Scheme of a street barbecue with a brick oven. Building a barbecue: from simple to complex - canons, ideas, projects, nuances

Good day to all!

Today we will talk about how to put a barbecue in your summer cottage. Not portable metal, but brick stationary. What is good about this grill? First of all, design qualities. Made not only in the original form, but even in a simple design, it will bring an element of landscape design to your summer cottage and become a place of comfortable rest.

Step-by-step instructions for a brick barbecue

So, we decided to build a brick brazier. What do we need for this? Let's start with tools and materials. First of all, since we have a brick brazier, then we will need a brick. Since we are building a kind of oven, therefore, we will need a special oven, or fireclay brick. It is a fire-resistant brick that can withstand large temperature fluctuations. The mortar for laying bricks is a mixture of clay and sand, pre-soaked. For the barbecue, since it is stationary, a foundation will be needed. For its manufacture, we need cement, sand, formwork boards, rebar, stones and crushed stone. To fasten additional elements, it is necessary to prepare metal corners, gratings, various valves and a sheet of iron.

As for tools, a shovel, trowel, buckets, a trough for mortar will be needed here.

The number of bricks depends on the project that you draw yourself, or find one already finished. Below are several options for a brick brazier.

If you do not want to bother with complex schemes of your structure, but simply want to put up a fairly simple brazier, then the following scheme may be suitable.

We make the foundation

The foundation of the brazier must be even, for which you can use the building level. Also for waterproofing it will be necessary to use roofing material

Based on the size of the brazier in the project, we dig a hole. We lay out the bottom of this pit with a stone with rubble and install the formwork. After that, we fill the pit with a concrete mixture (if anyone does not remember its proportions of cement and sand are 1: 3), while laying a reinforcing mesh.

In the meantime, the concrete is curing, you can prepare a clay mortar for masonry. To do this, in a special container (tub, barrel) we soak the clay for a week. Stir occasionally and add water if necessary. After that, we pour sand. To check the quality of the solution, you need to mix a little clay with dry sand, then roll the mixture into a bundle with a diameter of 1 cm. If it does not lose its shape, does not crack or spread, then everything is fine.

After the concrete has completely hardened, you can start laying bricks.

Brickwork

We begin laying with the construction of three supporting walls - two side and one back. If you need a through design option, then the back wall can be omitted.

The figures below show the ordering of the bricks.

If necessary, in the brazier, you can make compartments, one for frying, and the other for dishes. To do this, we arrange cavities in the supporting part by placing another intermediate wall in half a brick.

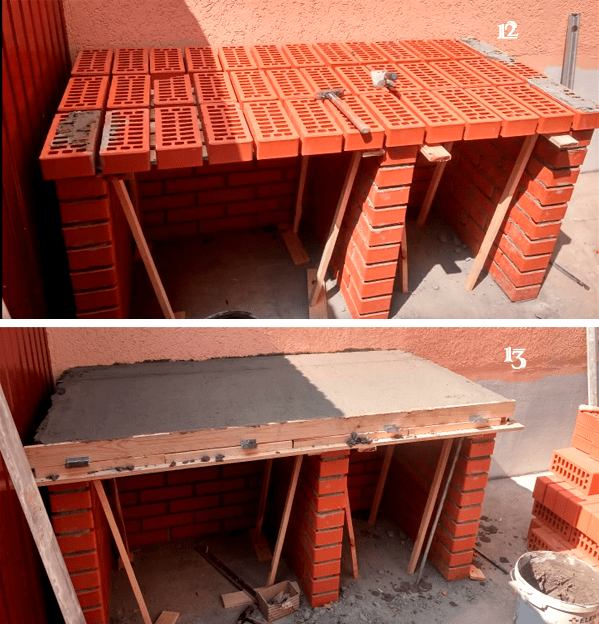

After laying out all the walls, we block them with a concrete slab. For this purpose, we use an OSB board of a suitable size. We install it from below in such a way that after the concrete has hardened, it is possible to safely remove the formwork. On top we put a square frame of edged boards, the height of which is equal to the thickness of the slab to be poured.

We put dense polyethylene on the OSB and fill it with a solution with a layer thickness of 1-2 cm. After that, we lay four reinforcing bars with a diameter of 12-14 mm and fill the entire formwork with fine-grained concrete (crushed stone fraction 0.5-1 cm).

In general, there are a lot of options for a simple barbecue. You don’t even have to bother with mortars, but simply stack bricks on top of each other, as in the figure below:

But if you want a design, then you can offer such models.

Brazier made of bricks with a stove under the cauldron. Brick ordering

Another version of the brazier that you can put at home is the brazier, which has an oven for a cauldron added.

It means that next to the brazier a traditional oven is installed under the cauldron. Both of these designs are separate, but for aesthetics and to give the appearance of a single whole, a connecting seam is made between them.

The order of construction of such a brazier is the same as in the previous version. Just add the installation of the furnace under the cauldron.

