Technology for the manufacture of interior. Simple and clear: the procedure for manufacturing wooden doors

The veneered interior door, manufactured by the Vladimir Door Factory (VFD), has a well-deserved reputation as an elite product, which is due, first of all, to materials and production technology.

Veneered doors are made from natural high-quality wood, MDF (medium density wood fibers), restructured wood veneer and finishing materials - glue, varnish, paint. All materials are rigorously and carefully selected and tested for compliance with quality standards and environmental regulations.

Veneered door design

The door may consist of a blank (solid, unglazed) leaf or contain decorative elements and glass inserts, but, in general, it is a frame structure.

Glazed door leafs consist of:

External frame made of softwood timber;

Its filling elements - strips of special cardboard, combined with each other in the form of a structure resembling a honeycomb;

Inserts from bars for inserting a lock;

The internal frame required for the subsequent installation of the glass filling of the glazed door;

Veneered MDF boards.

Deaf door leafs have a similar structure, with the exception of the inner frame for glazing.

Door production materials

The raw material used to create the frame is pine wood, which has a strictly defined moisture level: no more than 7 ± 1%.

To achieve the desired moisture content, the manufacturer uses a special process cycle in which the wood passes through a system of four front-loading drying chambers, each of which can hold up to 50 cubic meters. m. of raw materials. The chambers are equipped with reversible fans, humidification, cleaning and air conditioning systems. The process is automated; the accuracy of the set indicators is achieved thanks to a system of sensors-controllers.

At the end of the drying process, the wood moves to the cooling room, where it stays for the next 48 hours. This stage eliminates internal stresses in the lumber, due to which the products made from it are reliable and have an extremely long service life.

MDF (medium density fibreboard), used for lining the base frame, is made from hardwood, hardwood. The plate is produced in a highly environmentally friendly way - by hot dry pressing, with the addition of special binders that meet safety standards. This not only saves the material from the presence of harmful substances and components that are usually found in MDF - phenol and epoxy resins - but also guarantees it an increased density (850 kg / m. Cubic.)

MDF (medium density fibreboard), used for lining the base frame, is made from hardwood, hardwood. The plate is produced in a highly environmentally friendly way - by hot dry pressing, with the addition of special binders that meet safety standards. This not only saves the material from the presence of harmful substances and components that are usually found in MDF - phenol and epoxy resins - but also guarantees it an increased density (850 kg / m. Cubic.)

MDF produced in this way retains its density, strength, strength and geometry invariance for a very long time.

Honeycomb elements that fill the inside of the door frame between the skins give the structure the desired degree of rigidity, a hundred or more times higher than the rigidity guaranteed by other fillers. This is a high-tech material that gives super-strength and, at the same time, ultra-light construction.

Honeycomb elements that fill the inside of the door frame between the skins give the structure the desired degree of rigidity, a hundred or more times higher than the rigidity guaranteed by other fillers. This is a high-tech material that gives super-strength and, at the same time, ultra-light construction.

Doors with such a filler are not only extremely durable and lightweight (which reduces the load on the hinges), but also have excellent heat and sound insulation qualities.

The next design element is natural veneer. This is a thinly cut layer of wood that retains its rich natural texture and color, which cannot be imitated by any technique and tricks. Bonded securely to a fiberboard backing, this highly sustainable and durable material will not flake, crack or crack.

The application of veneer, as well as the assembly of the door frame, takes place in the previously mentioned method - hot pressing. Then the door leaf is formed in accordance with the specified dimensions and the ends are veneered.

Bringing it to perfection

The finished door leaf is milled along the contour specified by the template, depending on the desired type of door leaf. Each of the types has its own, special way of milling. Then it is polished by hand.

The finished door leaf is milled along the contour specified by the template, depending on the desired type of door leaf. Each of the types has its own, special way of milling. Then it is polished by hand.

To make the latter as efficient as possible, VFD specialists have developed a technology for step-by-step surface treatment, in which tools with different grain sizes are applied in a certain sequence.

Finishing involves the application of paints and varnishes. They are applied strictly by hand, and by masters of the highest category, real pros. As a coating, a Swedish two-component acrylic composition based on organic components "Becker Acroma" is used.

The varnish forms a thin but hard film on the surface of the door leaf, which has a high covering characteristic. It protects the wood from moisture changes, preventing the wood from swelling or, conversely, drying out. In addition, a full coat of lacquer brings out the richness of the colors and textures of the wood, giving the door a finished look.

Glazed doors are equipped with Bronze frosted glass, which is installed using six flexible gaskets that securely fix the glass and exclude its smallest vibrations. At the same time, the process of extracting the double-glazed window, if necessary, is very simple and does not present difficulties.

