Peltier element made of diodes. Peltier element: characteristics, operating principle and application

The Peltier element has been known to the world for a long time. Back in the 18th century, the French watchmaker Jean-Charles Peltier quite by accident discovered a new effect at the boundary of two metals: bismuth and antimony. It consisted of a sharp change in the temperature of a drop of water placed between the contacts, which turned into ice when current was applied. This property became new for the watchmaker, because until that moment no scientist in the world had ever presented such information in his materials.

Although the effect was interesting, it did not find practical application at that time, which was due to the small amount of electronic equipment that would require intensive cooling. After 2 centuries The scientist’s discovery was remembered because there was an urgent need to manufacture a device that could provide high-quality cooling of the heating microprocessor crystal.

As a result of numerous studies in this area and a huge number of practical experiments, scientists have found that a thermoelectric pair can generate a sufficient amount of cold for the normal operation of almost any microprocessor. And thanks to their small size, they have learned to integrate them into microcircuit housings, thus providing their own internal cold generator.

The discovery of Jean-Charles Pelte was a huge impetus for the entire industry for the production of mobile refrigeration units. Today the property of a thermoelectric element used in the following techniques:

- portable refrigerators;

- car air conditioners;

- portable coolers;

- cameras, telescopes and much more.

They are actively used for cooling microprocessors and other electronic components. In addition to the direct cooling effect, many began to use the Peltier element as a generator. An example of what could be flashlight with 3 elements.

Few people know that in order to carry out radio communication with the command, soldiers put a special pot on the fire and brewed tea, prepared porridge and other household items, and at the same time transmitted the necessary information via a portable radio station.

How to make a Peltier element with your own hands?

Many people are interested in the question, what is a Peltier element with their own hands, how to make it at home? This will require highly precise dosed addition of various substances and materials. It is impossible to make such a device at home, because it requires technology and the necessary metal processing methods. Also, especially pure materials are required in the same laboratories, which is impossible to achieve at home. Therefore, the question of how to make a Peltier thermoelectric module can be answered unambiguously. No way. But to build an effective cooling system, existing skills are quite enough.

Many people are interested in the question, what is a Peltier element with their own hands, how to make it at home? This will require highly precise dosed addition of various substances and materials. It is impossible to make such a device at home, because it requires technology and the necessary metal processing methods. Also, especially pure materials are required in the same laboratories, which is impossible to achieve at home. Therefore, the question of how to make a Peltier thermoelectric module can be answered unambiguously. No way. But to build an effective cooling system, existing skills are quite enough.

Making a Peltier element from diodes

There is an opinion about what can be done diode thermoelectric module. The fact is that each pair of dissimilar semiconductors is two materials with p and n conductivities. And a diode is just that. To detect changes in conductivity when heated, it is necessary to select certain elements. But no diodes will help to obtain a low temperature on the surface of the device. When applying a large current, only heating can be achieved.

Radio amateurs use low-power diodes in a glass case as a temperature sensor. When they are connected in the opposite direction and warmed up, the junction begins to open and pass current in the opposite direction. But it will not generate electricity.

How does the Pelte element work?

A Peltier thermoelectric module in a simplified form is a pair of plates made of different metals, which can be bismuth, antimony, tellurium or selenium. Between them there is a pair of n- and p-type semiconductors with different conductivities. All formed by different metals thermoelectric couples connected in series into a single circuit. The result is a kind of matrix of a large number of individual thermocouples located between two ceramic plates.

A Peltier thermoelectric module in a simplified form is a pair of plates made of different metals, which can be bismuth, antimony, tellurium or selenium. Between them there is a pair of n- and p-type semiconductors with different conductivities. All formed by different metals thermoelectric couples connected in series into a single circuit. The result is a kind of matrix of a large number of individual thermocouples located between two ceramic plates.

The thermoelectric module formed by thermocouples is manufactured in a single small-sized housing. When they are connected in series or in parallel, it is possible to enhance the cooling effect or generate electrical energy. In cooler mode, the positive terminal of the matrix is connected to the first pair with an n-type conductor, the negative contact is connected to p-type conductors. Special ceramics based on aluminum oxide and nitride are used as external linings. This ensures the best heat transfer performance on both sides at both high and low temperatures.

