Installing a heated towel rail: technology and connection features. Rules for connecting a heated towel rail, expert advice How to connect a heated towel rail from hot water

Greetings, comrades! Want to know how to connect a heated towel rail? And why is such a scheme of the 60s no longer used everywhere? Having accumulated sufficient experience, I am ready to talk about this method of connection, maintenance and repair. A photo report on the work done will clearly confirm my words. So, let's go.

Where is found

Let's find out where there was a similar scheme for connecting a heated towel rail to the heating system before.

In high-rise buildings

Apartments in "Khrushchev" were always far from ideal, but they were built more for ideological reasons - to resettle barracks and communal apartments. And since all new residential areas were transferred to centralized heating, it is quite logical that in the bathroom the heater was combined with a heated towel rail.

Such a design has its advantages and disadvantages.

Pros:

- The heated towel rail served as a heating device;

- It was launched into operation only in the winter, in the summer it turned off;

Minuses:

- Bulky design;

- In addition, a fee was charged for its availability (during the heating season).

A similar installation of a heated towel rail required the laying of a separate branch in the basement, but such “additional costs” of the state were more than offset by the rejection of elevators and garbage chutes. Let me remind you that the price of 1 m 2 of such housing cost the state only 95 rubles (prices of the 60s).

There were 2 ways to connect the heated towel rail to the heating, and where to place it in the apartment.

| Illustration | Connection Description |

|

In separate bathrooms - along the adjacent wall separating the toilet and bathroom:

|

|

In adjacent bathrooms- on the wall near the washbasin.

|

The most common, in which the heated towel rail was connected not from hot water, but from the heating system, were:

- series 1-434С - year of construction 1958-1964;

- series 1-434 - year of construction 1958-1967;

- series 1-335 - year of construction 1963-1967.

In private houses

There was no centralized hot water supply in the vast majority of private houses in the 1960s. Individually, it was carried out with the help of a wood-burning boiler of the "Titan" type, which was melted before use.

Accordingly, it was simply impossible to connect a heated towel rail to such a hot water supply system:

- due to design features- the tap crashed directly into the body of the device, respectively, there was simply no pipe on which to dry clothes;

- due to limited duration heating device - laying firewood was only enough to heat a tank of water.

With the advent of water heating in private homes, it became possible to install a water heated towel rail:

| Illustration | Description |

|

old version how to connect a heated towel rail in a private house - from a heating boiler. |

|

Modern version- a heated towel rail from heating in a private household is connected to a common system, including radiators and a warm floor system. |

Replacement and repair

As a rule, a modern resident of the "Khrushchev" is not satisfied with the fact that outside the heating season there is simply nowhere to dry a towel. And the most radical way to solve the problem is to dismantle the old heated towel rail and replace it with an electric one.

This method is possible if your neighbors in the porch are going to do the same. Otherwise, you will be forced to straighten the pipe in order to keep the water supply to neighboring apartments.

You will also need to obtain permission for such dismantling, since any intervention in the heating system threatens with large fines.

It is considered more reasonable to reconnect a heated towel rail with a side connection to the hot water supply.

And, finally, the easiest way is to replace the old device with a more modern one - made of stainless steel. This method has a lot of advantages:

- The home heating system remains unchanged;

- Improves device performance;

- Improves appearance;

- Material consumption is minimal.

There is only one drawback - the device will still work only during the heating season.

special case

I will describe a special case of replacing a heated towel rail in the apartment of my relatives. Actually, the instruction itself:

| Illustration | Description of works |

|

Scope of work.

We had to replace the old heated towel rail with a more modern one made of stainless steel, without disturbing the heating system in the house. |

|

Dismantling:

|

|

Installing a new one:

|

|

Soldering pipes.

Using a soldering iron, we make a new eyeliner to the heated towel rail. Installing a ball valve. The final installation of the heated towel rail was carried out after laying the tiles in the bathroom. |

What did it give?

- Firstly, the heating system remained unchanged, i.e. the intervention was minimal - only the heated towel rail was replaced and 2 taps appeared in addition. You should not neglect their installation, because in the event of a heated towel rail leak, it can be quickly turned off;

- Secondly, the appearance of the bathroom has improved - instead of a bulky pipe, a “ladder” made of stainless steel flaunts;

- Thirdly, thanks to the arrangement of forced ventilation, towels dry out in a few hours even without heating.

In conclusion

I hope that I was able to answer all the questions of the readers. You can learn more about how to repair and connect the appliance in the bathroom from the video in this article. I look forward to your additions and comments. Good luck, comrades!

Our today's topic is a heated towel rail in a hot water supply system. We will find out whether it is always possible to make it work continuously and around the clock and how to connect a heated towel rail in different water supply schemes. Let's get started.

DHW and circulation

Let's start with a small lyrical digression.

In an apartment building, it can be dead-end and circulation. In the first case, water moves through a single bottling and dead-end risers only when it is consumed through one of the plumbing fixtures.

In the absence of water intake, spills and risers gradually cool down due to inevitable heat losses.

This feature of the dead-end system has three practical consequences:

- With a long absence of hot water analysis (for example, in the morning), it has to be drained for a long time until a comfortable temperature is obtained;

- Due to heat losses, the water temperature in apartments far from the elevator unit can drop to 55 ° C and below;

Meanwhile: the current set of rules SP 30.13330.2012 directly indicates that, regardless of the method of preparation of hot water, it must be supplied to the points of analysis with a temperature of 60 to 75 degrees.

- A heated towel rail on hot water supply, by definition, cannot be hot around the clock: in the absence of water intake, it will cool down.

All these problems are successfully solved in systems with recirculation. How are they different from dead ends?

- There are two bottlings of hot water in the house;

- The risers are connected to them in turn. The number of risers connected to bottling does not have to be the same at all: often there is one return riser for three feeders;

- On the top floor or (less often) in the attic, the risers are connected by jumpers equipped with Mayevsky taps or automatic air vents to remove air jams;

- The pressure drop between fillings, depending on the heat supply scheme used and the hot water supply scheme, is provided by the pressure difference between the supply and return of the heating main, throttling washers in the elevator unit or circulation pumps.