The manufacturer has introduced a system for identifying performers, which makes it possible to detect "scumbags" and eliminate them from production operations. Thus, the maximum possible control over all manufacturing technologies is achieved. The marking of the performers is placed at the top or bottom - at the end of the door leaf.

The manufacturer has introduced a system for identifying performers, which makes it possible to detect "scumbags" and eliminate them from production operations. Thus, the maximum possible control over all manufacturing technologies is achieved. The marking of the performers is placed at the top or bottom - at the end of the door leaf.

Doors are packed in corrugated cardboard, wrapped on top with plastic wrap. Each door has a passport containing a description of the model, a section on warranty, recommendations for use.

Related door elements

No matter how good the door is, for its installation and successful long-term use, elements such as a box and platbands are needed. The technology of their production also has its own characteristics, which allow achieving excellent quality characteristics of the product.

box beam

The basis for the door frame is dry lumber (moisture index - no more than 8 ± 1%); , ten mm MDF and natural veneer.

Raw materials are connected by end splicing. In order for the alignment to be successful, any defects that exceed the tolerance limit are removed. Lumber gets rid of knots, cracks, rot, etc. the blanks are glued together and then brought to the specified dimensions on four-sided planers.

Raw materials are connected by end splicing. In order for the alignment to be successful, any defects that exceed the tolerance limit are removed. Lumber gets rid of knots, cracks, rot, etc. the blanks are glued together and then brought to the specified dimensions on four-sided planers.

MDF sheets are cut into blanks of the desired size, ideally matching the specified parameters. Such accuracy became possible thanks to the use of a special format-cutting machine.

Further, with the help of hot melt adhesive, the MDF is fixed to the prepared lumber. This takes place in a special workshop, on an automated line for facing molded products. The finished rough product is again processed by a four-sided planer, after which it again enters the cladding line, but this time for wrapping with veneer.

The timber that has been veneered is sent to the paint shop, where it undergoes finishing - grinding, priming, varnishing.

Platbands and additional level

Architraves and additional elements are made of profiled fibreboard, veneered and varnished, similar to the paintwork on the door leaf. To prevent damage, the products are packed in several layers of polyethylene.

Architraves and additional elements are made of profiled fibreboard, veneered and varnished, similar to the paintwork on the door leaf. To prevent damage, the products are packed in several layers of polyethylene.

The production of doors from wood and materials made from it is one of the most promising options for both large and small businesses. In order to open such a workshop, you will have to not only purchase a list of the necessary equipment, but also familiarize yourself with all the production nuances.

Based on the video in this article, we will discuss how the manufacture of an MDF door is carried out; consider the mechanisms by which certain technological operations are performed; and tell you what capabilities this or that machine or tool has in general.

If the company is engaged in the production of interior doors, then you should not focus it only on working with wood, or only with MDF. Moreover, most of the doors are combined: the frame is constructed from pine bars, and only then it is sheathed with sheet material. In general, for the successful sale of products, you need an extensive range covering different price ranges.

Therefore, the manufacturer must offer the buyer both cheap doors without a decorative coating, and elite ones made of natural wood, and a golden mean in the form of laminated and veneered products (see). The task is facilitated by the fact that the equipment for the production of MDF doors is also used with the same success for the manufacture of solid wood doors. Therefore, the list of machines and fixtures that we will present in the course of our article will be general.

Material preparation

Edged boards and timber used in door production must undergo a drying procedure. There are several ways to reduce wood moisture, and the easiest of them is natural.

But it takes a lot of time, so drying chambers are used in factories for this purpose. This is a stationary box with a ventilation system, in which the temperature is maintained from +40 to +100 degrees.

So:

- First, when the fan is running, the lumber is heated with steam, and then the temperature is gradually brought to the desired mode. Since the design features of the drying chambers may differ, the principle of working with them is determined by the manufacturer's instructions.

- Warm-up time depends on the type of wood, and the essence of drying is not only to normalize moisture, but also to relieve stress from its internal fibers. Upon reaching the required percentage of humidity, the tree is not immediately removed from the chamber, but kept in it for up to three hours. If poorly dried material is used in production, the products will be deformed.

- The cost of the drying chamber depends on its capacity, and at least it is 2 million rubles. Not everyone has such tools, so some craftsmen make them with their own hands. A room is allocated for this, the surfaces of which are qualitatively insulated, steam is isolated with foil, a fan and heating elements are installed. Often, infrared film for underfloor heating is used for this purpose, as it is very economical in terms of electricity consumption.

If there is a desire, information on this topic can be easily found on the Internet. The main issue that will need to be resolved in this case is the method of loading wood into the chamber. Usually this is, as in the photo, a trolley on rails, but a forklift can also be used. And, of course, you should take care of fire safety.

