Gasification of wood. Wood gasification Biomass resources for gasification

Gas generator car

During World War II in Europe, almost every vehicle was converted to use wood as fuel.

Cars running on wood gas(also called g gas generator vehicles) although they lose their elegance in appearance, they are very effective compared to their gasoline counterparts in terms of environmental friendliness and can be equal to electric cars.

Rising fuel prices are leading to renewed interest in this almost forgotten technology: all over the world, dozens of hobbyists are driving around city streets in their homemade gas-powered cars.

Process of gasifier gas formation (gas synthesis), in which organic material is converted into a flammable gas, begins to occur under the influence of heat at a temperature of 1400 °C.

The first use of wood to create flammable gas dates back to 1870, when it was used for street lighting and cooking.

In the 1920s, a German engineer Georges Humbert developed generator, generating wood gas for mobile use. The resulting gas was purified, cooled slightly, and then fed into the combustion chamber of the car engine, while the engine practically did not need modification.

Since 1931, mass production of Embera generators began. At the end of the 1930s, already about 9,000 vehicles used gas generators exclusively in Europe.

The Second World War

Gas-generating technologies became common in many European countries during World War II, due to restrictions and shortages of fossil and liquid fuels. In Germany alone, by the end of the war, about 500,000 cars were retrofitted with gas generators to run on wood gas.

Gas-generating civilian cars from World War II

About 3,000 “gas stations” were built where drivers could stock up on firewood. Not only cars, but also trucks, buses, tractors, motorcycles, ships and trains were equipped with gas generators. Even some tanks were equipped with gas generators, although for military purposes the Germans produced liquid synthetic fuels (made from wood or coal).

500,000 gas-powered civilian vehicles by the end of the war in Germany

In 1942 (when the technology had not yet reached the peak of its popularity), there were about 73,000 gas-powered cars in Sweden, 65,000 in France, 10,000 in Denmark, 9,000 in Austria and Norway, and almost 8,000 in Switzerland. There were 43,000 gas-powered vehicles in Finland in 1944, of which 30,000 were buses and trucks, 7,000 cars, 4,000 tractors and 600 boats.

Gas-powered cars also appeared in the US and Asia. There were approximately 72,000 gas-powered vehicles in Australia. In total, more than a million wood gas vehicles were in service during World War II.

After the war, when gasoline became available again, gas generator technology almost immediately fell into oblivion. At the beginning of the 1950s, only about 20,000 gas generators remained in West Germany.

Research program in Sweden

Rising fuel prices and global warming have led to renewed interest in wood as a direct fuel source. Many independent engineers around the world have been busy converting standard vehicles to use wood gas as a vehicle fuel. It is characteristic that most of these modern gas generators are being developed in Scandinavia.

In 1957, the Swedish government created a research program to prepare for the possibility of quickly switching cars to wood gas in the event of a sudden oil shortage. Sweden has no oil reserves, but it has huge forests that can be used as fuel. The goal of this study was to develop an improved, standardized installation that can be adapted for use on all types of vehicles. This research was supported by the car manufacturer Volvo. As a result of studying the operation of cars and tractors over a length of 100,000 km, great theoretical knowledge and practical experience were obtained.

Some Finnish amateur engineers have used this data to further develop the technology, such as Juha Sipilä (pictured left).

A wood gas generator looks like a large water heater. This unit can be placed on a trailer (although this makes parking the car difficult), in the trunk of a car (takes up almost the entire luggage compartment) or on a platform at the front or rear of the car (the most popular option in Europe). On American pickup trucks, the generator is placed in the bed. During World War II, some vehicles were equipped with a built-in generator, completely hidden from view.

Fuel for gas generator

Fuel for gas-powered vehicles consists of wood or wood chips (photo on the left). Charcoal can also be used, but this results in a loss of up to 50 percent of the energy contained in the original biomass. On the other hand, coal contains more energy due to its higher calorific value, so the range of fuels can be varied. In principle, any organic material can be used. During World War II, coal and peat were used, but wood was the main fuel.

Dutch Volvo 240

One of the most successful gas-generating cars was built in 2008 by the Dutchman John. Many cars equipped with gas generators were bulky and not very attractive. The Dutch Volvo 240 is equipped with a modern stainless steel gas generator system and has a modern, elegant look.

