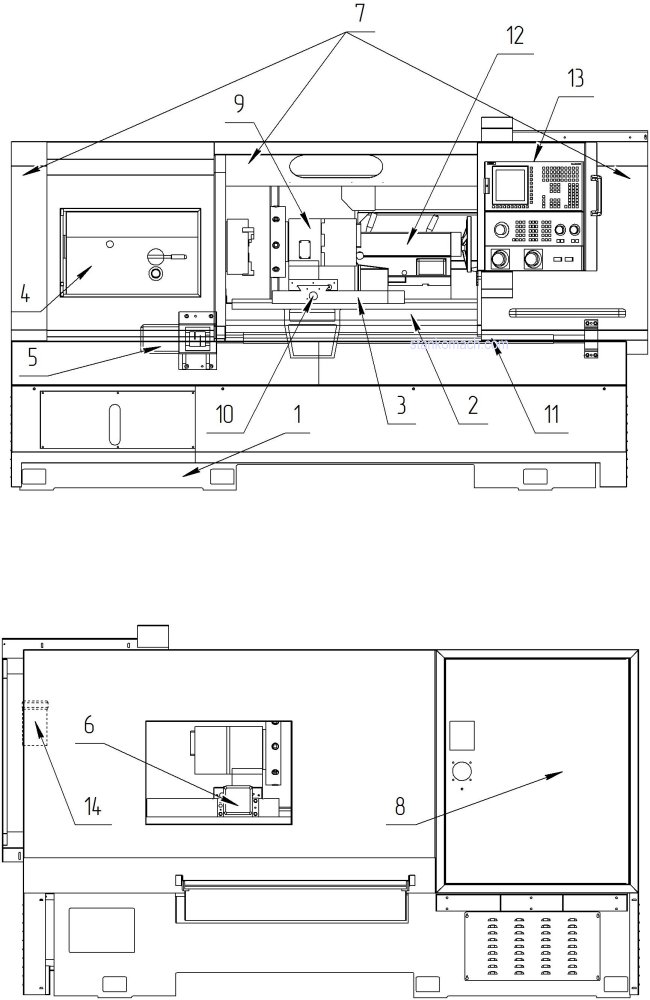

Main knots

1. Foundation

2. Bed

3. Caliper

4. Headstock

5. Longitudinal drive

6. Transverse drive

7. Fencing fixed and moving elements

8. Cabinet with electrical equipment

9. Turret

10. Screw ball pair of transverse movement

11. Screw ball pair of longitudinal movement

12. Grandma back

13. Control panel with CNC system

14. Centralized impulse lubrication system

The manufacturer of the machine also thought out the spindle lubrication system, without which a modern CNC device cannot work. The headstock houses a circulating lubrication system that supplies a pressurized lubricant jet to the gears and bearings. The circulation system delivers lubrication to all components and promotes heat dissipation, which increases the service life.

The Russian lathe, due to the large width of the guides, also has an enlarged tailstock base. The additional metal in this case provides the quills with additional rigidity, which is required when processing long shafts. A manufacturer from Russia has placed a new unloading system in the tailstock, which simplifies its movement along the frame.

Additional and optional systems of the Russian CNC lathe

The manufacturer of the Russian machine used enough effective scheme caliper. The longitudinal feed drive is driven by a precise servo motor, which is controlled by CNC. The drive is equipped with a backlash-free clutch and class C3 ball screw, which allows precise production of parts with a length of 1000 mm.

The Russian machine can be equipped with an additional three-jaw hydraulic chuck powered by a hydraulic station. This chuck has a diameter of 250mm and a bore of 65mm. Also, Russian CNC lathes are equipped with a hydraulic tailstock quill, which increases machine automation and productivity by reducing the time spent on auxiliary operations. Another way to improve productivity is to place a bar stock feeder. Max. product diameter over bed, mm

Full specification table

Equipment and options

| Basic equipment | Options |

|---|---|

| 1. CNC system Siemens Sinumerik 808D Advanced; 2. Automatic system lubrication of guides and ball screws; 3. Coolant supply system for each tool; 4. Lighting working area; 5. 8-position turret UG9326 6. 3-jaw chuck 250 mm 7. Tool kit for machine maintenance: Chuck clamp key; The key for removing the cartridge from the spindle; Adapter sleeve 90mm/KM5; Fixed center KM5 - 2 pcs; Set of keys: open-end 17/19,12/14; hex 3,5,6,8,10; Wedge shoe 6 pcs.; Anchor bolt М20х400 6 set. 8. traffic light indicating machine status |

