Concrete floors in the washing room in a wooden bath. How to insulate the floor in the washing department of the bath? Video: a variant of the organization of draining water from the bath

How to process the floors in the bath? This worries many. The problem is complicated by the fact that the most common material for finishing these structures is wood, which has low moisture resistance. Many building materials undergo accelerated destruction at high humidity and temperature. Even concrete requires special protection.

Problem Features

The floor in the bath during constant operation is in rather difficult conditions, especially for the coating in the steam room. Here, the material is exposed to water, saturated water vapor, which condenses on the walls and floor, and the temperature rises sharply to 60-70°C in a Russian bath and almost 100°C in a sauna.

The floor in the bath during constant operation is in rather difficult conditions

In the sink, the temperature is lower and there is no steam, but the chemical action of detergents is added. In addition, the soil also has a rather serious effect: water, especially during the flood period, is able to penetrate from below and flood the floor. It should also be mentioned that there is a huge difference in temperatures inside the room and under the floor. Under such conditions, various microorganisms, fungi and mold actively develop, which causes the process of decay of the material.

The need for special protective measures is not in doubt. The problem is not whether it is necessary to protect the material, but how to treat the floors in the bath from decay. This task is complicated by the same specific bath conditions. The products used should not decompose when exposed to temperature and hot water, releasing substances harmful to humans. Many fillers become dangerous in the steam room: you can not use chipboard, plywood, polystyrene, many paints and varnishes.

The products used must not decompose when exposed to temperature and hot water.

The products used must not decompose when exposed to temperature and hot water. How can you solve the question of how to process the floor in the steam room of the bath? The most popular material is wood, and it is it that undergoes active decay in wet conditions.

On a note! To protect the material, the most effective impregnation with maximum penetration of the antiseptic composition deep into the wood.

It is also possible to use external protective coatings, which give good results in other bath rooms except for the steam room.

It should not be assumed that other floor materials do not require protection. Concrete in a bath is able to collapse quickly enough, so the task of how to process a concrete floor in a bath is no less relevant than protecting wood. When strengthening the concrete screed, the necessary additives are introduced at the stage of preparing the mixture. They increase the water resistance of concrete, and exclude the destruction of metal reinforcement.

Principles of protection of wooden floors

When deciding how to process a wooden floor in a bath, the following goals are set:

- Ensuring moisture resistance. All impregnating compositions provide a different level of such protection, but all are based on blocking internal channels, which prevents water from penetrating deep. An important indicator is the depth of penetration of the substance into the wood.

- Antiseptic, antibacterial effect. Rotting wood is caused by the vital activity of fungi and wood-destroying microorganisms. The introduction of an antiseptic into the material does not allow these pests to develop.

- Fire protection. Wood is considered a flammable material, and taking into account the presence of a sauna stove and firebox, increasing resistance to fire becomes a necessary condition for arranging a sauna floor.

- Aesthetic properties. A side, but very important task of the impregnating composition is often the change in the color tone of the wood. It can emphasize the beautiful structure of the tree, darken or, conversely, whiten the material. Decorating abilities are invested in most modern protective mixtures for processing wood products. Of course, when considering how to process the logs of the bath floor, this property does not play any role, which means that you can choose a more economical option. But when choosing how to process the floor boards in the bath, which make up the top coating, it is advisable to take into account this possibility.

A side, but very important task of the impregnating composition is often the change in the color tone of the wood.

A side, but very important task of the impregnating composition is often the change in the color tone of the wood. The choice of compositions for a wooden floor

To protect the wooden elements of the floor bath covering, the following means can be used:

- Lacquer products. In bathing conditions, they can be used in all rooms, except for the steam room. Antiseptic ingredients are introduced into their composition to prevent decay.

- Impregnation agents. Their protective properties are based on the presence of phytoicides in the composition. With their help, logs and boards are processed.

- Antiseptics. These products are available in the form of solutions based on fungicides. Some compounds have increased toxicity, and therefore they must be coated with special varnishes or paint.

To protect the wooden elements of the bath floor covering, various means can be used.

To protect the wooden elements of the bath floor covering, various means can be used. In construction, impregnating compounds are widely used, with which it is necessary to process all, without exception, wooden elements at the construction stage of the bath. These funds are available in 4 categories:

- oil;

- water soluble;

- based on organic solvents and with a combined base.

On a note! Often, drying oil is used as an impregnation, which penetrates well into the wood, and after drying and polymerization forms a protective film.

Among branded compositions, such means are popular:

- Tikkurila;

- Texturol;

- Drevotex;

- BioZ;

- Pinotex;

- Senezh Ognebio;

- Neomid;

- Aquatex.

Film-forming composition Natura (Teknos)

Film-forming composition Natura (Teknos) The following compositions designed to protect wooden elements in the bath are distinguished by high environmental cleanliness:

- Water-soluble Sauna, made on an acrylic basis. With its help, a water-repellent polymer layer with heat-resistant properties is formed. At the same time, the film is able to pass air through itself. The composition has antimicrobial properties, destroying pathogens of infectious diseases.

- Waterproofing impregnation Schwartz prevents the development of fungi and the formation of mold.

- Natura (Teknos) film-forming compound creates a translucent coating that can reliably protect wooden surfaces.

- The Supi Arctic (Tikkurila) protective agent has high water-repellent characteristics. At the same time, the composition provides an attractive appearance, spectacular shine.

Protective agent Supi Arctic (Tikkurila)

Protective agent Supi Arctic (Tikkurila) A large group of protective agents are oil-based formulations. The following mixtures stand out: Supi Laudesuoja (Tikkurila), Sauna Natura (Teknos) and Rogneda. They are applied to dry and cleaned wooden surfaces with a brush or sponge. Drying time is 23-25 hours, after which you can heat the bath.

Impregnation Aquatex

Impregnation Aquatex Features of concrete floor processing

The concrete floor screed in the bath is subject to serious damage under the influence of humidity and temperature. To strengthen concrete, special additives and impregnating compounds are used. The following groups of such funds are distinguished:

- Strengthening compounds. By impregnating the surface layer of the material, such agents increase its strength. The principle of their operation is based on the filling of pores and microcracks, which ensures the solidity of concrete.

- Elimination of dust formation on the surface. The formation of cement dust on the concrete floor is considered their major drawback. This effect is enhanced after exposure to bath conditions. Special means form a protective layer that prevents dust formation.

- Moisture-repellent additives. Such impregnation significantly increases the water resistance of concrete. At the same time, resistance to various chemical influences of detergents and cleaners increases.

What compounds are used to protect the concrete floor in the bath? There are 2 main types: organic and inorganic impregnating compounds. Organic type products have an epoxy, acrylic or polyurethane base. Such substances have universal properties, ensuring the simultaneous implementation of all the above tasks. The most common polyurethane impregnation of concrete.

On a note! Inorganic-based products work on the principle of turning soluble components into insoluble substances, which makes it difficult for moisture to penetrate and wash out the concrete ingredients.

The concrete floor screed in the bath is subject to serious damage under the influence of humidity and temperature.

The concrete floor screed in the bath is subject to serious damage under the influence of humidity and temperature. It is this type of impregnation that provides resistance to aggressive substances. When using these products, it should be remembered that when they are used, a chemical reaction occurs on the concrete surface, which can change the appearance of the floor. When assessing the degree of such changes, you should first test the acquired composition in a small area. A complete floor treatment is carried out if whitish spots and stains do not appear.

The floor in the bath is in extreme conditions. As a result of the influence of high humidity and temperature, both wood and concrete are destroyed. Modern impregnating compositions make it possible to effectively deal with the destructive process, primarily with rotting. It is important to choose the right product and carefully treat the floor. This procedure is carried out during the construction of the bath or during its operation.