Material calibration and cutting equipment

It is clear that the wood used for the manufacture of doors must be calibrated - that is, it must have clear geometric dimensions. Therefore, after drying, the lumber is processed on a four-sided planer, which is able to process the workpiece from all sides at once. When the bar passes through it, four cutters not only level the surfaces, but also reveal defective places.

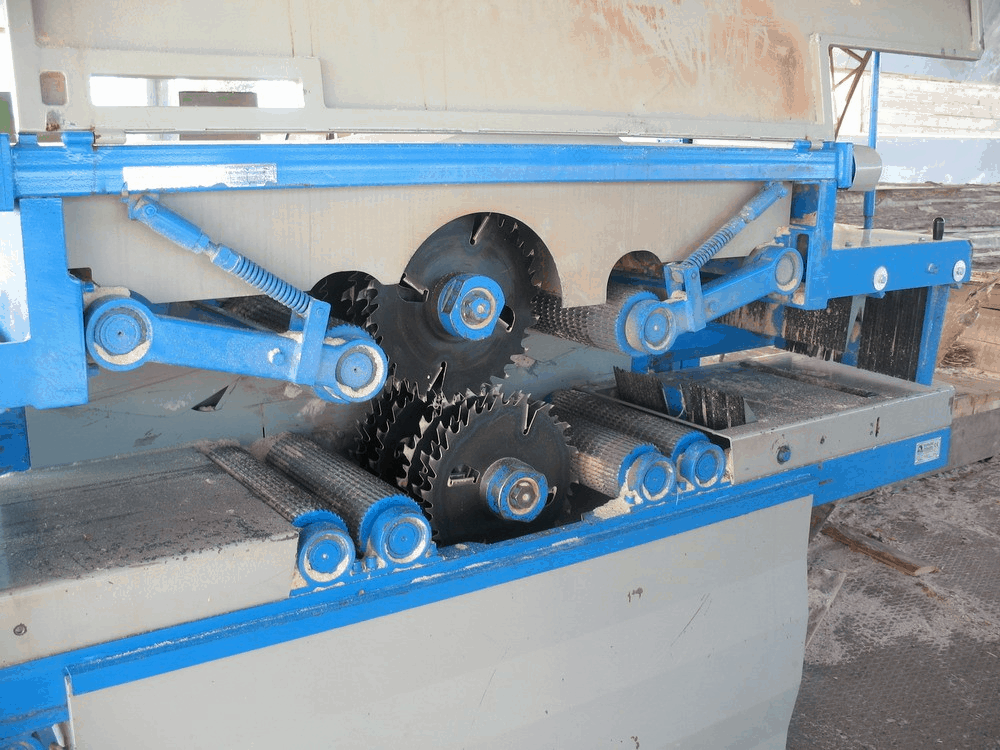

Multi saw machines

A business that has a multi-blade machine at its disposal can significantly increase productivity. Such equipment allows, in order to reduce costs, to purchase not a ready-made edged board, but round wood, and saw it on your own into boards and beams.

The capabilities of this machine make it possible to mass-produce molded blanks, including from sheet and plate material: plywood, chipboard, fiberboard, MDF, furniture board.

Note! Machines with a multi-blade system are suitable for both longitudinal and transverse processing. Depending on the type of unit, up to two dozen saws can be provided in it. Their layout is standard, and is very similar to a sawmill, but unlike a multi-saw machine, several blanks cannot be made at the sawmill at the same time.

- In addition, workpieces passed through a multi-saw unit are distinguished by greater geometric accuracy. All its working elements are located on the frame, and in some models there is also a material supply line, which is a roller conveyor.

- The material feed unit is driven by an electric motor, and consists of shafts with spikes that ensure uniform movement of the workpieces. The sawing unit can consist of several or one shaft, on which circular saws are mounted. By the way, they can be located not only in a vertical plane, but also horizontally.

If necessary, the multi-blade machine is equipped with a milling mechanism necessary for processing the ends, as well as an installation for trimming the edges. The complete set of the machine may vary depending on the parameters of the products that you want to receive.

Trimming machines

When working with any long material, it is impossible to do without miter saws. In a small workshop, carpenters can use manual options, but for large volumes of work, a machine is needed.

Facing is a cross-cutting of wood materials, with the help of which the workpiece is given the shape of a rectangle and a workpiece of a certain length is obtained.

So:

- When the company has a dryer, then one trimming machine can be installed on the site where the raw material is sorted, and the second is used for cutting the already calibrated timber or board. Such equipment has quite a lot of potential.

- In addition to trimming the ends, this is the division of the workpiece into 2 parts; determination of a section with a defect, which is automatically removed during sawing; cutting blanks of a certain length. All these operations can be performed by the machine either simultaneously or sequentially. Here much depends on the configuration of the machine, its settings, as well as the task.

