Horizontal milling machine for metal. CNC milling machine. The main advantages of CNC horizontal milling machines

In the manufacture of various metal parts, it is almost impossible to do without the use of. What is convenient, a milling machine for metal work is equally successfully used both in production conditions and in home workshops. It should be noted that the equipment of this category is the most common in the field of metalworking.

Almost all modifications milling equipment work on a similar principle and have a similar design. The differences between the models of such machines may lie in their functionality, which is formed by adding additional components and systems to their design.

Varieties of milling machines

We list the main types of milling machines, each variety of which sometimes differs significantly from its counterparts and has a lot of differences in design and in its working purpose.

Vertical millingA fairly common type of machine in this category is a vertical milling machine. The working tools for such machines are shaped, cylindrical, end mills, you can also perform drilling operations. The vertical milling machine allows you to perform the following technological operations: processing gears and various grooves, corners, frame elements, vertical and horizontal surfaces on parts made of various metals.

Milling machines of this type do not have a console in their design, and their desktop moves along the guides located on the equipment frame. Due to the peculiarities of its design, the vertical type machine is characterized by high rigidity, which makes it possible to process metal parts on it with high level quality. The gearbox of such a milling machine is located in the spindle head.

Vertical milling machines are divided into two categories, distinguished by the presence of a console in the design. Their names are respectively:

- consoleless vertical milling machines;

- vertical console milling machines.

With the console, it differs in that its spindle and sleeve can move relative to the axis of the equipment. The differences in their design can be clearly seen in the photo.

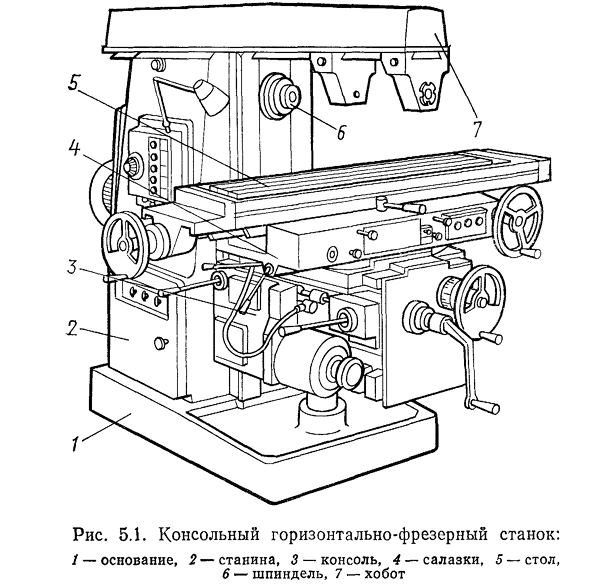

Horizontal milling

The horizontal milling machine is notable for the fact that its spindle is located in a horizontal plane. The equipment of this group allows processing parts that have small overall dimensions. Versatility this machine provided due to the fact that as a working tool it uses cutters end, cylindrical, shaped, end and corner type. The horizontal milling machine in its standard configuration does not allow processing the part along the helical surface, for this it must be equipped with auxiliary devices.

The device of the machines of the horizontal milling group allows you to install their desktop in parallel, as well as perpendicular to the spindle axis. All working and power units of this equipment are located on the frame, and the gearbox, which controls the speed of rotation of the spindle, is located in its inner part.

Drilling and millingMachines belonging to the category of drilling and milling are designed to process not only horizontal and vertical surfaces, but also inclined. They are also used to process the grooves of large-sized parts.

Such a metal milling machine has a drilling and milling head that allows you to perform tilted drilling operations and machine surfaces located at an angle to the horizontal axis. A distinctive feature of such a machine is that its working head can operate in reverse mode.

Due to their versatility, due to the ability to carry out the two most popular operations, such machines are very beneficial from an economic point of view, as well as in terms of saving space in the production area. Few of the home craftsmen will refuse to have such a machine at home, since such an apparatus combines several effective and useful devices in its design at once.

UniversalSuch metalworking machines are very convenient to use to equip private workshops or medium-sized workshops specializing in mechanical repair work. Universal machines allow processing of horizontal and vertical planes, as well as surfaces of a spiral type and stamps.

Such a machine for metal differs next design features: spindle assembly, box, as well as the main nodes are located in the inside of the bed. The design of the machine provides vertical and horizontal guides along which its console and desktop move. The working surface, in addition, can be set in relation to the equipment spindle at the desired angle, which allows it to process metal parts with even the most complex configuration.

Desktop

Such a very compact equipment installed at home, in workshops educational institutions and in small production shops, allows you to perform various technological operations: cut threads, drill holes, process all kinds of parts and materials various types cutters and more.

This type is distinguished by good accuracy, since their design has exceptional rigidity (of course, with proper installation). Such console milling machines are distinguished by high productivity, which makes it possible to use them for the production of products in batches. Despite their high performance and wide functionality, such machines are distinguished by low power consumption and compact size, which allows them to be conveniently placed even in a small area.

Such devices are actively used in various industries in the mass production of high-quality parts. CNC machines are highly productive and able to provide unsurpassed quality not in a single copy, but on a stream, which makes them indispensable equipment in any major industry. The differences between such machines from all other types of milling machines are so significant that they require detailed analysis in a separate article.

CNC machines that process parts from various metals with high productivity and accuracy have one big drawback: a decent cost, but it is fully compensated by the following positive factors:

- reducing the need for qualified specialists in production;

- high productivity relative to manual machines;

- reduction of the term of production cycles;

- accelerate the transition to the production of new products.

The difference between such devices and the previous type of milling machines lies in even greater versatility, even higher accuracy and speed. The range of work that such devices can perform includes a huge list of operations and processes that are in demand in the most high-tech and responsible industries. Modern software for machining centers is produced by large global companies. The work of machining centers will be discussed in detail in a separate article.

