Independent production of rod drawings. How to make dumbbells at home: basic methods

How to make dumbbells with your own hands, drawings, calculations, design description.

The sports equipment proposed for consideration consists of the following parts:

Handle (neck)

Castle

pancakes

Details are made of metal by turning. In the manufacture of parts, it is necessary to strictly observe the dimensions of the drawing and the metal grade of the corresponding density. When these conditions are met, each size will have its own weight.

PEN

Let's make from stainless steel (density - 0.00786 (g / mm³)). The handle has stops on both sides for fixing pancakes. A square thread is cut to the stop. The square thread profile is not subject to standardization. This type of thread is used in mechanisms where spontaneous unscrewing under the influence of applied loads should not occur.

CASTLE

Let's make from stainless steel (density - 0.00786 (g / mm³)). The lock has an internal square thread.

PANCAKES

We will produce from ductile iron (density - 0.0071 (g / mm³)) of four versions. Each size corresponds to its own weight. Metal pancakes, after turning, must be coated with a protective coating, preferably galvanized. This will give the product anti-corrosion resistance and a good presentation.

First performance

Second performance

Third performance

Fourth performance

The thicknesses and mounting diameters of all parts are the same, only the outer diameter and the diameter of the metal sample change.

It is not difficult to make dumbbells with your own hands according to the drawings if you yourself are a turner or have such acquaintances.

Consider the weight distribution table for the parts used (kg):

Handle - 2.0

lock - 0.5 + 0.5 = 1.0

pancake (first performance) - 1.0 + 1.0 = 2.0

pancake (second performance) - 1.5 + 1.5 = 3.0

pancake (third performance) - 2.0 + 2.0 = 4.0

pancake (fourth performance) - 2.5 + 2.5 = 5.0

With this distribution, various weight combinations can be assembled.

We already know how to make dumbbells with our own hands, now let's focus on weight combinations.

Not everyone who wants to play sports has enough time to visit the gym, and home workouts require certain equipment, the cost of which is quite high. The most popular are dumbbells. They are involved in almost all exercises. And if you do not plan to purchase sports equipment in the near future, you should not give up classes. You can make dumbbells with your own hands from fairly cheap materials. To do this, just read the instructions on how and what they are made of.

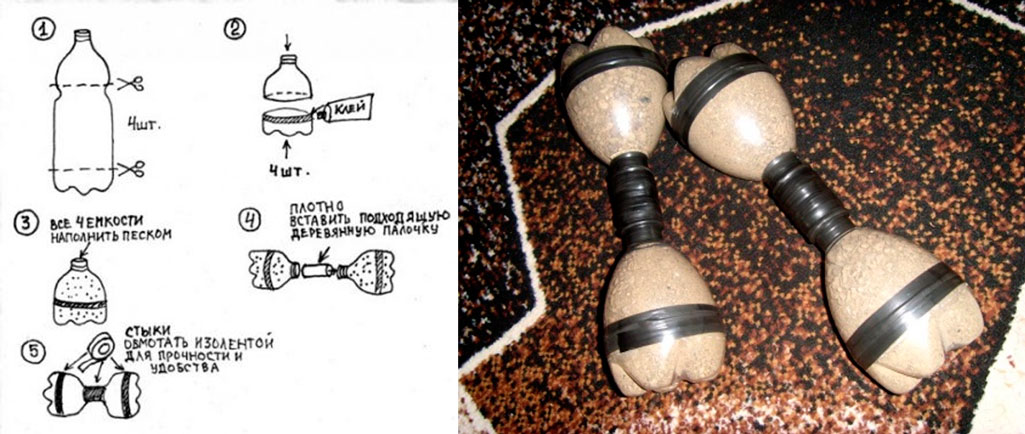

Ordinary plastic bottles allow you to make dumbbells with minimal cash costs in a short time, which you can use right away. The main thing is to fix the structural elements well so that it does not collapse during training.

To assemble one plastic projectile, you will need: 2 bottles, adhesive tape or insulating tape, filler.