CNC Siemens Sinumerik 828D Fanuc 0i mate FMS3000 hydraulic station Three-jaw hydraulic chuck with hole |

Terms of purchase and order

Universal with horizontal arrangement of guides of a bed. Rigid and reliable machines, well known to consumers and turners. The machines are fully assembled from new components produced in Russia and the CIS countries.

The 16K20 screw-cutting lathe is the most typical and widespread representative of the class of universal lathes. Designed for processing cylindrical, conical and complex surfaces - both internal and external, as well as for threading.

Processing diameter: 400 mm

Distance between centers: 1000, 1500 mm.

The 1M63 screw-cutting lathe is a widespread universal lathe that allows turning parts of medium and large sizes. Designed for processing cylindrical, conical and complex surfaces - both internal and external, as well as for threading.

Processing diameter: 630 mm

The 16K40 screw-cutting lathe is a universal lathe designed for processing medium and large parts. It is used for turning cylindrical, conical and complex surfaces - both internal and external, as well as for threading.

Processing diameter: 800 mm

RMC: 750, 1500, 2800, 5000, 8000, 10000 mm.

The 1M65 screw-cutting lathe is a universal lathe designed for processing medium and large parts. It is used for processing cylindrical, conical and complex surfaces - both internal and external, as well as for threading.

Processing diameter: 1000 mm

RMC: 1000, 3000, 5000, 6000, 8000, 10000, 12000 mm.

The PT317 screw-cutting lathe is a universal lathe designed for processing large parts. It is used for processing cylindrical, conical and complex surfaces - both internal and external, as well as for threading.

Processing diameter: 1700 mm

RMC: 1000, 3000, 4800, 6000, 8000, 10000, 12000, 16000mm

Lathes made in Russia

Lathes made in Russia find their application both in single and small-scale production. These are the easiest machines to operate and maintain, which do not require highly skilled operators. Universal machines are characterized by frequent tool change and changeover for processing different types details.

Machine tool accuracy

Lathes made in Russia according to accuracy are divided into five classes:

- H - normal accuracy - this is the majority of lathes;

- P - increased accuracy;

- B - high accuracy;

- A - especially high accuracy;

- C - especially precise, or master machines.

lathe sledge Russian production- This is a fairly relevant product in the market of equipment for metalworking. IN last years there is a tendency to increase the requirements for the accuracy of machining parts.

New alloys and materials, the need for precise cutting and sharpening led to the improvement of existing models and caused an increase in their cost. Affordable price and high quality have become the main factors in the growth of demand for domestic turning equipment.

Advantages of Russian machines

Russian lathes have high quality standards:- The machines are designed for processing workpieces from any materials, with a high degree of accuracy;

- High productivity of machine tools reduces the cost of finished products;

- Russian equipment is reliable in operation and serves for a long time without breakdowns and repairs;

- A large percentage of Russian analogues, in comparison with foreign machines, have best performance power, speed and vibration resistance;

- If repairs are needed, spare parts for domestic equipment are always available;

- Affordable price. This is one of the most important advantages of lathes produced at machine-building enterprises in Russia.

Price for Russian analogues

The advantage of domestic equipment is eloquently emphasized by Russian metal lathes. The price of similar equipment from Russian suppliers is significantly lower than from American ones. When processing workpieces 400 - 650 mm, Russian equipment is the leader in terms of power and speed.It is also cost-effective to attach devices to expand the functionality of a domestically produced machine. The use of local fixtures reduces the cost of grinding, milling, turning and drilling radial holes.

Where to buy a Russian lathe

In our Trading House a wide range of Russian turning equipment. The company's specialists offer not only high-quality products, but also help in choosing the right model.Regardless of whether you are buying a small desktop or a powerful industrial machine, we will arrange a sale with delivery in Moscow and other Russian cities.

We only sell competitive products High Quality, at the lowest price.