Desktop CNC

A separate category is made up of types of milling machines equipped with CNC (computer numerical control). Such equipment belongs to the category of professional, its operation is controlled by special controllers that must be connected to a computer device. Like other types of milling machines, CNC models can perform various technological operations on metal: drilling, countersinking, boring, etc.

Having at your disposal such a machine, you can perform any kind of milling operations with almost any material. If we compare a horizontal milling machine and a universal type machine, then its main difference is that its design provides for an additional spindle head, which is mounted on a special movable trunk and can be rotated at any angle with respect to the workpiece.

Conveniently, both spindles of such a machine can process parts both jointly and offline. Another overhead milling head can also be installed on the swivel head, with which you can process metal parts of an even more complex configuration - drilling, boring, countersinking, and so on.

There are also models of wide-purpose machines that do not have a console panel in their design. Instead, a carriage is installed that moves along vertical guides. On the vertical slide of this carriage, various devices can be used (for example, a dividing table). Such machines are somewhat cheaper, but are also capable of performing a fairly large list of technological tasks.

When choosing a milling machine, first of all, you need to decide what it is for. This approach to choosing equipment will give you the opportunity to purchase it in full accordance with your needs, and also not to overpay for features that you will never need.

The principle of operation of milling machines

Almost all milling machines work on the same principle. Differences can only be in their functionality.

The main structural elements of such machines are: a supporting frame, a work table, clamping elements, a collet and a collet chuck in which a working tool is fixed, a portal with a spindle fixed on it, which can move, a drive motor.

The working tool of any milling machine is a cutter, the design and dimensions of which depend on the configuration of the part to be processed. The working tool is fixed in the collet chuck with the help of a shank, and the rotation is transmitted to it from the drive motor through the gear system. The main purpose of the cutter is to remove an excess layer of metal from the workpiece, which, in fact, is the essence of processing on such a machine.

The machine spindle is placed on a movable portal, the movements of which are controlled by special controllers, if we are talking about CNC equipment. The electronic system of such equipment includes CNC controllers (numerical program control), auxiliary elements of the system and connecting parts. The principle of operation of CNC machine models is as follows: a special program reads the drawings of the part to be obtained as a result of processing, generates electronic commands that are transmitted to the working body of the machine.

Special attention should be paid to universal machines, which are a hybrid of horizontal and vertical models. Their design also has a collet, collet chuck and clamps, but the gearbox of such machines transmits all movements from one electric motor. Them distinctive feature is the presence of a manual mode, with which you can control the operation of the running block.

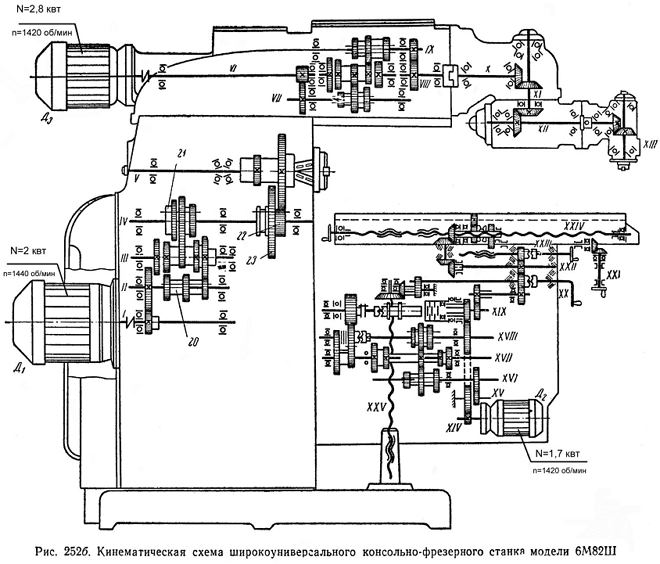

Example of a kinematic diagram (cantilever milling machine)

Additional elements have five-coordinate and engraving equipment in their design. Such equipment is equipped with additional clamping elements that allow you to install an engraver on it. The tool of such equipment rotates due to the cardan shaft, with which it is directly connected to the electric motor.

The simplest in design are manual milling machines for metal. Such equipment has low power, and its design consists of a collet with a collet chuck, a rotor, a drive head and an electric motor. Naturally, the functionality of such a machine is also limited: it can only be used to perform the most simple milling operations.

The resource of work, which the machine of the milling group of a manual type has, is also low and amounts to no more than 10,000 hours. The weakest components in such equipment, which are the first to fail, are the collet and collet chuck, clamps, attachment and spindle. But its low reliability and durability is fully compensated by the low cost. It makes sense to acquire it if you plan to use it irregularly.

Machine cost

The classification of milling machines according to their cost is quite extensive. Naturally, the cheapest models on this list are models from Chinese manufacturers. You can save even more on the purchase of such equipment if you buy it not through intermediaries, but directly from manufacturers. Which is convenient, manufacturers from China offer both the simplest manual machines, and professional, equipped with CNC. If we consider the minimum range of prices, then it varies between 7000-35000 rubles.

Chinese desktop drilling and milling machine Triod MMS-20E (cost about 60 thousand rubles)

A vertical machine will cost you quite a lot, the cost of such equipment starts from 20,000 rubles. Moreover, at this price you will purchase a machine with the simplest configuration: collet and collet chuck, clamps, attachment, spindle.

If you are considering purchasing for your manufacturing enterprise wide universal machine, then get ready for the fact that the price of such equipment starts from 250,000 rubles. Milling machines for metal work, which are equipped with CNC, cost starting from 2 million rubles.

In any case, if you set a goal, you can purchase a high-quality milling machine for metal of a serial model at a very attractive cost.