Hot-rolled steel circle GOST 2590 88

Group B22

INTERSTATE STANDARD

HOT ROLLED STEEL ROUND

Sorga "e., t 2590-88

Round steel bars. Dimensions

OKP 09 3100; 09 3200; 09 3300

Date of introduction 01.01.90

1. This standard applies to steel hot-rolled steel round section with a diameter of 5 to 270 mm inclusive.

Rolled products with a diameter of more than 270 mm are manufactured by agreement between the manufacturer and the consumer.

2. By accuracy, rolled products are manufactured:

A - high precision:

B - increased accuracy:

B - normal accuracy.

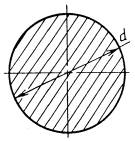

3. Diameter of rolled products, limit deviations for it, area cross section and mass I m of length must correspond to those indicated in the drawing and in table. one.

| Table 1 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Official edition Reprint resurrected |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

S. 2 GOST 2590-88

| Continuation of the table. I |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GOST 2590-88 S. 3

| Continued tab.). I |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

P and m with h and II and I:

1. The cross-sectional area and mass I m of the profile length are calculated using nominal dimensions. When calculating the mass of 1 m of rolled steel, the density of steel is assumed to be 7.85 g/cm 3 . The mass of 1 m of rolled products is a reference value.

2. For rolled products with a diameter of up to 9 mm inclusive, manufactured in coils on mills not equipped with numerical blocks, maximum diameter deviations of no more than ±0.5 mm are allowed until 01.01.92.

3. Limit deviations in the diameter of round rolled products intended for the manufacture of calibrated rolled products may be symmetrical, but should not exceed the established tolerance fields.

4. By agreement between the manufacturer and the consumer, bars with a diameter of more than 100 mm are produced in intermediate sizes with maximum deviations for the nearest smaller size.

4. At the request of the consumer, round bars are manufactured with positive deviations indicated in Table. 2.

5. The ovality of rolled products should not exceed 50% of the sum of the maximum deviations in diameter. Allowed for tool alloyed and high-speed rolled ovality, not

exceeding 60% of the sum of limit deviations in diameter.

6. Rolled products with a diameter of up to 9 mm are made in coils, over 9 mm - in bars.

S. 4 GOST 2590-88

By agreement between the manufacturer and the consumer, it is allowed to produce rolled products with a diameter of more than 9 mm in coils, less than 9 mm - in bars.

7. In accordance with the order, rolled products are produced: cut-to-length;

multiple measured length; unmeasured length.

8. Rolled products are made in length:

or 2 to 12 m - from carbon ordinary quality and low alloy steel; from 2 to 6 m - from high-quality carbon and alloy steel; from 1.0 to 6 m - from high-alloy steel.

9. At the request of the consumer, rolled products are manufactured in lengths from 2 to 24 m.

10. Limit deviations along the length of rolled products of measured and multiple measured lengths should not exceed:

30 mm - with a length of up to 4 m inclusive;

50 mm - with a length of St. 4 m to 6 m inclusive;

70 mm - with a length of more than 6 m.

At the request of the consumer, the maximum deviations should not exceed:

40 mm - for rolled products with a length of St. 4 to 7 m;

5 mm for each meter of length - over 7 m.

11. Curvature of round bars should not exceed the values specified in Table. 3.

12. At the request of the consumer, the curvature of round bars should not exceed 0.2% of the length.

13. The curvature of rolled products is measured over a length of at least 1 m at a distance of at least 150 mm from the ends.