We start the whole process by laying the first row without using a clay-sand mortar. To do this, first lay out all the corner bricks, which should form a rectangle. We stretch the string between these bricks. Next, we lay the bricks of the first row and check the correctness of the masonry. For this purpose, we measure the diagonals of the formed rectangle, if they are equal, then lay out the bricks on the mortar. If not, then we make adjustments to the masonry. We lay out the bricks of the first row on the mortar, the thickness of the seams should be equal to 3-4 mm.

Well, further laying is carried out according to the chosen order. Below are a few examples of this ordering that you can use for your construction.

Installing the oven under the cauldron includes the following steps.

Laying the 1st row.

We lay completely red brick. We start with a whole brick. Next, we apply this method to each odd row.

Masonry 2nd row.

A red brick is laid around the perimeter, and fireclay in the middle. The row starts with a half brick. The same is done with all other paired rows. The second row will be the bottom of the firebox. In the first two rows, we leave a place for the ash pan, where we build the door of this ash pan into the masonry.

3rd row masonry.

It is made solid, with the exception of the space above the ash pan. Here the grate is installed. To do this, we cut grooves in the brick of the third row. In addition, we block and fix the ash pan door in the same row.

Masonry 4 and 5 rows.

The brick is laid in such a way that holes are made for the firebox door and for the chimney. We divide the oven into two parts. One will become the outer wall of the stove, and the second will be its central part. We make a small space between them. The central part is made in the form of a square with a circle in the middle, which is a firebox.

The central part is laid out of fireclay bricks. We fix the firebox door.

Masonry of the 6th row.

We do everything in the same way as when laying the previous row. The only thing is to block the outer hole for the chimney. The brick should bandage the seams of the previous row.

Masonry 7-11 rows.

The 7th row covers the firebox door. In the 9th row, holes must be made through which flue gases will exit. In the 11th row we make a circulation hole in the front of the crucible. Next, we put the 12th row and fasten plates with a hole for the cauldron on it.

Brick brazier with a roof do-it-yourself drawings and photos

Sometimes, while preparing a delicious barbecue on your country grill, unexpected rain spoils the whole action. Naturally, the question arises about the need to place a brazier under the roof.

It should be noted that there are many factory designs of such barbecues. One of them is shown below.

But this, as you can see, is a completely metal barbecue, and we are building a brick one. The easiest and most natural option is to put up a canopy. Below are several options for such awnings.

If you are planning to make a brazier with a roof, then the drawing of the brazier itself is best done immediately with such a structure. Of course, you can first build the brazier itself and only then attach a canopy to it.

The choice of material for a canopy is an important step. For the roof itself, materials such as metal tiles, cellular polycarbonate or slate are best suited. The sides of the canopy can be assembled from metal pipes with a section of 30x30x1.5 mm or 40x40x1.5 mm

In general, it is not difficult to make a canopy, the main thing is to approach this issue creatively and everything will work out.

And finally, two videos showing how to make a brick brazier yourself.

Good luck with your construction and delicious kebabs!

In our guide, we will tell you how to make a barbecue outdoor complex and a brick barbecue oven yourself. Step-by-step instructions with a photo of the construction process will help you understand the details of the self-laying of this structure.

As a result, you should get a barbecue grill as shown in the photo below.

So, you have decided on the type of barbecue, its size and location. Now you need to build a foundation for it.

Usually such buildings are made on the street, in a gazebo or on a terrace. If the foundation of the gazebo or terrace can withstand the weight of a brick oven, which is about 3 tons, then you can start building immediately. If you are going to build a brazier from scratch, then first of all fill in a suitable foundation under it: tape or tile.

Instructions for the construction of such foundations can be found in our section "".

The next step will be a waterproofing device for a brick barbecue. It is done to prevent the lower bricks from getting wet by capillary suction. It will be enough to lay a roll of roofing material or waterproofing. At the end of the construction, cut off the excess with a knife.

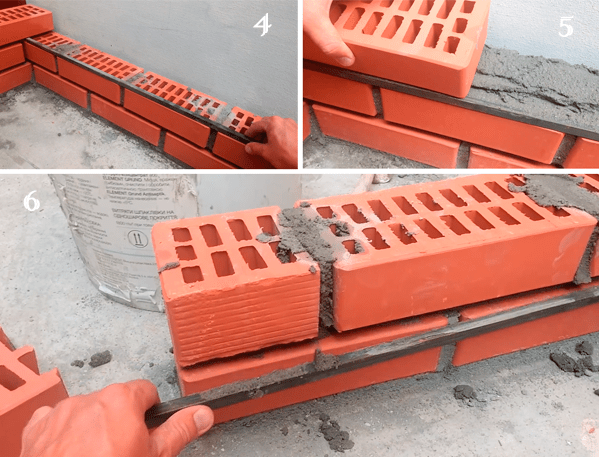

Do-it-yourself barbecue grill made of bricks. Step by step instructions with photos.

We proceed directly to the laying of the barbecue.

We recommend that you first lay out the first row of bricks without mortar and evaluate how your future structure fits into the foundation. Do not forget to leave 1 cm gaps between the bricks. Also check the diagonals, they must match.