Number of thermocouples in the module is not limited by anything and can be up to several hundred. The more there are, the better the cooling effect is felt. To increase the efficiency of the Peltier element, a radiator with the largest heat transfer area is attached to its cold side. The difference in temperature between the plates should be at least two tens of degrees.

When voltage is applied to the plates, one side becomes hot and the other cold. When the polarity of the supply voltage changes, the temperature of the plates changes places.

Considering the complexity and manufacturability, it is not possible to make a thermoelectric element with your own hands. But still there are craftsmen who offer their developments. The effect is observed, but it is impossible to achieve an increase in efficiency without a special research laboratory. You can even find a video on this topic with step-by-step guidance.

Features of the Peltier element

To the features element based on bimetallic pairs should include:

Formula display

The Peltier effect involves the flow of current through the contact of two metals with different conductivities. As a result, heat or cold is released, which depends on the direction of current flow.

In formulaic expression, the Peltier effect can be depicted:

Q p=P12 j, where P12 is the Peltier coefficient. The indicator depends on the type of metal used and its thermoelectric properties.

In addition to the advantages, the device also has some disadvantages, which include:

Low efficiency. In order to obtain a significant temperature difference, it is necessary to supply a sufficiently large current to the plates.

To effectively remove thermal energy, it is necessary to provide a radiator.

Generator mode of the Peltier element

The discovery of Jacques-Charles Peltier literally turned the world upside down, since the device can be used as a universal generator of heat and cold. In addition to these functions, another important effect was noted - the generator mode. If the warm side of the device is heated and the cold side is cooled, then a potential difference occurs at the terminals, and when the circuit is closed, current begins to flow.

The discovery of Jacques-Charles Peltier literally turned the world upside down, since the device can be used as a universal generator of heat and cold. In addition to these functions, another important effect was noted - the generator mode. If the warm side of the device is heated and the cold side is cooled, then a potential difference occurs at the terminals, and when the circuit is closed, current begins to flow.

Generator based on a Peltier element You can do it yourself and it doesn’t require any special skills. But you should understand that the material used by Chinese developers does not have ideal characteristics that allow them to obtain maximum energy. Available thermoelectric modules on sale are sufficient for:

- charging mobile devices;

- power supply for LED lighting;

- manufacturing an autonomous radio receiver and other purposes.

You can find a lot of videos on this topic with a detailed description of all stages. Therefore, if you want to make a thermoelectric module to generate energy, then this is quite possible.

The first step is to order the required number of Peltier elements, taking into account their characteristics. A device with a power of 10 W on the same e-Bay costs $15. And this will be quite enough to charge smartphones. Next, it is necessary to ensure effective heat removal. For these purposes, you can design a liquid cooling system with natural circulation. And heat the hot side with any heat source, including open fire. As a result any radio amateur can make an excellent thermoelectric generator himself, which you can take with you on a hike, fishing or to the country.

One standard cell produces 5 V and 1 W of power, which is enough for small lighting. For example, for making a flashlight heated by the heat of your hands. Ready-made elements with output voltages up to 12 V are also available for sale.

Portable thermoelectric stove with generator mode

Today you can find a lot of ways to make a fairly efficient thermoelectric generator based on a Peltier element with your own hands. As one of them - portable stove with firebox from an old computer power supply. The Peltier thermoelectric element itself is attached to one of the sides of the case through thermal paste with an impressively sized radiator. This installation will allow you to get heat in any convenient place, cook food and charge your phone.

Many new electricians are interested in one very popular question - how to make electricity free and at the same time autonomous. Very often, for example, when going out into nature, there is a catastrophic lack of an outlet to recharge a phone or turn on a lamp. In this case, a homemade thermoelectric module assembled on the basis of a Peltier element will help you. Using such a device, you can generate current with a voltage of up to 5 Volts, which is quite enough to charge the device and connect a lamp. Next, we will tell you how to make a thermoelectric generator with your own hands, providing a simple master class in pictures and with a video example!