“Wood gas isn't that hard to make,” John says, but pure wood gas is much more difficult to make. John has many complaints about automobile gas generator systems, since the gas they produce contains many impurities.

John from Holland firmly believes that gas generating units producing wood gas are much more promising for stationary use, for example, for space heating and for domestic needs, for electricity generation, and for similar industries. The Volvo 240 gas generator vehicle is designed primarily to demonstrate the capabilities of gas generator technology.

A lot of admiring and interested people always gather near John's car and near similar gas-generating cars. Nevertheless, automobile gas generator units are for idealists and for times of crisis, says John.

Technical capabilities

The gas-powered Volvo 240 reaches a top speed of 120 kilometers per hour (75 mph) and can maintain a cruising speed of 110 km/h (68 mph). The “fuel tank” can contain 30 kg (66 lb) of wood, enough for about 100 kilometers (62 miles), comparable to an electric car.

If the rear seat is loaded with bags of wood, the range increases to 400 kilometers (250 miles). Again, this is comparable to an electric car if passenger space is sacrificed to install additional batteries, as is the case with the Tesla Roadster or Mini Cooper electric car. (In addition to everything else in a gas generator, you periodically need to take a bag of wood from the back seat and pour it into the tank).

Trailed gas generator

There is a fundamentally different approach to retrofitting cars with gas generator systems. This is a method of placing gas on a trailer. Vesa Mikkonen took this approach. His latest work is the gas-powered Lincoln Continental 1979 Mark V, a large, heavy American coupe. The Lincoln consumes 50 kg (110 lb) of wood for every 100 kilometers (62 miles) driven and is significantly less fuel efficient than John's Volvo. Wes Mikkonen also converted a Toyota Camry, a more fuel-efficient car. This car consumes only 20 kg (44 lb) of wood for the same mileage. However, the trailer remained almost as large as the car itself.

Optimization of electric vehicles can be achieved by reducing the size and reducing the overall weight. This method does not work with its cousins gas-generating cars. Although since World War II, gas-powered cars have become much more advanced. Wartime cars could travel 20 - 50 kilometers on one gas station and had low dynamic and speed characteristics.

Jost Konin's gas generator wooden car

“Move around the world with a saw and an axe,” was the motto of Dutchman Joost Conijn, who took his gas-powered car and trailer on a two-month trip across Europe without worrying about gas stations (which he didn’t see in Romania).

Although the trailer in this car was used for other purposes, to store an additional supply of firewood, thereby increasing the distance between “refuelings”. Interestingly, Jost used wood not only as fuel for the car, but also as a building material for the car itself.

In the 1990s, hydrogen was considered as an alternative fuel of the future. Then great hopes were placed on biofuels. Later, the development of electrical technologies in the automotive industry attracted much attention. If this technology does not receive further continuation (there are objective prerequisites for this), then our attention will again be able to switch to gas-generating cars.

Despite the high development of industrial technologies, the use of wood gas in cars is of interest from an environmental point of view, compared to other alternative fuels. Wood gasification is somewhat more efficient than conventional wood combustion, since conventional combustion loses up to 25 percent of the contained energy. When using a gas generator in a car, energy consumption increases by 1.5 times compared to a car running on gasoline fuel (including losses for preheating the system and an increase in the weight of the car itself). If we take into account that the energy necessary for needs is transported and then produced from oil, then gasification of wood remains effective compared to gasoline. It should also be taken into account that wood is a renewable source of energy, while gasoline is not.

Advantages of gas generator cars

The biggest advantage of natural gas vehicles is that they use renewable fuel without any pre-treatment. And converting biomass into liquid fuels such as ethanol or biodiesel can require more energy (including CO2) than is contained in the original feedstock. In a gas-powered vehicle, no energy is used to produce fuel, except for cutting and chopping wood.

A gas-generating car does not need powerful chemical batteries and this is an advantage over an electric car. Chemical batteries tend to self-discharge and you must remember to charge them before use. Devices that produce wood gas are, as it were, natural batteries. There is no need for high-tech processing of used and faulty chemical batteries. The waste product from the gas generator plant is ash, which can be used as fertilizer.

A properly designed automotive gas generator causes significantly less air pollution than a gasoline or diesel vehicle.

Wood gasification is much cleaner than direct wood combustion: emissions into the atmosphere are comparable to those from burning natural gas. During operation, an electric car does not pollute the atmosphere, but later, to charge the batteries, you need to apply energy, which is currently extracted in the traditional way.