As a result, we get two extremely pleasant features of the system - instantaneous heating of water when the tap is opened, regardless of the location of the apartment within the house, and round-the-clock operation of heated towel rails.

Of course, if they are connected correctly. Which brings us close to the next question: how to properly connect heated towel rails to hot water supply?

Wiring diagrams

We have three scenarios to consider:

- Apartment building with dead-end hot water supply;

- Apartment building with circulating hot water supply;

- Private house or autonomous water heater in the apartment. In this case, we have complete freedom of action: hot water systems with heated towel rails can be designed from scratch.

The video in this article will help you learn more about how heated towel rails are mounted: the connection diagram, auxiliary fittings and the DHW circuit diagram will be presented to your attention.

Dead End DHW

The heated towel rail is connected between the riser and the hot water supply. A shut-off valve is installed at the water supply inlet to the dryer. Heating the coil, for obvious reasons, is only possible with the flow of water through your taps.

Is it really impossible to implement continuous circulation through the coil - at least by creating a closed circuit and supplying it with a circulation pump?

It's possible, but it doesn't make any sense.

There are two reasons:

- The circulation system must have a heat source for heating water, compensating for heat loss through pipes. An obvious candidate for the role of such a source is a hot water supply riser. Only - that's the trouble! - he, like the coil itself, cools down in the absence of water intake;

- An inexpensive circulation pump costs about 2000 rubles and consumes 50-70 watts. An inexpensive electric towel warmer costs the same and has a power consumption of 30-80 watts. The principle of Occam's razor, which does not recommend unnecessarily complicating the task for itself, cuts off the circulating hot water supply as an unreasonably complicated solution.

DHW circulation

Comprehensive instructions for connecting the dryer to the circulating water supply are contained in the already mentioned joint venture 30.13330.2012. According to the text of the document, heated towel rails must be connected to the DHW supply pipelines (read - they are placed in the break of hot water risers connected to the supply bottling). Connection to the circulation risers (return) is allowed provided that the shut-off valves and bypass are installed.

Please note: the author strongly advises to adhere to this connection scheme even when mounting the supply coil. Shut-off valves will ensure the possibility of turning off the dryer in the summer heat, and the bypass will prevent the circulation in the riser group from stopping when it is turned off.

Autonomous DHW system

How to implement hot water supply with a heated towel rail in a system with autonomous hot water preparation when installing it yourself?

The device is installed in the gap of the looped bottling or DHW supply. The circulation in them is provided by the pump.

The connection of the circuit to the heat source is determined not so much by its type, but by the presence or absence of an additional outlet for connecting the circulation pipeline.

Here are two examples of wiring diagrams.

The pump forces the water to circulate in a closed loop between the boiler tie-ins. The boiler (in this case, indirect heating) must have three tie-ins: two for connecting the DHW circuit and one for make-up.

Captain Evidence suggests: the connection of an electric boiler with a circulation pipe is completely identical to that shown in the diagram.

If the boiler or any other device (geyser, double-circuit boiler, flow-through electric pressure-type heater) does not have a circulation tie-in, a three-way thermostatic mixer circuit is implemented: hot water circulates in a closed circuit and is heated to compensate for heat loss. As water is consumed, the circuit is fed from the cold water system.

Conclusion

We hope that we were able to answer the reader's questions. Good luck!

Add site to bookmarks

- Kinds

- Choice

- Mounting

- Finishing

- Repair

- Installation

- Device

- Cleaning

How to connect a heated towel rail to heating?

What do we have to do?

A towel dryer is a device in the form of a pipe designed for drying towels. According to the type of coolant, the device is divided into electric and water type. And although an electric appliance has more advantages, it is the water type of the device that is more often used. Water heated towel rails can be connected to two hot water systems: to a water supply system or a heating system. The first option is more often chosen, since tap hot water is always supplied, but heating works only in the cold season.

How to connect the heated towel rail to the heating system?

The scheme is quite simple, the whole process consists of the following steps:

- dismantling of old equipment (if it was previously);

- installation of a bypass (i.e. jumpers) and ball valves;

- connecting a heated towel rail;

- quality control of the work performed, connections.

When connecting the device to the heating system, it is important to know that the installation is carried out in the warm season, when the heating season is closed, since the coolant supply must be turned off. In winter, no one will do this. It is worth noting that the electric type of device does not require similar actions.

The following materials are required for installation:

- heated towel rail with fasteners (comes, as a rule, in a complete set);

- ball valve - 3 pieces;

- stainless pipe (for bypass).

After the materials are prepared, you can start work. Instructions for work are presented below.

Back to index

Preparatory work

Dismantling the old device. Before proceeding with the dismantling of the old appliance, it is necessary to turn off the water supply in the heating system. Shutdown should be coordinated with the relevant services (housing office, management company). If the towel dryer is connected to pipes with threaded connections, then it is enough to simply unscrew it and remove it from the fasteners. If the device is welded to pipes, then it is necessary to cut it off with a grinder. In this case, a piece of pipe should be left on which threading will be carried out.

Installation of bypass and taps. A bypass is required to circulate water in the event that the heated towel rail is turned off. This is a kind of jumper, on which it is also necessary to install a ball valve. A tap is required to supply and disconnect water to pass through the bypass (the electrical device does not require the installation of additional elements).

To properly connect the bypass, you must. The circuit is also very simple. To do this, threads are cut on the pipes (if there was none). A ball valve is installed at the inlet and outlet of the coolant from the coil. When installing, it is necessary to carefully check the tightness of the connection so that there are no leaks in the future.

A heated towel rail in the bathroom is an extremely handy device. Thanks to him, the comfort of using this room increases significantly. There is always the opportunity to dry wet towels, put on a warm bathrobe after a shower, and for young mothers, drying children's things after express washings, which sometimes happen several times a day, is a very important point. And in the bathroom itself, from the heated towel rail located on the wall, it is much warmer, since it also plays the role of a kind.