After that, you can start laying barbecue. The front brick is placed on a cement-sand mortar (cement-sand ratio 1: 3). For the plasticity of the solution, lime or a special masonry plasticizer from the nearest hardware store is added. The seams are made in sizes of 8-10 mm, for this they use a metal rod, reinforcement, etc. In places where bricks adjoin without dressing, the masonry is reinforced with perforated tape, wire, etc.

We make laying with the displacement of each subsequent row by half a brick. For sawing bricks, you will need a grinder with a stone disc.

We continue to lay out the barbecue grill.

Do not forget to check the verticality of the masonry in the corners at least every 3 rows. And also, check the coincidence of the length of the diagonals of the brazier.

We continue laying.

After you make 8 rows of masonry, it's time to make jumpers for the barbecue and countertops. They should look like the photo below.

There are several ways to make such jumpers.

First, you can fasten the bricks with a metal stud and mortar.

Secondly, you can use metal corners.

In our case, we used the second method. We folded the corners with each other in the form of an inverted letter T and sawed off half of the shelf. Here's what happened.

Take a corner with a size of at least 45x45 mm. A smaller corner will sag. But do not take too big so that it does not protrude beyond the edges of the brick.

Make a slot in the brick with a good margin so that the metal does not tear the masonry when heated.

Such a shelf is not visible to the eye, reliable and beautiful.

We begin to lay out under (bottom) the brazier. We use refractory fireclay bricks for the firebox. We make laying on a ready-made refractory mixture from a building supermarket from clay and sand. Can be used mortar. We make the seams as thin as possible, about 3-4 mm.

We use corners to support the bottom of the brazier. Remember to leave at least 1 cm gap between the ends of the corners and the brick. So you save the masonry from cracking when expanding the corner.

On the first row of the bottom of the firebox we put the second row, overlapping all the seams of the first. This will prevent the seams from burning through and coal from getting on the firewood in the firewood from below. You can, of course, pour a concrete slab instead of the corners and the first row of the firebox. But in our case it was cheaper and faster to do so.

If you are pouring a concrete floor, then one row of refractory bricks is enough for the bottom of the firebox.

We continue to lay out the walls of the barbecue.

The laying of the front brick and the firebox can be done both in parallel and alternately. You can first make the walls of the firebox, and then overlay it with a face brick.

Important! We leave a gap of 1 cm between the facing and refractory bricks. The firebox and lining should not touch.

We put the next rows of barbecue ovens.

We approach the moment of construction of the furnace arch. We make a circle (an arc structure made of wood) and install a brazier in the portal. Then, we carry out the laying of the arch, cutting the bricks to the desired size. In the middle of the upper point we put a brick castle. The arch is ready.

Note! The front brick arch is covered from the inside with a fireclay brick lintel. It is placed on a metal corner a little higher than the top of the arch so that it is not noticeable. It looks like this.

The arch is assembled, we continue to display the walls of the barbecue grill.

Do not forget to check the verticality of the masonry.

We are approaching the moment of construction of the smoke box.

We bring the top of the firebox and lining to the same level and begin to lay out the smoke box. We make masonry from solid bricks of a brand not lower than M150. We put on a cement-sand mortar. We put the first row flush with the inner wall of the firebox. The remaining rows are laid with an offset of about a third of the brick.

Don't move the bricks more than half way or they will fall into the firebox.

We carry out the laying of the smoke box until the moment when there is no hole for the chimney measuring 27x27 cm, taking into account the seams. Your chimney size may differ from ours. In this case, make a flue according to the dimensions of your chimney.

Some stove-setters cut off the inner edges of the bricks so that the inside of the smoke box is smooth. We did not notice any differences in operation between the smooth and ribbed inner surface of the smoke box. Of course, this is only true if you observed the correct proportions between the dimensions of the portal - the smoke box - the pipe (read about the proportions below).

This is what the smoke box looks like without cut bricks from the inside.

We continue laying pipes. Its dimensions depend on the size of your barbecue grill portal.

After finishing the laying of the chimney, we cover it with a cap to protect the firebox from precipitation.

We successfully built a brazier, which is also a barbecue oven made of bricks with our own hands! Wait until the solution dries and you can do a test run.

Here we will analyze the most frequently asked questions about laying a brick brazier (grill) with our own hands and the answers to them.

What size should the smoke box be?

The size of the smoke box depends on the size of the furnace portal. The optimal ratio should be at least 100-120%. So in our step-by-step instructions, the height of the portal is 6 rows, and the height of the smoke box is 8 rows.

What is the height of the pipe?

The height of the pipe is proportional to the height of the smoke collector and is not less than 100-120% of its height.

What diameter should the chimney be?

The cross section of the chimney pipe depends on the area of the furnace portal. The optimal chimney area is 1/8 - 1/10 of the portal area. Extreme sizes from 1/6 to 1/13.

How to fill the gap between the firebox and the cladding?

In front, around the portal, you can fill the gap with basalt cardboard. The rest of the space does not make sense to fill. Therefore, it is left empty.

Do I need to paint the metal corner in the lintels?

Brazier (grill) - do-it-yourself barbecue made of bricks. Step by step video instruction.

Ordinary and facing stone made of burnt clay is a universal structural material. Therefore, a simple brick brazier can be built even without mortar in haste. A stationary hearth made of this material is considered simple if there is no chimney in its design.