Briefly about the principle of operation

So that in the future you understand why certain spare parts are needed when assembling a homemade thermoelectric generator, let’s first talk about the structure of the Peltier element and how it works. This module consists of serially connected thermocouples located between ceramic plates, as shown in the picture below.

When an electric current passes through such a circuit, the so-called Peltier effect occurs - one side of the module heats up, and the other cools. Why do we need this? Everything is very simple, if you act in the reverse order: heat one side of the plate and cool the other, accordingly you can generate electricity of low voltage and current. We hope that at this stage everything is clear, so we move on to master classes that will clearly show what and how to make a thermoelectric generator with your own hands.

Assembly master class

So, we found on the Internet very detailed and at the same time simple instructions for assembling a homemade electricity generator based on a furnace and a Peltier element. To begin, you need to prepare the following materials:

- The Peltier element itself with the parameters: maximum current 10 A, voltage 15 Volts, dimensions 40 * 40 * 3.4 mm. Marking – TEC 1-12710.

- An old power supply from a computer (only the case is needed from it).

- Voltage stabilizer with the following technical characteristics: input voltage 1-5 Volts, output voltage – 5 Volts. This instruction for assembling a thermoelectric generator uses a module with a USB output, which will simplify the process of recharging a modern phone or tablet.

- Radiator. You can take it from the processor immediately with a cooler, as shown in the photo.

- Thermal paste.

Having prepared all the materials, you can proceed to making the device yourself. So, to make it clearer to you how to make a generator yourself, we provide a step-by-step master class with pictures and a detailed explanation:

The thermoelectric generator works as follows: you put wood inside the furnace, set it on fire and wait a few minutes until one side of the plate heats up. To recharge the phone, the difference between the temperatures of different sides must be about 100 o C. If the cooling part (radiator) gets hot, it needs to be cooled by all possible methods - gently pour water on it, put a mug of ice on it, etc.

And here is a video that clearly shows how a homemade wood-burning electric generator works:

Generating electricity from fire

You can also install a computer fan on the cold side, as shown in the second version of a homemade thermoelectric generator with a Peltier element:

In this case, the cooler will use a small fraction of the power of the generator set, but the resulting system will be more efficient. In addition to telephone charging, the Peltier module can be used as a source of electricity for LEDs, which is an equally useful option for using a generator. By the way, the second version of a homemade thermoelectric generator is a little similar in appearance and design. The only upgrade, besides the cooling system, is the ability to adjust the height of the so-called burner. To do this, the author of the element uses the “body” of a CD-ROM (one of the photos clearly shows how you can make the design yourself).

If you make a thermoelectric generator with your own hands using this method, you can have up to 8 Volts of voltage at the output, so to charge your phone, do not forget to connect a converter that will leave only 5 V at the output.

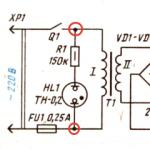

Well, the last version of a homemade power source for the home can be represented by the following diagram: an element - two aluminum “bricks”, a copper pipe (water cooling) and a burner. The result is an effective generator that allows you to create free electricity at home!

Using simple devices, you can use heat loss from heating air or liquids. In this article we will tell you how to use the waste energy of stoves, boilers and open fires, converting it into a direct electric current of low strength.

Any chemical process occurs with the release of various types of energy. Such a powerful source as combustion has been used at all times. It can be called the primary source of heat and light. Almost all substances on Earth burn, releasing heat and light in different quantities. Converting thermal energy into electrical energy is not difficult if you have a working steam turbine at hand, similar to those installed in thermal power plants. This is a bulky and complex device that is unlikely to find a place in the boiler room of a country house. We will try to benefit from the heat generated by stove heating or heating water.

The Peltier effect is a phenomenon of temperature difference when thermocouples of two different types of conductors (p-type and n-type) interact when a direct current passes through them. The Seebeck effect is a consequence of the Peltier effect, when an electric current is generated when one of the thermocouples is heated. We will not describe in detail the thermodynamics of the process - this difficult-to-understand information can be easily found in reference literature. We are interested in the result and options for its practical use.

Thermoelectric module design

A thermoelectric module (TEM) consists of many thermocouples connected to each other by a copper plate. The thermocouple field is glued between two ceramic plates. It is possible to assemble such a module only in a factory environment. But you can also assemble several TEMs for your own needs at home. Peltier-Seebeck elements are available for free sale in specialized stores (and on websites) selling technological equipment.

