Designer lamps made of wood and plywood - we embody ideas from the master class. Wooden lamp in the interior

Today, in order to give individuality to the home interior, we use many different design techniques. Lighting is often a very important part of decor. Sometimes all you need to do is add the right element of lighting and everything falls into place. In this article, the author describes a method for making an original wooden lamp that anyone can make. The work is not difficult, and any unprepared person can cope with it.

For the manufacture of this work we need.

Tool:

Ruler;

- scissors for metal;

- a hammer;

- pencil;

- hacksaw for wood;

- clamps;

- grinding tool.

Materials:

Rail with a section of 1 x 1cm;

- joiner's glue;

- small nails.

Let's start manufacturing.

We take a rail with a section of 1 x 1 cm and cut it into equal parts, in this case the author chose a length of 15 cm, but you can take the size of the rails at your discretion.

In order for the rail not to move during cutting, we fix it with a clamp. We use a hacksaw as a cutting tool.

You should get something like this.

Next, we take the received parts and put them in the so-called "well", we build them until we reach the height we need.

Since the ends of the workpieces can be cut unevenly and have defects, we grind them with sandpaper or use a burr machine with a special grinding nozzle.

We get, approximately, the following.

Then we fix the finished parts together with carpentry glue, while trying to set them as evenly as possible again in the shape of a “well”. In order to avoid any displacements, we put the workpiece under the press and let the glue dry.

The next day, we look at what we got.

Since the lamp generates heat, the design of the lamp is best done so that the wood does not come into contact with the light bulb. Next, we take a perforated tape, the thickness of which is 0.75 mm, we will make a mount from it.

We additionally strengthen the finishing upper rails with carnations, since they will be the main load. Then we fasten two strips of tape with small self-tapping screws.

In order to make the glow of the lamp a little softer and more pleasant for perception, we make the so-called diffuser lampshade, use tracing paper, or organza, or other available material. This design will be fireproof, because the lamp will be fixed strictly in the center, and will not come into contact with the inside of the lamp. We check whether everything is qualitatively fixed, nothing should hang out. Next, we put the cartridge on the suspension and clamp it with a clamping ring. We hang the lamp in the right place for us.

A photo

In the design of private houses, wood is most often associated with antiquity. Therefore, wood lamps have an old look. The most popular designs are cart wheel chandeliers.

Scheme of the device of a table wooden lamp.

How to make a lamp with your own hands from wood?

Advantages and disadvantages of wooden structures

This type of structure has the following advantages:

- if you evenly place candles, then the design will give the same illumination to all elements of the room;

- the spokes will practically not create obstacles to the light.

Modern stylizations have the same advantages, but today lamps are used instead of candles made of wax and torches. In most cases, such designs are made in the form of a candle.

Wood structures have the following advantages:

Scheme of a round wooden lamp: 1 - segments for the rim, 2 - turned spoke, 3 - hub.

- The material is environmentally friendly. Not only will it not emit harmful substances, but it will also saturate the air with aromatic resins that make it easier for people to breathe.

- Wood can be easily processed. If special tools are needed for the production of a plastic or metal structure, then do-it-yourself lamps from wood can be made using a minimum set of fixtures.

Disadvantages of wooden structures:

- Wood is a combustible material. It is not recommended to place elements of this material next to incandescent lamps. If the contact burns in the lamp socket, the structure may ignite.

- Wooden ceiling fixtures are attacked by bugs, fungus and other pests. Coniferous trees suffer the least from rot and pests. For hardwoods, it is recommended to use antiseptic agents that can reduce the combustibility of the material.

- Wood is a hygroscopic material. It absorbs moisture from the air, as a result of which, during the drying process, the material may change volume, shape, or crack. In order for the structure to serve for a long time, it will be necessary to provide it with a constant temperature and humidity.

Nuances to be considered in the manufacture of wooden structures

In the process of constructing lamps made of wood, the following nuances must be taken into account:

Scheme of assembling a lamp from wooden rings.

- The structures must be of such a shape that all heating elements are removed from fixtures that are made of wood. The lamps should look upwards, because only in this case the upward air flow will not cause deformation of the tree.

- Fire safety rules prohibit placing wooden chandeliers under flammable elements.

- Wood lamp is great for bedroom or living room. In the kitchen or bathroom, where there is a sufficiently large amount of steam, such structures are not allowed to be placed.

In the event of a phase short, you can easily get an electric shock.