Those old heated towel rails, which were previously installed everywhere in city apartments, no longer satisfy many from an aesthetic point of view. Therefore, when planning a repair in a bathroom or in a combined bathroom, the owners also plan to install a new device, in the old place, or with a transfer to a more convenient, from their point of view, position. But for all the seeming simplicity of such an operation, installing a heated towel rail in the bathroom still obeys a number of important rules. If they are not taken into account, then either the device will not function as we would like, or, even worse, the normal operation of the entire hot water supply or heating system will be disrupted.

The main focus of this publication will be to give the owners of the apartment an idea of which heated towel rail connection schemes are considered acceptable and effective. It should be assumed that if a home master takes on such a thing, he should no longer be taught the basic techniques of plumbing installation. Well, if a third-party specialist is nevertheless invited, there will be an opportunity to control his work, since a considerable number of frank hacks work in this environment.

General ideas about the operation of a heated towel rail

There are several types of such devices. The vast majority of them are designed to work when connected to a pipeline through which heated liquid circulates. In our time, a lot of electric models have appeared on sale, which only need a connection to the mains. This is, so to speak, a “separate” category of heated towel rails, the installation of which does not require compliance with special requirements - it is only important to follow the rules of electrical safety. By and large, the installation of such a device is not much different from connecting, say, a lamp or a heating convector.

The most “problematic” were and still are heated towel rails of the water principle of operation - it is with their installation that the greatest number of questions arise. Devices of this type will be mainly devoted to further presentation.

We’ll make a reservation right away that you can purchase a combined type model that will work thanks to the circulation of hot water, but can, if necessary, switch to electric heating. However, the connection of such heated towel rails to pipe circuits is subject to general rules, so we will not put them in a separate category.

How to understand the variety of heated towel rails?

The proposed range of such devices is extremely wide, which can even confuse the choice. A special publication of our portal - will help in this matter.

So, for the normal operation of the heated towel rail, a flow of heated liquid through it is necessary. In multi-storey buildings, where hot water supply was organized on the principle of constant water circulation, this device, as a rule, was just an ordinary loop of a hot riser pipe, most often on the descending part of the “ring”, that is, with a flow directed from top to bottom. This was the meaning that consumers receive hot water of the required temperature, regardless of the floor of their residence, and already when the flow returned, additional heat was taken from the heated towel rails.

Pay attention - the pipe forming the loop (one, in U-type towel warmers, or two - M-type) has the same diameter as on the riser itself, or even more. This is a requirement to ensure normal, without interference and excessive hydraulic resistance, circulation in the local DHW circuit.

It is clear that nowadays such heated towel rails very often do not satisfy the owners in terms of their appearance. A decision is made to replace them with more modern ones, most suitable in terms of their aesthetic qualities to the interior created in the bathroom. And this is where the miracles begin. The incompetent intervention of home craftsmen or even "unfortunate plumbers" (of which, unfortunately, there are quite a few) leads to the fact that, at best, the heated towel rail does not work at all or warms up unevenly (this is especially true for devices such as "ladder"). And at worst, the functioning of the hot water supply system in the entire entrance riser is disrupted, which entails administrative measures and, of course, aggravation of relations with all neighbors.

The fact is that ill-conceived decisions, most often based on the desire to hide the supply pipes or purchase a device of the original form, without taking into account the features of its connection, lead to a violation of the hydraulic balance in the system. Therefore, further in the article, options for connecting heated towel rails will be proposed, from which you can choose the most suitable one. In addition, attention will be paid to controversial schemes, obviously non-working, and even completely prohibited for implementation.

One more caveat before moving on to consideration of schemes. In the future, we will talk more about installing a heated towel rail in the hot water supply system. The fact is that in private houses or apartments where autonomous heating is organized, these devices are often an integral part of the heating system. On the one hand, it seems to be convenient, but on the other hand, in the summer, when heating the house is not needed, the device becomes “incapacitated”.

Another option is to connect the heated towel rail to an autonomous hot water supply system equipped with an automated circulation scheme.

Schemes in both variants of autonomous systems can be very diverse, complex, but subject to somewhat different rules. Therefore, this question will also be “bracketed”, as it already belongs to another section, more related to heating systems.

Prices for heated towel rails

Towel dryers

Which towel warmer connection scheme to choose?

The simplest schemes for tie-in heated towel rails

So, earlier heated towel rails were most often an integral part of the hot water circulation riser. With such a connection scheme, absolutely nothing can interfere with their work - since the diameter of the “coil” is not less than the diameter of the riser pipe, the hydraulic resistance, even by lengthening the line, practically does not increase. While hot water circulates in the system, the device itself will also be heated.

Pay attention to the red arrows shown. The direction of the flow does not affect the performance of the heated towel rail with such a connection. The simplicity and reliability of such a connection encourages apartment owners not to refuse it when changing a heated towel rail. It is enough to choose a modern model with the appropriate center distance and pipe diameter in order to prevent narrowing of the riser.

Installation also does not look too complicated. It is necessary to agree with the public utilities on the temporary disconnection of the riser and the discharge of water from it. Then the old heated towel rail is dismantled (or cut off). In its place, a new one is installed, according to the technology most suitable for specific conditions. This can be welding of threaded pipes with further “packing” of the device, using, if possible, preserved threaded sections, etc. Often they also resort to updating the riser itself - for example, they change it to without reducing the inner diameter of the pipe. Then the installation will be even easier - the appropriate fittings are welded in to go to the thread, and a heated towel rail is already mounted to them.

The riser itself is often hidden behind a decorative box that “masks” the entire piping in the bathroom or bathroom. But in principle, with any connection scheme, this should not affect its configuration.

No matter how the installation is carried out, two mistakes should not be made:

- Often, when installing metal-plastic pipes, an involuntary narrowing of the passage occurs, which is associated with structural features of press fittings. This may affect the overall performance of the entire riser, since hydraulic resistance sharply increases in local areas.