Disadvantages of gas-generating cars

Despite the many advantages in operating gas-generating vehicles, it should be understood that this is not the most optimal solution. The installation that produces gas takes up a lot of space and weighs several hundred kilograms - and this entire “plant” has to be carried with you and on yourself. Gas equipment is large due to the fact that wood gas has a low specific energy. The energy value of wood gas is about 5.7 MJ/kg, compared to 44 MJ/kg for gasoline and 56 MJ/kg for natural gas.

When running on natural gas, it is not possible to achieve speed and acceleration as with gasoline. This is because wood gas is made up of approximately 50 percent nitrogen, 20 percent carbon monoxide, 18 percent hydrogen, 8 percent carbon dioxide and 4 percent methane. Nitrogen does not support combustion, and carbon compounds reduce the combustion of gas. Due to the high nitrogen content, the engine receives less fuel, resulting in a 30-50 percent reduction in power. Due to the slow combustion of gas, high speeds are practically not used, and the dynamic characteristics of the car are reduced.

Opel Cadet equipped with a gas generator unit

Cars with a small engine capacity can also be equipped with wood gas generators (for example, the Opel Kadett in the picture above), but it is still better to equip large cars with powerful engines with gas generators. On low-power engines, in some situations, there is a severe lack of engine power and dynamics.

The gas generating unit itself can be made smaller for a small car, but this reduction will not be proportional to the size of the car. Gas generators have also been designed for motorcycles, but their overall dimensions are comparable to a motorcycle sidecar. Although this size is significantly smaller than devices for a bus, truck, train or ship.

Ease of use of a gas generator vehicle

Another known problem with gas-powered cars is that they are not very user-friendly (although they have improved greatly over the technology used during the war). However, despite the improvements, a modern gas generator takes about 10 minutes to reach operating temperature, so you won't be able to get into your car and drive away immediately.

In addition, before each subsequent refueling, it is necessary to remove the ash with a spatula - waste from the previous combustion. Resin formation is no longer as problematic as it was 70 years ago, but even now it is a very critical moment, since filters must be cleaned regularly and efficiently, which requires additional frequent maintenance. In general, a gas-powered car requires additional hassle that is completely absent in the operation of a gasoline car.

High concentrations of deadly carbon monoxide require additional precautions and monitoring against possible pipeline leaks. If the installation is located in the trunk, then you should not skimp on the CO sensor in the car. You cannot start the gas generating system in a room (garage), since there must be an open flame when starting up and entering the operating mode (picture on the left).

Mass production of gas-powered cars

Gas generator Volkswagen Beetle produced at the plant

All vehicles described above were built by amateur engineers. It can be assumed that if it had been decided to produce gas-generating cars professionally in factory conditions, then, most likely, many of the shortcomings would have been eliminated, and there would have been more advantages. Such cars could look more attractive.

For example, in factory-produced Volkswagens during World War II, the entire gas-generating mechanism was hidden under the hood. On the front side of the hood there was only a hatch for loading firewood. All other parts of the installation were not visible.

Another option for a factory-produced gas generator car is Mercedes-Benz. As you can see in the photo below, the entire gas generator mechanism is hidden under the trunk hood.

Deforestation

Unfortunately, the increased use of wood gas and biofuels may create a new problem. And mass production of gas-powered cars could make this problem worse. If we start to significantly increase the number of cars using wood gas or biofuel, the supply of trees will begin to decline by the same amount, and agricultural land will be sacrificed to grow biofuel crops, which could lead to famine. The use of gas generating equipment in France during World War II caused a sharp decrease in forest reserves. Likewise, other biofuel production technologies lead to a decrease in the cultivation of plants useful to humans.

Although, the presence of a gas-generating car may lead to its more moderate use:

warm up the gas generator for 10 minutes or use a bicycle to go to the grocery store - most likely the choice will be made in favor of the latter;

chopping wood for 3 hours for a trip to the beach or taking the train - the choice will probably be in favor of the latter.

You need to spend at least 10 minutes to start and warm up the gas generator

Be that as it may, gas-powered cars are no match for petrol and diesel cars. Only a global shortage of oil or a very large increase in its price can force us to switch to a gas-generating car.