Assembling a 5 V TEM

What you will need:

- Peltier module TEC1-12705 (40x40) - 2 pcs.;

- boost DC voltage converter EK-1674;

- duralumin sheet 3 mm thick;

- a water container with a perfectly flat bottom (ladle);

- hot glue;

- soldering iron

We cut out two identical plates from a sheet of duralumin, slightly larger than two modules lying next to each other. We strengthen the plates on the modules on both sides with hot glue. We fix (with hot glue) the resulting “sandwich” to the bottom of the ladle. This design can already be put on fire, but we will get a useless 1.5 V at the output. To improve the performance, we need a boost converter, which we solder into the circuit. It will increase the voltage to 5 V, and this is already enough to charge a mobile phone.

Attention! The converter has dimensions of 1.5x1.5 cm. If you do not have professional skills, entrust soldering to a specialist.

The temperature difference in our design is obtained by heating one side (from the furnace or flame) and cooling the other (water in the ladle). Of course, the greater the difference, the more efficient the module is. Therefore, to operate in microgenerator mode, you will need a relatively low water temperature in the ladle (it is better to replace it periodically). To generate the coveted 5 V, it is enough to place the structure on a glass with a burning candle.

By proportionally combining more modules, we get a more efficient energy generation system. Accordingly, by increasing the structure, we proportionally increase the heat exchanger. In this case, the surface to be cooled should be completely covered with a container of water (the simplest and most affordable option).

Everything is so simple that you immediately feel the desire to assemble more modules into one system and generate 220 V from the fire. And then connect the oil heater or air conditioner. Such a simple system has its drawbacks, and the main one is low efficiency. Typically this figure does not exceed 5%. This results in a relatively low current of 0.5 - 0.8 A and very low power - up to 4 W.

For a pump or incandescent lamp this is negligible, but quite enough for:

- charging batteries up to motorcycle batteries (in variants proportional to the requirements);

- operation of light-emitting diode (LED) lamps;

- radio receiver

In winter, a system placed on a heat source located outside will work as efficiently as possible.

Material costs for assembling a 5V thermoelectric microgenerator:

*- this element model was chosen for price reasons. The range of TEMs from supplier companies is quite wide, which allows you to select more productive (up to 8 V) models (they are significantly more expensive).

Factory-made products of this design are just beginning to appear on sale. Serial production is carried out in small batches, and the range is small. The cost of such a “bucket” starts at 2,500 rubles.

A factory thermal generator is a device based on the Peltier-Seebeck effect, which can be attached directly to a heated surface. It is distinguished from the design described above by its factory execution (and therefore reliability), the absence of a liquid heat exchanger (instead there are fins for air cooling) and a higher price.

A standard “travelling” thermogenerator has the following characteristics:

As can be seen from the table, factory reliability and utility are not cheap. However, it cannot be said that it is functionally superior to the homemade version with a bucket. An impressive 13.5 V will speed up charging your mobile phone, but for this you will need to carry 2 kg of weight with you on a hike, and this is an unaffordable luxury (considering the size of the device). And, of course, the price makes you think. With this amount, you can assemble not a “thermal ladle”, but a “thermal pan” and easily charge your laptop. And one more nuance - the device still requires fastening to a metal plate if an open fire is used.

Overall, this is a nice and convenient addition for those who have no problems with money and free space in the trunk.

Energy furnace

Today, the energy furnace is the apotheosis of the use of TEMs in everyday life. This is a factory product, essentially a “potbelly stove” firebox for any type of solid fuel with an integrated thermoelectric module. An ideal option for hunting lodges, summer cottages, remote winter quarters and generally any type of life away from civilization. Designed for autonomous use (without peripheral heat sinks), it has only a hearth and a chimney. Includes food preparation. The most powerful Peltier-Seebeck elements are installed on this furnace.