The second amateurish mistake is the installation of locking devices in front of the heated towel rail. No words - the presence of taps allows you to independently turn off the device when it is not needed, and if necessary, to carry out dismantling or any repair work. Cranes are usually installed, but not as shown in the illustration below.

Shutting off any faucet practically paralyzes the operation of the entire riser. The circulation stops, the water supply from the mixers may continue, but the immobilized volume will quickly cool down, and in order to get hot water at the outlet, a considerable amount of chilled water will have to be drained. In addition, when the tap is closed, airing of the riser is not excluded. In a word, no locking devices on the riser (and in this case, a heated towel rail is its integral part) are not allowed.

Considering that the taps in front of the heated towel rail are still very useful, the scheme shown above is increasingly being abandoned, organizing a system in which there is a bypass. This is a jumper connecting those going from the riser to the heated towel rail. The options here may vary. So, the riser itself can also act as a bypass, to which pipes for connecting a heated towel rail are welded - in modern new buildings, such wiring is most often planned, which gives the owners the maximum number of connection options.

If the old piping is being redone, like the one shown above, then the bypass can be welded or threaded on the horizontal sections extending from the riser to the device. In any of their cases, it is quite possible to install taps after the bypass - this will not affect the general circulation in the riser system.

Installing a bypass solves a lot of problems at once. Firstly, hot water is supplied at approximately the same temperature to all apartments located in the riser, regardless of the floor. The owner of the apartment is free to turn off his heated towel rail at any time or even remove it altogether by closing the shut-off ball valves. Moreover, he may well install a thermostatic regulator on the heated towel rail, which is able to maintain the temperature in the "coil" at a certain level, by analogy with heating radiators.

There is a common opinion that the bypass must be either offset or narrowed (one diameter less than the inlet). Indeed, this approach should somewhat improve the circulation of water through the heated towel rail. But practice shows that there is no particular difference with devices that are simple in configuration - water circulates perfectly even with a direct, not narrowed bypass, since, in addition to the forced circulation flow, gravitational flow also interferes with the matter, due to the difference in density of the heated and somewhat cooled liquid in the heated towel rails. By the way, a narrowed bypass can even play a negative role under some circumstances. In the future, several schemes will be considered with a different location of the bypass or branch pipes cut into the DHW riser.

But what is completely unacceptable is to install shutoff valves on any bypass. No excuses, they say, this tap improves circulation through the dryer, and will always open if the taps to the device itself are closed - should not be taken into account. According to the existing rules, the owner of an apartment in a high-rise building, in principle, should not be able to independently block the riser. The fact that he can vouch for his prudence does not at all exclude accidents, due to which the circulation of hot water for the entire entrance can be blocked.

By the way, such a connection scheme “walks” very widely across the Internet (even with attached photos of the work performed), where unscrupulous authors of articles give it out as one of the possible options. It is worth being very biased towards such a publication!

In the conditions of a private house, where the heating and hot water supply system is completely autonomous, the owner can install any shut-off valves he wants where he sees fit. However, even in this case, the need for such a faucet on the bypass looks very doubtful - everything can be solved by properly balancing the system and installing thermostatic devices.

The range of heated towel rails is not limited to the simplest models with side connection. Many people choose towel warmers with a bottom, diagonal or even a universal arrangement of nozzles for mounting to supply pipes. It is with such devices that the most confusion arises, the maximum number of errors are allowed when, after installation and connection, it turns out that the heated towel rail either barely heats up, or is even tightly “locked”. Therefore, further consideration will be devoted to various mounting options for more complex schemes.

Read how to do it with full instructions and photos in our new article.

Recommended and impermissible connection schemes for heated towel rails

Lateral or diagonal connection

In the first place, we put a scheme that is highly versatile and therefore used extremely often. In principle, it largely repeats the simplest options, which have already been described above.

The scheme works equally well with a towel warmer of the "ladder" type of universal connection, with water supply in the rack from above or below. It does not require any offset or narrowing of the bypass. There is no dependence on the pressure of water in the riser and the speed of its movement. Removal from the riser, in principle, is also not regulated. Subject to all connection rules, there is no need to resort to bleeding air if there was a temporary shutdown of the water supply.

In order for such a scheme to demonstrate all its advantages, it is necessary to adhere to the following rules:

- The lower point of the tie-in to the riser must be lower than the lower connection pipe for the heated towel rail. Accordingly, the upper inset is higher than the upper connection point. At the same time, a slope of approximately 20-30 mm per linear meter of eyeliner is observed. True, this condition becomes even optional if the heated towel rail is located at a distance of no more than 2 meters from the riser, and pipes with a diameter of 32 mm and above are used for the connection. In such conditions, it is quite possible to confine yourself to a horizontal eyeliner.

- No bends are allowed on the supply lines, as they become potential "air collectors" that prevent the normal circulation of water.

- No narrowing or offset of the bypass is required. Moreover, when water is supplied from below, the narrowed bypass becomes only an obstacle, which can completely block the internal circulation through the coolant. When supplying water from above, it is possible to narrow the bypass, based on one step of diameter less than the riser, although with such a scheme this will not matter much, and the expediency is doubtful, since the universality of the system simply disappears.

- The diameter of the supply pipes must be at least DN20: 25 for polypropylene with high-quality internal reinforcement or ¾ inch for VGP steel pipes. When installing ball valves - the size is also at least ¾ inch.

- The practice-proven allowable distance from the riser when using PPR pipes is up to 4.5 meters.

- It is desirable to place pipes in a layer of thermal insulation, and when they are hidden (that is, located in a slot cut in the wall), this becomes a prerequisite for normal operation.

Find out some of the available ways in our new article.

By the way, despite popular belief, the diagonal connection in this case does not have any special advantages. Apparently, they think so by association with heating radiators, where, in fact, with a diagonal tie-in with an upper coolant supply, the total heat transfer of the battery increases by 5 ÷ 7%.

Such a scheme allows some modification, for example, when there is a need to arrange the supply pipes a little differently.

