The device of a cold attic gable roof. How to make a cold roof from a metal tile - installation instructions

All roofs for houses according to their configuration can be divided into: flat, pitched. Flat, have a flat roof with an angle of inclination of 3-5 degrees. These are rarely used today, because they often have stagnant water. This type of roof device is suitable exclusively for outbuildings, as well as for small-sized baths.

In turn, pitched roofs are used much more often. They, in turn, are divided into:

- (forceps);

- semi-hip duo-slope;

- half-hip four-slope;

- multi-tweezers (polyhedral).

The most popular among the above are one- and two-pitched roofs, which are often also called “cold” and “warm” because of the construction of the rafter system and the roofing pie.

Cold roof technology

It can only be used in cases where the room is characterized by the necessary thermal insulation, including from the side of the ceiling adjacent to the attic, or if a small room is being built.

The main difference between the "cold" roof is that it is installed directly with emphasis on the wall of the house. That is, the main load will not go to the rafters, but to the room. The bars will hold the roof directly on themselves, so their thickness can be selected from 5 centimeters or more.

The emphasis of the rafters is on the Mauerlat. Runs, struts, racks and beds, in most cases, are not equipped, since even ordinary crossbars are quite enough to securely hold the shape of the roof and prevent it from beveling in the future during operation (due to wind and rain). The ridge run rests directly on the rafter legs.

The roofing pie for a “cold” roof consists of one level of lathing, an external roof (which can be tiles, slate), vapor and waterproofing. A layer of insulation is not provided, since the cold roof attic is not intended to be used as a living space.

However, thanks to a properly arranged ventilation system, the temperature inside the roof attic is 5-10 degrees higher than that of the environment. Thermal insulation is attached to the floor of the attic space, which protects the interior of the residential part of the house from cold air. Ventilation pipes are also laid here, a vapor barrier membrane is laid, which protects the house from condensate.

The device of the cold roof is simple, therefore it is suitable for the construction of summer kitchens, closed gazebos, the construction of modular block containers (which are initially insulated).

For more information about installing a cold roof under a metal tile, see the video.

The device of the truss system of a warm roof

The rafter system for warm roofs is somewhat more complicated, since it involves the operation of the attic as a living space. The best option for this type of roof is the attic system, which allows you to get a fairly large amount of free space. The device of the roofing pie in this case is as follows:

- roof;

- crate and counter-crate;

- steam and waterproofing;

- thermal insulation (mineral wool or polystyrene foam plate);

- decorative layer (interior decoration).

The main difference between the design of the truss system is that it is held by support

beams, as well as Mauerlat. Additionally, the roof is divided into runs and struts (for gable systems). The angle of inclination of such roofs, as a rule, is divided into two parts: at first it is about 120 degrees, then (after the last support beam) - about 35.

A fairly well-known technology for arranging roofs is a system with sent rafters. But today it is rarely used, because it requires a large amount of wood materials, although it does not make it possible to equip a full-fledged living space in the attic.

The undeniable advantages of this technology include: high-quality load distribution, adjustable roof height (the angle can be easily changed during construction). But still, roof structures with hanging rafters are much more often used.

Also in the truss systems of warm roofs, the so-called "wind beam" is provided, which is responsible for the stability of the roof. The lateral rafter legs, as a rule, are lengthened due to wooden "fillies", to which it is later convenient to mount drainage systems.

Installation of the central beam is carried out in cases where the running length of the roof is more than 7 meters. If the length is shorter, the decision should be made depending on the load on the ridge span. If it turns out to be too high, this will lead to the penetration of additional moisture into the interior of the attic, condensate, which, of course, must be avoided.

Sheathing and reinforcing bars

The counter-lattice is an additional layer of thin rafters that are used in warm roofs for installing internal thermal insulation. A crate of this type can also be attached directly to the retaining strips, if they are provided for by the overall design.

Installation of reinforcement strips begins with the installation of the upper retaining beam. A Mauerlat is laid along the perimeter of the roof, which is pulled together with puffs (the bars are laid directly on the roof and fastened with solid brackets or studs). The retaining bars are fastened to the main beams through metal corners (tightened with 4-6 self-tapping screws).