Based on materials from: sintezgaz.org.ua

gas generator, DIY gas generator, Gas generator, household gas generators, generator, gas generator car

Ecology of knowledge. Science and technology: A homemade wood-burning gas generator, made with your own hands, is best used in conjunction with an internal combustion engine. That is why home craftsmen adapt it to generate electricity at home, or even install it on a car.

The wood-burning internal combustion engine is not a ghost from the distant past. Cars and power plants using wood as an energy source can still be found today. It is worth clarifying: the engine operates on gas obtained from wood by burning it in a certain way. Installations that produce such gas are called gas generators; they have been used in industrial enterprises for quite a long time. But is it possible to make a gas generator with your own hands and is it worth doing? These are the questions that our article aims to answer.

How does a gas generator work?

To understand what benefits a gas generator can have in a household, you need to understand its operating principle, and then its structure. Then it will be possible to estimate the costs of its production, and most importantly, what kind of result will be obtained.

So, a pyrolysis gas generator is a complex of components and assemblies designed to separate a mixture of combustible gases from solid fuel for the purpose of its use in internal combustion engines.

For reference. The designs of generators differ from each other depending on the type of solid fuel burned; we will consider the most relevant of them - wood-burning.

If wood is burned in a closed space, limiting the supply of oxygen, then the output can be a mixture of combustible gases. Here is their list:

- carbon monoxide (carbon monoxide CO);

- hydrogen (H2);

- methane (CH4);

- other unsaturated hydrocarbons (CnHm).

Note. The mixture also contains non-flammable ballast gases: carbon dioxide (carbon dioxide), oxygen, nitrogen and water vapor.

An effective wood gas generator must not only produce a combustible mixture, but also make it suitable for use. Therefore, the entire cycle of obtaining fuel for internal combustion engines can be safely called a technological process consisting of the following stages:

- gasification: wood does not even burn, but smolders when the amount of oxygen supplied is 33-35% of that required for complete combustion;

- primary rough cleaning: volatile particles of combustion products produced by wood gas generators after the first stage are separated using a dry vortex filter - a cyclone;

- secondary rough cleaning: carried out in a scrubber - purifier, where a flow of fuel is passed through water;

- cooling: combustion products with temperatures up to 700 ºС pass through it in an air or water heat exchanger;

- fine cleaning;

- sending to the consumer: this can be pumping fuel by a compressor into the distribution tank or supplying it to the mixer, and then directly to the internal combustion engine.

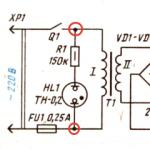

You can consider the design and operating principle of an industrial gas generator in the technological diagram presented below:

The full gas production cycle is quite complex, since it includes several different installations. The most basic one is a gas generator, which is a metal column of cylindrical or rectangular shape, narrowing downwards. The column has pipes for air and gas outlet, as well as an access hatch to the ash pit. The unit is equipped with a lid on top for loading fuel; the chimney is not connected to the body; it is simply missing. The combustion and pyrolysis process taking place inside the column is well reflected by the gas generator diagram:

Without going into the intricacies of the chemical reactions taking place inside the column, we note that the mixture of gases described above is obtained at the exit from it. Only it is contaminated with particles and combustion byproducts and has a high temperature. Having studied the drawings of gas generators of any design, you will notice that all other equipment is designed to bring gas back to normal. Air is forced into the combustion zone by a traction or blowing machine (in simple words - a fan).

It must be said that a homemade wood-burning gas generator is made by home craftsmen with a less complex design and the technology for releasing gas in it is somewhat simplified, which will be discussed below.

Myths about gas generators

On the Internet there are often many unsubstantiated claims about the operation of such units and conflicting information is given about the use of gas generators. Let's try to dispel all these myths.

The first myth sounds like this: the efficiency of a gas generator unit reaches 95%, which is disproportionately greater than that of solid fuel boilers with an efficiency of 60-70%. Therefore, heating a house with its help is much more profitable. The information is incorrect from the outset; you cannot compare a household gas generator for a home and a solid fuel boiler; these units perform different functions. The task of the first is to produce flammable gas, the second is to heat water.

When talking about generating equipment, its efficiency is the ratio of the amount of product obtained to the volume of gas, which can theoretically be isolated from wood, multiplied by 100%. Boiler efficiency is the ratio of the generated thermal energy of wood to the theoretical calorific value, also multiplied by 100%. In addition, not every biogas plant, let alone a gas generator, can extract 95% of combustible fuel from organic matter.