In principle, even according to the scheme of this option, it can be seen that no conditions have been changed - the only difference is in the tie-in points into the riser and in the presence of vertical sections at the inlet and outlet of the heated towel rail. This does not affect the efficiency of the device and its performance in any direction of water supply.

The illustration shows another version of the side connection. It happens that the installation conditions do not allow to spread the tie-in pipes into the riser to the height of the heated towel rail. This means that we can apply this option, however, with such a tie-in, it is already impossible to do without installing an air vent on the device itself - due to the resulting step, after a temporary shutdown of water, an air lock is formed in the heated towel rail, which will have to be released manually.

Now - several valid schemes with a narrowed or offset bypass. As already mentioned, there is no particular need for such measures, but still many plumbers adhere strictly to their points of view and try to do the sidebar in this way. Another option is that an offset or narrowed bypass was already installed on the previously standing heated towel rail, and there is no desire to completely redo the riser design.

So, the same two schemes, with lateral and diagonal connections, but only on the riser between the outlets to the heated towel rail, a narrowing was made - by one diameter step.

It would seem that such an approach is obvious. But then again - apparently, the associativity of thinking is triggered, caused by the requirements for such an installation of heating radiators in a single-pipe system. But a heated towel rail is still not quite a radiator, and such alterations are not needed here. Moreover, such a scheme will work only with the upper water supply. If the supply is carried out from below, or even in the case when the direction of flow on the riser is unknown to the owner of the apartment, it is better to refuse this approach.

And in the rest - the top feed scheme is quite efficient and effective, not particularly limited by the distance from the riser to the heated towel rail. The basic requirements in it are the same as with a direct, not narrowed bypass.

Now - a variant with an offset bypass. Displacement is also often used when wiring radiators, it is also used by craftsmen when installing heated towel rails. This approach is especially justified when trying to keep the old riser bends, to which the most primitive loop, which was described at the beginning of the section, was attached. In order not to change the entire riser, you can simply embed the bypass.

But at the same time, it must be borne in mind that the flow direction must also be from top to bottom. Otherwise, situations are quite likely when the device will remain cold.

Another point is important - with a displaced bypass, you should not use a narrowed pipe for its installation. This can significantly reduce the efficiency of the heated towel rail, unbalance the normal circulation of water. In general, it is always advised to strive to ensure that the bypass in front of the heated towel rail is equal in diameter to the riser.

Otherwise, all the requirements and tolerances for the installation of such a circuit are similar to the side connection with a direct bypass.

Bottom connection of heated towel rail

This method of mounting a heated towel rail is popular because it allows you to covertly lay out the supply pipes without resorting to large-scale chiselling - some of the lines can simply be hidden by accessories standing along the walls. In addition, a number of models are designed specifically for this type of installation. I must say that the heated towel rails-“ladders” with a lower connection look very impressive, although in terms of efficiency they still lose to appliances with a side or diagonal connection.

The connection of such heated towel rails, despite its apparent simplicity, is also subject to certain rules. Let's look at a few acceptable schemes.

This scheme works regardless of the direction of water flow. A prerequisite is the presence on one of the vertical collectors of the "ladder" of the Mayevsky crane - any shutdown of the water always leads to airing the device. Usually, drain taps are included with the heated towel rail and are covered with a decorative cap so as not to be out of harmony with the general background. If the hot water supply in the house is stable, you will often not have to resort to air release.

What basic requirements should such a scheme meet?

- The lower outlet from the riser in any case should always be located below the heated towel rail.

- The upper outlet, in the case when a narrowed or offset bypass is used, should also be located below the heated towel rail - only in this case will versatility be achieved, that is, the device will function in any direction of water flow. With a smooth, unbiased bypass, this requirement is optional, but it is better if, on any horizontal section, the supply pipe still has a slight upward slope, from the riser to the heated towel rail, at least from 5 to 30 mm per linear meter of length. A strictly horizontal arrangement of the liner from the upper outlet is allowed only at small distances from the riser or when using pipes with a diameter of more than 32 mm.

- Naturally, "humps" where air can accumulate should be completely excluded along the entire length of the pipes.

- With a lower connection, the pipes are most often hidden in the thickness of the wall, so you will have to put them in a thermal insulation shell anyway.

Variants of the scheme shown above can be as follows:

The need to place the supply pipes from the riser to the heated towel rail at a minimum distance from the floor makes it necessary to lengthen the vertical sections before connecting to the device. But it doesn't really change anything. Both outlets are located below the heated towel rail, which is optimal for all such schemes. The direction of the flow is any, it does not affect the efficiency in any way.

If such a situation arises, then it is necessary to follow the rule so that on the upper branch, in the horizontal section, the rule of a small rise upwards is still observed (shown by the blue arrow), even if only by 5 ÷ 20 mm per meter. In this case, the universality of the circuit will remain, that is, its independence from the direction of water flow in the rack.

This scheme meets the same requirements as the one above. The only requirement is that the diameter of the bypass must not be less than the diameter of the riser.

But what if you plan to connect the bottom connection of a heated towel rail, and the old tie-in with a displaced bypass remains on the riser, and I would not want to redo it all. At the same time, the upper outlet is located high enough, and if you follow the rule that it should be below the connection point, you will have to lift the device to the ceiling itself. There is also a solution to this, but only if two important conditions are met.

- Firstly, such a scheme will be guaranteed to work stably only with the upper water supply. When feeding from below, it is very likely that the internal circuit will "lock" and the appliance will remain cold.

- Secondly, the upper outlet of the riser in any case should be located below the upper edge of the heated towel rail, otherwise the device will not be able to work in principle.

If at least one of these conditions is not met, then there is nothing to think about - you will have to deal with altering the riser on a straight line, with a smooth and not narrowed bypass. Then there will be a full opportunity to choose the optimal connection scheme.

Obviously NOT working, erroneous wiring diagrams

For the sake of the external design of the bathroom or in pursuit of maximum savings in effort and money (for example, when using old sections of wiring or channels punched for other needs in the walls), inexperienced craftsmen sometimes make mistakes. These omissions lead to the fact that, with a visual, seemingly correct tie-in, the heated towel rail remains cold, despite the correct operation of the hot water supply.