Roof insulation and waterproofing

As a waterproofing for warm roofs, a mineral wool reinforcing mesh or a simple polyethylene film is used. In some cases, it is recommended to install it in two layers: above the thermal insulation and under the thermal insulation. It should be borne in mind that this option is possible only in cases where a basalt mat resistant to moisture is used as a heater.

It is important to note one more point: waterproofing will reliably protect the roof from condensate only if it is laid between the crate and counter-batten. At the same time, it is most convenient and most reliable to install the heat-insulating layer directly along the inner bars (laying mats vertically between them). But it is also possible in two layers, while the inner one must be installed horizontally (depending on how the counter-lattice was mounted).

In most cases, installation of sound insulation is not needed, but if you decide to use it, then it is recommended to lay a layer already behind the insulation before interior finishing (gypsum board).

Roof ventilation system

The roof ventilation system can be equipped in two ways. The first is suitable if you do not intend to use the attic for living. It is most rational to equip traditional natural ventilation through the side bevels. But keep in mind that if a warm chimney passes through the attic, cold air will accumulate in the lower part of the room. If, however, internal ventilation is simply removed through the attic, cold air, as well as condensate, will form directly under the roof.

In systems of warm roofs, as a rule, artificial ventilation of the room is provided. Its performance is calculated based on the volume of the attic divided by 3 or 4. This system is necessary in any case, since an anti-condensation membrane is additionally installed in such roofs. And it significantly worsens the air exchange between the external and internal environment.

Instructions for laying metal tiles

It starts with the installation of the cornice strip, the lower valley, as well as the adjoining panels. Then, along the rafters, the sheets of metal tiles themselves are laid, which are attached to the wood base using self-tapping screws (it is roofing fasteners that are used) and ends with the installation of the ridge element, the upper valley and end plank.

For more information about editing and its main mistakes, see the video.

The cost of work on the installation of metal tiles depends on the complexity of the work (high roofs, slope angles), whether it is insulated or not. On average, in Moscow, the price for installation will cost 400-450 rubles per sq.m., if insulation is necessary, then the cost increases by 70 rubles per sq.m. for each layer (50 mm.). Often, in addition to laying, it is necessary to dismantle the old roof, and this is a plus to the cost of about 100 rubles. per sq.m.

Completion of roofing works

Work on the arrangement of the roof and roofing ends with cleaning the roof from unnecessary elements: sticks, tools, sawdust, shavings, etc. It is necessary to paint over the metal roofing with paint in the color of the roof in places where metal tiles are trimmed and cut to prevent corrosion of the metal.

If interior decoration of the attic space is expected, it is most convenient to use drywall or plywood board. In order for the inner decorative layer to turn out to be absolutely smooth and even, it should be mounted on aluminum profiles (they are also attached to the counter-lattice with the help of corners and belts). After that, you can do the installation of gutters around the perimeter of the roof.

When arranging an unheated attic, there is no need to spend money on roof insulation. It is enough to close it from precipitation to give a presentable appearance. The most common materials for roof decoration are soft and metal tiles, corrugated board.

Design

Any non-insulated roof includes standard components:

- Rafters that act as a frame that carries the coating.

- Waterproofing is laid to protect the attic from water in case of violation of the integrity of the finishing roof.

- Bars for organizing roof ventilation.

- The horizontal crate acts as a base for the corrugated board, a solid plywood flooring is laid under the flexible tiles.

This is the backbone of any roof, when using different materials and technologies for laying them, the cake is supplemented with different components. Let's consider the options for arranging roofing pies.

Basic layers

Installation of a cold roof begins with a waterproofing device. Some experts believe that this layer can be neglected and save time and money. To be or not to be waterproofing? Let's take it in order:

- No master will give a 100% guarantee that nothing will happen to the roof. Natural disasters, improper preparation of wood, the human factor during construction and operation can lead to a violation of the integrity of the roofing at any time. As you know, the cladding has a hydrophobic property, which means it protects the under-roof space from water penetration. Imagine that the layer is broken. Where will the water go - on the floor, flooding the ceiling and the attic.

- Removing condensate is another task of waterproofing. As a result of convection, the steam settling on the lower part of the roof will escape, and not linger on the wood, degrading its quality.

Do you need waterproofing of a cold roof or not - experts are actively arguing about this. We recommend playing it safe and still making a protective layer. Moreover, you can buy a membrane quite inexpensively.