Conclusion. The essence of the myth is that they are trying to compare mass or volume with units of energy through efficiency, and this is unacceptable.

It is easier and more efficient to heat a house with a conventional pyrolysis boiler, which in the same way releases flammable gases from wood and immediately burns them using the supply of secondary air to an additional combustion chamber.

The second myth is that you can put fuel of any moisture content into the bunker. You can load it, but only the amount of gas released drops by 10-25%, or even more. In this regard, the ideal option is a gas generator that runs on charcoal, which contains almost no moisture. And so the thermal energy of pyrolysis is spent on the evaporation of water, the temperature in the furnace drops, and the process slows down.

Myth three – the cost of heating a building is reduced. This is not difficult to check; just compare the cost of a wood-burning gas generator and a conventional solid fuel boiler, also made by yourself. Plus you need a water heating device that burns wood gases, for example, a convector. Finally, operating this entire system will take a lot of time and effort.

Conclusion. A homemade wood-burning gas generator, made with your own hands, is best used in conjunction with an internal combustion engine. That is why home craftsmen adapt it to generate electricity at home, or even install it on a car.

Automotive gas generator

You need to understand that a gas generator for a car must be quite compact, not too heavy and at the same time efficient. Foreign colleagues, whose incomes are much higher than ours, make the generator housing, cyclone and cooling filter from stainless steel. This allows you to take half the thickness of the metal, which means the unit will come out much lighter. In our realities, pipes, old propane cylinders, fire extinguishers and other available materials are used to assemble a gas generator.

Below is a drawing of a gas generator installed on old UralZIS-352 trucks, and you should use it to guide you when assembling the unit:

Our craftsmen most often make the outer tank from liquefied propane cylinders; the inner tank can be made from the receiver of a ZIL or KamAZ truck. The grate is made of thick metal, the pipes are made of the corresponding pipe diameter. The lid with clamps can be made from the cut off top of the cylinder or from sheet steel. The lid seal is made of asbestos cord with graphite impregnation.

A coarse filter - a cyclone for cars - is made from an old fire extinguisher or a simple piece of pipe. At the bottom of the pipe there is a conical nozzle with a fitting for unloading ash, and at the top the end is closed with a tightly welded lid. The outlet pipe for purified gases is cut into it, and on the side there is a second fitting where combustion products will be supplied. The functional cross-sectional diagram of the cyclone is shown in the figure:

Since a car gas generator produces gases at high temperatures, they need to be cooled. There are two reasons:

- hot gaseous fuel has too low a density and it will not be easy to ignite it in the cylinders of an internal combustion engine;

- There is a danger of spontaneous outbreak when contacting hot surfaces of the motor.

The movement of gases throughout the entire path during ignition is ensured by a fan, and after starting the engine, the necessary vacuum appears in the system, the fan turns off.

For cooling, craftsmen use ordinary finned heating radiators, placing them on the car in such a way that they are blown with air as much as possible while driving. Sometimes modern bimetallic radiators are even used. Before entering the gas generator engine, the fuel requires fine cleaning; for this, various types of filters are used at their discretion. All nodes are combined into one installation in accordance with the diagram:

And the last part is the mixer, which is needed to regulate the proportions of the gas-air mixture. The fact is that wood gas has a calorific value of only 4.5 MJ/m3, while natural gas used in cars has a calorific value of as much as 34 MJ/m3. Therefore, the proportions of fuel and air must be different and will need to be adjusted using a damper.

Conclusion

Despite the attractiveness of the idea of burning wood instead of gasoline, in modern conditions it is practically unviable. Long ignition, driving at medium and high speeds, which affects the life of the internal combustion engine, lack of comfort - all this makes existing installations ordinary curiosities that are not widely used. But making a gas generator for a home power plant is a completely different matter. A stationary unit together with a converted diesel internal combustion engine can be an excellent option for powering a home. Published

Let's make a reservation right away: if a car runs on wood, this does not mean that it is a steam locomotive without rails. The low efficiency of the steam engine with its separate firebox, boiler and double-triple expansion cylinders left steam cars among the forgotten exotics. And today we will talk about “wood-burning” transport with the familiar internal combustion engines, motors that burn fuel inside themselves.