We give as examples the most common incorrect connection schemes.

Probably, everything is clear without words - wanting to bring the pipe from above (usually for the purpose of some kind of disguise, for example, over a false ceiling, because it’s hard to think of other reasons), the “master” created a “hump” in the section of the piping from the top outlet. The result is a loop in which air will definitely begin to accumulate. Moreover, this will happen even with a relatively stable operation of the hot water supply system - small air bubbles in hot water are present almost constantly. Sooner or later, a situation will arise when an air lock simply blocks the circulation through the heated towel rail, and the device will remain cold.

In theory, all this is solved by installing the Mayevsky crane loop on the upper section of the resulting loop. But then, in general, what's the point of starting all this, if there is a desire to perform hidden eyeliner?

In this example, the key condition is not met - the location of the lower outlet below the bottom point of the heated towel rail. It turns out that the mechanisms of forced and natural (gravitational) circulation of water come into "antagonism".

The water that has cooled down in the heated towel rail tends to sink down and involuntarily finds itself in a kind of “trap” formed by the loop created between the point of the lower tie-in into the riser and the lower edge of the device. It is difficult for her to freely enter the riser, and hot water does not allow her to overthrow.

It is possible that at first the heated towel rail will seem to be efficient, however, a rather significant gradation in temperature will be felt - the bottom is clearly colder. At a certain “critical mass” will reach, when it will be much easier for water to flow through the riser, bypassing the device. The circulation will stop, the heated towel rail will simply turn into a “decoration” of the bathroom.

Here, in general, everything is wrong - the lower eyeliner, and both cut-in points are located above the lower edge of the heated towel rail. There is no incentive for water to flow through the small circuit at all, and in addition, two “trap bags” are formed at once for the cooled water, which are described above.

The “master” decided to hide the upper eyeliner from the ceiling, and put the lower one into the screed. The result is a "scheme" that will not work immediately for two reasons. Air will accumulate from above, and from below - again, a “bag” has formed, making it difficult for normal circulation. The result is the same - very soon the heated towel rail will “stand up” tightly.

Finally, consider the side connection scheme, already mentioned above, but which can be considered conditionally working, only with the top water supply. Again, we are talking about the "hobby" by some plumbers with narrowed or offset bypasses.

What is the matter here, after all, it would seem that all the requirements are met? And the snag is in the narrowed or displaced bypass.

Due to the fact that a displacement or narrowing is made, at the lower point the fluid pressure at the inlet is higher than at the upper one. This means that a working pump that circulates in the riser will tend to “pump” water into the heated towel rail from below. But the gravitational flow of cooled water necessarily goes towards it. It turns out that they meet at the bottom point and begin to mutually inhibit each other.

And here it is - "how lucky." If the circulation pump is powerful enough, then it will, of course, push through the gravitational oncoming flow. True, at the same time, areas of uneven heating may well appear in the heated towel rail itself, since the forced flow will most likely choose the path of least resistance, while pushing the cooled water “to the periphery”.

But even in this case, it is impossible to exclude a pronounced direct dependence of the performance of the heated towel rail on the pressure in the riser. It is worth the pressure of hot water to drop to a certain mark - and the circulation through the device will completely stop. Moreover, this pressure drop does not necessarily have to be associated with any emergency situations. Simply, for example, in the evening, the total water intake in a multi-storey building increases - and this may already be enough for the heated towel rail to become slightly warm, or even completely cold.

Attempts to understand the effectiveness of a heated towel rail in such a situation using a diagonal connection will only aggravate the situation, and the likelihood of normal operation will become even less. Forced flow will have to overcome a much greater hydraulic resistance, passing the device diagonally, while the gravitational back pressure remains at the same level. So instead of improving, you can get a completely inoperable heated towel rail.

The conclusion is obvious - a narrowed or offset bypass with a side connection of the device will be justified only when hot water is supplied from above, so that the forced and gravitational flows go in the same direction, reinforcing each other.

So, the most popular correct schemes for installing a heated towel rail in the bathroom were considered, and an analysis of possible errors was carried out. The author will consider his mission fully accomplished if the home master has a clear idea of which installation option to choose in order to guarantee an efficient working device.

As for the installation work itself, it is very difficult to give any ready-made recipes here. A lot depends on the type of heated towel rail, and on the type of pipes chosen, and on the desire to hide them or leave them in sight, the skills of the master to apply one or another technology for their connection.

Therefore, we will limit ourselves to the fact that, as an example, we will post several videos that demonstrate the process of installing heated towel rails of various models.

A few illustrative examples of the installation of heated towel rails of various models

Video: Installing an M-shaped heated towel rail directly on the riser outlets

Video: Mounting an M-shaped heated towel rail on "water outlets"

Video: installation of a vertical heated towel rail - "ladders" with a bottom connection

Currently, there is a catastrophic situation with unskilled intervention in the operation of common house systems, in particular, during the installation or alteration of heated towel rails (PS) connected to hot water risers.

This article describes the principles of the functioning of the PS, provides examples of both competent connection and initially non-working or unstable options, explaining the reasons for their inoperability.

I will make a reservation that the article will talk about relatively new houses in which heated towel rails are connected to the same hot water riser, from which the apartments are supplied with hot water. But in some houses (the overwhelming percentage of the secondary housing stock), a separate hot water recirculation riser is intended for heated towel rails. Or the riser of heated towel rails is powered by central heating, i.e. PS do not work in the summer. The topic of this article does not apply to such houses.

All diagrams and photos increase when you click on them.

A bit of history, old types of PS.

Twenty years ago, the substation "from the developer" was a monolithic riser pipe, curved in the form of the letter P or M.

Figure 1: U-shaped substation, which is part of the riser a.

Figure 2: M-shaped SS, which is part of the riser.

Despite the unsightly appearance, this type of substation had undeniable advantages: it was constantly hot, did not introduce any noticeable hydraulic resistance, and did not allow residents to disturb the operation of the hot water supply (DHW) riser in any way.