14. Diameter, ovality of round steel is measured at a distance of at least 150 mm from the end of the bar and at least 1.5 m from the end of the coil with its mass up to 250 kg and at a distance of at least 3.0 m with a coil mass of more than 250 kg.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED State Committee USSR by standards

2. APPROVED AND INTRODUCED BY Decree of the USSR State Committee for Standards No. 2519 dated June 29, 1988

3. REPLACE GOST 2590-71

4. The limitation of the validity period was removed according to the protocol No. 4-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 4-94)

STATE STANDARD OF THE UNION OF THE SSR

HOT ROLLED STEEL ROUND

ASSORTMENT

GOST 2590-88

(ST SEV 3898-82)

USSR STATE COMMITTEE ON STANDARDS

Moscow

STATE STANDARD OF THE UNION OF THE SSR

|

HOT ROLLED STEEL ROUND AssortmentRound steel bars. Dimensions |

GOST

|

Validity from 01.01.90

until 01.01.95

1. This standard applies to steel hot-rolled round sections with a diameter of 5 to 270 mm inclusive.

Rolled products with a diameter of more than 270 mm are manufactured by agreement between the manufacturer and the consumer.

2. By accuracy, rolled products are manufactured:

A - high accuracy;

B - increased accuracy;

B - normal accuracy.

3. The diameter of the rolled product, the maximum deviations along it, the cross-sectional area and the mass of 1 m of length must correspond to those indicated in the drawing and in table. one .

Table 1

|

Diameter d, mm |

Limit deviations, mm, with rolling accuracy |

Cross-sectional area, cm 2 |

Weight of 1 m profile, kg |

||

Notes :

1. The cross-sectional area and the mass of 1 m of the length of the profile are calculated from the nominal dimensions. When calculating the mass of 1 m of rolled steel, the density of steel is assumed to be 7.85 g/cm 3 . The mass of 1 m of rolled products is a reference value.

2. For rolled products with a diameter of up to 9 mm inclusive, manufactured in coils on mills not equipped with finishing blocks, maximum diameter deviations of no more than ± 0.5 mm are allowed until 01.01.92.

3. Limit deviations in diameter of round rolled products intended for the manufacture of calibrated rolled products may be symmetrical, but should not exceed the established tolerance fields.

4. By agreement between the manufacturer and the consumer, bars with a diameter of more than 100 mm are produced in intermediate sizes with maximum deviations for the nearest smaller size.

4. At the request of the consumer, round bars are manufactured with positive deviations indicated in Table. 2.

Table 2

mm

5. The ovality of rolled products should not exceed 50% of the sum of the maximum deviations in diameter.

It is allowed for tool alloyed and high-speed rolled products to have an ovality that does not exceed 60% of the sum of the maximum deviations in diameter.

6. Rolled products with a diameter of up to 9 mm are made in coils, over 9 mm - in bars.

By agreement between the manufacturer and the consumer, it is allowed to produce rolled products with a diameter of more than 9 mm in coils, less than 9 mm - in bars.

7. In accordance with the order, rolled products are produced:

measured length;

multiple measured length;

unmeasured length.

8. Rolled products are made in length:

from 2 to 12 m - from carbon ordinary quality and low alloy steel;

from 2 to 6 m - from high-quality carbon and alloy steel;

from 1.0 to 6 m - from high-alloy steel.

9. At the request of the consumer, rolled products are manufactured in lengths from 2 to 24 m.

10. Limit deviations along the length of rolled products of measured and multiple measured lengths should not exceed:

30 mm - with a length of up to 4 m inclusive;

50 mm - with a length of St. 4 m to 6 m inclusive;

70 mm - with a length of more than 6 m.

At the request of the consumer, the maximum deviations should not exceed:

40 mm - for rolled products with a length of St. 4 to 7 m;

5 mm for each meter of length - over 7 m.

11. Curvature of round bars should not exceed the values specified in Table. 3 .

Table 3

mm

12. At the request of the consumer, the curvature of round bars should not exceed 0.2% of the length.

13. The curvature of rolled products is measured over a length of at least 1 m at a distance of at least 150 mm from the ends.

14. Diameter, ovality of round steel is measured at a distance of at least 150 mm from the end of the bar and at least 1.5 m from the end of the coil with its mass up to 250 kg and at a distance of at least 3.0 m with a coil mass of more than 250 kg.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR State Committee for Standards

PERFORMERS

K. F. Peretyatko, G. I. Snimshchikova (topic leaders); S. I. Rudyuk, cand. tech. sciences; V. F. Kovalenko, cand. tech. sciences; X. M. Saprykin, cand. tech. sciences; V. A. Yena, cand. tech. sciences; E. I. Bulgakov; Zh. M. Roeva, cand. economy sciences; V. I. Krasnova; I. E. Patseka, cand. tech. Sciences

Valid from 01.01.90

until 01.01.95

1. This standard applies to steel hot-rolled round sections with a diameter of 5 to 270 mm inclusive.

Rolled products with a diameter of more than 270 mm are manufactured by agreement between the manufacturer and the consumer.