Of course, no one has yet succeeded in pushing wood (or something similar) into a carburetor instead of gasoline, but the idea of obtaining flammable gas from wood directly on board the car and feeding it into the cylinders as fuel has caught on for many years. We are talking about gas-generating cars, cars whose classic internal combustion engines run on generator gas, which is obtained from wood, organic briquettes, or coal. By the way, such machines also do not refuse the usual liquid fuel - they can also run on gasoline.

Holy simplicity

Producer gas is a mixture of gases consisting mainly of carbon monoxide CO and hydrogen H2. Such gas can be obtained by burning wood placed in a thick layer under conditions of a limited amount of air. An automobile gas generator, an essentially simple unit, but bulky and structurally complicated by additional systems, works on this simple principle.

Also, in addition to the actual production of generator gas, an automobile gas generator unit cools it, purifies it and mixes it with air. Accordingly, the design of the classic installation includes the gas generator itself, coarse and fine filters, coolers, an electric fan to speed up the ignition process and pipelines.

I take the refinery with me

The simplest gas generator has the form of a vertical cylinder into which fuel is loaded almost to the top - firewood, coal, peat, pressed pellets, etc. The combustion zone is located below, it is here, in the lower layer of burning fuel, that a high temperature is created (up to 1,500 degrees Celsius), necessary for the separation of future components of the fuel mixture - carbon monoxide CO and hydrogen H2 - from the upper layers. Next, the hot mixture of these gases enters the cooler, which reduces the temperature, thus increasing the specific calorie content of the gas. This rather large unit usually had to be placed under the car body. A filter-cleaner located next to the gas flow removes impurities and ash from the future fuel mixture. Next, the gas is sent to the mixer, where it is combined with air, and the finally prepared mixture is sent to the combustion chamber of the car engine.

Diagram of a ZIS-21 car with a gas generator

As you can see, the fuel production system directly on board a truck or car took up quite a lot of space and weighed a lot. But the game was worth the candle. Thanks to their own - and also free - fuel, enterprises located hundreds and thousands of kilometers from fuel supply bases could afford their own autonomous transport. For a long time, this advantage could not overshadow all the shortcomings of gas-generating vehicles, and there were many of them:

— significant reduction in mileage per fill-up;

— reduction of the vehicle’s carrying capacity by 150-400 kg;

— reduction in the useful volume of the body;

— the troublesome process of “refueling” a gas generator;

— an additional set of routine maintenance work;

— starting the generator takes 10-15 minutes;

- significant reduction in engine power.

ZiS 150UM, experimental model with gas generator unit NAMI 015UM

There are no gas stations in the taiga

Wood has always been the main fuel for gas-powered vehicles. First of all, of course, where there is an abundance of firewood - in logging, in furniture and construction production. Traditional wood processing technologies for the industrial use of wood in the era of the heyday of “gasgens” used to waste about 30% of the forest mass. They were used as automobile fuel. It is interesting that the rules for the operation of domestic “gasgens” strictly prohibited the use of industrial wood, since there was an abundance of waste from the forestry industry. Both soft and hard woods were suitable for gas generators.

The only requirement is that there is no rot on the chocks. As shown by numerous studies conducted in the 30s at the Scientific Automotive and Tractor Institute of the USSR, oak, beech, ash and birch are best suited as fuel. The lumps with which gas generator boilers were fueled most often had a rectangular shape with a side of 5-6 centimeters. Agricultural waste (straw, husks, sawdust, bark, pine cones, etc.) was pressed into special briquettes and gas generators were also “filled” with them.

The main disadvantage of gas engines, as we have already said, is their low mileage per fill-up. So, one load of wood logs on Soviet trucks (see below) was enough for no more than 80-85 km. Considering that the operating manual recommends “refueling” when the tank is 50-60% empty, the mileage between refills is reduced to 40-50 km. Secondly, the installation itself, which produces generator gas, weighs several hundred kilograms. In addition, engines running on this gas produce 30-35% less power than their gasoline counterparts.

Refinishing cars for firewood

Cars had to be adapted to run on a gas generator, but the changes were not serious and were sometimes available even outside the factory. Firstly, the compression ratio in the engines was increased so that the loss of power was not so significant. In some cases, turbocharging was even used to improve the filling of engine cylinders. Many “gasified” cars were equipped with an electrical generator with increased efficiency, since a fairly powerful electric fan was used to blow air into the firebox.