Treatment of the floor in the bath: choose the impregnation for wooden boards

The quality of wood allows you to create an optimal microclimate for a steam room and effectively retain heat, making it the most common material for the construction of bath facilities. But such shortcomings as easy flammability, high susceptibility to moisture, susceptibility to damage by microorganisms and insects (fungi, rotting, etc.) dictate the need for processing boards, timber, logs with special protective compounds.

Types and characteristics of various compositions

All the compositions used are a special chemical liquid that has a disinfecting effect on the treated surface, eliminating mold and dirt.

- Acrylic-based, water-based formulations impart dirt-repellent qualities to wood, moisture resistance and reduce the likelihood of biological damage. These funds are preferable to use in the rest room and dressing room.

- Organic impregnations are characterized by high moisture resistance and strength of the protective film they form.

- Compositions based on natural wax and urethane oils are absorbed to a considerable depth, perfectly protect against the destructive effects of water, and give the surface a pleasant velvety. The disadvantage is the need to ventilate the room from a strong smell for 2 days.

- Combined products increase not only the moisture resistance of the material, but also its fire safety.

Important! Impregnations used for bath floors should be odorless and emit toxic substances.

Supporters of the use of absolutely natural materials can use waste products from the production of sunflower oil for wood processing. They are impregnated twice, with a three-day break. This is a fairly effective tool, but somewhat inferior in quality to synthetic compounds, but significantly superior to them in terms of environmental safety.

The use of impregnations at the stages of construction and operation of the bath

The use of antiseptics during construction allows you to extend the life of the building by 5-7 years. They pre-process all wooden elements - boards, logs, timber.

Attention! The only way to refuse the use of impregnations is to use a more expensive material that has undergone heat treatment.

During the operation of the bath, the need for antiseptics remains. To wash surfaces, you can use products that are harmless to humans with them.

Bath floor processing technology

Depending on the tasks, you can choose compositions with a tinting effect. The main thing when carrying out internal work is the absence of harmful components in the composition of the product that can be released into the atmosphere. Impregnation for floors of saunas and baths should not give the surface a slip effect. Before starting work, you must carefully study the instructions, in their process, for safety reasons, use protective gloves and goggles.

Wood processing procedure:

- Cleaning the floor surface from dirt and dust;

- Sanding wood if it has darkened;

- The optimum temperature for work is above + 5 ° С;

- Application of impregnation in at least 2 layers with a roller, brush or spray gun in the direction along the fibers;

Advice! Slots and end faces require especially careful processing - here moisture is absorbed most actively.

- After finishing work, the bath must be heated and well ventilated.

The acquisition of unknown products due to their low price in the future may result in harm to health due to the release of toxins by wood when heated - dubious quality may be hidden behind cheapness.

When buying impregnation for a bath floor, you need to pay attention to the following factors:

- Material condition:

- Fresh lumber;

- Wood without lesions;

- Partially damaged material;

- Surfaces with significant lesions.

- Purpose for internal work;

- Availability of a sanitary-epidemiological conclusion on harmlessness to people;

- Suitability for the treatment of the bath floor - when the skin comes into contact with it in conditions of high temperature and humidity, there should be no discomfort.

The compositions of Finnish production, in particular, Tikkurila, are considered the most effective. High-quality impregnation can increase the service life of the flooring in the sauna by 10 years.

How to process the floors in the bath - the question is attached if the tree is already selected

No, there is no negative attitude towards the use of wood as floors in the bathhouse. It’s just that in advance it is necessary not only to plan and saw, but to be aware of how this or that decision can affect the further course of events.

Wood in a sauna, where external temperature and humidity influences will be great on the material, is prone to very large and unpleasant surprises if you do not take care of it. The construction market will come to the rescue if the situation has not yet been brought to an extreme.

Responsible for previous decisions

Moreover, at your disposal a huge amount of means for processing floors in the bath.

What do we choose from

All these means are subject to two indispensable requirements - they must, on the one hand, be ecologically impeccable, and on the other hand, successfully fight organisms that love the wooden structures of baths so much with us.

From this, the manufacturers of the following products proceed:

- Antiseptic "Sauna". Diluted with water, it is produced on an acrylic basis and creates a waterproof, polymer coating on the treated surface. The created film, however, does not interfere with good air exchange and has an antimicrobial character, and this is already the protection of the bath visitors themselves.

- Waterproofing "Schwartz". The penetration of this agent into the very structure of the tree effectively protects it from the effects of temperature and moisture. "Schwartz" helps to keep the shape of the treated surfaces of the bath and prevents the appearance of fungus.

- Protective composition Natura. The main advantage of this tool is its transparency, so it does not change the tone and pattern of wood. The protective capabilities of Natura are no worse than those of competitors.

- Supi Arctic is from Finnish Tikkurila. The Finns know a lot about baths and woodworking, and this tool they offer also has a water-repellent effect. Do not be afraid that SupiArctic gives the wooden surface a very pleasant sheen - it is completely harmless and does not increase the degree of sliding of the surface.

- Well, and, finally, a whole parade of oil products that successfully absorb into the tree, but at the same time do not cause an increase in surface temperature. Among the oils at your disposal are Supi Laudesuoja from the Finnish Tikkurila, Sauna Natura from Teknos, Eurotex Sauna. Before applying oils, the surface must be thoroughly cleaned and dried. After a day, the bath is heated, and the excess oil that has appeared is removed.

Helpful advice!

All of the above tools will perfectly fulfill their task of protecting the tree.

The only question is whether you want to use the bath after that.

Therefore, the most important and strict rule is that when using them, you must carefully follow all the rules of application, and if you wait 24 hours after application and at a temperature of 25 degrees, then wait just that much and not an hour less.

Only in this case will you be able to successfully overcome the widespread belief that there is no place for wooden floors in baths.

Still, the tree needs help

Whatever means of wood protection you use, if special design solutions are not applied in the manufacture and use of the bath, then no means will be able to correct our mistakes.

To help impregnation

Among these solutions, we highlight the following:

- Careful preparation of the foundation, if possible - ventilated;

- Mandatory use of waterproofing when creating a multilayer structure of the bath floor;

- The use of wood species that are resistant to moisture and microbes - oak is the best fit here;

- Accurate design study and implementation of the entire process of waste water removal and in no case under the foundation of the bath building;

- Complete ventilation and drying of the entire bath after its next use.

Helpful advice!

But still, we advise you to take seriously the organization of tiled floors in the bathhouse, covered without fail with wooden removable panels.

Only this approach, which provides complete control over the situation, will allow you to keep the floor in perfect order.

findings

Strictly speaking, with a responsible attitude to business, there is no reasonable explanation - why, when choosing the floors in the bath, preference was given to wooden floors over tiled ones. Neither in laboriousness, nor in convenience, nor in safety, they give any advantages, but they require constant care.

Nevertheless, if the tree on the floor is the fate of your bath, be prepared for periodic maintenance of the floor. Moreover, there can be no other options: the question is put very directly - either the floor or no bath.

Watch the attached video in this article - we're talking about wood flooring, of course, but look ahead and make an informed decision when choosing the flooring itself.

How and with what to process the shelves in the bath - proven means for processing

When starting the construction of a bath, many beginners believe that the entire range of work will be completed after the interior finishing of the steam room, but this is not entirely true, because the steam room must be treated with special compounds that protect the wood from heat and moisture. In this article we will tell you about the best way to process a bath inside.

Do I need to treat wooden surfaces in the steam room

If you built a bathhouse following the right technologies, then you probably isolated the steam room from external cold, as well as moisture. Having taken care of the wood from the outside, do not forget to process the internal components of the steam room, because this will increase the strength and durability of any structure in the bath.