Making a lamp in the shape of a coffee service

To make a lamp with your own hands, you will need to prepare the following elements:

Diagram of a LED wooden lamp.

- Dry board made of wood of any kind. You can use both ordinary pine or birch, and ash. Oak is also suitable, which does not need to be painted or varnished.

- Several translucent coffee cups and saucers for them.

- Several cartridges for a small base with fasteners for them.

- The required number of bulbs. In this case, it is recommended to use LED elements.

- A small amount of rubber pads. Their number will depend on the method of fixing the cartridges.

- A two-core copper wire of small cross section and short length. It is best to use a wire with a cross section of 0.75 mm.

- Small chain or twisted cord. These elements will be used to secure the product to the ceiling structure.

- The required number of screws with rings. The luminaire will be suspended using these elements.

- Electric drill.

- Drills for working with wood and tiles.

- Pliers.

- Screwdriver or screwdriver.

The construction process is as follows:

- The planed board is processed with sandpaper (first - rough, then - thin).

- Next, you will need to drill a few holes in the places where you plan to place the cartridges.

- If noble types of wood are used, then further processing of the material will not be required. If other types of wood are used, then the material must be stained, then dried and varnished in several layers. In the open air, nitrolac will dry for several hours, so this process will not take much time.

- In the next step, you will need to drill holes in the coffee cups and saucers, while it is very important not to damage them. In this case, you need to use only a drill for working with glass and tiles. It is not allowed to make great efforts. You need to drill at a low speed, in the process you need to ensure that there are no distortions. If you press hard on the electric drill, the bowl or saucer may break.

- Wires must be attached to all available cartridges. At this stage, you should not fasten them to each other.

- The whole structure is screwed together. If the cartridges will use platforms with holes for fasteners, then they must be pulled to the board through the holes in saucers or cups. If there is a threaded pipe and a nut on the end of the cartridge, then they must be passed through the cups, saucers and board. Rubber gaskets must be installed between metal and glass elements. Such a device can be made independently from an unused camera from a bicycle or car.

- Screws with rings will need to be screwed into the back of the board.

- Cartridges are connected in parallel. No need to leave twists that are wrapped with electrical tape. Carefully you need to make even that part of the lamp that no one can see. To fasten the wires, you will need to use a block.

- The block must be fixed on the back of the board by any method: a small amount of adhesive mixture or screws. In it you need to clamp a piece of wire that will be connected to the wiring.

- On the back, chains or cords are attached to the rings. The second end of these elements is attached to a hook in the ceiling. The wire must be run through one of the circuits. At the end, you need to install light bulbs.

Plywood lace design

Tools for making a wooden lamp.

It should be noted that this design is not ideal in terms of fire safety. However, in this case, LED lamps are used, which are economical. It should be remembered that such devices practically do not heat up. Therefore, the risk of fire in this case is excluded.

From plywood of small thickness, using a manual jigsaw, you can make masterpieces of applied art. You can make such lamps with your own hands as follows:

- First of all, you need to grind a sheet of plywood.

- By using carbon paper, you need to transfer the drawing of the details.

- Structural elements will need to be cut along the contour.

- Inside each of the pieces that will need to be removed, you will need to drill holes. In this case, it is recommended to use a drill with a thickness of 1 mm.

- The next step is to cut out the inner parts.

- Small files of various shapes will need to clean the edges of the structure.

- Next, you need to fasten all the elements together. For this, it is recommended to use an adhesive mixture. It should be noted that PVA glue may turn yellow after a while. Therefore, it is best to use a special adhesive solution for wood. Residues of the adhesive mixture on the visible parts of the structure will need to be carefully removed.

- At the end, the product should be varnished.

If you plan to use incandescent lamps, then you should remember that their power should be less than 40 watts.

You need to place them at the maximum possible distance from the elements of wood. Only in this case can overheating of the lamp be avoided.

Other options for wooden lamps

You can make other lamps with your own hands:

- Plank and rope construction. In this case, several matte shades are used as light sources. There is nothing complicated in the manufacture of such a design. It should be noted that in this case, only energy-saving or LED light bulbs should be used. High power incandescent lamps quite often create a fire.

- Bars with pots. In order to drill the bottoms of the pots, you should use a tile drill. In this case, it is not allowed to install incandescent lamps of any power.

- Chopped log with spotlights. It must be borne in mind that it is difficult to hollow out the product.

It is quite simple to make lamps from wood with your own hands. You just need to show imagination and prepare all the elements that will be needed to make the structure.