- As in gang saws, circular saws with teeth made of hard alloys are used here. However, they have a different sharpening angle, since the wood has to be cut across the grain. A saw with the right teeth cuts through the material like clockwork, and does not tear or crumple it.

- Since the cross-cutting cycle is periodic, the moving parts of the machine do not have time to heat up much, so the mechanism works properly for a long time. The only thing, for the convenience of work, the trimming machine must have a convenient device for feeding workpieces. Usually this is either a conveyor or a roller table - a roller table, the price of which, depending on the length, varies between 16,000-25,000 rubles.

So that when sawing there is no discrepancy between the required and actual dimensions of the products, all measuring instruments on the machine, as well as the stop ruler on the roller table, must be periodically checked and adjusted. To obtain the most accurate parameters, modern cross-cutting machines are equipped with optical instruments, which also need to be verified from time to time.

Panel saw

When working with sheet wood material, which is MDF, you can not do without a machine for format cutting. It cuts in a straight line or at an angle: both long-length and slab material is processed, and you can also cut a whole stack of slabs at once according to a single template.

- To do this through any other machines or tools, if possible, it will take a lot of time and effort, which is simply unacceptable for the mass production of joinery. In general, production efficiency largely depends on the overall functionality of sizing machines.

- All of them are professional, and are divided into three categories. The first group contains the simplest economy class models, with small dimensions, and without additional equipment with stops, rulers and clamps. Such machines can work no more than five hours in a row, and are designed for a relatively small volume - ideal for a small private workshop.

- The second category includes machines of medium power, which can work a full shift (at least 8 hours), and are provided with all the necessary devices and assemblies. In particular, they can be equipped with a dust extraction device. Well, the third option is industrial machines that have the most durable design, complete set, electronic control circuit, and are able to work for two work shifts.

- The basis of any machine is the frame on which all working mechanisms are mounted. The stiffer and heavier it is, the less vibration and the higher the cutting accuracy. Two saw blades are fixed on the bed. A scoring disc is located in front - it has a smaller diameter, and its function is to cut the upper (facing) layer on the workpiece.

- The main disk finally cuts the material, the size of which determines the depth of cut. This arrangement of the discs allows you to make a high-quality cut, with smooth edges and without chips. The sizing machine has three working tables: one is movable, along which a full-sized MDF sheet is fed for cutting; the second support, which should support the cut off parts. The third, fixed table, on which, in fact, the saw unit is fixed, is the main one.

To cut a workpiece on such a machine, the sheet is placed on a movable table, which moves along the guides with a carriage. Using the stop, measure the desired length, and start the saw mechanism. As soon as it gains momentum, by shifting the table, the sheet is fed to the saw unit, and a fragment is cut off. From the settings in the format machine: only the depth and angle of cut.

Equipment for milling and cutting spikes

Without a milling machine, it is impossible to imagine any carpentry workshop, because cutting profiles, grooves, volumetric reliefs, large radius curved cuts, and even wood engraving are performed mechanized.

The only difference is that the milling machines used in one case or another differ somewhat in design. There are six types of removable tools, the use of which is due to the need to obtain one or another type of processing.

- Thus, a wood milling machine can be considered a universal mechanism. The height of the cutter, located on a movable vertical shaft, can be adjusted. But the position of the part being processed is limited by stops and guides.

- In a small workshop, you can get by with a manual milling cutter, a variant of which is presented above, but for the mass production of joinery, machines with program numerical control are used. Manufacturers offer a huge range of such equipment, which has a variety of characteristics, and is controlled by operating systems.

- With a milling cutter on a vertical shaft, you can countersink, that is, get conical holes; bore them; dado. With the help of such machines, the edges of blanks are processed, frames are made. But mirror-symmetrical, or absolutely identical curly blanks: drawers, panels (see), cannot be made without a copy-type milling machine.

- most often collected by spike method. Spikes on the ends of the blanks, as well as recesses for them (lugs), can only be obtained using a tenoning machine. In it, the working mechanisms are also cutters and saws. Just like other milling machines, tenoning units can be equipped with a CNC and controlled by a microprocessor.

- In any case, an oval or round spike can only be made on such equipment. In addition to cutting spikes, on CNC machines, it is possible to overtake the perimeter of the door leaf, process calibrated sheet material, splice bars along the length, which is sometimes necessary for the manufacture of panel doors.

Note! In addition to the main woodworking machines mentioned above, additional equipment will also be needed in the door production, with the help of which the finished canvases and molded products are finished.

- This is a hydraulic press, with the help of which the MDF door paneling is pasted with veneer, and an edge banding machine, through which narrow strips of veneer are glued to the ends of the canvases. This includes a spray booth, and a press for gluing bars, and a surface grinder, and a packaging machine - otherwise how to transport products?