The center of the steam room is the shelf where visitors spend most of their time, so it must be strong and secure. Despite the fact that wood is a material that is unstable to moisture, it is customary to use it to build a shelf, which, with the wrong approach, will last no more than a year.

To achieve the strength and long service life of the shelf, it is necessary to choose the right wood, as well as treat the finished product with a suitable impregnation, which can be made on the basis of natural or artificial components.

First, let's talk about the choice of wood. The following types of wood are excellent for structures inside the steam room:

- Alder- an ideal material for a steam room, but it is difficult to find it on the market;

- Linden- inexpensive, but high-quality material with a soft texture, great for a steam room;

- Aspen- it is also an excellent tree for a bath with high moisture resistance (for more details: "Which aspen is best for a bath - planning a log house");

- Oak, ash, saddle abash, ofram and miranti- expensive types of wood, rarely used for finishing the bath.

There are cheaper alternatives, such as pine or spruce, but they have several disadvantages and the savings are small, so it is recommended to use the above wood, which has good moisture resistance and is easy to process.

Next, it is worth talking about the processing of the regiment with special compounds. Before processing the shelves in the bath and sauna, you should think about whether it is worth doing. It is impossible to give a definite answer, so we will help you solve this issue by providing some facts:

- Long-term contact of human skin with poor-quality impregnation can lead to unpleasant consequences, such as a rash;

- If excellent ventilation is made in the steam room, then the shelves can be simply sanded;

- An untreated shelf can quickly turn black, and mold will appear on its surface.

Everything that has been said about the shelves and their processing also applies to other elements of the bath, such as doors, benches and walls.

Means for processing elements of the steam room

All means by which wood is processed inside the bath are divided into two groups: impregnating and covering means. They are also often divided into colored and colorless, for example, wax, varnish and some impregnations.

Less often, bleaching agents are isolated, which are used in cases where the shelves have already darkened. Next, we will talk in detail about specific types of processing agents.

Lacquering

When thinking about how to cover the shelves in the bath, most often lacquer comes to mind, which refers to covering agents. Varnish is in demand due to its moisture resistance, but for a bath this is not always the best remedy. The problem is that at high temperatures, the varnish begins to release toxins and crack, after which, the surface fragments will stick to the body, and the water will again fall on the wood.

If you decide to use a varnish, then you should apply special acrylic varnishes from companies: Tikkurila, Belinka or Supi Saunasoja. Such varnishes for steam rooms are distinguished by a natural base that does not emit harmful substances.

The hardened surface perfectly withstands temperature extremes. Using varnish, you do not have to additionally apply antiseptics, because they are already part of the varnish. Taking care of how to process the doors in the bath, you can safely use a special acrylic varnish.

How to apply varnish on the surface:

- Before painting the shelves in the bath, it is necessary to prepare the wooden surface. Take sandpaper of different grain sizes and sand the shelves, starting with coarse grain and ending with the smallest (read also: "How to paint the floors in the bath - how to choose the best coating");

- Rinse the surface of the shelf, then dry it;

- Apply the first coat of varnish with a brush or roller;

- After the first layer has dried (drying time is indicated on the package), apply the second and wait for it to dry.

If you are using colored polish, you can thin it down for the first coat to get a more even color.

It is necessary to carry out work in a warm (from + 5 ° C) and dry room. Remember that it will be problematic to remove dirt from under the varnish, so make sure that there are no small debris on your hands and the tool.

Impregnations and bleaches for the shelf

Bleaches and impregnations are quite popular on the Russian market, but they are used much less often, despite the fact that they are not inferior to varnish. Among all the impregnations, one can single out such brands as Belinka-sauna from a Slovenian manufacturer, Prime Thermo, etc.

Special impregnation for a shelf in a bath or sauna has the following advantages:

- It is colorless and does not change the shade of the wood;

- Impregnation is easy to apply;

- The composition is quickly absorbed and hardens;

- Provides good protection at a low price.

It is not recommended to replace special solutions with improvised means. For example, instead of bleach, some use a bleach solution, but this is a big mistake. Chlorine, when heated, releases many chemicals into the air, which negatively affects human health and well-being. Also an unpleasant consequence of such treatment is a second-degree burn.

Proper application of impregnation:

- Clean, sand and rinse the surface;

- Before soaking the wood in the bath, wait for the surface to dry and apply the first layer;

- After the impregnation dries, apply a second layer;

- Just need to apply 2-3 layers.

It takes about 40-50 minutes to dry each layer, and you can see an example of the correct processing of wood in the photo.

Separately, it is worth highlighting the wax for the sauna. It can be applied with a cloth or a disc machine. It allows you to create heat-resistant protection against moisture and mold. Wax has two significant advantages: it takes only 24 hours to dry completely, and the protective layer that it forms is highly breathable, which allows the wood to “breathe”.

Next, it’s worth talking about how to process the shelves in the bath if it has already begun to collapse. If the shelves or other wooden surface of the bath has begun to rot, then you can prevent complete destruction by using the Nortex tool. The composition is applied with a sponge to damaged areas.

Any safe bleach designed for wood, for example, "Doctor for Wood" from Belinka, will help get rid of darkening. The solution is also applied with a sponge only to damaged areas. It will take about 2 hours to whiten, but once may not be enough.

The subtleties of applying protective compounds

If you don’t know how to impregnate the walls in the bath, then this article will also be relevant for you, because special impregnations for the bath will suit any wooden surface, but you should also remember some subtleties:

- It is much easier to handle an unassembled structure, therefore, if you have such an opportunity, impregnate the elements of the bath before assembling them;

- Protective products can adversely affect the skin, therefore, to eliminate this trouble, you can not treat the side of the shelf in contact with the person. You can process the rest of the tree in the bath without fear for your health, because only the shelves can affect the skin;

- Carry out work in the summer to make it easier to dry the steam room;

- It takes at least 4 days to completely dry the varnish and impregnations, after which you can relax in your bath;

- In no case do not use highly toxic products, such as stains, because they negatively affect your health not only through the skin, but also through the respiratory tract;

Do not save on protective solutions, because your health and longevity of wood structures depend on their quality.

How to cover the lining inside the bath

No one doubts that the best finishing material for a bath is wood. And almost everyone uses lining for interior decoration. But here it is necessary or not to process the lining in the bath, everyone decides for himself. Opinions are divided here: some say that without treatment with special means, the wood darkens, loses its attractiveness, rots and is affected by diseases. All this is so. But their opponents are definitely right: the combination of high temperature and humidity in the steam room, to which fumes from processed boards are added, cannot be called a healing effect. But people come to the bathhouse for their health.

For the most part, lovers of baths and saunas make a compromise: they leave the lining in the steam room without processing, and for the rest room, the washing room uses special tools. Lining without processing, of course, becomes unusable over time, but it will have to be changed no more than once every 2-5 years (depending on the type of wood and the intensity of use of the steam room). These are not such big costs, especially since rarely anyone has a steam room that is large. For those who decide to process wood in the steam room, there are several folk recipes or special (mandatory !!) compositions for a bath / sauna.

How to process the lining in the washing and dressing room

The most popular ready-made products are special impregnations and oils. Finns are the favorites in this segment: Sauna (by Belinka), Supi Saunasoja (by Tikkurila).

Domestic producers also try to lag far behind world manufacturers.

The product of the domestic company "Usadba" - "U-409"

- impregnation for baths, saunas, wet and residential premises. All these compositions are made on the basis of natural ingredients. They create a thin film on the surface, which makes the removal of contaminants easier.