Clay and ceramic bricks withstand extreme temperatures, but they have a much smaller resource in furnaces and hearths than refractory fireclay. Therefore, the simplest temporary barbecues are made of ordinary bricks, and in stationary hearths of a simple design, the inside of the firebox can be lined with fireclay lining.

Even if legs made of the same material are added to a rectangular brick box, the structure will still remain a brazier. As soon as the master covers the firebox with a roof, it will automatically turn into a barbecue oven, although without a chimney, but with a hole for removing combustion products.

"Marching"

From a few bricks accidentally found or specially taken for a country picnic, you get the simplest hearth for frying meat on skewers over coals. In this case, it is necessary to take into account the nuances:

- the brick has standard dimensions of 25 x 12.5 x 6 cm; to save building materials and space in the trunk of a car, it should be installed on edge;

- for normal frying of meat without burning, skewers should be 20–25 cm away from coals, so at least 2 rows of bricks will be required;

- the width of the brick "box" is taken for standard skewers 37 cm, that is, 1 brick;

- the length of the brazier for a small company is 75 cm, that is, 3 bricks.

We just took a few bricks and made such a super fast construction on the spot, according to this drawing!

Thus, in total, a minimum of 16 bricks of a standard format will be needed. Each of them weighs 3.5 kg, for a total of 56 kg minimum. The manufacturing technology of the hearth is as follows:

After the coals have cooled, the structure is disassembled, the turf is laid in place.

Classic barbecue

For a stationary hearth on the site, a base made of non-metallic material (sand or crushed stone) compacted with a vibrating plate or manual rammer will be required. If the weight of the structure exceeds 450 kg, a monolithic reinforced concrete foundation will be required. For a home craftsman with minimal bricklayer skills, a do-it-yourself brazier made of bricks is more suitable, the simplest and most inexpensive in the bottom photo in the form of a rectangular box.

Manufacturing technology is as follows:

You can make such the most inexpensive stationary barbecue grill

The main nuances for this modification of the focus are:

- no ordering scheme is needed, since it is impossible to make a mistake in this case;

- the bottom row (called a hearth in furnaces) is necessary to prevent the destruction of concrete from extreme temperatures, it is recommended to lay out refractory bricks;

- waterproofing is needed to prevent the destruction of the concrete foundation and masonry from soil moisture (not to be confused with groundwater!), It is made from rolled bituminous materials, pieces of which are placed under the foundation before it is poured or the first row on the base of non-metallic material.

Don't forget to waterproof under the bottom row

All other designs of brick barbecues are more complicated, so ordering is required. But they are more convenient to use. Here are some more photos where you can see other interesting options:

Option with firewood

Well, and a video on how to do masonry in general:

BBQ oven

Unlike a classic brazier, a barbecue simplifies the preparation of meat by placing it on a grill, and not on skewers. A simple budget barbecue grill made of bricks is being built according to the technology:

The scheme of the finished budget brick barbecue

Attention: A brazier with a drawer for ash and a grate above it for placing coals is considered more convenient to maintain.

The specified design is slightly different from the described option:

- after making the legs under the back and side walls of the brazier on the spoon row, the brick of the next level is laid with a poke (only side walls);

- then one more spoon and tychkovy rows are laid out.

bogie

On the resulting lower ledge is a metal drawer for ash. A grate for coals is laid on the upper ledge. If you make another ledge in the same way, you get a convenient dryer for berries and mushrooms.

Well, and a detailed video, for clarity:

Without solution

If there is a brick remaining from the construction site on the site, you can build an inexpensive temporary brazier from it as soon as you see suddenly arrived guests. The main nuances of manufacturing are:

- without mortar, half-brick legs are too unstable, so it is better to replace them with 4 pedestals (columns) 1 x 1 brick with dressing in order;

- instead of a sheet of iron, you can use a piece of any sheet material (OSB, plywood), but, above it, you need to lay 2 continuous rows of bricks;

- the height of the barbecue box is 2 - 3 rows, the dimensions are at the discretion of the home master.

We fold in haste without a solution

Attention: The construction is considered temporary “in haste”, brick stained with coals and ash is difficult to wash, so it is better to use an ordinary, rather than a facing stone.

For detailed instructions, see the video:

A fairly attractive barbecue grill of the original design is a variant of several rows of bricks without mortar in the form of a round pedestal.

Barbecue in the form of a pipe without mortar

This can be quickly built simply from what is at hand.

Additional elements for simple barbecues

When adding additional functions of a stationary hearth to the design, you will need to make freehand drawings or sketches for it. Since the hearth will turn out to be more difficult, errors are possible during the construction of the masonry. The main additional elements for a simple barbecue are: a cutting table, a brazier and a sink.

Cutting table

An inexpensive option that significantly increases the comfort of use is the simplest do-it-yourself brick brazier with a cutting table according to the technology:

- the posterior wall lengthens, ligation with the central wall-rack becomes more difficult;

- in addition to the above structures, on the side, close to the masonry of the hearth, another rack wall is being built;

- a countertop made of natural / artificial stone is laid on it and the side wall of the brazier.