Characteristics of energy furnaces:

Although the stove is portable, it is certainly a “super heavyweight” among household appliances. However, the range of tasks for an energy furnace is quite wide - it can even charge car batteries and illuminate entire rooms with LED lamps. There is a place for it in an expeditionary convoy and in a hunting all-terrain vehicle, in a technical room and in the country. In other words, in this case we always have the heat source with us, all we have to do is find fuel.

In its niche, the energy furnace is indispensable, although the service life declared by the manufacturer is a little alarming - 10 years. It should be noted that, as in a thermogenerator, there is the possibility of preventive (or emergency) replacement of all parts down to the housing.

Thermoelectric modules are extremely interesting objects. In addition to the application methods described, they are also used for water and air conditioning. At the same time, direct current is supplied to the same element and it works “in the opposite direction” - it cools the air. This technology is successfully used in automobile air conditioners and water coolers, in the automotive industry and in the production of microprocessors. We will describe these devices in the next article.

Vitaly Dolbinov, rmnt.ru

In 1834, the French physicist Jean Charles Peltier, while studying the effect of electricity on conductors, discovered a very interesting effect. If you pass current through two dissimilar conductors located in close proximity to each other, then one of these conductors begins to heat up very much, and the second, on the contrary, begins to cool down very much. The amount of heat generated and absorbed directly depends on the strength and direction of the electric current. If you change the direction of the current, the cold and hot sides will change places. A little later, this phenomenon was called the Peltier effect and was conveniently forgotten due to its practical lack of demand at that time.

And only after more than a hundred years, with the rise of the semiconductor era, there is an urgent need for compact, inexpensive and efficient coolers. Thus, in the 60s of the 20th century, the first semiconductor thermoelectric modules appeared, which were called Peltier elements.

The basis of any thermoelectric module is the fact that different conductors have different electron energy levels. In other words, one conductor can be represented as a high-energy region, the second conductor as a low-energy region. When two conductive materials come into contact, while an electric current is passed through them, an electron from a low-energy region must move to a high-energy region.

This will not happen if the electron does not acquire the required amount of energy. At the moment this energy is absorbed by the electron, the contact point between the two conductors cools. If you change the direction of current flow, on the contrary, the effect of heating the contact point will occur.

Any conductors can be used, but this effect becomes physically noticeable and significant only when semiconductors are used. For example, when metals come into contact, the Peltier effect is so insignificant that it is practically unnoticeable against the background of ohmic heating.

A thermoelectric module (TEM), regardless of its size and place of application, consists of a different number of so-called thermocouples. A thermocouple is the very building block from which any TEM is built. It consists of two semiconductors with different conductivity types. As is known, there are two types of conductivity p and n type. Accordingly, there are two types of semiconductors. These two dissimilar elements are connected in a thermocouple using a copper bridge. Salts of metals such as bismuth, tellurium, selenium or antimony are used as semiconductors.

TEM is a set of similar thermocouples connected to each other in series. All thermocouples are located between two ceramic plates. Peltier plate. The plates are made of aluminum nitride or aluminum oxide. The number of thermocouples in one element can vary within very wide limits, from a few pieces to several hundreds or thousands.

In other words, Peltier elements can be of absolutely any power, from hundredths to several hundred or thousand watts. Direct current sequentially passes through all thermocouples and as a result, the upper ceramic plate is cooled, and the lower one, on the contrary, is heated. If you change the direction of the current, the plates will change places, the top one will start to heat up, and the bottom one will start to cool down.

There is one feature in the operation of the element that is actively used to enhance the cooling efficiency of this device. As is known, when current is passed through a Peltier element, a temperature difference arises between the surface that is heating up and the surface that is cooling. So, if the surface that is actively heating up is subjected to forced cooling. For example, using a special cooler, this will lead to even stronger cooling of the surface, that is, the one that is being cooled. In this case, the temperature difference with the surrounding air can reach several tens of degrees.

Advantages and disadvantages

Like any technical device, a thermoelectric module has its advantages and disadvantages:

The problem of increasing the efficiency of TEMs rests on a technical puzzle that is so far unsolvable. Free electrons have, in fact, a dual nature, which is manifested in practice and they are simultaneously carriers of both electric current and thermal energy. As a consequence, a highly efficient Peltier element must be made of a material that simultaneously has two mutually exclusive properties. This material should conduct electricity well and conduct heat poorly. So far, such material does not exist in nature, but scientists are actively working in this direction.