The product of the domestic company "Usadba" - "U-409"

- impregnation for baths, saunas, wet and residential premises. All these compositions are made on the basis of natural ingredients. They create a thin film on the surface, which makes the removal of contaminants easier.

Also, the impregnation contains fungicidal and insecticidal additives that prevent the formation and reproduction of fungus in the bath.

"Eurotex Sauna" - antiseptic with wax for saunas and baths. This is a colorless coating that creates a protective film on the surface of the wood. The composition is ideal for benches and shelves (for those who decide to process them).

Impregnation EURO

TEX-sauna can be purchased in various packaging sizes. A bucket with a capacity of 2.5 liters (per 35 square meters) costs about 450 rubles.

TEX-sauna can be purchased in various packaging sizes. A bucket with a capacity of 2.5 liters (per 35 square meters) costs about 450 rubles.

Given the cost of lining and other wood products, the cost of impregnation does not seem very high. In addition, it should be noted that after processing, the wood looks much more attractive, it is easier to clean and does not darken for a long time. However, there are also disadvantages: for 3-5 visits to the bath there is a not very strong, but rather obvious specific smell.

In the rest room, you can use the composition "UnicaSuper" from the same Tikkurila. But this composition changes the color of the wood, so for lovers of "natural", Supi Saunasoja is again suitable.

Impregnation and oils for the steam room

Most fans of the bath agree that there is no need to cover the lining inside the steam room. But if there is such a need, then you can use natural oils and wax. Some connoisseurs advise soaking the boards with linseed oil, to which you can add natural aromatic oils of your choice. You can use hemp oil, and, the cheapest option, sunflower oil, but refined, with a minimal smell.

Such treatment will create a greasy film on the surface of the wood and will not allow dirt to penetrate deep into the wood. But you need to be prepared for the fact that for some time, parts of the body from contact with the processed shelf will be greasy. After a while, the oil will be absorbed (or wiped off), but the protective film will remain.

Similarly, you can treat the steam room with melted natural wax. Before applying the wax, the surface must be carefully sanded and only then the melted wax should be applied.

There is a fairly large selection of impregnations for industrial shelves. For example, in the same Russian firm Manor there is oil for shelves, there is a similar composition of Eurotex-sauna. Of course, Tikkurila also has them - this is Supi Laudesuoja oil.

Important! What definitely cannot be done is to use ordinary varnishes or paints for a bath or sauna. The tree must "breathe", first absorbing excess moisture, and then giving it away. When using conventional compositions, wood is completely deprived of this property, in addition, evaporation of the chemicals included in the composition is added, which are very dangerous to health at high temperatures and humidity. It's like covering a steam room with linoleum or siding: the materials are good, but not for these purposes.

If you use the steam room correctly, ventilate and dry it in time, then fungi and bark beetles will not start in it. They die at high and low temperatures:

- At a temperature of 70-80 ° C, spores of all fungi and protozoa die within 10 minutes.

- At -15 ° C, young larvae of the shashel perish, and if the temperature is below -15 ° C for a week, then adult larvae also die.

- Temperature + 60 ° C is the upper limit at which bark beetles survive.

If you then heat the bath to high temperatures, then freeze it, then no misfortunes are terrible for it, and you can deal with the remaining problems quite simply: clean or cover the most used surfaces with natural compounds more often.

The floors in the bath are not at all a trifle, as it might seem initially. The way they are installed differs from the technologies used in residential premises, primarily in that bath floors are part of the sewer system. With proper installation, the bath compartments will be dry, despite the constant humidity in these rooms. And this means the absence of mold, fungus and a long service life of this institution, which is cult for all Russians. There are different methods of flooring in the bath, so you need to choose an acceptable one and adapt it to your building. Bath floors can be made independently, you just need to have a general understanding of the principles of their installation and the differences between the schemes.

Laying floors in the washroom

Washing area, perhaps, the main room of the bath. Here, between short visits to the steam room, visitors spend most of their time.

In the washing compartment, water constantly flows in large volumes, which is why maximum attention should be paid to the arrangement of this bath area. Especially when laying floors, since they are the most exposed to moisture and temperature changes, it depends on them whether the washroom will be comfortable and warm or uncomfortable and cold.

There is always a lot of water in the washing room, so the floors should be well ventilated and dry quickly.

The high humidity of this room puts forward special requirements for flooring so that they do not collapse in a fairly short time. Washroom floors should:

- resist thermal shocks and do not let in a draft;

- be breathable and dry quickly;

- ensure normal ventilation, free outflow of water, acceptable temperature of the floor covering.

With these requirements in mind, the owner of the bath must consider all types of floors and choose the most suitable one. Moreover, it is necessary to decide on the materials for the floor even before pouring the screed.

Floor structures for washing

The surface temperature of the sauna floor rarely exceeds 30 °C, because the floor should be warm, not hot, pleasant even for bare feet, and not so that even bath slippers will melt. Therefore, you can use any material for its assembly - wood, tile, clay, concrete and others.

Do not use synthetic coatings. Chemistry has no place where high temperature and humidity are present.

Every floor covering has its pros and cons:

Consider the most common options for bath floors.

Wooden floor in the washroom

Hardwood and coniferous lumber is suitable for its arrangement: cedar, spruce, oak, ash, larch, fir. It is better to choose softwoods, since the resin they produce significantly increases the life of the floors. In addition, the tree has a healing effect on the body, and wet wooden flooring does not slip, and this is additional safety for visitors.

The advantages of wooden floors include:

- simplicity and ease of installation;

- naturalness, environmental friendliness and durability;

- low labor cost.

The disadvantages are the following:

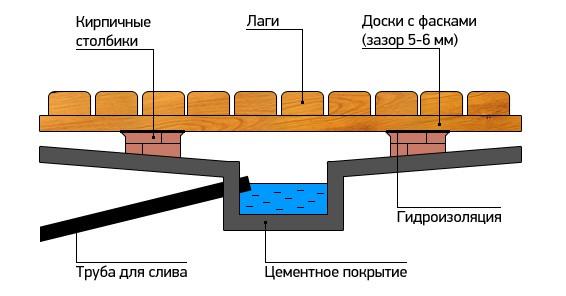

If you settled on wooden floors, then you should know that, depending on the drain device, they are of two types: leaking and non-leaking structures.

In turn, leaking floors differ in the laying pattern:

Consider the sequence of work for the installation of leaking floors.

- A hole is dug in the middle of the basement.

- A trench breaks from its bottom in the direction of the drain cuvette, in which a sewer (drainage) pipe is laid with an inclination towards the water collector by about 3–4 ° (approximate difference in height over the entire trench is 5 cm per linear meter).

The sewer pipe for draining water is laid with a slope towards the water intake

- The foundation of the bath is being erected and waterproofed.

- After that, along the entire border of the subfloor, from the walls of the base (or pillars), the earth is again taken out with a slope of 10 ° towards the dug hole.

- Then the slope slopes are covered with crushed stone and well compacted (for greater strength, a reinforcing mesh with cells of the order of 80x80 mm can be laid on top of the crushed stone). Everything is poured with a dense concrete mortar, which is leveled and smoothed. To reduce the cost of work, well-mixed clay can be used instead of concrete. It is laid out with a 10-centimeter layer, leveled and, as it dries, moistened with water and smoothed.

- Further, the walls of the foundation, if this is provided for by the technology, are tied with a metal belt and beam structures treated with an antiseptic are mounted. The lower coronal rungs are attached to the harness, and if there is none, then to the walls of the base with the help of anchors or studs).

Sexual logs in the bath do not need to be cut into the crown crown, then they can be easily replaced if necessary

- Floor boards with gaps are laid on the floor beams. The thickness of the boards depends on the distance between the joists, but should not be less than 20 mm.