Overall dimensions of the lamp, mm: 337x559x419 (width x depth x height)

Form the base

The free-form details of the base provide a good opportunity to practice building contours using the zoom-to-scale grid method, since these details should first of all look expressive, and the accuracy of sizing in this case is not very important in this case.

1. Enlarge all templates to the specified sizes. From 19 mm material, cut out two blanks for base A and one bracket B. From 10 mm boards, make two blanks for racks C. Fasten the base and rack blanks in pairs with double-sided tape.

2. Use spray adhesive to attach the paper templates to the blanks. Mark with an awl the center of a 6mm hole on one of the C-pillars. Then cut the pieces along the contour, leaving a small allowance on the outside, and sand to the line. Save the 19mm offcut to make spacer D shown in fig. one.

3. Now remove the templates, separate and sand the parts. Planing or grinding  align the edges of the halves of the base A, which will be glued together. Mill lamellar nests in both edges and glue the base, squeezing the parts with your hands for several minutes, until the glue begins to set; then gently lay the adhesive on a flat surface to dry. When the glue is completely dry, sand parts A, B and C with #220 sandpaper.

align the edges of the halves of the base A, which will be glued together. Mill lamellar nests in both edges and glue the base, squeezing the parts with your hands for several minutes, until the glue begins to set; then gently lay the adhesive on a flat surface to dry. When the glue is completely dry, sand parts A, B and C with #220 sandpaper.

Note. When sanding the C-pillars, keep the center of the hole marked earlier. If necessary, deepen the hole with an awl.

4. Take the cut saved for the D spacer and transfer the contours of the C-pillars to it (photo A). Then mark the height according to the dimensions shown in fig. 1. File the height spacer and sand the top and bottom edges. Apply glue between the lines on both sides of the spacer (photo B) and clamp the part between the posts, aligning it with the marked contour lines.

Note. When gluing the posts, make sure that the marked center of the hole is located on the outside of the gluing.

When the glue dries, saw off the protruding parts and sand the spacer flush with the edges of the uprights.

5. Stick a piece of double-sided tape on the bottom edge of the C / D gluing and attach it to the base A (photo C). Do the same with bracket B, aligning it with the center of the hole in the uprights (photo D). Then drill and countersink pilot holes through the base and secure the B/C/D assembly with screws as shown.

6. Drill a 6mm hole through the posts and bracket at the marked point (photo E) and glue the dowel into the hole. When the glue is dry, cut off the protruding ends of the dowel and sand flush with the surfaces of the C-pillars.

Unscrew the screws from the base, separate the bracket with the uprights and remove the adhesive tape. Then reattach the assembly to the base with screws and some glue.

Make a wooden lampshade

Make a wooden lampshade

We made the lampshade using two tools: a circular (for a band saw) and a milling tool (described in the "Advice of the Craftsman").

1. Using a compass, mark a center and a circle with a diameter of 158 mm on a 6 mm board. Drill a 3mm hole in the center, cut out the disc and sand the edges. Mill an annular groove on the underside of disc E,.

2. For shell F, saw off a strip 1 mm thick from the edge of the workpiece with dimensions of 25x32x485 mm.

Note. Install a splinter guard in the saw table and saw off the strip from the outside to avoid dangerous kickback.

Sand the strip and cut it to the final length.

3. Mark the line where the ends of the strip overlap. Then glue the shell F (photos F and G). When the glue is dry, gently sand the outside of the piece to make the overlapped edge invisible. Glue the shell to disc E (photo H) and leave to dry.

4. Countersink the hole on the inside of disk E and attach the lampshade with a screw to bracket B. Apply any finish. (We sprayed semi-gloss nitro varnish from an aerosol can three times.)

The compact LED light with magnetic base is easy to install and provides easy access for changing batteries. Secure the mounting plate with small pan head screws. Then just insert the batteries and turn on the lamp to make the world a little brighter.

Do-it-yourself wooden table lamp - drawings

Born Pretty, R³ ° Ð Ð Ð Ð Ð Ð Ð ° РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРг €Ð°Ð´Ð¸ÐµÐ½Ñ‚ Ð¾ÐºÑƒÐ½Ð°Ð½Ð¸Ñ Ð±Ð»ÐµÑ Ðº…

Born Pretty, R³ ° Ð Ð Ð Ð Ð Ð Ð ° РРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРРг €Ð°Ð´Ð¸ÐµÐ½Ñ‚ Ð¾ÐºÑƒÐ½Ð°Ð½Ð¸Ñ Ð±Ð»ÐµÑ Ðº…

The kitchen with one sad but very economical light bulb in the middle of the ceiling has been waiting for its own lamp for a couple of years, which we, as usual, decided to make with our own hands. In addition to this idea, there were a couple of different ideas in my head: a lamp made of ropes or bottles, a lamp made of cups or twigs, or maybe made of veneer or clay? In short, it didn’t work out for us with the lighting of the kitchen. True, a vintage lampshade from the 60s hung over the work table.