ZIS-13

To maintain traction characteristics, especially for trucks, with reduced engine power, transmission ratios were made higher. The speed of movement fell, but for cars used in the wilderness and other desert and remote areas this was not of decisive importance. To compensate for the change in weight distribution due to the heavy gas generator, the suspension was strengthened in some cars.

In addition, due to the bulkiness of the “gas” equipment, it was partly necessary to rearrange the car: change, move the cargo platform or cut down the truck cabin, abandon the trunk, move the exhaust system.

The golden era of "gasgen" in the USSR and abroad

The heyday of gas-generating cars occurred in the 30-40s of the last century. At the same time, in several countries with large needs for cars and small proven oil reserves (USSR, Germany, Sweden), engineers from large enterprises and scientific institutes began developing wood-powered vehicles. Soviet specialists were more successful in creating trucks.

GAZ-42

From 1935 until the very beginning of the Great Patriotic War, at various enterprises of the Ministry of Forestry Industry and the Gulag (the Main Directorate of Camps, alas, the realities of that time), GAZ-AA one and a half trucks and ZIS-5 three-ton trucks, as well as buses based on them, were rebuilt for working on wood. Also, gas generator versions of trucks were produced in separate batches by the vehicle manufacturers themselves. For example, Soviet auto historians cite the figure 33,840 - this is how many gas-generating “one and a half” GAZ-42 were produced. More than 16 thousand units of gas generator ZIS models ZIS-13 and ZIS-21 were produced in Moscow.

ZIS-21

During the pre-war period, Soviet engineers created more than 300 different versions of gas generator units, of which 10 reached mass production. During the war, serial factories prepared drawings of simplified installations that could be manufactured locally in auto repair shops without the use of complex equipment. According to the recollections of residents of the northern and northeastern regions of the USSR, wood-burning trucks could be found in the outback until the 70s of the twentieth century.

In Germany during World War II, there was an acute shortage of gasoline. The design bureaus of two companies (Volkswagen and Mercedes-Benz) were tasked with developing gas-generating versions of their popular compact cars. Both companies completed the task in a fairly short time. The Volkswagen Beetle and Mercedes-Benz 230 entered the production line. It is interesting that the additional equipment of the production cars did not even extend beyond the standard dimensions of the “passenger cars”. Volkswagen went even further and created a prototype of the “wood-burning” army Volkswagen Tour 82 (“Kübelwagen”).

Volkswagen Tour 82

Wood burning machines today

Fortunately, the main advantage of gas-generating cars - independence from the gas station network - has become less relevant today. However, in the light of modern environmental trends, another advantage of wood-burning cars has come to the fore - running on renewable fuel without any chemical preparation, without additional energy consumption for fuel production. As theoretical calculations and practical tests show, a wood-burning engine harms the atmosphere less with its emissions than a similar engine, but already running on gasoline or diesel fuel. The exhaust gas content is very similar to emissions from internal combustion engines running on natural gas.

And yet, the topic of wood-burning cars has lost its former popularity. It is mainly enthusiastic engineers who, in order to save on fuel or as an experiment, convert their personal cars to run on generator gas to avoid forgetting about gas generators. In the post-Soviet space, there are successful examples of “gasgens” based on the AZLK-2141 and GAZ-24 cars, the GAZ-52 truck, the RAF-2203 minibus, etc. According to the designers, their creations can travel up to 120 km at a speed of 80- 90 km/h.

GAZ-52

For example, the GAZ-52, which was converted to firewood by Zhytomyr engineers in 2009, consumes about 50 kg of wood lumps per 100 km. According to the designers, firewood needs to be added every 75-80 km. The gas generator unit, traditionally for trucks, is located between the cab and the body. After igniting the firebox, about 20 minutes must pass before the GAZ-52 can start moving (in the first minutes of operation of the generator, the gas it produces does not have the necessary combustible properties). According to the developers' calculations, 1 km using wood is 3-4 times cheaper than using diesel fuel or gasoline.

Gas generator unit GAZ-52

The only country today in which wood-burning cars are widely used is North Korea. Due to total global isolation, there is a certain shortage of liquid fuel there. And firewood again comes to the rescue of those who find themselves in difficult situations.

During gasification, the organic part of wood is converted into flammable gas and liquid products. Gasification is carried out in vertical shafts of devices called gas generators. Three main processes take place in the gas generator shaft, which can be roughly divided into the zones indicated in the diagram (Fig. 23).