Simple and reliable floors with slots for draining water are quickly installed and easily replaced with new ones

Often, the boards are not attached to the beam vault, but are connected to each other with a bar and ready-made shields are simply placed on top. The beam must be located among the floor beams. Such shields are very convenient to take out to dry.

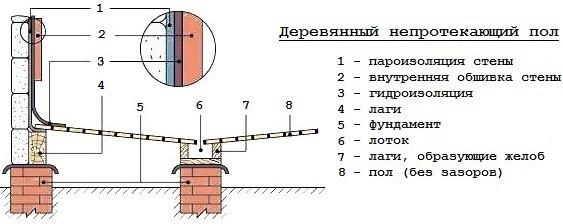

The scheme of equipment for non-leaking floors is not much different from the one described above in principle, although it is more difficult to implement. The difference is that the boards are laid without gaps on the rough flooring, for which second-grade wood is quite suitable.

For such floors, the logs are deepened into a concrete or clay layer (possibly into the soil itself), waterproofing is laid on top, sealed with a sealant. The space between the lags is filled with insulation. The draft floor is made with a slope towards the grated drain hole, through which water from the washing room enters the sewer network or sewage pit and is covered with polyethylene, then a wooden flooring is mounted.

In the arrangement of non-leaking floors, water flows into a specially equipped hole along an inclined plane

It is impossible to disassemble such floors for drying, so you need to provide excellent ventilation so that the wooden floor of a leak-proof structure does not rot ahead of time. This is its minus, but the non-leaking assembly is more durable and durable and provides for the possibility of a heating device to ensure maximum comfort from water procedures even in severe frosts.

Under the finish coating of a non-leaking floor, heating can be arranged

The choice of materials for the drain device

Let's say right away that it is impossible to save on materials for arranging floors in a washroom. You need to choose the best, modern ones that will be effective for years. To create a sewage system, it is necessary to use plastic building materials that do not corrode, are resistant to getting wet, are easy to assemble and operate without losing their qualities for more than 50 years.

These can be pipes made of PVC, HDPE, PVC (chlorinated polyvinyl chloride), polypropylene or corrugated polyethylene products. Any of them are perfect for an internal drainage device in a bath.

The diameter of the pipes is selected according to the intensity of use of the bath:

- if a steam room, sauna, toilet (i.e., several drain points) are provided, then pipes Ø 100–110 mm will be required;

- without the use of plumbing, only pipes Ø 50 mm are enough to drain water.

Material calculation and tools

To organize an internal drain in the washing department, you need:

- pipes Ø 110 or Ø 50 - the amount is calculated depending on the length of the drainage network;

- adapters from Ø 50 to Ø 110 for connecting pipes of different diameters;

- tees 110x110x90 and elbow 90° - 3 pieces each;

- vertical pipes for water inlets (Ø 110 or Ø 50);

- cement, crushed stone and sand.

Materials are purchased according to the chosen installation method. The same applies to tools. But in any case, you will need:

- building level;

- Bulgarian;

- bayonet shovel.

Concrete floor in washroom

Concrete flooring is the most common due to its low cost and ease of installation.

After hardening, you can make flooring from cork slabs or wooden gratings and install a drain.

For safety reasons, it is better not to cover the concrete floor with tiles or lay wooden lattice panels on top.

Other types of floors in the washroom

Those who revere old bathing traditions equip an earthen floor in the washroom. The process of laying it is extremely simple - cut off the top layer of the earth by about 15 cm around the entire perimeter of the room and tamp the remaining earth.

If you really respect the customs of your ancestors, then you need to dig a foundation pit half a meter deep and fill it with a mixture of fine sand and gravel. If desired, boards can be laid on top.

Previously, the floors in the bath were arranged directly on the ground, after cutting off its top layer and ramming the base

We have already talked about the clay floor, but despite all the advantages of the clay itself, such a floor has a big drawback - the clay dries poorly, and when it dries, it forms cracks into which water seeps. As a result of this, a persistent unpleasant marsh odor appears in the washing room over time.

In a word, wood would be the best choice, although it can be combined with other materials.

Video: do-it-yourself correct floors in a washing bath

Floor covering in the washing room

The floor is ready, it's time to think about protecting it. Everyone knows about the antiseptic, you should not neglect it and save on it. They process wooden elements even before the start of the main work, otherwise the wooden flooring can be ruined. The antiseptic does not change the texture of wood, does not contain heavy metals and harmful salts, and perfectly protects wooden components from biological damage.

It is also recommended to use a good varnish. Before applying it, you need to prepare the surface well. It must be clean, free of grease, polished to a mirror finish and dry. The varnish is applied in several layers, after it has completely dried, the bath must be heated and ventilated.

Lacquer must be applied to a previously sanded and well-cleaned surface.

Floors can be painted. Only the paint must be of the highest quality and absolutely harmless when heated.

In addition, there are folk remedies for flooring - the use of waste after processing sunflower oil. They are applied with a roller on a thoroughly cleaned and dried surface. Repeat 2-3 times at intervals of three days. Such a coating is safe, gives the wood a beautiful shade, and besides, it will cost almost free.

If the floor in the bath is concrete, then it must be covered with a finishing material, since by itself it looks unattractive. They cover the concrete floor with a massive floor board, porcelain stoneware or ceramic slabs, parquet, cork products.

In principle, any material is suitable, as long as it meets all safety rules. And the rest, it all depends on the intended design, on the personal preferences of the owner of the bath and on his financial capabilities.

Laying the floor in the steam room

Although the steam room is the heart of the bath, the floors in it, surprisingly, are the least significant segment of the entire bath project. The main thing here is the wall partitions and the ceiling. Remember how primitive everything was with our great-grandfathers. They threw plank blocks or split logs on the ground, and this was enough to take a bath with pleasure even in areas with severe winters. Cold feet? Splashed hot water and everything. No one complained and health was excellent.

Therefore, too much attention should not be paid to laying the floors in the steam room. Some advise equipping floors with insulation, vapor barrier and rough flooring in the steam room. Of course, this is very modern, but for a steam room it will be a waste of money.

As practice shows, a simple scheme for arranging floors in a bath is the best

And why drive moisture deep into the wood. It is much better and easier to create conditions for the free passage of water, and then take care of drying and ventilation. And it is much more important to make the floors in the steam room non-slip to avoid injury.

If the steam room is combined with the washing department, then there is no structural difference between them, everything is common and the same, the floors in this case are equipped according to the methods described above.

When the steam room is a separate area and there is no need to drain a large amount of water, then the floor is laid from an edged board with small chamfers (deck board). The slots may be slightly narrower.

The deck board is made from larch and therefore resists moisture well.

It is much easier with concrete floors - they are made in the same way as in all sections of the bath. A wooden ladder is certainly laid on top, since a bare bare concrete slab is not very pleasant.

The arrangement of the floor in the steam room, as, indeed, in the entire bath, is an excellent indicator: if it is cold in the bath after laying it, then look at the ceiling, most likely, there are problems with vapor barrier there.

What to make the floor in the steam room from: choosing the best material

Of course, wood is out of competition:

And what absolutely cannot be used for floors in a steam room is linoleum, chipboard and fiberboard. Wood boards ignite easily, and non-natural materials are capable of releasing hazardous substances at high temperatures.

Concrete floor equipment in the steam room

It is advisable to purchase all the necessary building materials from one manufacturer. This will add strength to the entire structure as a whole. Need to buy:

- edge tape;

- sand, cement M200 or 300 and gravel;

- primer, roofing felt and dry mix of self-leveling screed.