However, time passed, and the tenants in the old housing stock, making repairs, changed the old and ugly substation to a new and shiny one. In a good scenario, it turned out like this:

Figure 3: New substation, which is part of the riser, a competent replacement.

The diameter of the substation corresponds to the diameter of the riser, the connection is made without narrowing and without stop valves (cocks).

In case of an unsuccessful scenario - like this:

Figure 4: New substation, which is part of the riser, illiterate replacement.

Four extra constrictions from the used fittings appeared in the riser:

Figure 5: Internal section of a fitting for multilayer pipes.

But it gets much worse:

Figure 6: The new SS, which is part of the riser, is a completely illiterate replacement.

In addition to the narrowing already mentioned above, shut-off valves have been added. When any of them is blocked in the riser, the circulation stops completely, the pressure in the apartments following in the direction of supply drops down to zero (water can somehow come from the “return” line), the riser cools down in the absence of water intake, when the mixer is opened, cold water has to be drained for a long time .

Installation of shut-off and control valves (faucets) on risers is strictly prohibited!

Branches from the DHW riser for heated towel rails.

Over time, developers began to use more modern technologies and, instead of a terrible bent pipe, they began to make two branches from the riser to connect the substation at the choice of the residents themselves. However, unfortunately, neither the type, nor the height of these outlets from the floor, nor the distance between them is in any way standardized. This leads to massive problems when connecting the PS, which will be discussed below.

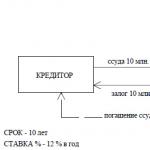

Figure 7: Riser taps, unshifted and unrestricted bypass.

Figure 8: Riser taps, narrowed bypass.

Figure 9: Riser taps, offset open bypass.

Between the taps there is always a bypass - a pipe section with a diameter equal to the diameter of the riser or 1 step less.

The bypass at the heated towel rail solves several problems:

- Maintaining the normal circulation rate throughout the hot water riser (HW). Forced circulation in the riser ensures the supply of evenly hot water (according to the norms - 60 degrees) to any apartment, on any floor, regardless of its distance from the start of supply to the riser.

- Only part of the total flow (water) passes through one substation, the other part goes by, keeping more heat for the next bathrooms. After all, one or two dozen heated towel rails can work from one riser.

- It is possible to completely turn off the substation or adjust its temperature by residents without affecting the rest of the apartments (the latter requires the installation of an additional control valve on one of the outlets, since it is impossible to regulate anything using a ball valve).

Let's talk about physics. Gravity pump in PS.

If the performance of the substation at a narrowed or displaced bypass still somehow fits in the heads of plumbers who think in terms of “push through or not push through”, then the scheme without shifting the bypass and without narrowing the riser plunges them into a complete stupor: “All water passes by the towel! It won't go there! It can never work!"

However, the PS with this connection works great! At the heart of its performance is the "gravity pump":

improves the circulation of the PS, increasing the pressure of the "gravity pump" in the PS itself.

a.) Slows down the circulation in the entire riser (the temperature of hot water drops from the points of water intake in the apartments).

To improve the circulation according to this scheme, the local widening of the unbiased (axial) bypass in the area of the upper branch to the substation can be improved. A photo of such a bypass is shown below.

Permissible options for the execution of scheme No. 1.

.

.

Figure 14: Side connection, example of correct execution.

The vertical substation is located entirely between the taps, no conditions for the operation of the circuit are violated.

Figure 15: Side connection, example of acceptable design.

The top of the PS is above the top outlet. It will be necessary to bleed air from the PS after turning off the water.

Scheme No. 2: bottom connection.

Less effective than lateral has its advantages and disadvantages.

Figure 16: Connection of a PS ladder running on natural circulation, without constriction and without offset bypass. Bottom connection.

Figure 17: PS-ladder connection operating on a combination of forced and natural circulation, with bypass offset. Bottom connection.

Figure 18: Connection of a PS ladder, operating on a combination of forced and natural circulation, with a narrowed bypass. Bottom connection.

Site author's opinion:In my opinion, the operation of schemes No. 16-18 may be unstable with a lower supply through the riser. Or even completely impossible.

Especially schemes No. 17-18. Therefore, I would not advise using these schemes, especially with a lower supply through the riser. Or when the riser supply is unknown.

Also, in my opinion, these circuits practically do not use pressure. And they use only forced circulation. Therefore, I personally do not like the bottom-bottom connection of the PS at all. And I do not advise anyone to use them only with gravitational circulation. And use only the lateral or diagonal top-bottom connection. And the bottom-bottom connection, from my point of view, to obtain a guaranteed result, can only be used with purely forced circulation, in private houses and apartments with individual autonomous heating.

Benefits of the scheme:

Works with any direction of supply in the riser.

The ability to run pipes somewhere hidden under the bathroom, without shoveling the walls.

The disadvantages of the scheme:

It is required to bleed air through Mayevsky's taps.

Less efficient than side or diagonal connections.

The upper branch of the riser with an offset or narrowed bypass must be below the connection point to the substation. This guarantees the independence of the work of the PS from the direction of filing.

The lower tap must be below the PS in all variants of this scheme.

The slope of the supply pipes must be observed (the direction is shown in the figure)

3 - 5 mm per meter.

There should be no “humps” (completely unacceptable, air will accumulate in them and

circulation will stop) or dips on horizontal routes (permissible only in

small limits, deep "pits" will air the liner to the substation).Pipe diameter for maximum circulation - preferably at least 3/4”

(32mm for PPR), ball valves - at least 3/4”. The use of pipes and taps smaller

section is allowed only with a small length of pipes leading to the substation, but in this case uneven heating may become noticeable

PS - hotter on top, colder on the bottom.It is highly desirable to place the supply pipes in thermal insulation. Besides what it is

a prerequisite for embedding pipes in the walls of the PPR, such insulationimproves the circulation work of the PS.