2. By accuracy, rolled products are manufactured:

A - high accuracy;

B - increased accuracy;

B - normal accuracy.

3. The diameter of the rolled product, the maximum deviations along it, the cross-sectional area and the mass of 1 m of length must correspond to those indicated in the drawing and in table. one.

Table 1

|

Diameter d, mm |

Limit deviations, mm, with rolling accuracy |

Cross-sectional area, cm 2 |

Weight of 1 m profile, kg |

||

Notes:

1. The cross-sectional area and the mass of 1 m of the length of the profile are calculated from the nominal dimensions. When calculating the mass of 1 m of rolled steel, the density of steel is assumed to be 7.85 g/cm 3 . The mass of 1 m of rolled products is a reference value.

2. For rolled products with a diameter of up to 9 mm inclusive, manufactured in coils on mills not equipped with finishing blocks, maximum diameter deviations of no more than ± 0.5 mm are allowed until 01.01.92.

3. Limit deviations in diameter of round rolled products intended for the manufacture of calibrated rolled products may be symmetrical, but should not exceed the established tolerance fields.

4. By agreement between the manufacturer and the consumer, bars with a diameter of more than 100 mm are produced in intermediate sizes with maximum deviations for the nearest smaller size.

4. At the request of the consumer, round bars are manufactured with positive deviations indicated in Table. 2.

table 2

5. The ovality of rolled products should not exceed 50% of the sum of the maximum deviations in diameter.

It is allowed for tool alloyed and high-speed rolled products to have an ovality that does not exceed 60% of the sum of the maximum deviations in diameter.

6. Rolled products with a diameter of up to 9 mm are made in coils, over 9 mm - in bars.

By agreement between the manufacturer and the consumer, it is allowed to produce rolled products with a diameter of more than 9 mm in coils, less than 9 mm - in bars.

7. In accordance with the order, rolled products are produced:

measured length;

multiple measured length;

unmeasured length.

8. Rolled products are made in length:

from 2 to 12 m - from carbon ordinary quality and low alloy steel;

from 2 to 6 m - from high-quality carbon and alloy steel;

from 1.0 to 6 m - from high-alloy steel.

9. At the request of the consumer, rolled products are manufactured in lengths from 2 to 24 m.

10. Limit deviations along the length of rolled products of measured and multiple measured lengths should not exceed:

30 mm - with a length of up to 4 m inclusive;

50 mm - with a length of St. 4 m to 6 m inclusive;

70 mm - with a length of more than 6 m.

At the request of the consumer, the maximum deviations should not exceed:

40 mm - for rolled products with a length of St. 4 to 7 m;

5 mm for each meter of length - over 7 m.

11. Curvature of round bars should not exceed the values specified in Table. 3.

Table 3

12. At the request of the consumer, the curvature of round bars should not exceed 0.2% of the length.

13. The curvature of rolled products is measured over a length of at least 1 m at a distance of at least 150 mm from the ends.

14. Diameter, ovality of round steel is measured at a distance of at least 150 mm from the end of the bar and at least 1.5 m from the end of the coil with its mass up to 250 kg and at a distance of at least 3.0 m with a coil mass of more than 250 kg.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR State Committee for Standards

PERFORMERS

K. F. Peretyatko, G. I. Snimshchikova(topic leaders); S. I. Rudyuk, cand. tech. sciences; V. F. Kovalenko, cand. tech. sciences; X. M. Saprykin, cand. tech. sciences; V. A. Yena, cand. tech. sciences; E. I. Bulgakov; Zh. M. Roeva, cand. economy sciences; V. I. Krasnova; I. E. Patseka, cand. tech. Sciences