Then, having seen plenty of Scandinavian interiors, we caught fire with branches and snags. We decided that one must hang on the ceiling in the kitchen, especially since we dream of wooden kitchen furniture. Said not done. Because finding a snag is not an easy and protracted business.

In search of a suitable tree, we wandered along the banks of several rivers (Latoritsa, Southern Bug, Zbruch, Dnieper and Desenka), roamed the forests and puzzled friends who love hiking. And then to the nearest park and right in the middle of the central alley we found our future wooden lamp :)

A long-awaited find

Satisfied with the long-awaited find, we returned home and ... were confused, because doubts piled on us. And what will it look like? “What will people say?” (ukr). But how to hang such a lamp if there is no planned kitchen furniture?

In short, our branch first became a subject of interior design and special pride, and then it shortened slightly, because part of it went to the children for a wooden lotto with animals. How so? And like this: an unknown beast began to gnaw at the branch :) I had to cut off a part, and then - it wasn’t there - they made a loto out of another piece of the branch. There remained a snag, untouched by the beast, and just the right length.

A year has passed and then our beloved “The village” writes to us, they say, let's cooperate. We so wanted it! But we don’t have anything fresh and suitable for their theme. Well, in fact, I won’t do a master class for “The village” about sewing a felt giraffe :) What can we offer? Of course, the long-awaited driftwood lamp. It's mainstream and Scandinavia! We discuss this idea with the editor, she agrees and we start working on a lamp from a branch with our own hands.

Everything could be done simply and quickly, but we are not looking for easy ways, so we go back to the forest. This time we need thinner branches to make wooden cases for the cartridges in the lamp. Fortunately, we find a fallen and dried tree quickly, combining a pleasant find with a useful paddock of the younger generation.

While the kids are sleeping...

While the kids are sleeping...

Suitable branch

All the necessary materials for a lamp from a branch:

Large dry branch, wire, E-14 plastic cartridges, energy-saving light bulbs with a similar base, thin metal mounting cable, clips for it, dry branches with a diameter of 3.5 centimeters, small nails (about 10 pcs.), Wood screws (2 short , 1 long), square board (8 x 8 x 2 cm), white acrylic paint, acrylic lacquer, masking tape. Saw, drill (engraver), drill, soldering iron, pliers, screwdriver.

DIY kit :)

And now the process of creating a wooden lamp with your own hands:

1. We clean the remains of the bark on the branch with sandpaper. Some places are left untouched to give a natural look.

Sanding the branch with sandpaper

2. We mark places on the branch for drilling holes for wires. Also, at the top of the branch, draw a line along which we will make a groove for the wire.

Marking places for drilling holes

3. We drill holes with a drill. We make a groove with a drill (engraver).

Drilling holes

Making a groove for the wire

4. We drill holes in the square board for the cable, wire and mounting screw.

Sawing and drilling a square board

5. We saw branches with a diameter of 3.5 cm into pieces 5 cm long.

Sawing blanks

6. From these blanks, using a drill and a cutter, we drill out the core for a plastic cartridge 4.5 cm deep.

We fix the workpiece

Drilling a hole for a chuck

7. In them we make holes for the wires.

Drilling a hole for the wire

Ready-made set of cases for cartridges

8. We cut off the wire of the required length, connect the cartridge to it, put the cartridge in a wooden case. Then we pass the free end of the wire into the hole on the large branch.