The cutting table can be located on any side convenient for the user, relative to the hearth.

Stove-brazier

In addition to meat on skewers, or a barbecue grill, it is often necessary to prepare other dishes in pots, pans, heating or boiling a kettle. Therefore, instead of a cutting table, a place is allocated for a brazier.

To do this, you must perform the following operations:

- lengthen the structure starting from the bottom row;

- make a front wall with a door for the combustion chamber;

- equip the hob with concentric cast iron rings to adjust the power of the stove.

The top photo shows a barbecue diagram with a hob of the simplest type.

Washing

To equip the brazier with a sink, it is enough to mount a stove with a slot for the sink instead of a regular countertop, connect the water supply or increase the height of the rear stack and hang a washstand on it, as in the bottom photo.

The layout of the cold water supply (cold water supply) section is much more complicated than the collection of water in the washstand. Even during seasonal operation, it will be necessary to drain the liquid for the winter, to preserve the system.

Thus, the structural material brick is suitable for the manufacture of braziers in haste in the field and in the suburban area. When laying on a solution, you can increase the functionality of the simplest barbecues by washing, countertops, hob or something else that you find necessary and convenient when working. Here it is important to give free rein to your imagination and not be afraid, you will definitely succeed!

You have a cottage. You want to make it not only beautiful, but also convenient and comfortable for your family and friends to relax. And not to cost too much. Don't know where to start? Do-it-yourself braziers and barbecue for a summer cottage made of bricks from a photo are an ideal start for arranging a summer cottage. We assure you that after reading this article and looking at the drawings, you will build an ideal barbecue on your site, on which you will then cook delicious and healthy food.

A step-by-step guide to preparing and building a barbecue with your own hands from brick

Preliminary work (planning and drawings)

Before you build a brick brazier, you need to carefully consider what it will be like. We recommend paying attention to the following points:

When you decide what kind of barbecue you want to make, draw up detailed drawings with exact dimensions. Thanks to them, you will not only be able to correctly build the structure itself, but also calculate the amount of materials needed.

Choosing a place for the barbecue

Brick barbecue grills can be located anywhere in the summer cottage - in the garden, in the gazebo, on the terrace - as long as it is convenient. But we advise you to consider the following recommendations:

- The first and most important point is fire safety! Do not build garden barbecues near wooden buildings, dry trees and bushes.

- There should not be a playground nearby.

- It is convenient if the stove and the brick wall of the summer kitchen are located nearby so as not to run far for groceries and everything else.

If the project provided for a sink, build a water supply nearby.

In order for the future brazier to stand well and firmly for many years, make its base as reliable and stable as possible. The dimensions and strength of the foundation depend on the dimensions of the planned structure. In any case, the foundation area should be approximately 50 cm larger than the barbecue on each side.

After two weeks (if the heat is less), when everything hardens well, you can start building a barbecue with your own hands.

Choosing a barbecue brick

Here again, fire safety should be remembered. If the barbecue is indoors, you should take a special refractory fireclay brick, it has a lot of clay, due to which it withstands high temperatures well and quickly warms up the room.

Types of bricks that are used to build a barbecue

If the future construction is planned to be outdoors, then professionals do not recommend doing everything from fireclay bricks, as it does not like moisture. It is better to take a full-bodied ceramic brick M200 or facing. The inside of the firebox itself will be laid out from fireclay bricks.

Optionally, at the final stage of building a barbecue, its decorative finish is done.

We prepare the solution

For lining, a cement-sand mixture is needed, and for laying the furnace itself, clay-sand mixture with the addition of a small amount of cement for strength. You can take the finished mixture for ovens and cook it according to the instructions.

To prepare a clay solution yourself, you will need:

- red clay;

- sand;

- cement;

- water.

Clay is filled with water and left for 5-6 days. Then it is thoroughly mixed, sand and cement are added little by little (a glass of cement 400 per bucket) and mixed again. The mixture is ready to use.

After the foundation has solidified before construction, two layers of roofing material must be laid on it for waterproofing. This is done so that the brick draws less moisture from the base, this will extend its life.

After that, we determine the position of the wall, apply the mortar and begin to build a brick brazier with our own hands.

Be sure to check everything with a level so that the masonry is even, as this will affect the quality of the furnace in the future.

Laying a simple brazier made of bricks (ordering)

To build such a brazier, carefully consider the scheme according to which step-by-step masonry is carried out, the so-called ordering.

The so-called half-brick laying is performed: each odd row (1.3, etc.) begins with a whole, and each even (2, 4, etc.) from a half. This is done for a bunch of bricks.

On top of the 4th row we lay the overlap, on which you can then put the dishes.

On the 8th row, you need to put 4 thick-walled corners, as shown in the figure. The 9th row is laid on the corners.

In the 10th row, all the beauty of this barbecue is “piano keys”. They can be cut with a grinder from white fireclay and red facing bricks.

The last 2 rows - and the brazier is ready. Please note that in the 11th and 12th rows, longitudinal halves of bricks are used.

Skewers and a grill will then lie on them.

View from all sides

This is how our brazier-piano made of bricks looks like from different sides.