As you can see, the list of equipment is quite large, and it is clear that in order to equip a carpentry shop, you need to spend a lot of money. But do not forget this: the availability of machines and the necessary tools does not guarantee a quality result. Ultimately, it all depends on the professional competence of the people working on this equipment.

In the production of MDF boards, special chips are used. Raw materials are pressed on special equipment, resulting in a material that later serves for the manufacture of furniture facades and interior doors. To make the plate durable and reliable, the composition contains resins, as well as a number of other adhesive components with an environmentally friendly composition.

today direction production many companies are engaged in door designs. The whole process production of MDF interior doors is similar to low density board technology. But it also has its own distinctive characteristics, which also act as advantages. AT production MDF boards do not use toxic substances, formaldehydes, synthetic adhesives, phenol, which further release harmful components into the environment and are unsafe for human health.

In many respects, the equipment and technology ensures the bonding of fibers by activating the natural properties of the wood itself. Under the influence of high pressure, the components release lignin, an environmentally friendly adhesive substance. That's why production of MDF interior doors- one of the few that is completely environmentally friendly and safe.

MDF interior doors: what determines the final cost of the structure?

Cost per MDF interior doors depends on a number of factors. First of all, the price varies depending on the quality of the plate itself, compliance with the technology of the production process, and the thickness of the canvas used. There are also several types of canvas, which determine the final cost. MDF doors. Let's talk about them in more detail.

According to the design of the MDF door leaf, they are divided into 2 types:

Panel doors . Externally, the design is a solid canvas. Most often, these doors are decorated with a variety of artistic inserts and ornaments to enhance the decorative qualities. The frame of such MDF interior doors can be made from various materials. The use of a bar is also allowed. MDF sheets are attached directly to the frame, and the space between them is filled with cardboard or other material.

Paneled doors. This type is more durable. This design has an additional insert in the canvas itself, which is thinner than the frame itself. With this technology production of MDF doors they are given not only increased reliability characteristics, but also expand decorative possibilities. It is the paneled doors that can most often be found in modern apartments.

Back to the question production of interior doors from MDF. Like any other technology, it has certain stages. Only if all the rules and sequence are followed, you can get high-quality and reliable plates. If the structure is made of such plates, you will be satisfied MDF interior doors installed in your house or apartment.

Technological stages of production of MDF boards for interior doors:

- Logs after special preparation are crushed to the size of a chip, after which they are washed and completely cleaned, heated with steam.

- Repeated grinding process, during which the chips are converted into a fibrous structure, which is mixed with special adhesives, resins of natural origin.

- The distribution of fibers in special forms, the raw material is preliminarily dried, and excess air is pumped out.

- Distribution in fiber forms by means of special rollers, pre-compression during which the board enters the pressing machine.

- The plates come out of the machine as a continuous sheet, which is cut to the required dimensions, polished and finished.

If the technological process production of MDF doors observed, you will receive a high-quality design with a long service life and excellent performance.

Sections of the article:

Often, choosing from a wide range of door designs, a person cannot choose a door that is ideal in all respects. Many as a result opt for one of the most functional models. Others decide to manufacture wooden doors that fully meet the requirements of the owner on their own.

Undoubtedly, having the skills of a carpenter is a significant advantage. However, if desired, even a person without such experience, through diligence, improvisation and with the help of some instructions, is able to make the necessary design.

Material for work

A popular and inexpensive material suitable for making doors is lumber from pine trees. The use of spruce is undesirable, since the structure of the tree is rather unstable and a large number of knots and chips are formed during processing.

Making beautiful and even doors from pine wood implies, first of all, the right choice and technology for preparing boards. It is necessary to choose lumber of an even structure, without obvious chips and flaws. You also need to pay attention to the color of the boards. The presence of some blue on the surface of the boards is a direct evidence of gross violations in the storage technology. The use of such boards is highly undesirable, since rotting processes will soon begin in them.

Board drying technology

For absolute confidence in the quality of the material used, and subsequently the entire structure of the door, after purchasing the board, it is necessary to dry it additionally. This must be done even if their appearance is perfect. To do this, each of the boards is laid on a gasket that separates the bars so that they do not touch each other in a warm room with low humidity.

The manufacture of wooden doors using such manipulations is necessary to remove excess moisture, which is necessarily inside the wood fibers. If you miss this stage, mold will grow in the material, which will subsequently destroy the door made from such boards.

The place for drying wood must meet the following parameters:

- Air temperature not lower than 25°C;

- Low humidity level;

- Good ventilation.