We collect details

9. We insert the steel cable into the holes on the branch and fix it with screws.

We fix the steel cable

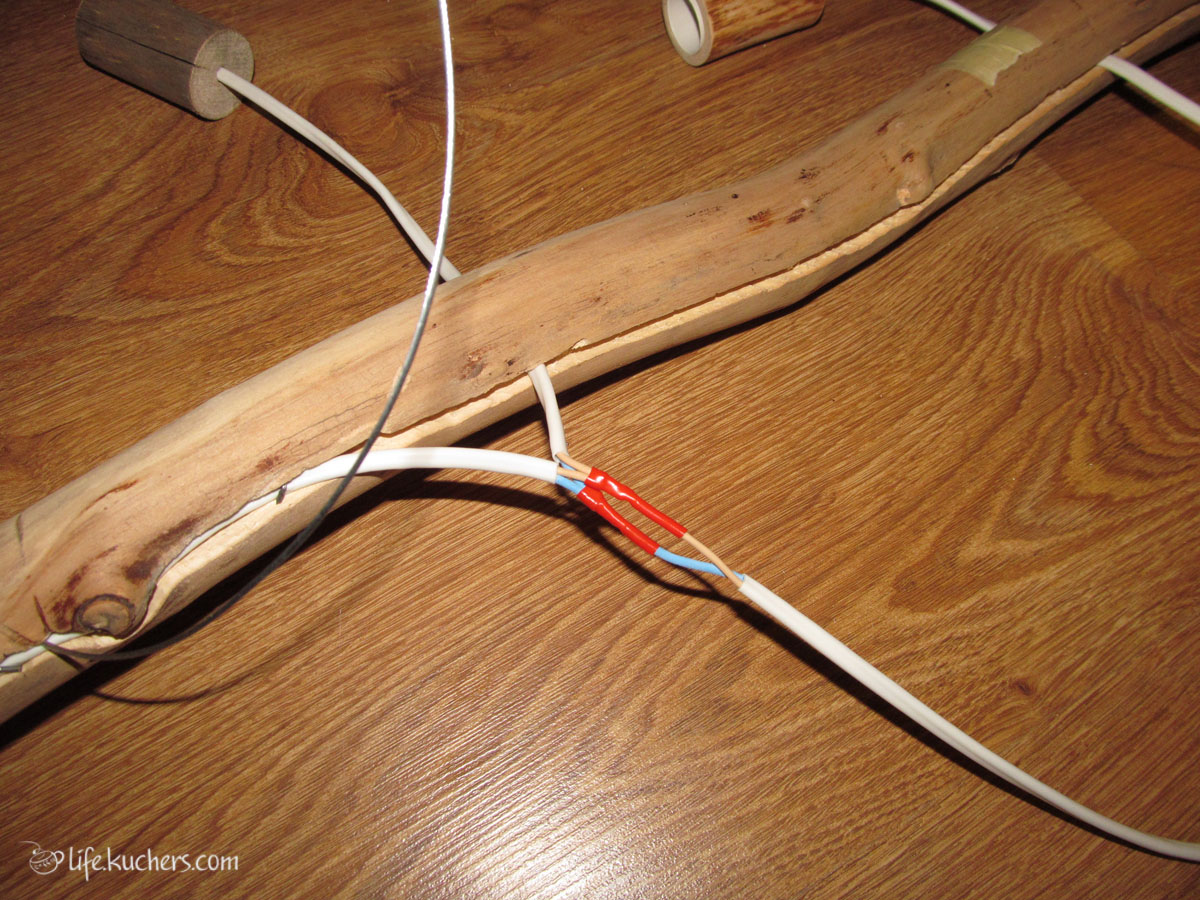

10. We lay the wire along the groove, fix it with nails bent into the letter G. We solder the joints of the wires, isolate the soldering points with the help of heat-shrinkable cambric.

Soldering the wiring

Connection point for wires in heat shrink tubing

We fix the wire with L-shaped carnations

11. We process all wooden parts of the lamp with sandpaper, cover with one layer of matte acrylic varnish. We pre-paint the square board with white paint, and then varnish it. We did this so that the wooden overlay does not stand out against the white ceiling.

Sanding and painting a square board

Varnishing a branch

12. We pass 2 ends of the steel cable and the power supply wire of the lamp into a square wooden blank. We set the desired height of the lamp with a cable, fix the cable with clamps.

Wooden handmade lamps perfectly complement the interior, making the atmosphere of the home warmer and more comfortable. Original wooden lamps have been in rather high demand lately, becoming a familiar element not only in home furnishings - they can often be found in cafes, restaurants, museums, and other public places.

Such a thing can perfectly fit into the interior and ennoble it, if you choose materials that best suit the situation.

Material Features

Natural wood, in addition to its aesthetic properties, has a number of significant advantages. Products from it are easy to use and environmentally friendly. When heated, wood does not emit toxic substances, but on the contrary, it has a beneficial effect on people with chronic respiratory diseases, having healing properties. This action is especially characteristic for conifers.