Option 1 - drawing with dimensions (click to enlarge)

Final result with dimensions.

Option 2, improved - drawing with dimensions (click to enlarge)

Another version of the barbecue grill. It is wider and the back wall is built from the bottom. Watch the video for the laying process of this option.

It was the most, which is easy to build on your own, even without experience in this area.

DIY brick barbecue - step by step construction with real photos

Consider another option, more complicated - how to make a brick barbecue with your own hands, which includes two lower compartments for firewood, dishes and other small things, a combustion chamber, a countertop and a chimney at the top.

For the construction of the structure itself, in this case, facing bricks were used, and refractory for the inside of the furnace.

Initial construction stage

We start laying in the same way as described above. The lower part will be in the form of the letter "Ш", only the branches are different in width. What will be wider for firewood, above it there will be a firebox and a chimney. The second is for dishes and other accessories, there will be a countertop at the top.

We make even seams between rows

So that everywhere between the bricks there is the same and even seam, here, when laying, a metal bar is used, in the section of which there is a square with a side of 12 mm. But we advise you to take thinner - 5-10 mm will be enough. You also need to constantly control the level of verticality and horizontal masonry.

Brick laying process

The bar is placed on the edge, as shown in photo 4, then carefully smeared with mortar. On the side where they put the bar, we put the mixture on a par with it, on the other a little more, a slide. We lay a brick, from the side of the plank we hold it with our hand, and on the other, lightly tapping with a hammer, we align it to the level. When the solution dries a little, remove the bar.

In order for the masonry process to progress faster, there should be several planks, as they are needed for each row.

Lay out the bottom part - the first 10 rows

According to this principle, 10 rows are laid out.

We prepare the basis for the firebox and countertops

Next will be the firebox and countertop. On the 10th row we put reinforcement with a diameter of 12 mm. The distance between the rods is 70 mm. Formwork is placed between the reinforcement so that the mixture does not fall down when the seams between the bricks are filled.

Professional advice: it is better to take metal corners, as there is a possibility that the reinforcement will bend under the weight.

We lay out the brick and fill it with mortar

At the same distance from each other, bricks are laid out over the entire area. Those that fall on previously erected walls are placed on the mortar, the rest are simply on the formwork. Then the gaps between the bricks and the surface are filled with mortar.

We form the combustion chamber and the vault

After drying, a firebox is erected - 8 rows are laid out vertically. Further, the back part, which is located near the wall, is also erected, and the remaining three sides taper up by half a brick. So 9 more rows are laid out.

Building a chimney

The next step is the chimney. In this case, 20 rows are made of bricks, and at the top there is a stainless chimney. A high pipe is needed so that the smoke does not interfere with either you or your neighbors, and the draft is better.

The last stage of construction - we finish the countertop and firebox

And the finishing touches - the countertop is laid out with tiles, and the inside of the firebox - with refractory bricks.

Final result

After a few days to dry completely, the barbecue is ready to use.

We recommend watching a video where there is the whole process of laying a garden brick oven.

Below in the gallery you can see more photos of barbecues and barbecues for summer cottages made of bricks with your own hands, and choose the one that suits your site in terms of style, functionality and location.

In the gazebo

In the gazebo  On the terrace

On the terrace  With hob

With hob  On the street

On the street  With built-in smokehouse

With built-in smokehouse

There is no fundamental difference between barbecues and barbecues, except that on the first one, food is cooked on skewers, and the second on the grill. Both can be done on the same structure, the construction of which will be discussed.

Often, a country barbecue is a simple outdoor building in the open. A brick barbecue is a more complex device that can be located in a summer kitchen, gazebo or outdoors, but it already has a chimney and in most cases a cover to protect it from rain and snow.

A temporary brick cooking device is a great summer option

If you do not plan to visit the country house in winter, then a barbecue or barbecue made of bricks without mortar is perfect for this purpose. In the spring it can be easily and quickly folded, and disassembled for the winter.

Masonry scheme without mortar

Here is a diagram and step-by-step instructions that show the manufacture of such barbecues and brick barbecues.

If the barbecue is planned to be small (9-10 rows of bricks), you can simply level and compact the ground well. For a larger structure, it is better to fill the foundation.

We begin to lay out bricks according to the same principle as in the previous versions, but in a circle and with gaps of about 50 mm.

On top of the 5th row we lay a steel sheet, which will serve as a pallet for coal.

We put 2 more rows and install the grate for cooking. Then 2 more rows for protection from the wind.

To build such a round barbecue brick, you need a little more than 100 pieces.

This is one example of a temporary barbecue, you can change it at your own discretion. Or choose for yourself and build one of the options presented below in the photo.

What could be more beautiful than relaxing with family or friends in the fresh air. A pleasant pastime is most often complemented by a picnic with cooking meat or fish. To do this, various folding devices such as a prefabricated brazier or grill are used on the road. If you are the owner of a suburban area, then once built a barbecue oven will become the very place around which you can gather with loved ones for a delicious lunch and pleasant conversations. Despite the apparent complexity, a brick barbecue can be easily built with your own hands. Photos of existing structures, drawings and schemes of orders, advice and recommendations from experienced stove-makers will greatly facilitate the work.