By the way, you should not use an ordinary film for waterproofing - it does not conduct moisture, which means that condensate cannot be released from the attic. The cold roof pie includes membranes having a similar polymer composition, but equipped with a finely porous structure.

The membrane is attached to the rafters, allowing the material to sag a little. The waterproofing should be fixed with lathing bars, which will provide the necessary ventilation corridor through which steam will be removed.

Further arrangement of the pie depends on the choice of roofing material.

metal tile

Cold metal roofing is a frequent choice of developers. This is an aesthetic facing material with excellent performance, easy to install. Much can be said about the advantages:

- Long service life;

- Resistant coating;

- Bright color that does not fade in the sun;

- High bending strength, which is important in snowy climates.

Sheet metal dimensions:

- Length from 40 cm to 8 meters;

- Width - 1.16 ... 1.19 meters;

- Thickness - 0.45 ... 0.5 mm;

- Profile height - 1.8 ... 2.5 cm;

- Wave step - 35 ... 40 cm.

The length of the sheet is the vertical dimension, that is, the metal tile is laid in one sheet from the ridge to the eaves. Accordingly, the width is a measure of the cornice or ridge.

The choice of sizes must be approached comprehensively:

- The length should be chosen based on the length of the roof. In addition, it should be borne in mind that long sheets will be inconvenient to transport and carry, stack, so at this stage it is necessary to think over the technical side of the organization of installation.

- The thickness of the sheet determines the strength of the sheet along with the height of the profile and the pitch of the wave, which is the stiffener.

The procedure for constructing a pie of a cold roof from a metal tile:

- On the bars of the ventilation crate, slats 100 × 30 are collected with a step equal to the transverse step of one sheet.

- The first rail should run along the lower edge of the roof, it is stuffed with a double bar (2 rails are nailed to each other). Brackets for the drainage chute are attached to them.

- Installation of sheets starts from the extreme row, leaving a small overhang. The sheets are fastened with self-tapping screws through the wave to the horizontal crate.

- Subsequent sheets overlap the previous one by at least 80 mm.

- The ridge is decorated with a special corner bar made of metal. It completes the design of the slopes and protects against leaks.

Decking

The profiled metal sheet is similar in structure and method of installation to metal tiles. The corrugated board has longitudinal stiffening ribs, which provide rigidity to the coating. The greater their height, the stronger the sheet.

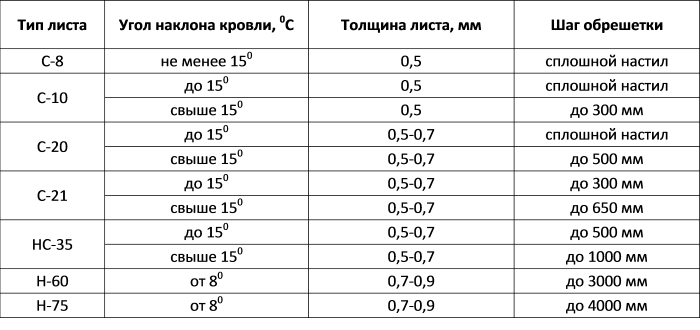

The transverse crate for corrugated board is calculated as follows:

- With a roof slope of less than 150, the pitch of the boards is 400 mm;

- Angle 15-30° - pitch 300…400 mm;

- An angle of more than 30° suggests a batten with a pitch of 100 mm or a continuous flooring.

The step can be determined by the characteristics of a particular sheet:

The device of a cold roof from a professional flooring:

- Cross slats are stuffed onto the ventilation crate with a step determined by the angle of inclination.

- They make out the bottom rail, the brackets of the drainage chute are screwed to it.

- Installation of profiled sheets is carried out in a horizontal or vertical direction, starting from the bottom row, moving towards the roof ridge. The sheets are fixed with screws to the crate in increments.

- They crown the roof with a ridge.

Soft tiles

The soft tile is a polymeric and fiber glass imitation of a natural tile. Unlike ceramics, fragments of improved bitumen are easy to install, they are resilient and not at all brittle, and easily withstand any weather conditions. Soft tile (shinglas) is reinforced with mineral powder, which adds resistance to precipitation, snow and small debris raised by the wind. The main limitation of its use is the slope of the roof, it must be more than 12 °.