Under such conditions, the drying stage takes about 1.5-2 months. However, this process can be greatly accelerated by using special cameras. In such rooms, the air temperature is pumped up to about 50 ° C, but this value must not be exceeded.

The production of wooden doors in violation of technology and exceeding the permissible temperature during drying will result in the leakage of resinous substances from the wood, the main function of which is to bond wood fibers.

The drying chamber can be equipped in any place suitable in terms of parameters, whether it is a garage, a warehouse or a shed. In the process of such drying, lumber is stacked in the same way as when drying without air heating.

Necessary tools and materials

For the manufacture of a high-quality design that allows you to effectively absorb noise and protect from the cold, you must have the following tools:

- A set of dried boards;

- Fiberboard sheets;

- Insulation material;

- Joiner's glue;

- Roulette;

- Level;

- Plane;

- Chisel;

- Drill;

- Hammer with nails and screws;

- Sandpaper;

- Frazier;

- Door hinges.

As the manufacturing technology of wooden doors prescribes, one of the sides of the canvas must be made completely flat and pasted over with fiberboard, followed by laying insulation.

Fabric making

Based on the internal dimensions of the door frame, the dimensions of the future door are calculated. In addition, it is important to determine the dimensions of the gaps at the top and bottom. When the measurements are taken, it is necessary to cut a rectangle from the fiberboard sheet, repeating the shape and dimensions of the future door. During the manufacturing process, special attention must be paid to the corners. Their dimensions should be exactly 90 °.

For a standard box with dimensions of 200 * 90 cm, it is necessary to plan 2 boards to a thickness of 50 mm and a width of 110 mm. Since gaps are necessary for the free movement of the door, the canvas should be planed to dimensions of 192 * 82 cm. Panels in the amount of 5 pieces are often used for the entrance structure. This allows you to use solid pieces of lumber.

Next, you need to cut 2 boards of 192 cm in length and 4 pieces of 72 cm each. In addition, it is necessary to take into account 50 mm studs on each side. In the production of wooden doors, it is best to use a strictly symmetrical arrangement of panels. However, if it is necessary to create doors with asymmetric shapes, the parts will be fixed in the place necessary for this. This structure will not affect the functionality of the product. But do not forget about the grooves of 50 mm.

During the test assembly of parts, in case of complete coincidence of the elements and the absence of slots in the grooves, the structure is assembled with gluing. If additional strengthening of the structure is required, 10 mm wide chopsticks can be driven in at the joints. After the glue has dried, it is necessary to level the structure to absolute smoothness.

In the production of wooden doors for fixing the panels, it is necessary to choose a suitable material, half as thin as the main one.

Panel making

These elements are cut from solid wood. The panel should fit snugly into the groove without leaving any gaps. One of the sides must be absolutely smooth. The other, if desired, can be decorated with carvings or in any other way. Panels, in order to avoid subsequent deformation of the fiberboard sheet, during installation should be located flush with the main surface.

After checking the accuracy of the ratio of all parameters, the panels are fixed with self-tapping screws, which are placed at an angle from the side of the subsequent lining of the fiberboard sheet. To give aesthetics, the finished product is covered with paints and varnishes or stain.

Hinge installation

The next step in how do-it-yourself doors are made of wood is the installation of hinges. One of the most popular are products of the hemispherical type. With their help, the door is installed by pushing the door hinges on the axle from above in the open position.

Initially, the loops are marked at the end of the canvas and the box. The hinges themselves are attached to the canvas with the help of self-tapping screws of suitable size. In case of distortions, it is necessary to correct the position of the loops. Otherwise, the structure will be subject to self-opening or closing.

Warming

In most cases, the production of wooden doors also implies their insulation and the provision of noise-absorbing properties. To achieve this effect, it is possible to apply the outer upholstery of the product. This is done by gluing the fiberboard web with a layer of foam rubber, while retreating from each edge by 10 mm. Subsequently, decorative outer material will be nailed onto these free strips. However, this option is more suitable for front doors.

The easiest way to insulate the interior fabric is by filling the voids under the fiberboard sheet with a layer of cotton wool or foam rubber.

Interior doors are a necessary part of residential, industrial and office premises. When choosing door panels and additional elements, you need to know how and by what rules they are made, as well as to understand the advantages and disadvantages of the materials used in the production of doors. Modern manufacturers use high-tech equipment that allows them to produce a large number of high-quality products with various types of coating and modern design.

Manufacturing technology of interior doors

Doors serve to separate the various functional parts of the room and provide sound insulation, protection from extraneous odors and excessive moisture. Methods for the manufacture of door panels and additional elements depend on the materials used in the production. The most popular doors are made of solid wood or prefabricated on a wooden frame. Glass inserts make the canvas partially transparent to light and visually expand the space of rooms or corridors.