Tools for the job

To complete the entire process of equipping the floor in the steam room, you will need:

- protective equipment for eyes and hands;

- bayonet shovel and building level;

- a basin for mixing a solution or a bucket;

- concrete mixer and mixer;

- rollers (needle and primer);

- rules and construction trowel;

- gas burner for soldering roofing material.

Step-by-step instructions for laying a concrete floor in a steam room

- Solution preparation. You will need a concrete mixer in which the components of the solution are placed - sand, cement grade 200 or 300 and gravel in a ratio of 2: 1: 3. It does not make sense to use other brands of cement (higher ones), this will only increase the cost of the work. Add water and bring to the desired consistency.

To prepare the solution, sand, gravel, cement and water are used.

- Subfloor fitting. The soil in the steam room is covered with roofing material cut into sheets, and the seams are soldered with a gas burner. It is needed as a waterproofing agent. A 10-cm concrete layer is applied over the roofing material with a construction trowel, after which the entire screed is leveled to the level using the rule. When the solution is completely dry, proceed to the next step.

After the pouring is completed, the concrete layer must be leveled with the rule

- Final alignment. Literally to the millimeter, the final leveling of the concrete layer is done. For this, a self-leveling compound is used. Before laying it, the surface is cleaned of debris and dust, and then primed. The primer is applied with a conventional roller.

- Application of self-leveling screed. Along the entire length of the steam room, the bottom of the wall is glued with edge tape. This is done so that the screed does not stick to the wall and does not burst in the future. The dry self-levelling mixture is diluted with water in the proportions indicated on the package and mixed with a mixer until smooth. Following this, it is evenly poured over the entire surface and leveled with a spiked roller to remove air bubbles.

- Finishing work. The floor filled with a self-leveling screed is left to dry and only then proceed to the finishing work.

Video: pouring the screed in the bath with your own hands

Floor covering in the steam room

Some people believe that no impregnation should be used in the steam room, arguing that the bath should give health, and not emit harmful fumes at high temperatures. It's hard to disagree with this. But there is another side of the coin - physical wear and tear and decay.

Not only the wood with which the steam room is sheathed needs protection, but even the concrete floor screed loses its properties over the years. Plus, untreated, it accumulates dust that lovers of hot steam breathe.

If this is of little concern to the owner of the bath and he is ready to change the lining of the steam room (including replacing or repairing the floor) every 5 years, then, of course, no impregnations and oils. Otherwise, it is necessary to do the processing of the steam room and it is advisable to use natural wax and oils for this, specially designed for saunas and steam rooms.

Linseed oil emphasizes the structure of wood, creates a protective film on its surface and does not emit harmful substances when heated.

Concrete floor screed can be treated with organic and inorganic impregnations. This will increase the wear resistance of concrete, prevent excessive accumulation of dust. But it is necessary to apply impregnations in a steam room thoughtfully, carefully studying the instructions and composition.

There are many schemes for arranging floors in the washroom and steam room. All of them are accessible and understandable. They can be implemented independently. You can even apply several technologies at the same time, such a combination will give good drainage and a flat surface. But as practice shows, the technology that is simpler is better. Good luck and light steam.

The floor in the washing room is always made with a mandatory slope of the surface to the drain hole. This allows you to effectively remove water from the room and does not allow moisture to linger on the floor for a long time. The task of arranging the slope of the entire plane to one point is solved in various ways and the choice of a method depends on the design of a particular bath. If this is a building on a strip foundation, then a warm concrete or insulated wooden floor with ceramic granite tiles is more often used. In baths on screw piles and columnar foundations, it is more preferable to use a wooden pouring floor.

Concrete floors on the ground in the washing

If a tape structure is used as a base, then both a wooden pouring floor and concrete floors on the ground can be made. Consider an example of making a warm floor based on a screed finished with ceramic tiles.

Preparation of communications for draining is carried out even at the stage before pouring the concrete tape. The main thing here is to observe the slope of the pipe at least 2-3 cm per meter. The optimal location of the drain hole is in the center of the room, since the water drain organized at this point will provide the most efficient collection of drains from the entire floor surface.

If there is a fertile layer of earth under the future floor, then it should be completely removed and sprinkled with a layer of sand 15-20 cm thick. Then this layer is spilled with water and compacted with a manual rammer. When the surface is leveled and dense enough, a 50 mm thick extruded polystyrene foam (EPS) insulation is laid on top of the sand.

Small sections of heat-insulating plates are installed along the perimeter, after which foil waterproofing is laid on them. The joints between the strips of material are glued with foil waterproofing tape so that the waterproofing layer is completely sealed and does not let moisture into the insulation.

Further, low objects are laid out on the hydrobarrier, on which a metal mesh is installed to reinforce the future concrete slab. A heated floor heating tape is attached to the grid with a wire and this entire structure is poured with a concrete solution 10 cm thick.

As a finishing coating on a concrete screed, porcelain tiles are usually glued.

Thanks to the active underfloor heating system installed in the concrete slab, it will be comfortable to use such a sink even in the cold season.

Pouring wooden floor in the bath on stilts

The floors in the bath on piles require careful observance of the installation technology, since improper ventilation of the underground space leads to the rapid decay of wooden structural elements.

Let us first consider the scheme for arranging a concrete screed, as a more complex, but also more durable solution to the issue of organizing a floor for a bath on a columnar or pile foundation.

First of all, at the level of the lower plane of the wooden beams, the subfloor flooring is attached.

If you look closely at the beams, you can see that the boards are not nailed to the bottom of the joists, but are installed on a small support, fixed on the inside of the beam. This support is called the cranial bar and its location is well shown in the following diagram.

Also in this plan, you can see the sequence of placement of each of the necessary layers when constructing a concrete slab and pouring floor from a wooden board. The only thing that is not indicated here is a waterproofing flooring, which is desirable to be placed on top of a concrete screed to protect it from constant contact with water.

The following diagram describes an effective solution for arranging insulated concrete floors without expanded clay spillage. Here, both mineral wool and extruded polystyrene foam boards can act as thermal protection.

In practice, often a concrete screed is not made, but a simple pouring floor system is made that does not require grouting. The beginning of work is the same as in the previous version.

Mineral wool is laid between the lags on the rough flooring. A drain valve is installed to ensure efficient water flow.

In the direction from the walls to the hole, wooden guides are arranged in such a way as to form a general slope at one point.

On top of the guides, sheets of galvanized steel with a slight overlap on the walls are attached to the screws.

Logs are installed above the metal surface for laying poured floor boards on top of them.

The final stage is the laying of finishing floors from boards located at a distance of at least 3-5 mm relative to each other.

It is important to provide for the possibility of removing the flooring to ventilate and clean the underground space from debris that has got there. The better the ventilation is performed, the longer the entire structure will last as a result. The best solution would be to organize a vent in the subfloor, as shown in the photo below.

This air duct will allow not only to ventilate the wood of the finished floor with high quality, but also guarantees the flow of fresh air into the washing room.

Do-it-yourself floor in a washing bath - concrete and wood

The floor in the washing bath is always made with a mandatory slope of the surface to the drain hole. This allows you to effectively remove water from the room and does not allow moisture to linger on the floor for a long time.

Do-it-yourself floor in a bathhouse sink

In the construction of small bathhouses for private use today, few strictly adhere to the canons of their traditional construction. Sometimes the boundaries between different types of baths are so blurred that it is already difficult to unambiguously determine its type. The top is taken not by blind adherence to standards, but by the creation of a comfortable, individualized and, often, multifunctional building. More than half of all baths are now equipped with universal steam rooms, in which procedures can be carried out both with “wet” steam, like Russian baths, and with “dry” steam, like Finnish saunas. But for whipping with a broom or washing in the neighborhood through the wall, soap (washing) ones are provided. They can be equipped with massage beds, ordinary and shock showers, washstands, fonts, and even small pools. Such a functional layout raises a number of questions about how to make a floor in a bath sink, one or another workable design.