The design of a cold roof for soft tiles includes a solid flooring of OSB, plywood or boards laid with a continuous carpet without gaps. Such a rigid base is necessary to provide rigidity under the soft material.

The order of the device of a roof from a soft tile:

- On the prepared base (rafters with waterproofing and lathing), horizontal slats with a thickness of at least 30 mm are stuffed. They are necessary to ensure good ventilation and secure fastening of solid decking.

- Lay a solid flooring of plywood or OSB. The edges of the sheets should be located strictly on the projection of the rafter legs to ensure sufficient rigidity.

- The shinglas cold roof pie includes a lining carpet under soft textile tiles. It is fixed with a construction stapler along the guides.

- A dropper, drain brackets are attached along the lower edge.

- The fixation of the tiles starts from the bottom row towards the ridge. Each next part is overlapped with the lower one in a checkerboard pattern, overlapping the fixation points with petals. Fasten the tiles with mounting glue and nails.

- An aerator is built into the upper part of the roof, through which moisture is removed from the roofing cake, it is closed with a ridge corner.

- At the junction with the pipes or walls, bars are installed to them, on which the carpet and fragments of the tile are placed, glued with mounting glue.

Summary

The design of a cold roof is similar for all types of topcoat, only the types of battens differ:

- For metal tiles - a horizontal crate with a step equal to the step of the wave;

- For corrugated board - a horizontal crate with a step depending on the type of sheet and the slope of the roof;

- For a soft roof - a continuous flooring.

It is important to choose the right waterproofing - a vapor-permeable membrane. If a decision is made to equip the roof without a moisture-proof layer, it is necessary to take a particularly responsible approach to the choice of the finish coating and its installation.

The ventilation gap will ensure the safety of the wood components from decay and create a natural steam removal, which will significantly extend the life of the roof.

Most modern houses have a cold attic. Compared to a warm attic or attic, such a roof is less expensive in terms of materials and installation time, but don't let the simplicity of the device fool you. To avoid mistakes when constructing a cold roof, use the instructions from RMNT.

Thermal engineering of a cold attic

Warm air always moves upward, penetrating even the slightest cracks and gaps in the ceiling. To keep maximum heat inside the house, a sufficiently powerful heat protection belt up to 300-350 mm thick is arranged above the ceiling. Thermal insulation is laid as tightly as possible in order to slow down the ascending hot flow as much as possible.

The insulation needs to be protected from getting wet, so the steam that is carried by warm air needs to be blocked. For these purposes, the ceiling is covered from the inside with a vapor barrier - a special membrane that allows gases to pass through, but retains evaporated moisture, and rmnt.ru has already talked about these materials in more detail in a separate article. On the inside, the heat insulator has a sufficiently high temperature and therefore condensate does not fall on the vapor barrier membrane.

The outer side of the heater is cold. It is ventilated with outside air, so that moisture does not accumulate in the insulation. The attic floor is the only stage of thermal protection; no other cold attic structures perform this function.

The main problem with a cold roof is that condensation forms on the back of the roof during temperature changes. Since the air in the attic remains warm for a long time after sunset, and the roof almost immediately takes on the temperature of the outdoor environment, the appearance of moisture drops is an inevitable phenomenon. Falling down, they fall on the floor cake, moistening it. This leads to the weighting of the filler, the loss of heat-insulating properties, the formation of dampness and mold. That is why, when installing the roof of a cold attic, it is mandatory to install under-roof waterproofing.

truss system

Since no insulation will be laid between the rafter legs, their pitch and section can be chosen absolutely freely. The kalk.pro service will help in this matter: in the “Roofs” section, it is possible to model and calculate load-bearing elements and sheathing for any type of roofs.

The most suitable lumber for rafter legs is a board 50-70 mm thick and 100-200 mm wide. Based on the weight of the roof and the predicted snow load, the step between the rafters of this section is adjusted in the range of 60-120 cm. It must be taken into account that the rafters during installation are reinforced with a counter-lattice 30-40 mm thick, so it is reasonable to initially choose a slightly smaller width of the board.

When installing the rafter system, it is imperative to set the legs in common planes in order to subsequently avoid problems with leveling the crate. For these purposes, it is recommended to rigidly fix the extreme rafters on the struts, pull the cords in the upper and lower parts of the ramp, and then put the rest of the legs along them. The rafters must be temporarily fastened from the inside of the roof until the waterproofing and counter battens with the batten are installed on the outside.