The most complex and multi-link technological process occurs in the manufacture of doors using wooden elements. The fact is that timber that has not gone through the full cycle of pre-drying and processing is subject to warping and cracking. To avoid losses in the quality of the final product, it is necessary to pay great attention to the preliminary preparation of wood using certain technological methods. The manufacturing process of interior doors includes the following steps:

- Timber (round timber) of pine species is sawn into blanks using band saws with automatic feeding of logs.

Logs are sawn into blanks of the required thickness.

- The blanks are treated with high temperature and steam in drying chambers to avoid uneven drying and warping of the wood. At the end of the drying process, a mandatory moisture control is carried out.

Drying of lumber is carried out under the influence of steam and high temperature.

- Dried blanks are cut into bars of a technological section and defective fragments (chips, knots, cracked and rotten areas) are removed from them, which can affect the quality of the door frame and leaf.

Defective areas are cut out of a blank cut into a beam

- Then, the blanks are spliced with the help of spikes, glue and a vertical press into a shield, from which, after drying and trimming, a door leaf is obtained.

With the help of a vertical press, a panel blank of the door leaf is obtained

- After sanding, the canvas is covered with three-layer veneer or MDF panels with one layer of veneer and placed in a gluing press.

- At the next stage, figured decorating elements, panels or openings for glazing are cut out with a milling and engraving machine, and after assembly, the door leafs are covered with three layers of varnish with intermediate and final polishing.

Panel elements or glazing are mounted during final assembly

- After the final drying, the products are packed, if necessary, supplied with fittings and sent to the consumer.

The technological sequence of manufacturing doors may be different and it depends on the material, equipment and design of the product. For example, for expensive doors made of solid wood, the use of veneer is not typical and they are made using complex CNC machines, while budget doors often use corrugated cardboard inserts and cheap laminating film.

It is important to note that under the factory conditions, fittings are usually not installed on a door with a symmetrical decor, since during installation at the consumer's, the product can open both to the left and to the right, respectively, hinges and handles are installed by installers on site.

Video: making solid wood doors

Rules and norms for the production of interior doors

Door blocks are manufactured on equipment that is located on large production areas. These premises are subject to certain requirements, as to industrial facilities, which include timber warehouses, dryers, a processing shop, a paint shop and a warehouse for finished products. Each production site is equipped according to the rules and regulations, in accordance with the technical conditions for a specific task. The main requirements for production facilities for the manufacture of doors are the following criteria:

- availability of free access roads;

- buildings must be provided with a stable temperature, humidity, natural and artificial lighting;

- power supply, heating, ventilation, water supply and sewerage should be equipped;

- the premises must be equipped with fire alarms, fire extinguishers and emergency exits;

- it is necessary to ensure safe working conditions at workplaces;

- paintwork areas should be isolated from the rest of the premises and provided with forced ventilation.

Personnel are required to undergo professional training and training in labor protection, fire and electrical safety, as well as to undergo unscheduled, repeated and initial briefings at the workplace.

The production room must be equipped in accordance with the standards

The main norm for the production process is technological documentation, which is based on the Technical conditions for the production of TU 5361-001-58037723-2015 "INTERIOR DOORS, PARTITIONS AND MOLDINGS TO THEM". This document sets out the requirements for the design of interior doors, the quality of the material and coating of the front surface, as well as environmental requirements. The regulations specify the procedure for acceptance of finished products, certification and installation of a warranty period of operation.

For the buyer, it is important to have a certificate, a warranty period and the compliance of the door, frame and additional elements with the requirements of technical specifications, since this confirms the quality of the product and allows you to count on a long service life.

Current GOSTs for the production of interior doors

The technical characteristics of the doors are determined by the standards that set the general technical conditions or methods for determining the physical parameters and dimensions of the finished product. Many manufacturers create products according to non-standard sizes, but with strict observance of quality requirements. The consumer may be interested in the list of regulatory standards that manufacturers of interior doors work on, namely:

- General requirements for wooden doors with a list of regulatory documents are established by GOST 6629-88, and the requirements for wood products are set out in GOST 475-78.

- Design options for interior doors, their types and sizes are specified in GOST 24698–81.

- Requirements for extensions, fasteners and hinges are assigned by GOST 538–88.

- Methods for determining sound insulation, heat transfer resistance and air permeability are regulated by GOST 26602.

- The determination of the flatness of the door leaf is carried out according to the standard ST SEV 4181–83.

- The reliability test methodology is set out in ST SEV 3285–81.

- Impact load resistance is produced according to the method specified in ST SEV 4180-83.