Requirements for floors in soap rooms

Washing is the realm of water. After all, it is found here everywhere in the form of spills, streams and splashes. Therefore, regardless of whether there are local wastewater receivers near each of the plumbing fixtures or not, the floor of the room acts as an element of the sewer system. It can completely collect and divert spilled liquid or complement the drainage system, making it easier to keep clean. However, in any case, a properly installed floor in a washing bath must meet the following requirements:

- be equipped with an easy-to-maintain, but effective liquid removal system;

- ensure the comfort of walking on it with bare feet, cause pleasant tactile sensations;

- be non-slippery, safe;

- dry and ventilate quickly;

- withstand long-term direct exposure to fluid and thermal stress;

- comply with sanitary and aesthetic standards.

In addition, according to construction requirements, the washing compartment should have a floor level 20-30 mm lower than the coatings in non-wetted adjacent rooms.

Concrete floor in a washing bath

It is the most practical and durable construction, capable of serving as a stand-alone tiled floor, as well as the basis for leaking or non-leaking modern plank flooring. The device of floors in a bath in a washing department made of concrete with a surface subjected to direct use must fully comply with all the requirements described above. At the same time, for each list item, there is some variability in the choice of how to implement them.

Drainage

To collect wastewater, the floor surface in the soap compartment is equipped with a slope towards the receiving unit of the sewer system. Building codes set this value at 0.01-0.015%. That is, after the completion of the finishing of the concrete floor slab, the levels of the facing forming surfaces should have a deviation from the horizontal of 10-15 mm per 1 m. Latches of trap-type siphons act as receiving units for tile coverings. They should be positioned so that neither they nor the streams of water to them cross the main and side passages.

Important! The floor in the washing bath is equipped with a ladder, based, first of all, not on the form factor or design of its lattice (rounded, square, elongated rectangular), but on the throughput of the device. The performance of a plumbing fixture largely depends on the diameter of its outlet, which are manufactured according to size standards of 52, 62 and 90 mm. This factor should be taken into account so as not to stand in the shower ankle-deep in dirty water.

From the waste receiving unit of the floor to the washing water, they are discharged through sewer pipes outside the bath building. For their disposal, especially during intensive use of the bath, it is advisable to make a separate storage tank, a drain pit or a septic tank, and not load public sanitary facilities.

Installation of a warm floor slab

When assembling a concrete floor in a washing bath with your own hands from the zero stage of construction, you should not neglect measures to reduce heat transfer through the ceiling. Concrete and tiles have a fairly high thermal conductivity, so if you do not take appropriate measures to insulate them, then in winter you will feel cold on your feet. Neither the use of wooden gratings nor powerful heating in the room can resist such discomfort.

The creation of a warm floor slab can be implemented in the following areas:

- installation of elements of the underfloor heating system in it (with mandatory insulation of the base);

- its thorough thermal protection and waterproofing.

Floor heating in the washroom

In terms of the device for heating floor coverings, the washing room in the bath is not too different from any other household premises. You can read more about installing a water-heated floor system here, and about electric heating here. However, when choosing a heating method, two important points should be considered:

- Bath mode. So, for permanent use, both water and electrical circuits are suitable. If the room will warm up only for the duration of the procedures, then it is better to choose the electric option. He is not afraid of freezing, has less inertia when entering the operating mode (if the heater is mounted in a thin layer of mortar under the tile).

- Operational safety. Of course, water circuits do not pose a threat to human life, even in a damaged state. When installing an electric underfloor heating in a washing bath, you will have to take all possible protective measures. Firstly, a steel mesh with a cell of 30 * 30 mm should be placed above the electric heater in the solution and grounded securely to it. Secondly, an RCD must be installed, designed for a leakage current of 10 mA. Thirdly, we will have to deal with the issues of potential equalization. Taken together, it is desirable to carry out these measures for the arrangement of electric heating in the soap department under the guidance of a professional electrician.

"Pie" of the insulated floor in the washing room

Regardless of whether heated underfloor heating is assembled in the bath in the washing room or not, concrete bases are insulated and waterproofed. The method of practical implementation of thermal and hydroprotection is selected depending on the position of the overlap relative to the ground. The slab can be placed directly on the ground preparation or on the logs. The isolation of the concrete floor on the ground was discussed in detail in the article: "Features of making floors in steam rooms with your own hands." At the same time, it is no different from creating a similar design in the soap department.

In the case when the bath box is placed on poles, beam schemes (beams, logs) are often used for flooring in all rooms, equipping them with leaking or non-leaking flooring from boards. But sometimes, with such a supporting structure, it is necessary to assemble the floor in the washroom of a monolithic type, for example, to lay ceramic tiles or install an efficient floor heating system. Its schematic structure is shown in the figure below.

Wooden base assembly

Logs and all other lumber are used only from well-dried wood, treated at least 2-3 times with antiseptic and hydrophobic impregnations.

- When installing a beam frame, you can basically be guided by the same principles as when preparing it for finishing boardwalk, described here. There will be only some adjustment of the design parameters for the thickness of the insulation and increased loads. So, the height of the first layer of thermal insulation between the lags will be 100 mm, if an additional insulating layer (at least 50 mm) is still laid for the underfloor heating system. You can consider, for example, the option of a “skeleton” for floor insulation in the washing department of the bath on wooden beams 100 * 50 with a step of 450 mm (see tab. 1 on the link), reducing the length of the free span between the lag supports to 1 m.

- The board of the underlying roll and the cranial bar under it are used with the smallest possible thickness from low-grade wood (without signs of biological damage).

- Lay film rolled waterproofing with a high vapor permeability and the first layer of inter-beam thermal insulation, as described here.

- A ventilated space is arranged above the insulation - a ventilation gap. It is formed by punching from above the log bars of the counter-lattice. The thickness of the beams is selected based on the final clearance height of 20-30 mm. It is preferable to install a floor in the washing compartment, in which the formed horizontal ventilation gap communicates with the ventilation gaps behind the interior wall cladding of the room.

- The counter-lattice is covered with dice of the subfloor. Boards with the parameters indicated in table 2 are suitable for it (see link). They can also be replaced with sheet materials (OSB, DSP, etc.) with identical bearing parameters.

Installation of insulated concrete slab on wooden flooring

- Above the boards of rough rolling, a continuous carpet of dense waterproofing material is arranged. For these purposes, rolled sheets of bituminous euroroofing material are excellent. They are welded into a monolithic coating with a continuation under the cladding on walls with a height of at least 400 mm. Thus, a sealed waterproof bowl is formed.

- Lay the second layer of 50 mm thermal insulation boards made of extruded polystyrene foam (EPS). A similar thermal protection scheme is necessarily used if the washing room in the bath is equipped with a floor heating system. Otherwise, you can not mount an additional heat shield, but then you should increase the height of the inter-beam insulation to at least 150 mm.

- If EPPS was used, then a film is spread over it and a concrete slab is formed with slopes to the sewer receiving unit. If expanded polystyrene sheets were not used, then concreting can be carried out directly into the bowl from the waterproofing on the subfloor. The height of the reinforced casting should be 80-100 mm. Plasticizers and water repellents are introduced into the solution at the stage of its mixing.

Important! Only with such an integrated approach, heat and waterproofing of the floors in the washing bath will be able to provide you with the comfort of using the facility, as well as the long-term preservation of structural and finishing materials.