Roof waterproofing

Micro-perforated film is best suited for waterproofing a cold roof. This is one of the cheapest and easiest materials to install, which completely solves the problem of condensation. During installation, the roll of film is rolled out across the slope of the slope, starting from the bottom. Each subsequent sheet should be laid with an overlap on the lower one with a width of about 70 mm.

Installation of the hydrobarrier is best done in calm weather. Temporary fastening is carried out with brackets to the upper edge of the rafter legs, while adjusting the stapler spring force so that the bracket does not press close to the film, pushing it through, but forms a gap of about 0.5 mm. The film must be fixed in such a way that a sag of about 20-25 mm is formed between the rafters. This way, water will not soak the counter grille, collecting at the lowest point.

When the entire slope is covered with a hydro-barrier, you need to nail a counter-lattice - slats of the same thickness as the rafter legs. Before nailing the rail, the side with which it is adjacent to the rafters can be coated with any alkyd enamel. Lumber for counter-battens and battens should be pre-treated with fire-bioprotective impregnation. It is recommended to fasten the counter-lattice with either buffed nails or anodized screws. Black hardened screws are not suitable for this purpose.

The counter-lattice performs several functions at once. Firstly, it reliably presses the hydro-barrier, while blocking the punctures at the attachment points. Secondly, due to the increased distance between the coating and the waterproofing, a path for an upward air flow appears, due to which the formed moisture quickly evaporates.

Lathing installation

The type and method of installation of the transverse lathing depends on the roofing used. For a cold roof, both slate and profiled sheet, metal and bituminous tiles are well suited. It all depends on aesthetic preferences and the slope of the slopes.

In total, two types of lathing for a cold roof can be distinguished: solid and plank. A solid crate is well suited for, as well as materials like corrugated board, which make a lot of noise during rain. Tight pressing of the coating to a solid massive base eliminates the unwanted acoustic effect and greatly facilitates the installation of the roof.

A solid crate is made either from OSB of classes 3 and 4, or from moisture-resistant plywood on phenol-formaldehyde resins. The minimum thickness of plywood is 8 mm with a rafter pitch of 60 cm. OSB has a looser structure; for reliable fixation of fasteners in it, the thickness must be at least 12 mm.

It is recommended to install a continuous crate, starting from the front gable, laying solid sheets and shifting the extensions to the least visible part of the slope. Between the plates it is necessary to leave a deformation gap of the order of 10-15 mm. If the joint between the plates is not in the area of the rafter leg, it is allowed to fasten through a backing rail 20-25 mm thick according to the same principle as fastening horizontal joints.

When all sheets are fixed, the joints must be filled with non-hardening bituminous mastic or special roofing sealant. After sealing, it is recommended to check the plane of the crate using a stretched cord, if necessary, installing linings of different thicknesses in the places of the main fastening.

The device of a plank crate is much simpler. Both edged and unedged boards are suitable for it, it is only important not to use materials that are not calibrated in thickness. Sheathing boards are nailed perpendicular to the rafters. In doing so, two factors must be taken into account:

- The main boards to which the coating of the selected format is attached should be located on the overlap line between the sheets. For these purposes, it is recommended to select the widest boards.

- In the range between the main boards, several additional boards should be installed, taking into account the degree of filling of the crate recommended by the manufacturer and the number of intermediate rows of fastening.

If you choose an unedged board, it must be placed with a wider plane up. For fastening it is better not to use screws and self-tapping screws, ordinary nails will work better than any other fastener.

Cold attic ventilation

The last question in the arrangement of a cold roof is the ventilation of the attic. It should be adjustable so that in the summer heat at the level of the attic floor the temperature is close to the air temperature, and in the event of a sharp cold snap there is no heavy condensation. In winter, the ventilation is blocked, which makes it possible to exclude intensive blowing of the insulation and save as much heat as possible.

As a rule, in a private house, an entrance door to the attic and one openable window in the upper part of the gable on the opposite side is enough. If the roof is hip, you need to make a small ledge under the window.