Step by step instructions for making dumbbells from plastic bottles:

- Cut out the middle part of the bottles. Fasten the separated elements (upper and lower) with adhesive tape.

- The filler is poured into the container. If the projectile is made of low weight, cement with sand is used. Dumbbells with a larger mass require the addition of metal inclusions, which can be balls from bearings, nails, various metal. The choice depends entirely on the availability of a particular material.

- When the bottle necks are filled, a pipe or a stick made of metal or wood is inserted. Wrap the joint with electrical tape or tape. Thanks to this manipulation, you get a non-slip, soft and rather comfortable handle.

Before starting classes, you should carefully check all connections so that the filler does not “leak out”.

Ordinary plastic bottles are suitable not only for collecting dumbbells, but also barbells. This projectile weighs much more, and therefore the amount of source material increases.

To assemble the rod, you will need: at least 8 plastic bottles, a neck, filler material, electrical tape or adhesive tape.

Instructions for making a plastic rod:

- Bottles are filled in the same way as dumbbells.

- Choose the material for the neck. It is better to take fittings or a pipe that lie comfortably in your hand.

- Ready-made weights from filled plastic bottles are placed at each end of the neck and wrapped with adhesive tape. On each side, four weights are obtained.

- Check the quality of fastening. The neck should not move out or form a backlash. If the connection is weak, wind more electrical tape.

- To increase the weight of the rod allows laying additional weights in the form of bars between the loads from the bottles and so on.

- Each additional load must be wrapped with a new layer of electrical tape. You can increase the load up to 100 kg.

It is quite difficult to navigate the choice of material. The approximate weight of a dumbbell or barbell can be calculated based on the data presented:

Weight of a two-liter plastic bottle with various fillers:

- water - 1.997;

- compacted sand - 3.360;

- wet sand - 3,840;

- crushed stone (sandstone) - 2,600;

- lead - 22,800.

Weight is given in kilograms.

We collect shells from concrete

The cement base allows you to get heavier dumbbells and barbells than using plastic bottles. Pancakes are obtained not only more impressive weight, but also look much more solid. They are cast from cement mortar in a special mold, inside of which there is a neck. The disadvantage of this design is that the load of the projectile cannot be adjusted or adjusted to fit anyone else.

To start working with a different weight, you will need to make a new barbell or dumbbells. The weighting agents, in fact, are obtained individually, and also quite fragile and “loose”. The last drawback is eliminated by introducing glue into the PVA solution. And if the classes are not conducted according to the principle of powerlifting, when the projectile is thrown to the floor, then it will last quite a long time.

For the manufacture of concrete dumbbells (rods) you will need: a metal pipe with the required length, bolts or screws, cement mortar, PVA, as well as a mold for casting the load.

Step-by-step instructions for making cement shells:

- At the ends of the pipe, holes are made in four directions with a drill. Screws are screwed into the holes made so that they are fixed as securely as possible at the ends and form a kind of cross shape. They become the framework that holds the cement.

- A pancake pan is made from a flat bucket of mayonnaise or paint. You can also use other containers. The main thing is that the weight should be chosen in such a way that is necessary for classes and is suitable for the complexion of the student. Glue is added to the solution for hardness or oil paint is introduced.

- A pipe is placed in the poured mixture and wait about four days until it completely sets. Repeat the manipulations described in the previous paragraphs for the second side. Make a support. The structure is tied up or suspended for another four days.

- When the cement is fully set, the projectile is soaked at least twice in water over the next week to gain even greater strength.

Shells filled in a two-liter mold can weigh about 5 kg. The exact weight is determined by the composition of the mixture involved.

To complete a farmer's walk, it is not necessary to make shells. It is enough to take two ordinary canisters and hang them on a stick. You can use tires filled with sand or any other filler. Other exercises with a similar design are difficult to perform. They require the use of full-fledged dumbbells.

When sports become regular, it becomes necessary to purchase more professional shells or make them from metal. They practically do not differ from the factory ones. The difference is that do-it-yourself dumbbells will cost much less. From one pipe, you can simultaneously make both a neck and pancakes. It is best to make stacked dumbbells out of metal.

To make shells, you need to prepare in advance: a thin-walled pipe with a diameter slightly larger than that of the neck, which is better to take a metal rod, locking locks and sheet steel. Work on the manufacture of dumbbells should be carried out in a locksmith's workshop.

Step-by-step instruction:

- From scrap metal with a diameter of about 3 cm, a neck is sawn off about 35-40 cm. To make the projectile comfortable to hold in your hands, about 15 cm are cut off from a thin-walled pipe. The resulting segment is put on a neck. Further, if desired, it can be covered with a relief or wrapped with electrical tape.

- Pancakes are cut out by autogenous from sheet steel. The weight of one disk with a diameter of 18 cm and a thickness of 1 cm is 2 kg. This makes it easy to calculate the required number of pancakes to get a mass of 10, 20, 30, 40 kg. The dimensions of the discs also make it quite easy to change the weight of the weights from small to maximum. Cutting a whole set of pancakes allows you to constantly work with different weights.

- The next step is making locks. The diameter of the pipe is taken larger than that of the neck. Rings with a width of 3 cm are cut off from the product. They should move freely along the neck, but not slip off. One hole with a diameter of at least 1-1.20 cm is drilled in the rings. They are necessary for screwing in the screws, which allows the rings to hold the pancakes and press against the neck. The main thing is to take care of the high-quality pressing of the screw so that there are no backlashes.

- At the last stage, they begin to assemble the dumbbell. Pancakes are hung on a neck with a pipe section in the middle and secured with locking locks.

Dumbbells made in the described way are not inferior in quality to factory ones, they allow you to work with both small and large weights.

General Tips and Tricks for Assembling Dumbbells at Home

The best without any doubt are metal shells, but they are much more difficult to manufacture than other designs. It is necessary not only to make discs, but to choose the right width of the pancakes, to make high-quality locks according to the calculations. It is recommended to increase not the width, but the diameter of the discs. You can make several heavy and several small pancakes.

To make the dumbbells look presentable, the parts are sanded and painted. This will only slightly complicate the creation process and increase the cost of shells, but they will look no worse than factory ones, and have a much lower price. Classes with such equipment will bring more pleasure, and, consequently, the motivation and effect of training will increase.

You should not waste time and effort on creating dumbbells weighing up to 100 kg. There are plenty of instructions for assembling such structures on the Internet, but it is better to immediately make a barbell with the expectation of 200-300 kilos in order to deadlift. Dumbbells are not suitable for such loads. And if you pull iron, then with a serious projectile, that is, a barbell.

If there is such an opportunity, you can buy a neck with a handle in the store, and either make pancakes yourself or order them in the workshop. A well-made handle contributes to comfortable exercises, and home-made pancakes significantly reduce the cost of the overall cost of the projectile.

Sports can also be done at home. To gain a sporty, toned body, it is enough to exercise with your own weight. But in order to make great progress, additional weights should be used.

Many do not have the opportunity to purchase expensive sports equipment, but do not despair: you can make dumbbells and a barbell with your own hands at home, with a minimum set of tools and materials at hand.

What can replace dumbbells at home?

If you do not want to make dumbbells yourself or you do not have the necessary tools, you can use the heavy things that are at hand for training.

The most common items that are usually replaced with dumbbells are ordinary plastic bottles or bricks. The latter can be used immediately without additional modifications. A standard red brick weighs about 3.5 kg.

Use bottles as a weighting agent only with filler: water, gravel or sand. The weight of the inventory directly depends on the type of filler. 1 liter of water weighs approximately 1 kg. This is a small mass, so if you use water, it is better to take a 2 liter bottle. By filling it with crushed stone, you can get a weight of 2.6 kg, and with sand - 3.4 kg, and if you fill it with additional water, about 4 kg will come out.

Such weights are suitable for training only for girls. Men should use larger plastic bottles. Today you can easily find plastic containers of 5, 6 and 10 liters. Filling them with various fillers, you can get sports equipment weighing up to 40 kg. Such a load will be sufficient even for experienced athletes. But there is one problem: holding such a bottle is not very convenient, while its fastening is not designed for heavy weights. Therefore, it is better to make dumbbells with a comfortable handle yourself.

To do this, you can use a regular towel or other long and dense fabric. The towel should be tied so that a circle is formed. Then take it with your hand on one side, and on the other, step on the inside of the circle. Thus, when performing a biceps workout, by pressing the towel with your foot, you can adjust the level of load.

For those who live in the countryside, there is one more piece of advice. Instead of dumbbells for training, you can take logs of various weights. The main thing is that the diameter of the log allows you to comfortably grasp it. But you can also drive metal staples into the log, which will be comfortable to hold on to during the exercise.

How to make dumbbells from plastic bottles?

Do-it-yourself dumbbells from plastic bottles can be easily made at home, as the bottles are easy to find or buy, while their cost is minimal. The main thing is to use a heavy filler and securely fasten the elements.

To make a simple dumbbell, you need to have only 2 bottles of 2 liters, adhesive tape, a pen and a filler.

Consider the detailed instructions for mounting dumbbells from plastic bottles:

What can replace the squat bar at home?

The weight of homemade dumbbells can be a maximum of 10 kg, so it is more rational to make a barbell, which is also used to train the biceps.

You need to have the same set of tools and raw materials, only instead of a pen you need to use a fingerboard.

Such a sports equipment is perfect for doing squats and bench presses at home. The main thing is not to overload the neck, because homemade equipment can burst during the exercises and cause serious injury.

Making dumbbells and barbells using concrete

Concrete should be used to make heavier and more durable inventory. But it can only be used with an all-metal neck, which must be prepared in advance.

Pieces of metal pins must be welded to the ends of the neck. It turns out reinforced concrete, which is much stronger than usual. Another way to make the projectile more reliable is to add PVA glue to the solution.

Pieces of metal pins must be welded to the ends of the neck. It turns out reinforced concrete, which is much stronger than usual. Another way to make the projectile more reliable is to add PVA glue to the solution.

The mold for concrete weights can be plastic buckets. Having picked up a bucket of the required volume, you can get the desired weight of the finished rod. For dumbbells, containers from mayonnaise and other food products are suitable. The disadvantage of such equipment is that such a dumbbell is non-separable, that is, you will not be able to adjust the weight.

In order to make a rod, you need to mix the solution and pour it into the mold. Set the neck strictly in the center, this is very important for balancing the projectile. Four days later, when the solution dries, repeat the procedure on the other side. If the concrete cannot be removed from the mold, it can be easily broken. If the bucket is intact, then it can be reused.

When calculating the weight of the finished rod, it should be borne in mind that 1 liter of poured concrete weighs about 2.5 kg. In the same way, you can make a concrete weight.

DIY expander

Expander- A great tool for training the forearm. Such inventory is cheap, but if you like to do everything yourself, then you can easily make it yourself.

To do this, you need to have a steel wire with a diameter of 3 mm. Heating the wire with a gas burner, it must be twisted in the form of a spring into two turns. This can be done with a vise, pliers, a pipe around which coils are formed, and brute force.

The finished spring must be at the same time soft enough to give in to the efforts of one hand, but also hard to return to its original position.

Expander handles are made of wood, dense rubber and plastic, having drilled holes for the spring.

Attention, only TODAY!

An increasing number of young people have become more attentive to their health, but most gyms are inaccessible for a number of reasons. Since the purchase of sports equipment is beyond the means of many, the question arises: is it possible make a barbell with your own hands? Of course, yes, because nothing is impossible for us.

What is needed to make a barbell

Barbell at home It is made from ordinary plastic bottles that are in every home. Usually eight pieces are enough, but in our business you can’t do without packing wide stationery tape. These are our main production materials.

We will also need a shovel handle, 4 or 5 meters of aluminum wire and two buckets of clean, dry sand. Why does it have to be dry? Because the wet sand is heavier, but when it dries, it loses its weight. To have a clear idea of the weight of the resulting rod, you must have any scales for weighing. The barbell that we get is guaranteed to be in no way inferior to a professional neck in the gym.

How to make a barbell at home

Before proceeding with the creation of a barbell, it is necessary to determine how much should she weigh. To do this, you need to carry out elementary mathematical calculations. About two kilograms of dry sand are placed in an ordinary liter plastic bottle, which means that now you can independently calculate how much the barbell we created will weigh. More specifically, 3 kilograms 750 grams of sand are placed in a two-kilogram jar, which means that a home barbell will weigh thirty kilograms or more, depending on the strength of our handle.

The most important thing in our business is to make sure that homemade the bar had the same weight on an impromptu neck. To do this, the first bottle after filling must be weighed so that all subsequent bottles do not turn out to be lighter or heavier. Uneven distribution of weight can affect the muscles and lead to injuries, which is highly undesirable.

Having filled all the bottles, let's move on to the main part of creating a bar: four sand bottles must be placed side by side and wrapped tightly with tape. You should not spare the material, it is better to paste over the bottles with a margin so that the bar lasts longer. The basic rigidity of our structure will be provided by aluminum wire, which we prepared in advance. The same must be repeated with the remaining four bottles. And at the end we take the stalk and thread it between the bottles. Thanks to their narrowing, it sits perfectly.

So that at the most inopportune moment the bar does not break, you need to check whether the stalk sits tightly between the bottles. If it does not sit tight enough, you need to either cut it down or increase the volume, depending on the thickness of the handle. Remember to raise the barbell and check if the load is evenly distributed.

If you are not new to the sport, then the weight of the bar may seem too small for you. In this case, its weight can be increased by replacing the wooden handle with iron scrap. Such a bar will weigh much heavier than the original version and is perfect for your workouts.

In stores, sports equipment is quite expensive, so not everyone can do it. To achieve the same results as with real dumbbells, you can independently build simple power shells. The main constancy of the exercise - and the result is guaranteed.

The most affordable and easy way to make your own dumbbells is to take two plastic bottles and fill them with water. For more weight, you can fill the bottles with sand. This method is more suitable for girls because of the ease of execution and low weight. For guys, this method is not suitable, so some craftsmen have developed unique methods that will help everyone make dumbbells at home, spending a minimum of money on them.

Making cement dumbbells

A fairly common type of homemade dumbbells are cement, which are heavy. If desired, you can make dumbbells up to 15 kg each. To do this, you need to take a metal or plastic pipe, cement mortar and suitable containers. Any bucket of paint, mayonnaise, or just the bottom of a cut bottle can serve as a mold for the solution. At the same time, the larger the capacity, the heavier the dumbbell will be, so you can even cut off a five-liter bottle.

Then dilute the solution and fill the selected container. We insert a metal pipe into the center of the container and wait for the complete hardening of the solution. Half of the dumbbell is ready. The next day, he does the same with the other half, only with the load frozen at the other end. For additional fixation of the tube in the solution, you can screw self-tapping screws into its ends so that some of them protrude for greater adhesion.

Complete drying of the cement mortar occurs only after four days, before that it is not recommended to use them. To give homemade dumbbells an aesthetic look, they can be cleaned and painted with ordinary paint, or simply wrapped with colored tape. The rod is made in exactly the same way, only the containers must be of a larger diameter. The main thing is not to throw cement dumbbells on a hard surface, because they can break.

DVD Dumbbells

The next way to make dumbbells at home is even more interesting. Unnecessary DVD discs are taken, and the larger the better, and a metal tube with a diameter like a hole in the discs. In order to make such dumbbells, limiters for discs are needed, therefore it is desirable to have a thread at the ends of the pipe, onto which nuts are screwed on both sides of the stack of discs.

When using 100 discs per dumbbell, that is, 50 pieces on the sides of one dumbbell, we get a weight of 2 kg. For convenience, wrap the handle with either a rubber band or other thick material to increase the diameter.

If you don’t know how to make dumbbells with your own hands, or the listed methods are not suitable for some reason, you can turn to a turner who will turn all the metal parts. Such dumbbells will be most similar to professional ones, while their cost will be several times less.