It is strictly forbidden to install any taps on the bypass - this is vandalismand wrecking yourself and your neighbors. Overlapping or excessive narrowing of the bypass:a.) It slows down the circulation in the entire riser (the temperature of hot water drops at the points of water intake of apartments).

B.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - and at the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

B.) Does not improve the efficiency of the above scheme in any noticeable way.

Permissible options for the execution of scheme No. 2.

Figure 19: Bottom connection, acceptable design example 1.

All taps are below the PS, no conditions are violated.

Figure 20: Bottom connection, acceptable design example 2.

The top outlet is higher than the bottom of the substation.

Please note that this immediately imposes a restriction on the feed direction - only from above!

With a bottom feed, such a connection is unstable.Scheme No. 3: lateral and diagonal connections with a narrowed or offset bypass.

The vast majority of plumbers believe that there must be a narrowing between the taps on the substation - otherwise nothing will work. Firstly, this is not the case (see diagrams Nos. 1 and 2), and secondly, in the case of a lower water supply in the riser and poor circulation, the narrowing prevents the heated towel rail from working until it is completely cooled, despite the outwardly normal connection. Therefore, if possible, it is worth striving to ensure that the diameter of the bypass is equal to the diameter of the riser.

Figure 21: Connection of a PS-ladder operating on a combination of forced and natural circulation, with a narrowed bypass.

Side connection.

Figure 22: PS ladder connection operating on a combination of forced and natural circulation, with bypass offset. Side connection.

Figure 23: Connection of a PS ladder operating on a combination of forced and natural circulation, with a narrowed bypass. diagonal connection.

Figure 24: PS ladder connection operating on a combination of forced and natural circulation, with bypass offset. diagonal connection.

Note that the direction of supply in the riser is now unambiguously indicated by the top.

With the bottom feed, these options are categorically not recommended to use. the reasons will be described below.Cons of this scheme:

Stable operation is guaranteed for top feed only.

The advantages of this scheme:

Definitely and stably works at the top giving in a strut.

It is not required to bleed air from the PS after turning off the water.

The distance from the riser is arbitrarily large.Conditions for the scheme to work:

Once again, we recall that at the bottom feed, the narrowing / displacement between the taps prevents the operation of the PS up to its complete inoperability! At the top feed, the bypass can be narrowed by a maximum of 1 step from the diameter of the riser. Tapering of the offset bypass is never required at all.

The lower outlet of the riser should be below the bottom of the substation, and the upper outlet of the riser should be above the top of the substation.

It is necessary to observe the slope of the supply pipes (the direction is shown in the figure) of at least 3 mm per meter, but better than 30 mm per meter.

There should be no “humps” (completely unacceptable, air will accumulate in them and circulation will stop) or dips on horizontal routes (allowable only within small limits, deep “pits” will interfere with circulation).

Pipe diameter to ensure maximum circulation - preferably at least 3/4 "(32mm for PPR), ball valves - at least 3/4". The use of pipes and valves of a smaller cross section is allowed only with a small length of pipes leading to the substation.

It is desirable to place the supply pipes in thermal insulation. In addition to the fact that this is mandatory when embedding pipes in the walls of the PPR, such insulation will improve the operation of the substation in certain cases (sagging pipes or "pits" on them).

It is strictly forbidden to install any taps on the bypass - this is vandalismand wrecking yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

a.) Slows down circulation throughout the riser (hot water temperature drops).

B.) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - and at the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

C.) It does not noticeably improve the efficiency of the above scheme, and with a lower feed, on the contrary, it interferes with the operation of the PS.

Why is my PS not working?

Let's analyze typical PS connection errors (the section will be gradually updated with links to real examples).

Figure 25: Side connection, INCORRECT example 1.

Figure 26: Bottom connection, INCORRECT example 2.

PS is located below the lower outlet. The water that has cooled in the PS and descended is trapped in the lower part of the PS and the pipe (the stagnant zone is from the bottom of the PS to the level of the lower outlet), and is not pushed back into the riser, since lighter hot water presses on it from above.

The substation connected with such a violation operates until a certain height difference “lower outlet - bottom of the substation” is exceeded (it is impossible to predict the exact value) - then the natural circulation in the substation stops.

Figure 27: Side connection, INCORRECT example 3.

The upper pipe forms a loop in which air accumulates - the circulation in the PS stops. Operation is possible if there is an air bleeder (automatic or Mayevsky) at the top of the pipe.

Figure 28: Side connection, INCORRECT example 4.

A combination of previous non-working cases, usually formed when trying to lay one pipe behind the ceiling, and the second in the floor screed.

The upper pipe forms a loop in which air accumulates, and the water cooled in the SS ends up in the “sump” formed by the lower pipe loop and is not pushed back into the riser. The circulation in the PS stops.

Figure 29: Side connection, INCORRECT example 5.

The performance of the side connection with an offset or narrowed bypass and BOTTOM supply is critically dependent on the circulation in the riser.

At a low circulation rate, the PS does not work, because in the lower outlet due to displacement / narrowing, the pressure is greater than in the upper one - the circulation pump tends to supply water to the PS through the lower outlet, and the "gravity pump" inside the PS tends to lower the cooling water way down. Mutually opposite flows decelerate each other and the circulation in the PS stops.

If the riser has not yet been mutilated by the neighbors, and there is a powerful circulation pump in the basement, then as a rule the pump “wins” and circular circulation starts in the substation: hot water rises along the left collector, on the right - the cooling water goes down, gradually mixing with hot water in the left manifold through the horizontal jumpers.

However, if someone puts, for example, a barbarian tap on the bypass, the circulation rate may drop so much that the substation will stop working. Either it will either work or not, depending on the time of day (different water intake from the riser).The diagonal connection here is even worse than the side connection. The chances of a successful launch are less, because the hydraulic resistance of the PS increases, which the pump has to overcome, and the resistance of the pump remains the same.

Reprint is not allowed

with attribution and links to this site.If you have any questions - ask them in the forum topic of this site "How to connect a heated towel rail" -

Therefore, questions and answers this article is currently closed. Please ask questions in the above forum topic of this site.