For roofs with an area of more than 300 m 2, additional vents are recommended. They cut into the upper part of the slope and help to remove the air entering the attic in the Mauerlat area. To ensure full air circulation, when sewing spotlights, you need to insert perforated panels after 70-80 cm. It is possible to avoid the installation of vents when covering the roof with a material with a wavy profile. On the line of convergence of the slopes, you need to leave a gap of about 100-140 mm, which is covered with a wide ridge.

Related videos

rmnt.ru, Igor Maksimov

Today, a cold roof made of metal tiles is often erected. Such a product is perfect if the attic space will not be used as a residential building.

It should be noted that today metal tiles are not the market leader in roofing materials. However, the owners of private houses find a large number of advantages in this material, so the demand for it is constantly growing. Many companies make metal tiles, so every owner of a private house will find a suitable option.

If you follow the manufacturer's instructions and follow the advice of experienced craftsmen, then there will be no problems installing this material.

Features of the installation of a roof made of metal are that it is necessary to provide an outlet for ventilation through which condensate will be removed. This is necessary in order to protect the carrier rails and roofing from the negative effects of moisture.

Before carrying out construction work, it is necessary to perform calculations, determine the angle of inclination, the step of the crate and choose the method of fixing the material.

To install a roof of this design, the following elements are required:

- wooden boards;

- vapor barrier;

- waterproofing;

- metal tile;

- staples;

- twine;

- nails made of galvanized metal.

Features of a cold roof

Such a roof has a simple design. It differs from warm in its device. It is worth considering the option of roofing. When using metal sheets, it is necessary to provide a ventilation slot through which condensate will be removed from the space under the roof. In this case, the metal sheet will not corrode.

The device of such a roof is the installation of a rafter system, on which a polyethylene film is laid. After that, you need to nail the counter-lattice, the crate and the coating material. It is best to use a metal tile.

The features of such a roof are the absence of a heat-insulating layer, as well as the presence of exits for ventilation under the ridge and on the slopes through which moisture will be removed. Design and installation are not complex processes, the main thing is to correctly perform all the calculations.

The installation process has the following features:

- If you plan to arrange a warm roof, then special attention should be paid to the choice of a membrane to protect against excess moisture. For the attic device, you can use a membrane that is made of PVC.

- If it is not planned to insulate the structure, you can use microperforated waterproofing, which is intended exclusively for cold metal roofing. Such a film does not allow materials for thermal insulation to be placed next to it, and therefore, in the process of insulation, a new membrane must be purchased. If this condition is not met, the roof cannot be protected from excess moisture, the insulation material will be wet, and the roof coating will begin to corrode.

Back to index

The sequence of actions for the device of the roof

In order to properly install the membrane, it must be taken into account that its installation is carried out with a slight sag.

Such a gap will allow air to move freely in the space under the roof, removing all the condensate. The membrane must not be damaged. The element is fixed with a construction stapler. Definitely need to do an overlap. The extreme parts of the film are attached with adhesive tape.

The features of the cold roof include the fact that it can be arranged in regions with any climate. Most people mistakenly believe that this type of roof is not suitable for the northern regions, but this is not the case. The attic floor will be insulated, so the use of such a design will not affect the indoor climate on the upper floors. The attic space can be omitted, since installing a layer of insulation material between the top floor and the space under the roof can solve all the problems that relate to heat loss.

In the process of installing a roof of this type, it will be necessary to properly isolate technological gaps and exits.

To do this, all ventilation shafts, chimneys and entrances to the roof base must be thermally insulated. Thanks to this, the following troubles can be avoided:

- the appearance of condensate;

- ingress of precipitation;

- heat losses.

To cover this design, you can use almost any material for the roof. In most cases, a metal tile is used, which is very easy to install. This option is considered the most preferable, since all laying actions can be performed in a short period of time, and no additional actions will be required in the future.

Flexible shingles can also be used. However, in this case, some difficulties may arise, which will make installation more expensive and difficult. Therefore, it is recommended to use metal sheets.

Before mounting the material, several preparatory operations must be performed. The main one is the calculation of roof slopes for flatness and squareness. There may be several slopes, but in the end you should get a flat plane. Otherwise, the sheets will not converge at the junctions.

For marking, you need a twine of such a length that you can block the diagonal of the slopes. The rope should be stretched from the top corner of the slope to the bottom. At the intersection, they should slightly touch.