Barbecue Features and Benefits

Do-it-yourself barbecue will become not only a functional addition, but also a real decoration of a suburban area

The barbecue oven in its functionality is far superior to other designs designed for outdoor cooking. A brick barbecue allows you to cook barbecue or steak, bake fish or vegetables, smoke fish and meat products, cook first and second courses, dry fruits or mushrooms, and much more.

Being to some extent a symbiosis of a brazier, a grill, a smokehouse and a grate, a barbecue also has features that make this design unique and effective:

- The structure has a back wall, which allows you to evenly distribute the temperature throughout the entire internal volume and retain heat.

- The use of a chimney allows you to create draft and remove smoke from the cooking zone.

- The combustion of fuel takes place in the firebox, and not in a metal pan, as, for example, in a barbecue or grill. This makes the design safer and more durable.

- The heat in the barbecue oven is spent more rationally, because even after cooking, the bricks of the building maintain a high temperature.

A huge advantage of the design is that a barbecue allows you not only to cook food, but also to heat the room. This can be a real find for gazebos of a closed or semi-open type, allowing you to relax in comfort not only in summer, but also in the off-season.

Kinds

There are many garden barbecue ovens, among which there are several types of structures that have the following features:

- an enlarged open-type firebox (it is used as a garden or gazebo fireplace) and a built-in grate or spit;

- a Russian oven-type flame chamber for making pies, pastries, etc.;

- a barbecue area or a stationary structure for cooking barbecue;

- a niche for a cauldron;

- smoke chamber for homemade smoked meats;

- hob.

Truly universal structures are barbecue complexes, which are multifunctional structures, which include all the above additions.

Photo gallery: design options

Barbecue oven equipped with a smoking chamber

Barbecue oven equipped with a smoking chamber  One of the most popular designs is a barbecue with a firebox that resembles a conventional fireplace in form and function.

One of the most popular designs is a barbecue with a firebox that resembles a conventional fireplace in form and function.  Multifunctional BBQ oven with hob and smoker. A real summer kitchen, isn't it?

Multifunctional BBQ oven with hob and smoker. A real summer kitchen, isn't it?  Barbecue combined with a Russian stove

Barbecue combined with a Russian stove  Barbecue with barbecue and a niche for a cauldron

Barbecue with barbecue and a niche for a cauldron

Construction of a garden barbecue

The simplest barbecue oven is a brick building half a brick thick, laid in the shape of the letter P. The height of the structure can be from 1 meter or more. Of course, the larger the furnace, the stronger the concrete base on which it is installed should be.

Construction of a simple barbecue oven

Scheme of a simple garden oven with a grate

At a level of about 70 - 75 cm from the floor in the side walls of the structure, ledges were made of bricks laid across the masonry. During operation, a pallet rests on these protrusions, in which charcoal or firewood is burned. At a distance of 10, 15, 20, 25 cm from the brick ledges, guides are built into the side walls of the barbecue. Thanks to the ability to adjust the height of the grate for products at the desired height, you can choose the optimal temperature regime.

The side and rear walls of the stove perform both windproof and heat storage functions. I must say that in more complex designs, the working chamber of the barbecue has a vaulted shape and a narrow smoke channel, which improve the efficiency of the stove and increase its efficiency.

The combustion zone is laid out from fireclay refractory bricks, which are laid on a solution of heat-resistant cement and river sand. In some cases, a clay-sand composition is used, adjusting the mass fractions of the components depending on the fat content of the clay. The walls of the structure are erected from red facing bricks, using a conventional cement-sand mortar.

Often, the design of a barbecue is supplemented with comfortable work surfaces, a Russian stove, a sink, various niches and shelves. This makes the oven more functional and easy to use.

Preparatory stage

At the preparatory stage, they choose a place for future construction, determine the design and size of the barbecue, and stock up on the necessary tools and materials.

We decide on a place for a garden stove and its design

When choosing a design, size and place for a barbecue, several rules are followed:

- the distance from the building to the house should not be large, since during the cooking process you will have to repeatedly go back and forth;

- there should be no trees and shrubs near the hearth;

- during construction, the wind rose is taken into account - the smoke from the barbecue should not go towards the house;

- the design and style of the structure should match the style of the estate and emphasize its strengths;

- in a small area, a small oven with optimally located working areas will look harmonious;

- a large barbecue requires the construction of a solid foundation.

In addition, it is necessary to foresee how rain protection will be carried out, to consider the design of additional elements such as grates, smokehouses, work surfaces with a sink, etc.

Drawings and dimensions of the future furnace

Since each site has its own unique landscape and layout features, then, most likely, you yourself will determine the dimensions and appearance of the barbecue. However, when designing a scheme, it should be borne in mind that the height at which the grate is located should ensure convenience and safety. For people of average height, the grill and countertop are placed at the level of the ninth or tenth row of bricks. Otherwise, you will have to constantly bend over, or, even worse, be dangerously close to the fire. The pallet or grate is installed on metal rods laid between bricks or rested on ledges in the masonry. It is better if all additional equipment is removable. In the future, this will make it easier to care for him, and in addition, the grates, barbecue and pallet can be removed for the winter so that the metal does not rust.