All thermoelectric modules have the appropriate technical characteristics:

Application of TEMs

Despite the serious drawback inherent in all Peltier elements without exception, namely very low efficiency, these devices have found quite wide application both in science and technology, and in everyday life.

Thermoelectric modules are important design elements of such devices as:

Peltier element in the hands of a home craftsman

We must immediately make a reservation: making a thermoelectric element yourself is, to say the least, a meaningless task and unnecessary for anyone. Unless the manufacturer is a seventh grade student and thus consolidates the knowledge acquired in physics lessons.

Much easier to buy new thermoelectric element in the relevant store. Fortunately, they are inexpensive and there is no shortage of choice for a specific model. And besides the fact that there is nothing to break or wear out in them, any thermoelement removed from an old computer or car air conditioner will not differ in its technical characteristics from the new one.

The most popular thermoelement model is TEC1-12706. The dimensions of this device are 40 by 40 millimeters. It consists of 127 thermocouples connected to each other in series. Designed for a current of 5 A, with a circuit voltage of 12 V. Such an element costs on average from 200 to 300 rubles. But you can find it for a hundred, or, in general, for that if you remove it from an old computer or some other unnecessary device.

Using such an element, you can make at least two very interesting and useful devices for your household.

How to make a refrigerator with your own hands

The production of portable refrigerators, in particular for cars, is entirely based on the Peltier effect. To make such a device at home you will need:

- Thermocouple brand TEC1-12706. Costs 200 rubles in the nearest store (specialized).

- Radiator and fan. They are removed from an old computer that has served its purpose.

- Container. Any unnecessary container made of plastic, metal or wood. The outside and inside of such a container is covered with heat-saving plates made of polystyrene foam or expanded polystyrene.

The thermoelectric module is built into the lid of the container. In this case, the flow of cold will occur from top to bottom, which will lead to uniform cooling of the container. From inside the container, a radiator is attached to its lid using thermal paste and mounting bolts.

In order to increase the power of a future refrigeration device, you can increase the number of thermoelements to two or three or more. In this case, the modules are glued to each other, observing polarity. In other words, the hot side of the underlying element is in contact with the cold side of the overlying one.

Another radiator is attached to the outside of the lid along with a computer cooler. At the place where the radiators are mounted there must be good thermal insulation between the cold - inner and hot - outer sides. It is necessary to very carefully tighten the upper and lower radiators with fastening bolts so that the ceramic plates and thermoelements located between them do not crack.

Electricity is connected using a power supply, which can be taken from an old computer.

Portable thermoelectric generator

Such a mini-power station can be of great help to a tourist or hunter when the batteries of all electronic gadgets run out in the forest. In this situation, it is very romantic to take a few dry wood chips and cones, light a small fire and use it to charge the discharged batteries, and at the same time cook something to eat. This is exactly what a portable thermogenerator built on a thermoelement allows you to do.

Such a mini-power station can be of great help to a tourist or hunter when the batteries of all electronic gadgets run out in the forest. In this situation, it is very romantic to take a few dry wood chips and cones, light a small fire and use it to charge the discharged batteries, and at the same time cook something to eat. This is exactly what a portable thermogenerator built on a thermoelement allows you to do.

To build this miracle device, you need a portable camp stove that runs on any type of fuel. In extreme cases, even a small candle or a tablet of dry alcohol will do.

A fire is lit in the stove, and a thermoelectric module is attached to it from the outside using thermal paste. It is connected via wires to a voltage converter.

The amount of current received will directly depend on the temperature difference between the cold and hot sides of the thermoelement. For effective operation, a difference between cold and hot surfaces of at least 100 degrees is required.

In this case, it is necessary to understand that the maximum temperature is limited by the melting temperature of the solder with which the module itself is made. Therefore, for such devices, special thermal modules are used, which are made using special refractory solder. In conventional modules, the melting temperature of solder is 150 degrees. In refractory modules, the solder begins to melt at a temperature of 300 degrees.

A Peltier element is usually called a converter that is capable of operating from a temperature difference. This happens by flowing electric current through conductors through contacts. For this purpose, special plates are provided in the elements. Heat passes from one side to the other.