Accompanying documents for finished products must contain a symbol for door panels, for example, U05195 VERSAL pat. 1014 dec/or door leaf D3 91x 230 L, which means the following door parameters:

- article - U05195;

- the trade name of a particular collection is VERSAL;

- type of finish/color − pat. 1014 dec/oro;

- product name - canvas;

- product model - D3;

- width and height of the canvas - 91x230;

- type of opening, left − L.

Before ordering doors, it is necessary to carefully measure the doorways in order to select the required size of the frame, leaf and the required number of additional elements. For interior doors, there are standard dimensions of openings with the corresponding designation according to SNiP, and this approach makes it easier to choose a door frame according to the table.

Table: the ratio of the size of the opening to the size of the door leaf

Existing regulatory documents guarantee a high level of product quality, standardization in size and compliance with environmental requirements, in addition, the consumer can determine the compliance of the product properties declared by the manufacturer with the quality and price level.

Material for the manufacture of interior doors

In the production of interior doors and partitions, modern materials are used that are environmentally friendly, durable, lightweight and have a long service life. These include metal-plastic and glass doors, the frame for which is an aluminum profile, and the filler is plastic panels or tempered triplex glass with a matte finish. But traditional doors with a wooden frame and inserts made of glass, MDF panels and paneled elements occupy a major niche in the market. In the manufacture of such products, the following materials are used:

- Defect-free pine lumber with a moisture content of not more than 8%, spliced into a tenon using glue pressing.

- High density chipboard.

- Natural veneer from various types of wood with a thickness of 0.6 mm.

- Laminating film imitating fine wood.

Laminating film gives the doors the texture of natural wood

- MDF panels of various thicknesses are used for cladding door panels and creating paneled elements.

- Frosted, triplex or tempered glass is used for light-scattering and decorative inserts in the door leaf.

- Corrugated cardboard is used in budget options as soundproof inserts in the canvas between the frame bars.

Corrugated cardboard is used for insulation and sound insulation of inexpensive door panels.

- Wax and waterproof coatings, tinting compounds and varnishes.

- Glue type "Kleiberit 303.2", MERITIN ADHESIVE D3 and others, is used for industrial gluing of fragments of leaves, door frames and additional elements.

The production of inexpensive doors is based on the use of chipboard, laminating film, corrugated cardboard and MDF, while more expensive products use solid wood with milled elements, panels and tempered glass inserts.

Six years of experience in the operation of veneered panel doors by the author of the article shows their significant reliability. But in rooms with high humidity, I would like to recommend different types of laminated doors with an additional waterproof coating. After four years of service in the bathroom on the inner veneered canvas, despite the treatment with liquid wax twice a year, whitish stains and streaks appeared from exposure to steam and condensate. There was a need for cosmetic repairs, so I had to sand the plane of the door leaf, degrease it with a solvent, cover it with a tinting compound and waterproof varnish in two layers. To a lesser extent, the same problem appeared in the laundry room, and as for the other doors, minor damage to the veneer and scratches were eliminated by gluing and treating with hard, tinted wax in various shades. After such a minor repair, the canvas, boxes and extensions acquire their original appearance and serve for more than six years. Under the conditions of suburban operation during summer residence, wooden doors covered with waterproof varnish serve more than eight years. At the same time, there is no warping and drying out in conditions of temperature changes and changes in humidity. But it should be noted that the best option for summer cottage construction are metal-plastic doors and frames that do not change properties and retain geometry under changeable weather conditions.

Equipment for the production of interior doors

The most costly production of interior doors, in terms of the amount of equipment required, is the manufacture of wood products. Factory production of metal-plastic and glass requires a large number of components and a small number of machines for cutting frames and processing glass sheets. Lumber processing is more saturated with machine tools, presses and other equipment. Consider the equipment that is used for the production of wooden doors:

- Sawmills and band saws used for cutting round timber.

The sawmill allows you to get lumber of the required thickness from round timber

- Thermal chambers with steam supply for drying lumber.

Industrial drying chambers allow you to bring the lumber to the required moisture level and avoid warping of the workpieces

- Equipment for the production of veneer.

- Tenoning machine for frame and door leaf.

Using a pneumatic press, the door leaf is glued

- Circular saws and panel saws for sawing blanks to size.

- Copy-milling machines with program control for decorating door panels.

Using milling machines, figured and paneled elements are produced

- Grinding machines for intermediate and finishing processing of products.

- Paint equipment.

The list of the production park can be expanded due to the use of various technological and design solutions in the production of interior doors and components, which has a positive effect on the consumer properties of the final product.

Video: production of interior doors

We examined some types of interior doors, production technology, as well as regulatory documents and requirements governing the production of this type. For the correct choice of doors, it is necessary to know the properties of the coating and the material from which they are made. High-quality equipment and adherence to production technology ensures resistance to external influences and a long service life of products. A wide range of design solutions allows you to give the living room an individual look and unique style.