Barbecue drawing with orders

Barbecue order drawings

In your work, you can use the drawings of a barbecue oven with dimensions of 1500x7500 mm. Taking them as a basis and adding the necessary work surfaces, you will get a functional structure that will meet all your needs. If necessary, the dimensions can be changed while maintaining the proportions of the main parts. Do not forget to provide a place for fuel in your design. In addition, we remind you that the grill is installed at a height of about 70 cm, and the oven is placed 10 cm lower.

Materials and tools

During the construction process, you will need two types of bricks - fireclay, which lay out the firebox and facing. For masonry, it will be necessary to prepare two types of mortar - clay for the combustion zone and sand-cement for the furnace body. In the process of work, you can also use ready-made building mixtures. In addition to brick, clay, sand and cement, you will need:

- gravel or small gravel - for the foundation;

- bar or reinforcing mesh - for reinforcing concrete;

- formwork boards;

- sheet metal - according to the size of the barbecue;

- firebox and blower doors;

- grate;

- stove with burners;

- smoke channel door;

- steel corners or fittings for ceilings;

- plywood 20 mm thick - for the manufacture of an arched frame;

- ruberoid;

- concrete mixer;

- grinder with circles on stone and metal;

- mason's hammer and rubber;

- trowel;

- plumb line and bubble level;

- shovels (shovel and bayonet);

- rammers;

- buckets;

- cord and pegs.

After everything is ready, proceed to the marking and construction of the foundation.

Step-by-step instructions for building a barbecue

The construction of a brick barbecue oven with your own hands is best done in stages, proceeding to the next point in the plan only after the previous stage has been completed. This will allow you to do the job efficiently and without errors.

Arrangement of formwork and installation of armored belt

During construction, the structure is not allowed to get wet, so a canopy is installed over the structure or the masonry is covered with plastic wrap.

- The vaulted ceilings of the niches are laid out, starting from the 9th row of bricks.

The 9th row is completed by installing jumpers under the vaulted ceilings of the niches

- 10 and 11 row forms an overlap and a pedestal.

After laying rows 10 and 11, jumpers are installed under the countertop

- 12 row is continuous. This is a table top. To highlight it against the background of masonry and make the construction more convenient, a quarter-brick release is made at this level.

12th row. Starting from the countertop, the combustion zone is laid out with refractory bricks

- From the 13th to the 15th row lay out the firebox.

Rows 16 - 24 form the furnace space

- To ensure smooth narrowing of the furnace vault, each upper row is shifted relative to the lower one by ½ brick.

Barbecue Pipe Narrowing

- The chimney is driven to the desired height, completing it with the so-called cap - a ¼ masonry protrusion. In this case, only sand-cement mortar is used. To prevent precipitation from entering the structure, a metal cap is subsequently installed on the chimney.

To decorate the surface of the stove, masonry seams are embroidered during the construction process. In addition, if desired, the structure can be plastered and painted to match other structures located on the garden plot.

Operation features

In order for the barbecue oven to serve properly and delight you for many years, you should regularly take care of it. Each time after use, the grill is thoroughly cleaned of food residues, otherwise, during subsequent cooking, fumes and dirt will fall on fresh food. Washing barbecue parts can only be started after the stove has completely cooled down. By the way, it is the barbecue grill that is most prone to destruction, so it must be kept clean and dry.

The surface of the combustion chamber is washed from burning as it gets dirty, and the chimney is cleaned of soot at the beginning of each season.

When using a barbecue, you should follow a few simple rules:

- in the cold season or after rain, you should not immediately fire up the barbecue at full strength, as a sharp temperature drop will lead to cracks. It is better to dry the interior surfaces of the oven for 20 to 25 minutes with a small flame. In addition, if there is no head above the chimney, then water and snow must be removed from the firebox;

- to light a barbecue, use special liquids, charcoal and a device called a starter (a special container for fuel and charcoal). It is forbidden to use gasoline, kerosene and other fuels and lubricants;

- within 15 minutes after ignition, it is forbidden to cover the barbecue with a lid. Otherwise, the formation of combustible gas is possible, which, after removing the cover and a sudden supply of oxygen, may ignite with a flash and pop;

- The taste of barbecued foods is directly related to the quality of the fuel. It is no secret to anyone that in this case the best option is the wood of fruit trees;

- cleaning the hearth from the remnants of burnt fuel should be done after each cooking;

- when using a barbecue, you should strictly adhere to safety regulations, constantly monitoring the intensity of combustion and using protective gloves.

Treat your barbecue oven with care, and it will thank you for long, flawless service and delicious, nutritious meals.

Video: do-it-yourself brick barbecue

Having allocated a few days and a certain amount of money for the construction of a stationary brick barbecue, you will receive a unique building on your site, which will become the center of gatherings with friends and relatives. In addition to the fact that the garden stove will give you the opportunity to please your loved ones with delicious dishes, you will also gain invaluable experience that can raise your own self-esteem and increase your authority among colleagues and acquaintances.