Concrete flooring in washroom

Construction requirements prescribe that floor coverings in rooms with a wet operating mode should be made of hydrophobic materials with a corrugated surface. However, in practice, the number of important parameters taken into account for floors in washing rooms is much wider. It also includes convenience, safety and comfort of use, resistance to water and temperature gradients, and aesthetic perception. For the most part, ceramic cladding with a profile set of properties has all these characteristics. And if the washing room in the tile bath is also complemented by light removable gratings made of wooden laths, then the most practical floor covering is obtained. After all, the main finish will be made of ceramics, which has a practically unlimited service life. Lattices will ensure the safety of movement, will not interfere with cleaning, as they can always be lifted and taken out to dry.

Features of the choice and installation of tiles

Finishing the bathroom floor tiles in the bath will only be done correctly when they are selected and installed in accordance with the specific operating conditions. Please note that tiles must be:

- matte, with a rough surface against slipping, have a coefficient of friction R 11-R 13;

- with a homogeneous dense structure, slightly absorbing water. Suitable properties for porcelain stoneware with a water absorption coefficient of ≈3% or tiles - 3-10%. Ceramics with a hydrophilicity of more than 10% is suitable only for finishing walls that are not constantly exposed to water;

- with high frost resistance, if the floor in the washing bath can be exposed to negative temperatures in irregularly heated rooms. Otherwise, the tile will quickly become covered with cracks.

It is recommended to treat the concrete slab with penetrating cement compositions before gluing the ceramic material. They include components that can penetrate deep into the porous mineral structure and completely seal its capillary channels. As a result, the concrete surface becomes a reliable barrier to the migration of dropping liquid.

Tiles on the floor of the washing compartment should be laid on moisture-resistant adhesive mixtures. When using glue, one should also take into account the temperature loads on the reinforced concrete base and its decorative coating. For irregularly heated rooms, as well as ceilings with underfloor heating systems, an appropriate adhesive mixture of increased elasticity is selected that can withstand thermal deformations.

Wooden floor in the washing bath

Traditionally, a washing room in a wooden bath, namely, such buildings are still massively erected in Russia, was equipped with plank floors. And, despite the fact that they are now seriously competing with concrete structures lined with ceramic tiles, as more durable, wooden coatings are still relevant. The device of floors in a bath in a washing department on the basis of lumber can be leaking and non-leaking.

Floor of the flowing (flowing) type

A floor structure of this type can actually be considered the same age as the appearance of the entire technology of building baths in general. Today it has undergone some improvements, but its basic functional principles have remained unchanged. With its working surface, the pouring floor in the bath still has a surface of boards that are installed with drainage gaps. In the classical version, seeping into these cracks, water is absorbed directly into the soil or concentrated in an absorbing pit, where it subsequently also goes into the ground. Now, under the boardwalks, concrete drain surfaces are predominantly created with slopes, along which the liquid flows down to the receiving node of the sewer system.

It should be noted that there are also intermediate solutions, between the most primitive way of waste disposal and the modern one. So, instead of concrete surfaces, carefully compacted greasy clay is used, or drainage is carried out not just into the soil, but into a crushed stone pillow. The use of clay and gravel bedding, of course, significantly reduces the cost and speeds up the installation of a washing machine in a bath, however, it has nothing to do with the concept of modern approaches to this issue. It is rather difficult to provide thermal comfort with such a scheme for arranging floors in a sink, as well as a feeling of freshness - in such a room there will almost always be a smell of dampness.

Mounting features of leaky coatings

In a simple version, pouring floorings are assembled quickly enough. Their load-bearing structures are made on logs, guided by the choice of lumber similar to the installation of floors on poles. Finished plank sheathing is not insulated, and its stuffing is carried out with slots between adjacent lamellas of ≈10 mm. Leaving drainage gaps too wide is not worth it, otherwise they will create problems when moving. If the boards are fastened too tightly, then swollen under the influence of moisture, they can completely close.

When mounting the pouring floor in the bath with your own hands, use nails to fix the flooring. Gradually, even with the most effective hydrophobic treatment, the wood of the coating will become unusable, its lamellas will have to be replaced with new ones. Unscrewing a self-tapping screw after several years of being in raw material is an unrealistic task. If the floorboard was fastened with a nail, then it can always be easily hooked and torn off from the support beam.

Important! When hammering nails, their caps must be sunk into the material, and the resulting recesses must be puttied with moisture-resistant target compositions.

Equipping a concrete base under the pouring floor, they adopt the principles of organization of drainage described above. That is, observing the slopes, installing the sewerage receiving unit and, further, the entire waste disposal system. Instead of a plumbing ladder, a rubber ball is sometimes used. When it floats up, it lets liquid into the sewer, and when there is no inflow, it lies on the hole of the drain funnel and blocks the return draft of cold air from the sewer pipe.

To ensure the thermal comfort of those washing in the bath, the durability of the wooden floor structure, they also resort to the following measures:

- the basement of the foundation is made insulated, with hermetically sealed products;

- a concrete base under the flooring is made with interlayers of heat and waterproofing according to the technology of floors on the ground;

- mount the ventilation system so that warm air passes under the pouring cover before being removed from the washing room.

Non-leakage type floor

Making a high-quality non-leaking wooden flooring in a washing bath is a rather difficult task, since it requires an almost perfect fit of the elements of the finishing board, as well as a 100% guarantee of the reliability of the waterproofing layer under it. However, the general principles of floor slab construction are identical to joisted timber structures, with the exception of the following structural differences:

- waterproofing above the insulation is mounted with a significant overlap of the strips (at least 300-400 mm), taking into account the direction of the water flow. It is welcome to lay several layers of film, which can be duplicated with sheets of dense material, such as plastic or aluminum. The surface of the hydro-barrier should already have a runoff slope, provided in any convenient way: appropriate installation of beams, stuffing additional beveled bars of the counter-lattice on the logs, etc.;

- the floor in the non-spill type washing bath is assembled from high-quality softwood grooved boards. It is preferable to place the lamellas so that water flows along them along the wood fibers;

- the slope of the surface of the front cover ends with a receiving sewer unit (ladder).

Regardless of the floor design you choose, the installation of a high-performance ventilation system is mandatory in the room. But in addition, the washing room in the bath should be additionally dried after each cycle of hygiene procedures - it is recommended to ventilate it by briefly opening doors and windows. All this will extend the service life of not only the floors, but also other building elements of the building.

How to make a floor in a bathhouse sink with your own hands: device, installation

We analyze how to make a floor in a bathhouse sink with your own hands. Features and differences in the choice of materials and installation methods in comparison with other bath rooms

How to make a floor in a bath in a washing room - planning and installation rules

Since the washing room belongs to one of the main rooms in the bath building, work on its device must be carried out in full accordance with the technology, taking into account the slightest nuances. Even a minor mistake can degrade the performance of the washing department. The solution to the question of how to make the floor in the washing bath correctly deserves special attention.

The conditions in which the flooring in the washing room is used are characterized by the constant presence of an increased level of humidity and frequent temperature changes. In the process of designing a bath and during its construction, this should be taken into account.

Requirements for flooring in a car wash

In order for the floor in the bath in the washing room to be made with high quality and last long enough, it must meet a number of requirements:

- quickly and completely drain water, for which the floor covering is made with a slight slope towards the drain hole or equipped according to the so-called leaking technology;

- well ventilated and dry quickly;

- be resistant to high humidity and temperature changes;

- it should be laid so as to exclude the possibility of drafts.

Varieties of floor coverings in the washroom

In private households, in the washing departments of baths, wooden (they are leaking / non-leaking) and concrete floor structures are usually laid.