Today, this technology is in demand primarily due to its significant heat transfer power. Additionally, the devices can boast of compactness. The radiators installed on many models are weak. This is due to the fact that the heat flow cools quite quickly. As a result, the desired temperature is constantly maintained.

This element has no moving parts. The devices operate absolutely silently, and this is a definite advantage. It should also be said that they can be used for a very long time, and breakdowns occur extremely rarely. The simplest type consists of copper conductors with contacts and connecting wires. Additionally, there is an insulator on the cooling side. It is usually made from ceramic or

Why are Peltier elements needed?

Peltier elements are most often used to make refrigerators. Usually we are talking about compact models that can be used, for example, by motorists on the road. However, this is not the end of the range of applications of the devices. Recently, Peltier elements have been actively installed in sound and acoustic equipment. There they are able to perform the functions of a cooler.

As a result, the device amplifier is cooled without any noise. For portable compressors, Peltier elements are indispensable. If we talk about the scientific industry, scientists use these devices to cool the laser. In this case, it is possible to achieve significant stabilization of the study wave of LEDs.

Disadvantages of Peltier models

It would seem that such a simple and effective device has no drawbacks, but there are some. First of all, experts immediately noted the low penetration capacity of the module. This suggests that a person will have certain problems if he wants to cool a device that operates from a network with a voltage of 400 V. In this case, a special dielectric paste will partially help solve this problem. However, the current breakdown will still be high and the winding of the Peltier element may not withstand it.

Additionally, these models are not recommended for use in precision electronics. Since the design of the element contains metal plates, the sensitivity of the transistors may be impaired. The last disadvantage of the Peltier element is the low efficiency. These devices are not capable of achieving a significant temperature difference.

Module for regulator

Making a Peltier element for a regulator with your own hands is quite simple. To do this, you should prepare two metal plates in advance, as well as wiring with contacts. First of all, conductors are prepared for installation, which will be located at the base. They are usually purchased with the "PP" marking.

Additionally, for normal temperature control, semiconductors should be provided at the output. They are necessary in order to quickly transfer heat to the top plate. To install all elements, you should use a soldering iron. To complete the Peltier element with your own hands, last of all, connect two wires. The first is mounted at the lower base and fixed at the outermost conductor. Contact with the plate should be avoided.

Next, attach the second wire at the top part. Fixation is also carried out to the outermost element. In order to check the functionality of the device, a tester is used. To do this, two wires need to be connected to the device. As a result, the voltage deviation should be approximately 23 V. In this situation, much depends on the power of the regulator.

Refrigerators with thermistor

How to make a Peltier element with your own hands for a refrigerator with a thermistor? Answering this question, it is important to note that the plates for it are selected exclusively from ceramics. In this case, about 20 conductors are used. This is necessary so that the temperature difference is higher. You can increase it up to 70%. In this case, it is important to calculate

This can be done based on the power of the equipment. A refrigerator using liquid freon is ideal in this case. The Peltier element itself is installed near the evaporator, which is located next to the motor. To install it, you will need a standard set of tools, as well as gaskets. They are necessary in order to protect the model from the starting relay. Thus, the cooling of the lower part of the device will occur much faster.

To achieve a temperature difference (Peltier effect) with your own hands, you may need at least 16 conductors. The main thing is to reliably insulate the wires that will be connected to the compressor. In order to do everything correctly, you must first disconnect the refrigerator dryer. Only after this is it possible to connect all contacts. Once installation is complete, the voltage limit should be checked using a tester. If the element malfunctions, the thermostat is the first to suffer. In some cases it occurs

Model for refrigerator 15 V

You can make a Peltier refrigerator with your own hands with small modules. The modules are attached mainly near the radiators. In order to securely fasten them, experts use corners. The element should not lean against the filter, and this should be taken into account.

To complete a Peltier thermoelectric module with your own hands, the bottom plate is mainly chosen from stainless steel. Conductors, as a rule, are used with the marking "PR20". They can withstand a maximum load of 3 A. The maximum temperature deviation can reach 10 degrees. In this case, the efficiency can be 75%.