Wood is a material malleable enough so that in the skillful hands of the master to acquire exactly the forms that he conceived. Therefore, any creative design ideas are brought to life. Luxurious photos of exclusive wooden lamps easily convince of this.

The material is quite versatile, due to which it can be used widely, in almost any type of interior. Interesting configurations and a variety of shapes allow you to organically fit a thing into any style.

Wooden lamps in the interior look solid and noble, moreover, they perfectly coexist with objects made of a wide variety of materials: plastic, glass, metal.

Along with the listed advantages, the tree also has disadvantages. It is highly flammable, for this reason the products should not be placed in rooms where there are fireplaces, gas stoves and other sources of possible ignition.

The material is very sensitive to temperature changes and high humidity, so it is highly undesirable to place wooden lamps in the bathroom or kitchen. In addition, wood attracts small pests - termites and other insects. It is desirable to cover products with special protective compounds that will prevent their appearance and protect the material from deformation.

When using an electrical appliance, observe a number of simple precautions:

- place the light source at a sufficiently large distance from an open fire (fireplace, stove);

- remember that the optimal location for the device are rooms with a normal level of humidity and room temperature;

- wooden lamps do not allow the installation of conventional incandescent lamps in them: their heating temperature is too high, this is unsafe; use LED, halogen, fluorescent lamps.

Application in various interiors

The versatility of wooden lamps allows them to be used in the design of a wide variety of rooms, regardless of style. They are most appropriate in the setting of a country house, decorated in country style, Provence, Oriental styles. The combination of natural simplicity with sophistication is the most valuable quality of wood.

Original "antique" lamps made of wood are widely in demand in retro styles. Often they are made in the form of cart wheels, with candle-shaped lamps around the circumference. This design is usually used in restaurants, bars, hotels.

Ceiling models look great in large rooms and living rooms, bringing luxury and elegance to the interior. Spot lighting options are relevant for small rooms, especially if they have low ceilings.

For country style, fixtures of simple shapes are suitable, without any frills. They may look a little rough, but they will create a feeling of unity with nature and organically fit into the space without conflicting with other objects.

Oriental style requires the use of solid wood, welcomes clear shapes and lines, complemented by oriental motifs.

Retro is characterized by classic options or more original models, stylized as antiques.

The classic makes it possible to use stained glass, a lampshade for a lamp can be made from it; wooden structures have smooth, streamlined shapes.

Hi-tech allows you to create original designs by combining wood with metal, frosted glass and other materials.

How to make a wooden lamp with your own hands

Of course, by ordering a product in special workshops, you will receive a perfectly made, polished product. However, if you have experience working with wood, you can try to create an exclusive item yourself from the material that is available to you.

DIY wooden lamps are made from:

- branches;

- boards;

- bark;

- cuts;

- logs;

- veneer.

If you have an idea that you can't wait to implement, feel free to proceed. To begin with, the wood must be prepared by treating it with protective solutions and impregnations, and waiting for it to dry completely.

This stage is mandatory: an unfinished product will not serve you for a long time. Then the structure is assembled and fastened. We suggest you try out some original options.

Driftwood lamp

This creative idea will not require much effort and expense to implement - use the snags found in the forest under your feet. They are exclusive in themselves: each branch bend is unique. All you need to do is find a suitable specimen, clean it of bark and excess wood, then dry it thoroughly. For drying, a ventilated place away from direct sunlight is suitable.

After complete drying, it is necessary to sand the snag well with sandpaper. Determine the side that will be attached to the ceiling. With a blade, make grooves on it into which you will lay the wires. At the end of work with wires, the holes must be carefully puttied, and then stained with putty in the color of the tree.

Cartridges are attached to the ends of the driftwood, you can think of various ways to attach them. At the end, treat the wood with varnish. It is necessary to put several layers with drying each. Choose acrylic or waterproof varnish.

In a similar way, you can also design a table lamp or wall lamp - a snag will serve as an excellent base. Such an idea is easy to implement even if you do not have carpentry skills.

branch chandelier

Gather carefully selected medium-sized branches together so that some of them are perpendicular to the ceiling. Next, you need to fix the shades at the ends of the branches, and carefully wrap the wires around them. Instead of branches, you can use a real rhizome if you are lucky enough to find it in the forest.

Find and embody your own ideas - the tree gives a lot of opportunities to experiment using your imagination. You will be rewarded for your creative impulses by receiving an author's product that will become an interior decoration.

Photo of wooden lamps