In the upper part of the gas generator, wood is dried (zone I), then the dry fuel is subjected to low carbonization - thermal decomposition in a flow of heated gas moving from the grate and blowing tuyeres up to the neck of the gas generator (zone II).

In the third, last zone, the process of gasification itself takes place, to which it is no longer wood that is subjected, but coal, the product of low-temperature carbonization of wood. Here, coke carbon (charcoal) is oxidized in an atmosphere of air oxygen supplied to the mine through the grate and through the blast tuyeres. When gasifying other types of solid fuel (fossil coal, shale, coke and peat), steam-oxygen is sometimes used instead of air blast.

When atmospheric oxygen and coke interact, carbon oxidation can occur through the following reactions:

A) C + 03 COa + 97 650 kcal/kg - mol;

B) C + 4- O.. ->- CO + 29 450 kcal/kg - mol.

Part of carbon dioxide CO2, interacting with coke carbon heated to a high temperature, is converted into carbon monoxide CO by the reaction

C + CO 2 ^ 2 CO + 38,790 kcal/kg - mol.

Observations have shown that during the gasification of wood fuel in a thick layer, as a result of the mentioned reactions, mainly carbon monoxide is formed.

Pieces coals are covered with a gas film, through which gas molecules diffuse to the surface of the coal, and reaction products are removed from the surface, entering the gas space between individual pieces of the solid. The intensity of the diffusion flow depends on a number of factors.

When the rate of chemical interaction between a solid and gas molecules is very high, the overall result

The interactions between reacting substances in heterogeneous reactions will depend on the intensity of diffusion processes. In this case, the process of coal gasification occurs in the so-called diffusion region.

When the rate of a chemical reaction between a solid and gas molecules is a decisive factor, the interaction between the reacting substances moves into the kinetic region of the process.

As the gas velocity increases and the size of the coal pieces decreases, the thickness of the gas film decreases.

The speed of the gasification process in its diffusion region will increase with increasing temperature and speed of gas flows. The rate of chemical interaction between coke carbon and gas molecules, i.e., the gasification process itself, in its kinetic region will always increase with increasing temperature.

The reactivity of coke from different coals is not the same, and it is characterized by the rate of chemical interaction of carbon with CO2 and water vapor.

Charcoal has a higher reactivity compared to, for example, fossil coals.

Therefore, in the case of wood gasification, the oxidation of wood coke carbon will occur in the diffusion region of the process.

In zone III (gasification proper), high temperatures develop. Theoretically, it could be about 1600°. As a result, fuel ash is fused, and blowing devices become slagged and often destroyed. These phenomena lead to premature shutdown of the gas generator due to air supply disruption. To combat them, it is enough to add 90-120 g/n to the air supplied to the gas generator. l3 saturated water vapor.

The supply of steam in the blast provides a slight increase in the calorific value of the gas.

In contrast to air blast, artificially moistened with steam is called air-steam blast. The degree of humidification of the blast is regulated by its temperature, which is usually maintained within the range of 45-55°, and sometimes higher. By adding steam to the blast, the temperature of the gasification zone itself is reduced to 1100-1200°, which is already safe for blast devices.

During steam-air blasting, the following reactions occur:

A) C + H20 -> CO + Na - 28,300 kcal/kg - mol

B) C + 2 H20 COa + 2 H2 - 17,970 kcalkg - they say,

B) CO + H20 CO2 At ± 10 410 kcal/kg - mol.

The water vapor of the blast is usually not completely consumed by these reactions, but by 70-75%. With significant humidification of the blast with steam and a decrease in temperature, reactions “a” and “b” can move into the kinetic region of the process.

Due to the inevitable presence of nitrogen in the air, it is theoretically possible to imagine the formation of CO in the gas obtained in the gasification zone itself during air blast according to the following equation:

2 C + 02 + 3.76 N2 - 2 CO + 3.76 N3,

What corresponds to the composition of the gas V volume fractions: CO -34.7%-. N2 - 65.3%.

It has been experimentally established that the composition of the gas in the zone of the actual gasification of wood coke during air blast differs little from the theoretical one. From 1 kg carbon gas output

Equal to 5.37 n. m3 s calorific value 1060. From

The presented data shows that with an ideal air process, the thermal efficiency of gasification, counting on a cold

5.37 1060 _ _ gas, equal to g^ = 0.7.