Peltier elements in 24 V refrigerators

Using a Peltier element, you can make a refrigerator with your own hands only from conductors with good sealing. At the same time, they must be stacked in three rows for cooling. The operating current in the system must be maintained at 4 A. You can check it using a conventional tester.

If you use ceramic plates for the element, the maximum temperature deviation can be achieved at 15 degrees. The wires to the capacitor are installed only after the gasket has been placed. You can attach it to the wall of the device in different ways. The main thing in this situation is not to use glue, which is sensitive to temperatures above 30 degrees.

Peltier element for car cooler

To make a high-quality auto-refrigerator with your own hands, a Peltier module (module) is selected with a plate whose thickness is no more than 1.1 mm. It is best to use non-modular wires. Copper conductors will also be required for operation. Their capacity must be at least 4A.

Thus, the maximum temperature deviation will reach 10 degrees, this is considered normal. Conductors are most often used with the marking "PR20". They have recently shown themselves to be more stable. They are also suitable for various contacts. A soldering iron is used to connect the device to the capacitor. High-quality installation is only possible on the relay block gasket. The differences in this case will be minimal.

How to make an element for a drinking water cooler?

A DIY Peltier module (element) for a cooler is quite simple. It is important to select only ceramic plates for it. At least 12 conductors are used in the device. Thus, the resistance will be maintained high. The connection of elements is usually carried out using soldering. There must be two wires for connecting to the device. The element must be attached to the bottom of the cooler. In this case, it may come into contact with the cover of the device. In order to eliminate cases of short circuits, it is important to fix all wiring on the grid or housing.

Air conditioners

The Peltier module (element) is made with your own hands for an air conditioner only with class “PR12” conductors. They are chosen for this task mainly because they cope well with low temperatures. At most, the model is capable of producing a voltage of 23 V. The resistance indicator will be at the level of 3 ohms. The temperature difference reaches a maximum of 10 degrees, and the efficiency is 65%. Conductors can only be laid in one row between sheets.

Manufacturing of generators

You can make a generator using a Peltier module (element) with your own hands. Device performance will increase by a total of 10%. This is achieved due to greater cooling of the motor. The device can withstand a maximum load of 30 A. Due to the large number of conductors, the resistance can be 4 ohms. The temperature deviation in the system is approximately 13 degrees. The module is attached directly to the rotor. To do this, you must first disconnect the central shaft. In many cases the stator does not interfere. To prevent the rotor winding from heating up from the inductor, ceramic plates are used.

Cooling a video card on a computer

To cool the video card, you should prepare at least 14 conductors. It is best to select copper models. Their heat conductivity coefficient is quite high. To connect the device to the board, non-modular type wires are used. The model is mounted near the video card cooler. To secure it, small ones are usually used.

To fix them, you can use regular nuts. The appearance of excessive noise during operation indicates that the device is not working properly. In this case, it is necessary to check the integrity of the wiring. You also need to inspect the conductors.

Peltier element for air conditioner

To make a high-quality Peltier element with your own hands for an air conditioner, double plates are used. Their minimum thickness should be at least 1 mm. In this case, you can hope for a temperature deviation of 15 degrees. After equipping the modules, the performance of air conditioners increases on average by 20%. Much in this situation depends on the ambient temperature. The stability of the mains voltage should also be taken into account. With minor interference, the device can withstand a load of approximately 4 A.

When soldering conductors, they should not be placed too close to each other. To properly complete Peltier modules with your own hands, the input and output contacts must be installed only on one of the two plates. In this case, the device will be more compact. A serious mistake in this situation would be to connect the module directly to the unit. This will lead to inevitable damage to the element.

Installing the module on a capacitor

To install it yourself, it is important to evaluate the power of the capacitor. If it does not exceed 20 V, then the element should be mounted with conductors marked “PR30” or “PR26”. In order to fix the Peltier module (element) on the capacitor with your own hands, use small metal corners.

It is best to install them four on each side. In terms of performance, the capacitor can ultimately add plus 10%. If we talk about heat losses, they will be insignificant. The efficiency of the device is on average 80%. The modules are not designed for high-voltage capacitors. In this case, even a large number of conductors will not help.