The device of a cold attic in a building involves, as you know, the use of a lightweight version of the roof, which is also called "cold". A characteristic feature of such roofs is the absence of a layer of insulation in them, which is mounted between the vapor barrier layer and the membrane waterproofing.

Note! This type of coating is usually made in cases where the attic space located under them is not residential and is used only as an auxiliary room.

Thus, the implementation of the cold attic project is usually reduced to the arrangement of the roof, which should include the following elements:

- roofing material of your choice;

- protective waterproofing layer;

- main crate;

- counterlattice.

The presence of an additional crate with a waterproofing layer attached to it entails the formation of free spaces used as ventilation ducts that protect structural elements from condensate.

From a purely technical point of view, the installation of roof structures of this type is quite simple. When organizing it, due attention must be paid to the choice of roofing material that provides the required surface tightness and excludes the possibility of moisture penetration to wooden structures.

Roofing from a metal tile

Preparing a "cold" roof for a metal tile is the simplest and most convenient option for its arrangement, as a result of which a kind of cake is obtained from roofing material, a waterproofing layer and wooden crates.

The preparation of such a roof is not particularly difficult and includes the following simple operations:

- First of all, a waterproofing film is hemmed to the rafters with the help of small nails or a construction stapler.

- Then this film is covered with boards of a counter-lattice, which is mounted on the rafters using wood screws (the selected installation step depends on the size of the metal tile sheet).

- In some cases, to prepare the surface of the counter-lattice, a continuous coating is used, recruited from sheets of moisture-resistant plywood.

As a waterproofing layer, a special PVC membrane or an ordinary polyethylene film can be used, fastened at its location with a slight sag (from 15 to 25 mm). Such sagging creates conditions for ventilation of the waterproofing layer and removal of the condensate formed on it towards the eaves (gutter tray).

You should pay your attention to a number of conditions that must be considered when arranging a cold roof. Firstly, the boards of the counter-lattice must be packed parallel to the rafters used as the base of the entire structure, thereby providing additional fastening of the waterproofing hemmed to it.

Secondly, the lathing of such a roof should be made of a wooden beam with a section of 50 × 50 mm, installed in increments of 35–45 cm along its slopes. In this case, the choice of the step size (as well as the material for the crate) depends on the type of metal tile you use, as well as on the angle of inclination of the blood.

When installing a cold attic under the tiles, it should be understood that a thin metal sheet and a waterproofing layer will not provide you with proper sound insulation. At the same time, the noise level in the under-roof space (during heavy rain, for example) due to the lack of a layer of insulation can significantly exceed the value normalized in SNiP.

Some subtleties of roofing installation

Experienced experts advise paying attention to the following circumstances of arranging a cold attic:

- In the event that you plan to insulate the attic space in the future, it is necessary to approach the choice of a moisture-proof membrane with full responsibility. The best option in this case is the use of a waterproofing layer in the form of a PVC membrane.

- If roof insulation is not expected in the near future, it is best to use a micro-perforated waterproofing film designed specifically for cold roofs.

The fact is that when using such a film, its contact with insulating materials is unacceptable, therefore, in the case of insulation, you will first have to dismantle it and only after that lay a new waterproofing. If this condition is not observed, the required reliability of the structure protection is not guaranteed by the manufacturer, and the insulation placed in the "pie" will be exposed to moisture.

Among the materials present on the Russian market, most often used for arranging a cold roof, the following items can be distinguished:

- superdiffusion membrane brand "TechnoNIKOL";

- polymer coatings under the names "Pural" and "Prism";

- metal tile brand "Supermonterrey".

The product under the name "TechnoNIKOL" is a film membrane consisting of 2 layers of non-woven polypropylene and a layer of polypropylene film and providing the possibility of one-sided vapor diffusion.

Pural polymer coating is a membrane-type material made on the basis of polyurethane and has excellent anti-corrosion properties. In addition, it is resistant to mechanical stress and can be operated in a wide temperature range.

A product called "Prism" (UK) is a film metallized coating, consisting of 95% zinc and only 5% aluminum. The addition of aluminum to the material makes it possible to increase its protection against corrosive and mechanical influences.

The multi-colored tile covering "Supermonterrey" is made in the form of metal sheet blanks of a standard size, having a thickness of about 0.5 millimeters.

Video

This video provides an overview of cold roof materials: