Do-it-yourself seam roof installation: step by step instructions. The device and installation procedure for a folded roof, its pros and cons Rafter system for a folded roof

The price for the installation of a seam roof is 240 rubles per square meter.

The total cost of installing a roof is determined by the amount of work and the complexity of the structure, as well as the type of connection of sheets (paintings) of metal.

| Name of work on the installation of seam roofing (double standing seam) | Price, rub. | units rev. |

|---|---|---|

| Production of seam roof paintings | 370 | m2 |

| Installation of seam roof paintings | 500 | m2 |

| Manufacturing of ridge fittings | 215 | m / line |

| Installation of seam roof ridges | 445 | m / line |

| Manufacturing of cornice moldings | 215 | m / line |

| Installation of seam roof eaves | 295 | m / line |

| Manufacture of end fittings | 215 | m / line |

| Installation of the end strip of the seam roof | m / line | |

| Manufacture of valley fittings | 215 | m / line |

| Installation of seam roof valleys | 435 | m / line |

| Manufacturing of shaped products for adjoining | 215 | m / line |

| Installation of seam roof junctions | 435 | m / line |

If there was the right approach to the study of all the elements, then the house will turn out to be warm and outwardly attractive. Even the latest technologies and new materials will not bring positive results if the roof is of poor quality. And this means that the roof must be done with special attention, entrusting the work to experienced professionals. Seam roofing has gained great popularity because it has a number of positive features, in particular, a long period of operation.

Features of seam roofing and installation

The seam roof is so called because of the installation features. Fastening occurs with the help of folds that fasten the roof to the roof base.

This type has a lot of advantages, for example, its low weight, due to which it is not necessary to further strengthen the structure of the roof. In addition, there are other advantages:

- perfectly protects against moisture ingress, as it is well sealed;

- made of different metals: titanium, aluminum, copper, you can choose the right one;

- mounted differently depending on the situation;

- the service life is quite long;

- suitable for various roof shapes.

The disadvantages include excessive smoothness of the coating, which makes it dangerous to use it in cold weather. Due to falling snow from the roof, a person and surrounding objects may be harmed, therefore it is necessary to install snow retainers.

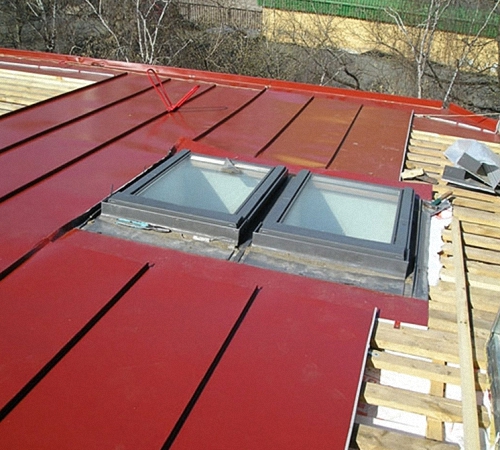

Examples of our work

Carrying out the installation of seam roofing

The installation of the crate also belongs to the preparatory stage. It is better to make the roof solid, this will not allow deflections to form. However, the use of battens is also possible, only the steps between the boards should be minimal. The use of a solid roof option is required when there are many angles and shapes in it.

Laying is done in two stages. To begin with, the sheets are prepared, they are cut to the desired size, a construction site is used to carry out such work. After that, mark the places where the flange will be fixed. With the help of a wooden hammer, the edges are bent, in addition, markings are made for the chimney pipes.

The next step is to install the roof. Using a rope or other device, the sheets are lifted to the roof. Then, with the help of clamps, they are attached to the crate. One side of the sheet is driven into the flange, and the other is nailed.

Using galvanized metal aprons, they frame the holes that were cut out for different pipes. The main thing is to carry out the correct installation of the first sheet, which will become a guide for all subsequent ones.

Order installation of seam roof

You can order the installation of a seam roof in our company. Leave a request - and a professional roofer will contact you, who will answer all your questions, recommend the best roofing option for you and make an estimate.

Pay attention to.

Compliance with the technology of installation of a seam roof helps prevent corrosion of the coating, its deformation and deflection. Properly installed material will serve its owners for many years. How to properly install a seam roof with your own hands, we will consider further.

Seam roof: features and benefits

Seam roofing is distinguished by a special installation technology, thanks to which a reliable seam lock is created that prevents water leakage. The appearance of the roof is particularly attractive, giving the building aristocracy and originality.

The roof itself consists of separate paintings, interconnected with the help of folds. For their manufacture, sheet or roll-type steel is used, always with a galvanized coating. To increase the durability of the structure, it is treated with a special coating of non-ferrous metals such as copper, aluminum, zinc, pural or plastizor. The most optimal and durable option in operation is copper. Despite the high cost of such a roof, it has an amazing appearance and good performance.

By connecting roofing sheets together, it is possible to obtain a connection called a seam. There are four types of such compounds:

- single type;

- double type;

- standing type;

- recumbent type.

The first option is relevant if the roof slopes are located at an angle of more than fifteen degrees. The second option is particularly waterproof and durable, although its arrangement will require more material and effort, but the result is worth it. Standing folds are relevant in the connection of strips of longitudinal purpose.

Among the advantages of seam roofing, we note:

- the possibility of using various coatings, which give it a unique shade and originality;

- thanks to seam joints, the roof does not leak

- does not need additional mounting holes, so the roof becomes resistant to changes in temperature conditions;

- a variety of installation technologies, materials, variations of sheet or roll laying, allows you to create an interesting roofing that will be in harmony with any building;

- the presence of a smooth surface provides a quick runoff of water and snow;

- due to the fact that the material is quite flexible, it is possible to equip such a roof on any type of roof;

- the light weight of the structure allows you not to mount the rafter system;

- such a roof is easy to maintain and repair;

- Duration of operation is another important advantage of this type of roof.

When installing a seam roof, you must also learn about its shortcomings, such as:

- the need for special equipment, which greatly simplifies the installation process;

- steel roof has a high thermal conductivity, therefore, it needs additional insulation;

- the roof needs to be equipped with additional nodes that reduce its noise output;

- in order to secure a home during a thunderstorm, it is necessary to install a lightning rod and grounding;

- on a smooth surface, it is necessary to install snow stoppers, as avalanches will fall to the ground during heavy snowfalls.

Varieties and technology of seam type roofing

The most durable copper roof in operation, it will serve its owners for more than one hundred and fifty years. In addition, this type of roof has an attractive appearance, as it has a special textured pattern that imitates various materials. However, the cost of such a roof is quite high, although it fully pays off during operation.

Aluminum roofing is lightweight, resistant to corrosion, mechanical damage and various kinds of loads. The service life of such a roof reaches a mark of one hundred years. The cost of such a roof is an order of magnitude lower than copper, but the performance is also at a high level.

Also, seam roofing is made of titanium-zinc coating, which is distinguished by its prestigious appearance, reliability and durability. In addition, a distinctive feature of this material is its high level of plasticity. After a certain period of operation, the roof is covered with a patina, which makes it even more elite.

The most affordable material for the manufacture of seam roofing is ordinary metal. The great demand for this type of roofing is primarily due to the affordable cost of coverage. The duration of operation of this design reaches the mark of 55 years. The option of choosing the color and appearance of steel is possible. In addition, zinc coating protects the roof from corrosion and destruction.

Seam roof - installation technology

Seam roofing differs not only in the materials from which it is made, but also in the technological aspects of its installation. In the process of manufacturing the roof, materials are used both in sheet and roll versions.

Using sheets is a classic option that is unfortunately losing popularity. The main rule of any seam roof installation is the creation of special conditions in the attic space that prevent the formation of condensate on the roof that destroys it.

An innovative method of roofing installation is the use of rolled materials. This installation technology is distinguished by the presence of better seams, which are easily equipped by specialists.

Among the advantages of the rolled seam roof installation technology, we note:

- installation of not only steel sheets, but also a material with a polymer layer, which has better performance characteristics;

- the use of a standing double fold, providing a high degree of tightness of materials;

- the use of technology in various areas of roof installation, regardless of the slope of the roof and its shape;

- speed and ease of work, thanks to the mobility of the equipment used in the installation of the roof.

Seam roof installation tool

The correct use of the tool in the process of performing installation work, half ensures the duration of the operation of the roofing. The main tool for the construction of the clamp, it is used in any case of installation, both in roll and in sheet. There are two types of tool used when seaming a fold:

- mechanical equipment;

- electric tool.

The first option involves the use of a set of pliers, which contain two frames that cover the folds. With their help, it is possible to create single and double folds.

An electric machine allows you to speed up the work several times, while after rolling it stops on its own at the final section of the roof.

Also, when installing a seam roof, you will need a tool in the form of:

- hammer;

- pliers;

- scissors for metal;

- mallets;

- drills and screwdriver;

- level and other measuring instruments.

Additional tools used in the process of installing the roof depend on the individual characteristics of the building and the method of installation of roofing materials.

Seam roof: manufacturing and installation

To begin work on the installation of a seam roof, you should choose a crate, for the manufacture of which a steel profile, board or wooden beam is used. The main requirement for the crate is its maximum evenness, the absence of recesses.

Seam roof installation instruction:

1. Initially, an insulating coating is laid on the surface of the roof trusses. The presence of a light crate will provide sufficient ventilation of the under-roof space. The interval for laying the crate is 40 cm.

3. Before starting the installation of sheets, install the eaves of the roof.

4. Install a support board on the ridge area as well. In order for the joints to be evenly spaced on the roof, the first and last sheet should be cut in proportion to the dimensions of the roof.

5. Arrange a solid boardwalk on the valley.

6. Alignment of the sheets is carried out in relation to an overlap of 4 cm. To fix the sheets on the cornice zone, the upper crate is used.

7. On the end sections of the roof, the fixing of the roofing material is carried out using self-tapping screws and washers, between which sealing gaskets are installed.

8. At the joints between the roofing sheets, snow barriers are laid. To perform longitudinal joining of sheets, also use an overlap.

Features of installation of a copper seam roof

The ridge and ribs on the seam roof should be straight. If wood is used to make the crate, then do not forget to cover it with an antiseptic composition.

Before starting installation work, fix the cornices along the lower edges. Also, the drainage system is installed at the initial stage. Valleys are fixed on the crate, and an anti-condensate film is installed on the rafter system, which provides waterproofing.

Before starting work on the roof, measure its slopes. The slopes of a rectangular shape should differ in equal diagonals. Equipping the longitudinal joints, fixing the sheets is carried out in the direction from the bottom to the top. If the length of one slope is more than six meters, then it is assembled from several parts.

Installation of sheets is carried out with a slight overlap. When installing a copper roof, it is destroyed to use a seaming machine, which significantly improves the tightness of the joints between the sheets.

The lifetime of a copper roof is more than a hundred years, however, in order to ensure the fulfillment of this condition, the roof is installed on a solid deck.

When equipping a flooring for a seam roof, you should be guided by the following recommendations:

- without fail, you should take care of the presence of a special ventilation gap, which allows you to remove the condensate formed inside the roof;

- thus, the crate prevents corrosion of metal parts and damage to the wooden crate;

- the crate should be able to reduce the noise generated during rain.

A solid base is also equipped if the roof slope is less than fourteen degrees. In order to improve the tightness of the connection between the sheets, after seaming, use silicone sealant.

Installation of a self-latching seam roof

In order to create a self-latching roof, galvanized steel sheets are used. Sheets should be in the form of large canvases, which are interconnected using special grooves.

The most popular types of folds are recumbent and standing ones, used in longitudinal and transverse joints. A self-latching roof is much faster and easier to install than a standard seam roof.

In addition, this type of roof is distinguished by a variety of color and texture forms. Therefore, you can choose the best option suitable for a particular building.

To arrange the connections between the sheets, no special equipment is required, and all work can be done independently, without the involvement of specialists. In addition, upon completion of the installation, an ideal coating is obtained, in the form of a continuous flooring, which absolutely does not allow moisture to pass through.

This version of the roof is suitable even for a roof whose slope angle is 8 degrees. Among the advantages of a self-latching roof, we note:

1. Possibility of installation on various kinds of roofs.

2. Long service life.

3. Thanks to the special installation technology, the connections are reliable, and the seams are durable and tight.

4. Seam roofing has high bearing capacity, good resistance to the external environment.

Therefore, when choosing a seam roof for a house that you plan to install on your own, we recommend that you stop at its self-latching version, since this design does not require the use of special equipment to obtain a high-quality connection between the sheets. Repairing a seam roof will not be difficult, since if certain elements of it are damaged, it is enough to replace them.

Seam roof installation video:

For more than 10 years, the specialists of our company have been manufacturing and professionally installing seam roofing from different metals on turnkey roofs of any complexity. The price for the installation of a turnkey roof is from 500 rubles per m2. In addition to the installation of the seam roof itself, we install all the accessories necessary for the proper operation of the roofing system: drainage systems, spotlights, snow retention, wind vanes, etc. We will help you choose the material for the roof of your own house, and for the installation of public coverings buildings.

Seam roof installation rules

Installation of a seam roof on a turnkey basis is a rather complicated and time-consuming process that requires a fairly long work experience and highly qualified specialists. In order to start making a seam roof, you need to purchase material - a metal strip. Its amount required for the installation of a seam roof can be roughly calculated as the roof area multiplied by one and a half. For a more accurate calculation, clear dimensions of all roof elements will be required.

- Work on the installation of a seam roof begins with the preparation of the base. As a rule, a crate with a distance between the boards of 50-150 mm is quite suitable for any type of metal. But such soft types of metals as copper or aluminum can, under the influence of snow load and heating, display the entire crate on its surface. Therefore, under copper and aluminum, a crate made of FSF moisture-resistant plywood (thickness from 12 mm), OSB boards (thickness from 11.3 mm), tongue-and-groove board (thickness from 25 mm);

- When the solid crate is ready, work is carried out on laying the lining carpet under the roofing. Since condensation-dew forms on any metal due to temperature differences, a continuous crate must be protected from moisture. The lining carpet successfully copes with this. If the crate is not continuous, then there is no need for its waterproofing from the metal;

- It is important to remember that each type of metal from which the roof is made needs its own fasteners. For example, fasteners made of copper and stainless steel are used for copper, for titanium-zinc and aluminum - stainless and galvanized steel, etc.;

- Seam roofing begins with the manufacture of all elements - picture panels, shaped strips, gutters (if a wall gutter is needed), embedded elements, type-setting frontal and gable strips. All components of the seam coating are made based on the width of the metal strip. On the panel there is 100% of the width of the tape, on additional elements from 20% to 100%. If you need any non-standard cornice or frontal plank that requires multiple cutting of metal, then this issue is agreed with the customer or architect;

- Installation of the seam covering is carried out starting with hooks for gutters, embedded strips on the eaves and ends of the roof, and also, if the roof is insulated, from the installation of a condensate drain. Next, a frontal board, gutters, cornice strips, valleys are mounted. Then panels-pictures, ridge and end elements are installed. The process of installing a seam roof is completed by installing wind vanes on pipes and connecting to vertical surfaces;

- For seam, as well as for any other, special security systems are needed. These include snow retention, walkways and roof ladders. The snow retention system prevents avalanche-like snow from the roof, and walkways and ladders help specialists of the facility maintenance service to move along the roof.

Seam roof maintenance

Properly manufactured and neatly installed seam roofing practically does not need any maintenance. The maximum that may be needed is to clean the snow in winter.

Our specialists

Thanks to their experience and high qualifications, our specialists are always ready to technically correctly and beautifully produce any seam coverings, whether it is a roof made of picture panels, rhombus, checkers and any other non-standard metal coverings in Moscow and the Moscow region.

Advantages of ordering the installation of a seam roof

When ordering a seam roof and its installation at Eurokrov, you get:

- Qualified assistance in the selection of seam roofing material;

- A single contract for the supply of roofing and its installation;

- Quality service and comprehensive approach;

- Roofing installation works using modern technologies;

- Comprehensive guarantee for seam roofing and installation.

The cost of installing a roof is from 500 rubles per m2.

Our team performs roofing installation services in Moscow and the Moscow region!

It is very convenient to use metal as a roofing coating - it is durable, non-flammable, highly resistant to atmospheric phenomena, and besides, it provides the maximum possible strength of the roof structure with its relative lightness in all its diversity. Among the materials used for waterproofing roofs, there are galvanized steel and copper, aluminum and steel profiles, both in the form and in combination with composites, imitating. In this article, we will look at how to install a seam roof made of galvanized steel.

Seam roof installation. Cost of work

| No. p / p | Name of works | unit of measurement | The cost of work excluding the cost of materials and taxation |

|---|---|---|---|

| 1 | Antiseptic materials | sq.m. | 45 rub. |

| 2 | Mounting Mauerlat 150*150mm | m. | from 190 rub. |

| 3 | Installation of the truss system | sq.m. | from 230 rub. |

| 4 | Mounting the inner lining with a board, with a step of 100 mm | sq.m. | from 80 rub. |

| 5 | Vapor barrier installation | sq.m. | from 45 rub. |

| 6 | Installation of insulation 150 mm. | sq.m. | from 120 rub. |

| 7 | Mounting the diffusion membrane | sq.m. | from 55 rub. |

| 8 | Installation of counter battens | sq.m. | from 65 rub. |

| 9 | Installation of a step crate with a board 100 * 25mm | sq.m. | from 120 rub. |

| 10 | Installation of folded paintings | sq.m. | from 490 rub. |

| 11 | Installation of connections to the wall / pipe | m. | from 530 rub. |

| 12 | Valley device | m. | from 560 rubles |

| 13 | Mounting skates | m. | from 340 rub. |

| 14 | Installation of end strips | m. | from 365 rubles |

What is a seam roof made of?

Seam roofing got its name from a special method of attaching metal sheets of roofing material to each other. A special system of joints guarantees absolute tightness without the use of rubber seals, adhesive seams, and most importantly - through holes, which will cause leaks. In addition, the stiffening ribs obtained during the folding process give the roof additional strength and expressiveness. It is used on roofs with a slope of at least 30%.

Galvanized roofing steel , one of the most popular roofing coatings, differs from ordinary cold-rolled steel in the presence of a thin anti-corrosion coating, a zinc layer about 0.2 mm thick, which significantly increases the life of the material.

The main parameters of galvanized roofing steel:

- length up to 2.5 m;

- width - 0.8 -1.25 m;

- thickness - 0.5 - 1 mm.

The best option for obtaining high-quality galvanized steel is the use of steel sheet metal grade ST 08PS, where the abbreviation PS means semi-quiet steel (a metallurgical term meaning steel containing a certain percentage of ferrous oxide in its composition, which causes the release of gases, without "boiling", from steel during its hardening after pouring).

A hot-rolled billet used to produce a galvanized sheet is pickled with acid to remove scale from its surface and brought to the required thickness by cold rolling. To give the workpiece the necessary strength characteristics, it is fired on a special bed.

Then the metal is immersed in baths with a zinc-based melt, the composition of which determines the main property of the future galvanized sheet - high resistance to the damaging effects of corrosion.

For galvanizing, zinc grades TsO and Ts1 (sometimes Ts2) are used. Their use is dictated by the requirements of GOST.

What to look for when choosing a material for seam roofing?

The right choice of material is the main requirement, following which you can perform a high-quality installation of a seam roof made of galvanized steel. The presence of defects in the material can lead to a significant reduction in the life of the roofing. Therefore, when buying material, you should pay attention to:

- presence / absence of cracks on the surface of the rolled product;

- zinc coating must be clean and uniform;

- a sheet of metal should be without "torn" edges;

- a continuous zinc coating should not be disturbed by sagging, dark dots, various grains, uneven crystallization of zinc, various kinds of roughness and scratches and other defects of this kind.

The minimum thickness of the material for the installation of a roofing sheet should be 0.5 mm, for the installation of overhangs and slopes - at least 0.7 mm.

Pictures and folds

Seam roofing with a continuous coating covers the entire length of the roof slope, where individual sheets are connected with a seam lock into “pictures”, and the latter, in turn, are connected to each other. What do such expressions as "picture" and "fold" mean?

Painting - a sheet of roofing steel, the edges of which are prepared for seam connection.

Falz - type of seam formed when connecting sheets of metal roofing material. The folds are divided by shape into standing and recumbent, and by density - into single and double. Recumbent seams are used for horizontal connection of roof sheets located along the water flow from the roof. Standing - for fastening vertical (side) strips of roofing material, fastening pictures on skates and ribs.

With slopes less than 60% of the roof, the recumbent folds in sheet steel roofs are made double and sealed with sealant. The size of the bending of paintings for the installation of recumbent folds is 15 mm, standing folds - 20 mm for one and 35 mm for another, adjacent picture.

In valleys, the folds of one slope should be at the same levels as the folds of the second slope

Folds are performed (rolled up) manually with a special tool or in a more modern way - with electromechanical seaming devices. Self-locking folds hermetically connect roof sheets without the use of tools. But the most reliable is considered a double standing fold.

Modern equipment for rolling folds allows you to make pictures of any shape: conical, radius and others, so the installation of a folded roof can be performed on roofs of various configurations. In this case, the seam seam can have a thickness of 5 mm and a height of 30-70 mm, depending on the slope of the roof.

Seam roof installation. Step by step instructions

Installation of a seam roof made of galvanized steel begins with the creation of a strong and even frame. It is made in the form of a crate of wooden beams with dimensions of 50x50 mm with a step of no more than 200 mm and boards 120-140 wide and 50 mm thick, laid every four bars with a step of 1390 mm (in places where the recumbent folds of joined pictures are laid). At the same time, the grooves, valleys and cornice overhangs are covered with a continuous boardwalk.

At the same time, pictures are being prepared. Folds are bent along the edges of the roofing sheets. Roofing sheets can be pre-connected to each other along the short side with a lying seam. The folds are bent towards the slope of the roof. In this case, the picture will consist of several roofing sheets. Steel sheets are cut with scissors or a guillotine, but in no case with a grinder.

If low roofs are covered, then the blank of the picture can be made for the entire length of the slope.

The next stage, which continues the installation of the seam roof, is the installation of cornice overhangs. Then install wall gutters and cover the grooves. And only after that, the pictures of the ordinary coating are lifted to the roof and laid on the crate, securely joining each other, first on the short sides with a recumbent fold, and then on the long sides with a standing fold.

The installation of a folded roof does not provide for fastening through a sheet of metal, so the roof is obtained without technological holes. Pictures are fastened to the crate with clamps - strips of roofing steel 50 mm wide and 150 mm long, one end of which is led into the fold, and the other is nailed to the bars of the crate. This is convenient if the width of the sheets from which the picture is assembled is 50-60 cm. The most common size of a galvanized sheet is 1 x 2 m, so it is cut lengthwise into two equal strips, 0.5 x 2 m in size. Clamp fixing step - 0.5 - 0.7 m.

On the overhangs, the roof elements are attached to T-shaped crutches, nailed to the boardwalk in increments of no more than 70 cm and with a 12 cm overhang of the boardwalk. .

Drainpipes are hung on the walls of buildings using mobile scaffolding or mechanical towers after the roofing work is completed. They are attached to the walls with pins and clamps so that the gap between the wall and the pipe is at least 120 mm.

Seam roof installation: scope of work

- The device of the truss system, steel or wood;

- Antiseptic and fire protection of roof structures;

- Installation of insulation, steam and waterproofing (in the case of installation of a mansard roof);

- Installation of the batten (counter-lattice);

- Installation of a seam roof covering with the installation of ridges, the device of valleys adjoining to vertical walls and chimneys;

- Installation of eaves gutters and overhangs, ridge and eaves vents, parapet coverings, ebbs;

- Installation of a safety railing, installation of a fence, a spillway system;

- Installation of dormer and dormer windows, running ladders, snow retention systems;

- Hemming of cornice overhangs.

Installation of seam roofing from rolled material

When performing repairs or re-roofing for industrial, administrative or multi-storey residential buildings, you should pay attention to seam roofs made of rolled materials: galvanized steel (including color-coated) or non-ferrous metals (copper, titanium-zinc, aluminum).

From rolls of galvanized (in the example under consideration) steel blanks, paintings, up to 625 mm wide and not less than the length of the roof slope are cut in a mechanized way.

| № | Name of works | unit of measurement | price, rub. |

| 1 | Dismantling of sheet steel roofing | sq.m. | from 50 |

| 2 | Dismantling of parapet gratings | m.p. | from 45 |

| 3 | Removing the wind vane | PCS. | from 50 |

| 4 | Dismantling of dormer windows rectangular shed | PCS. | from 52 |

| 5 | Change of rafter legs from bars | m.p. | from 420 |

| 6 | Change of lathing with gaps from bars 50 mm thick and above | sq.m. | from 112 |

| 7 | Replacing the sheathing with a continuous flooring of boards with a thickness of 32 mm | sq.m. | from 150 |

| 8 | Processing of wooden structures of attic spaces with fire-retardant composition "PP" ("Attic") | sq.m. | from 46 |

| 9 | Slope covering device with wall gutters and overhangs made of sheet steel | sq.m. | from 560 |

| 10 | Installation of ridge vents (vanes) made of galvanized roofing steel with a sheet weight of 4 kg | PCS. | from 320 |

| 11 | Device on the ridge of the roof of a device made of galvanized steel for attaching an insurance rope | m.p. | from 786 |

| 12 | Dormer window device | PCS. | from 5000 |

| 12 | Installation of aprons for dormer windows made of sheet steel | PCS. | from 260 |

| 12 | Roof railings | m.p. | from 467 |

| 12 | Fences from rolled and bent profiles of strip and round steel | T. | from 6450 |

| 13 | Painting with oil compositions for 2 times of metal surfaces of gratings and fences | sq.m. | from 274 |

| 14 | Single layer vapor barrier | sq.m. | from 40 |

| 14 | Dry thermal insulation of coatings and ceilings with products made of fibrous and granular materials | cube | from 150 |

This type of roofing material still has a lot of fans in our country. Of course, its main advantage is the price per square meter. Perhaps it loses in appearance to many other coatings (for example, repairs that we also carry out), but it provides reliable protection for the house from precipitation and other vagaries of the weather, is easy to operate and install. But poor-quality materials, an unreliable foundation, or installation errors can lead to the need for urgent repair or replacement of the seam roof. The good thing is that it is not so difficult to disassemble, especially if self-latching folds are used. For more information, we recommend calling a seam roofing specialist from our company.

Reasons for repairing a seam roof

According to the statistics cited by roofing professionals, seam roof repair in Moscow most often occurs after the following types of damage to the coating:

- ☑ The fold itself is damaged along the entire length or in a certain place - kinks, dents, tears, corrosion, etc.;

- ☑ Although the sheet is steel, it is rather thin, it is not able to withstand strong direct mechanical impact, especially from sharp objects. So also often it is damaged by area;

- ☑ Occurrence of leaks due to loss of tightness in the joints.

Repair in this case for a seam sheet roof is the only way to maintain comfort in the house. But what types of work are there in such cases? We'll talk about this below.

Roof rebate repair with patches or element replacement

An experienced specialist, even from a photo, will immediately determine whether it is worth trying to restore the picture by applying a patch to it, or whether it is necessary to change it entirely. The size of the damage usually influences the decision. In any case, the sheet is removed, and for this it is necessary to separate the bends that connect the parts of the roof.

Such a spot repair of individual parts of a metal seam sheet roofing can only be carried out if less than half of the elements are damaged. Otherwise, it is better to make a complete replacement.

Minor repair of a metal seam roof

Microrepair can also be justified, especially if these are small holes on sheets whose area does not exceed 20 cm. Such a repair of a seam roof in the Moscow region and other central regions, where the climate is not the most severe, is justified. Of course, these measures are temporary, but the procedure can be repeated once a season. There are two easy ways:

- ☑ Tissue patch. It is cut out of the tissue with a size exceeding the damage. The matter is placed in oil paint or a home-made mixture of drying oil and crushed metal minium. After squeezing, the material is applied to the sheet, smoothed and pressed at the edges. Next, he needs to dry, and after a few days this place must be painted over.

- ☑ Bituminous mastic or similar materials may be useful for small holes. You can simply cover them up, after cleaning them well.

Seam roof repair with rolled materials

There are cases when emergency restoration is required, and the damage is large enough and you are not able to pull the cost of work and replacement of materials at the moment. In this case, rolled materials mean roofing material - a universal material that can provide the necessary waterproofing. Yes, it is not so durable, but it should be enough for one season.